Car-mounted hydrogen generation system

A hydrogen generation technology, applied in the charging system, engine components, combustion engines, etc., can solve the problems of affecting processing and combustion, prone to failure, safety hazards, etc., to reduce moisture, reduce processing pressure, and change cooling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

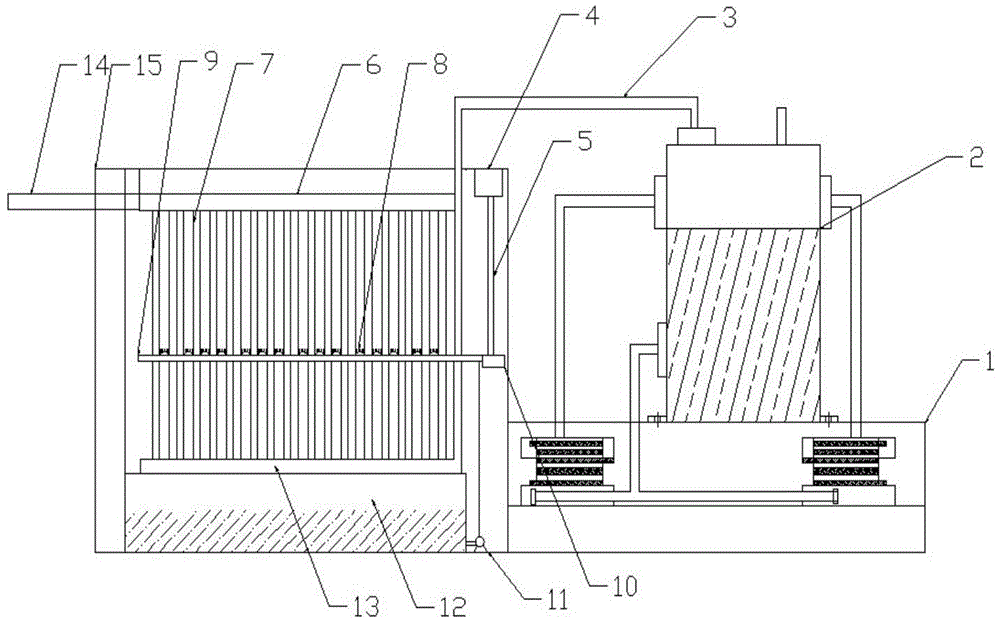

[0014] see figure 1 , a vehicle-mounted hydrogen generation system, including a liquid storage chamber 1 with an electrolytic aqueous solution built in, an electrolyzer 2 for electrolyzing the aqueous solution in the above-mentioned liquid storage chamber 1 to generate hydrogen, and a heat exchanger for cooling the generated hydrogen Device 14; the electrolysis machine 2 is connected with a DC power supply, the positive pole of the DC power supply is connected to the positive pole of the electrolysis machine 2 through a breaker, and the negative pole is connected to the negative pole of the electrolysis machine 2, and the breaker is connected to the electric door lock of the car through a relay Connected and disconnected or closed under the control of the electric door lock of the car; the electrolysis machine 2 forms a circulation with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com