Automatic capping machine

An automatic, capping technology, applied in conveyor objects, flanged caps, transportation and packaging, etc., can solve the problems of high labor intensity, scratches, low production efficiency of operators, and achieve high capping efficiency, Adapt to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiment:

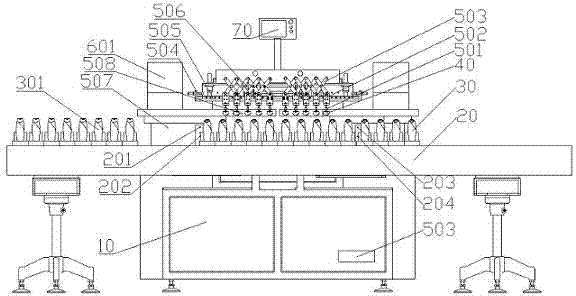

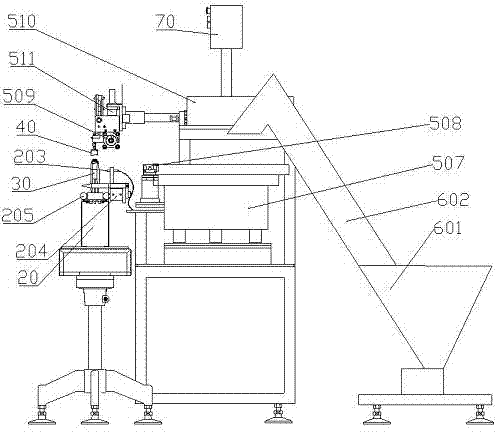

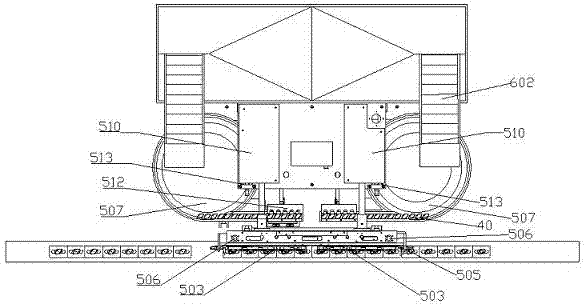

[0021] Such as figure 1 As shown, an automatic capping machine is used to automatically add a bottle cap 40 to the bottle body 30 to be capped, including a product conveyor belt 20 and a frame 10. The frame 10 is the main frame of the entire device, and the entire device Both the mechanical part and the control system are installed on the main body of the machine, and the product conveyor belt 20 ensures that the bottle body 30 to be capped is smoothly conveyed on the conveyor belt. The automatic capping machine also includes a capping device, a feeding device and a control system 70 . The upper cover device is the main action part of the whole equipment, and is composed of a cover gripping mechanism, a traverse mechanism 510 and a lifting mechanism 506. The cover grip mechanism includes a suction cup mounting block 502, a suction cup 501 installed on the suction cup mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com