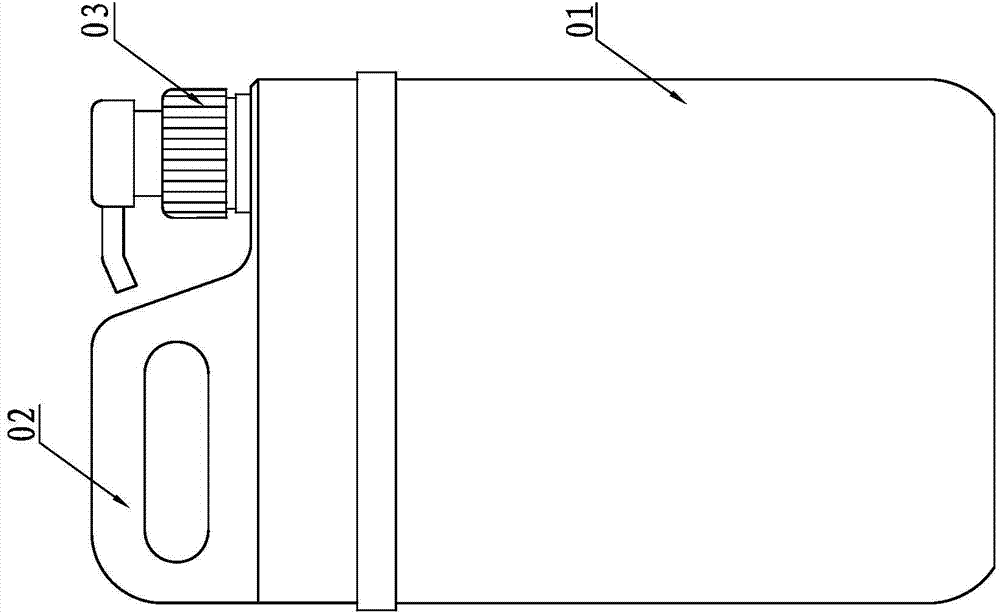

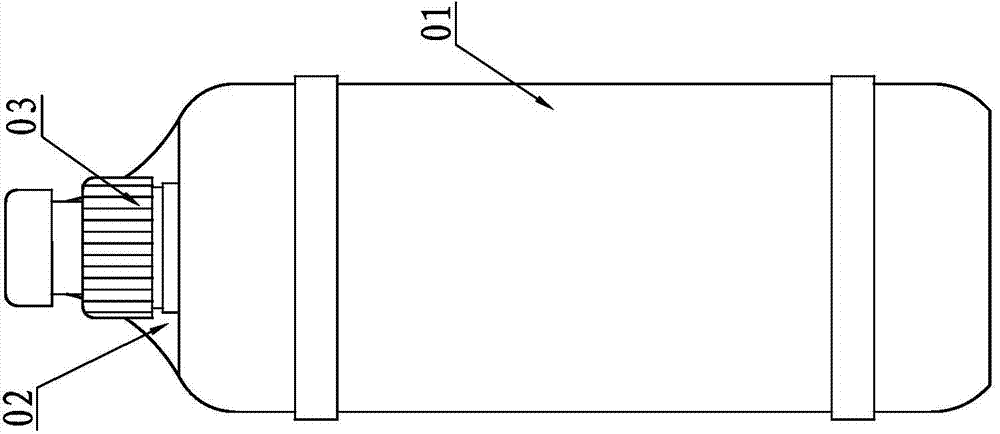

Clutch cap screwing device of linear pump cap screwing machine

A capping machine, a straight-line technology, is used in the directions of tightly capping containers, packaging, transportation and packaging with caps, which can solve the problems of high labor costs, inconsistent capping tightness, and high labor intensity, and achieve capping. High efficiency, good capping quality, and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

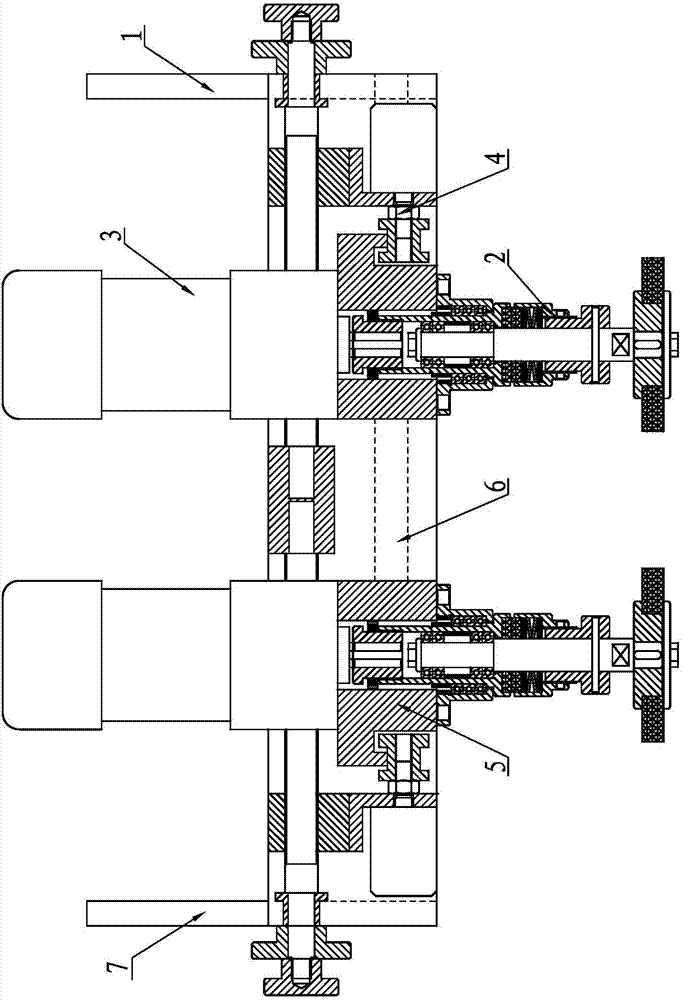

[0042] The specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

[0043] A clutch capping device of a linear pump capping machine, such as Figure 3 ~ Figure 13 As shown, it includes the front side plate 1 of the rack, the torque cap part 2, the rotary drive part 3, the centering linear drive adjustment mechanism 4, the sliding seat 5, the sliding guide rail 6 and the rear side plate 7 of the rack, and two sliding guide rails 6 It is horizontally and parallelly fixedly installed on the frame front side plate 1 and the frame rear side plate 7, and two guide holes 51 parallel to the upper and lower end faces are provided on the left and right sides of the sliding seat 5, and on the upper and lower end faces of the sliding seat 5 There is a connection through hole 52 on the top, the connection through hole 52 is located on the center line of the axis of the two guide holes 51, the axis of the connection throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com