Bottle cleaning mechanism and beverage loading equipment

A cleaning mechanism and bottle body technology, applied in bottling machines, bottle filling, transportation and packaging, etc., can solve problems such as low cleaning efficiency, low price efficiency, and easily damaged bottle body transmission mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

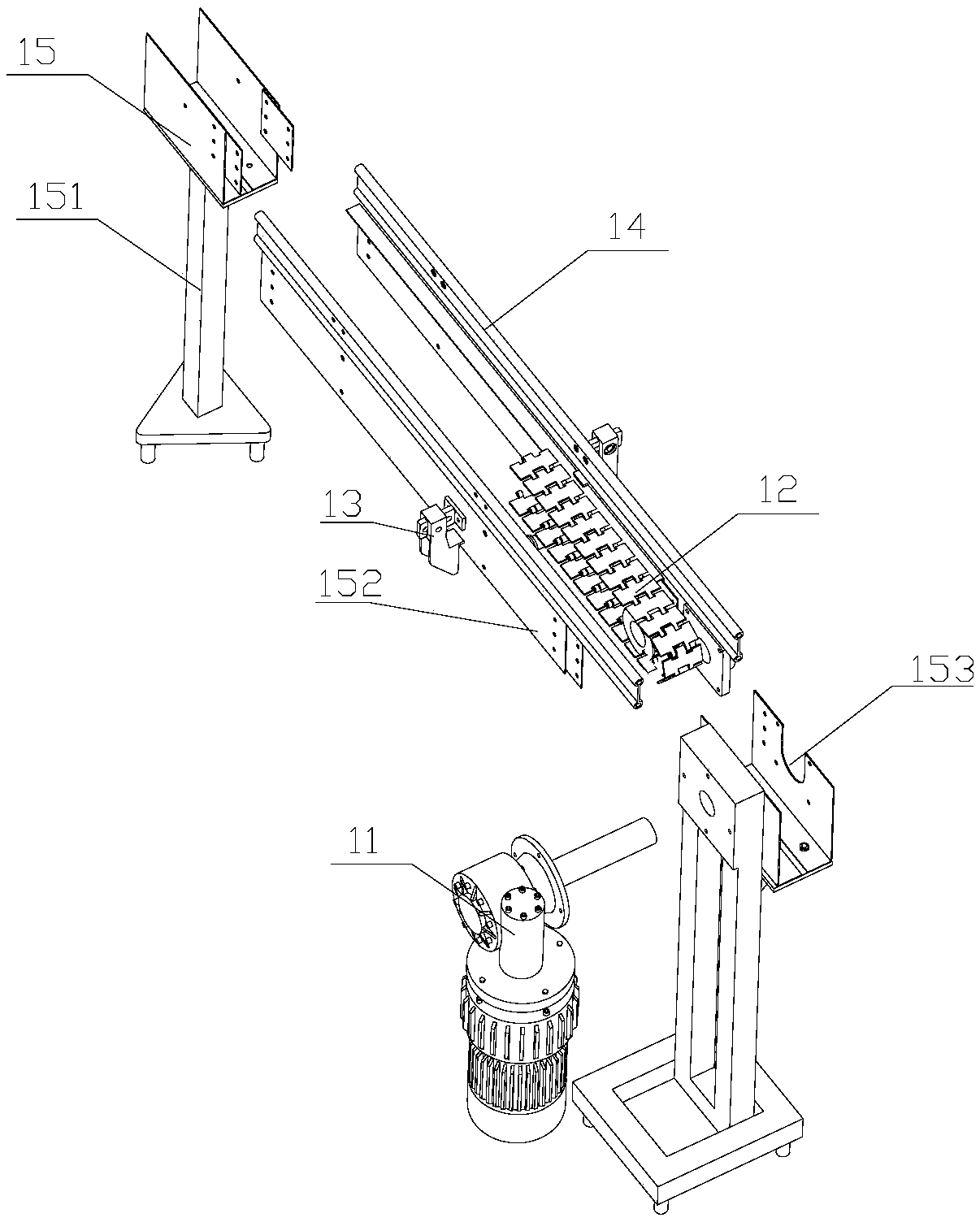

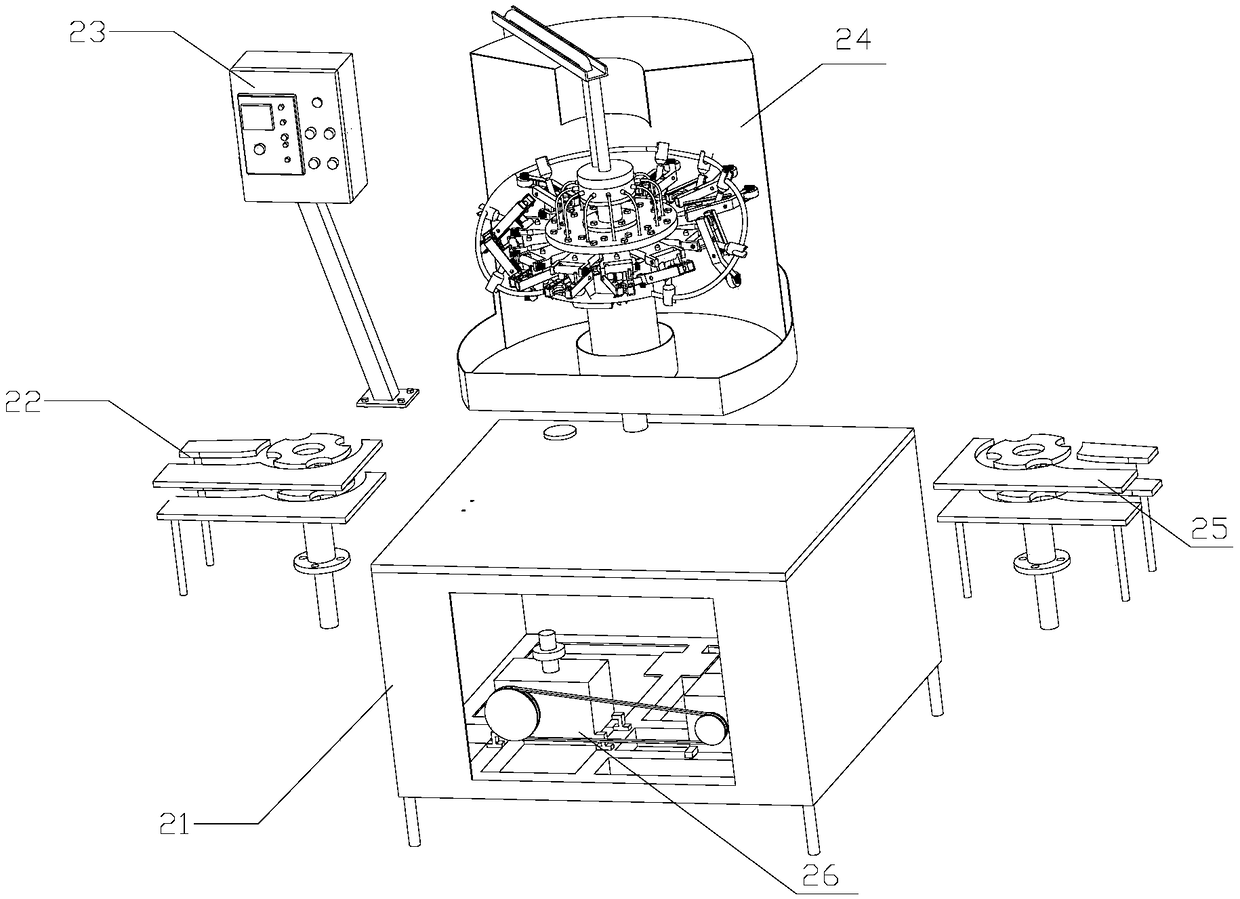

[0033] Combine below Figure 1-Figure 18 The present invention is further described. ,

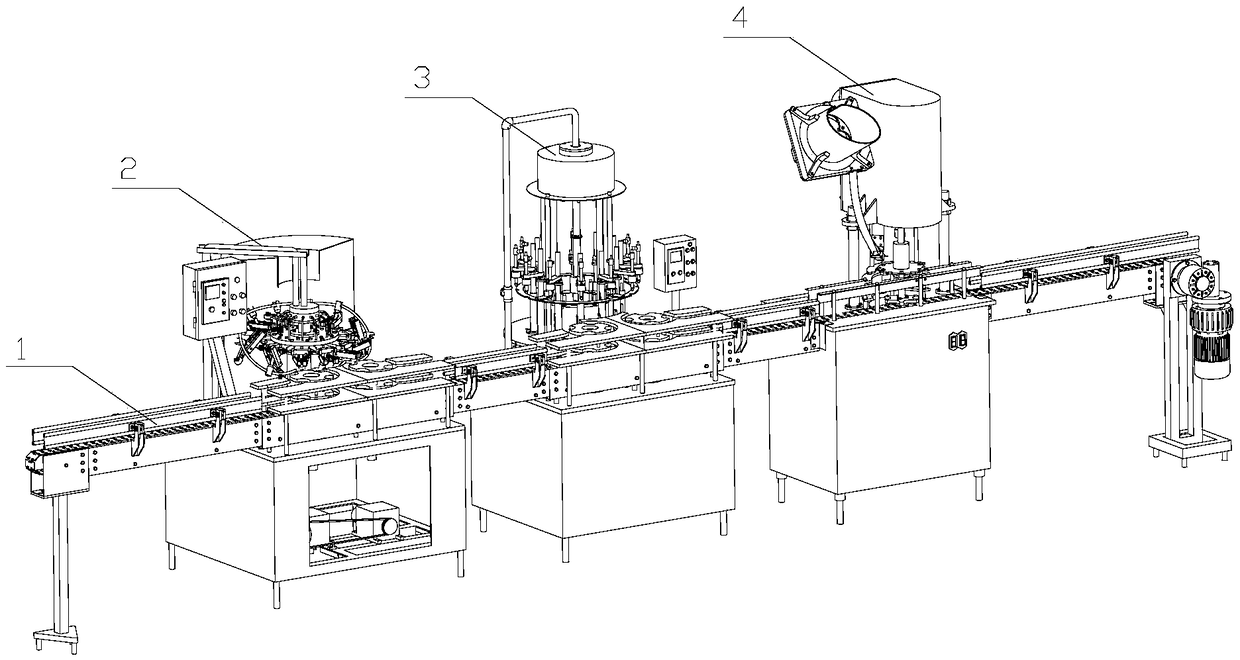

[0034] Such as Figure 1-18 The shown beverage filling equipment includes a chain conveying device 1, a bottle cleaning device 2, a beverage filling device 3 and a capping device 4. The chain conveying device 1 passes through the bottle cleaning device 2, the beverage filling device 3 and the pressing device in sequence. Cover device 4.

[0035] The bottle body is placed on the starting end on the chain conveyor 1, and the bottle body is transported to the bottle body cleaning device 2 by the chain conveyor device 1, and the bottle body cleaning device 2 cleans the bottle body. After the cleaning is completed, the chain conveyor 1 transports the bottle body to the beverage filling device 3, and the beverage filling device 3 injects the beverage into the bottle body. After the filling is completed, the chain conveyor 1 transports the filled bottle to the capping device 4, and the cappin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com