Automatic lid beating machine for sealing glue barrel

A rubber barrel and automatic technology, which is applied in the fields of capping the container tightly, capping machine safety/control, application, etc., can solve the problems affecting the stability of product quality, inconsistent sealing standards of forced products, etc., to achieve simple structure, Improved capping efficiency and guaranteed airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings.

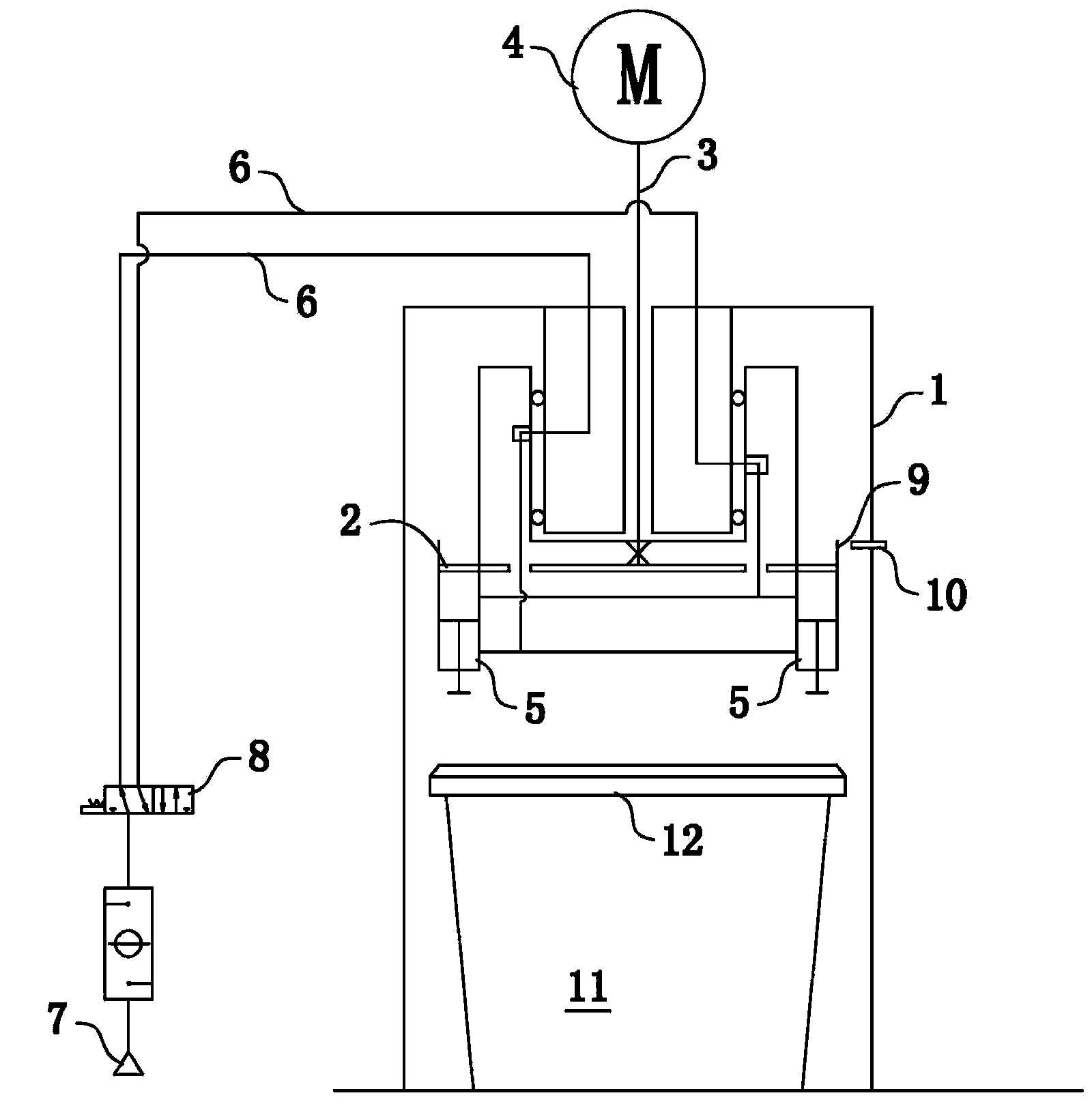

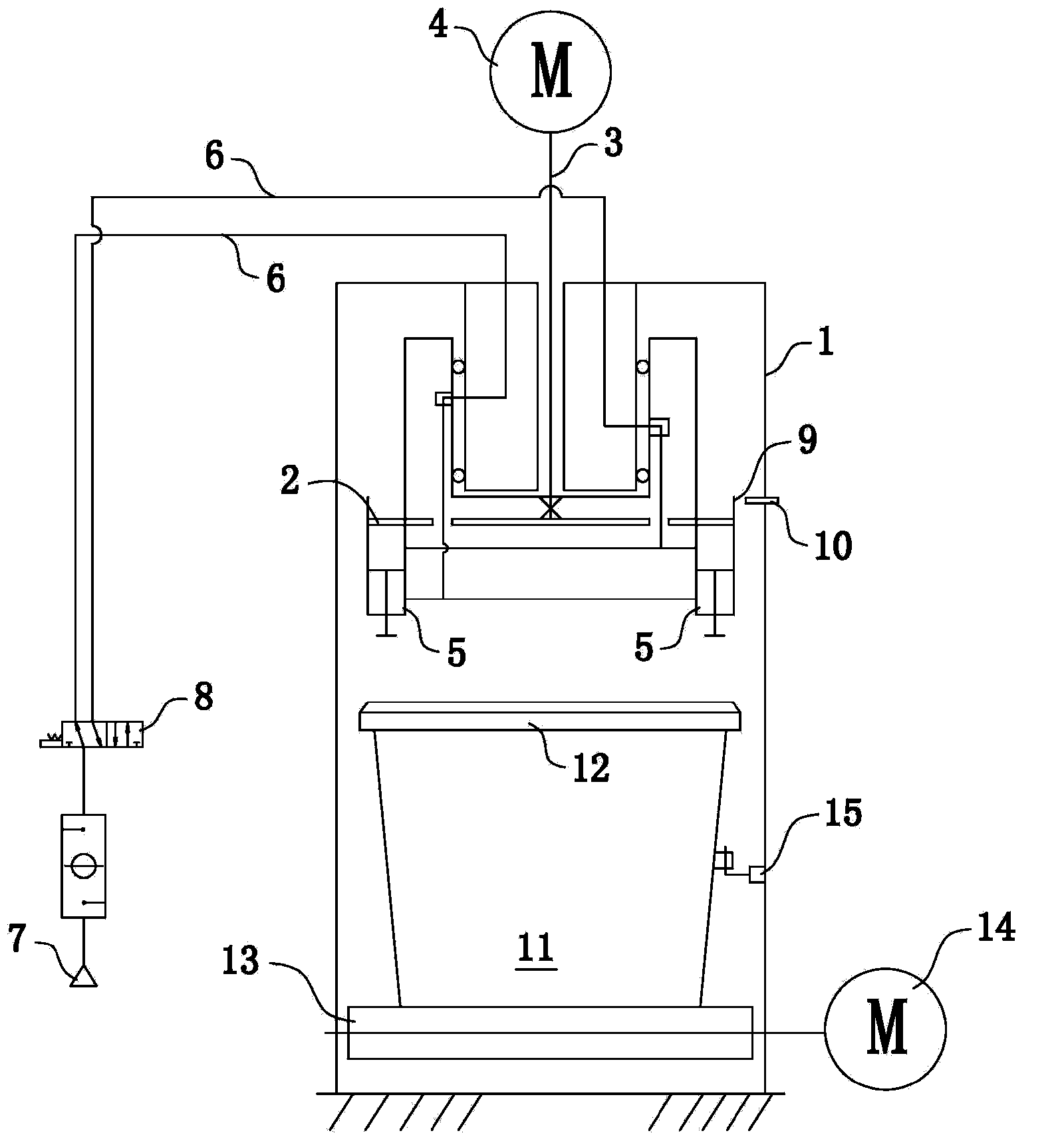

[0018] refer to figure 1 As shown, one embodiment of the present invention is an automatic capping machine for sealing rubber barrels, including a frame 1 on which a rotating disk 2 is installed, and the rotating disk 2 is connected to the second through a linkage rod 3 A motor 4 is connected with power, and its effect is that the first motor 4 drives the rotating disk 2 to rotate, and the rotating disk 2 is equipped with a cylinder 5, and the cylinder 5 communicates with the air supply source 7 through a pipeline 6, and the pipeline 6 is also provided with an electromagnetic reversing valve 8;

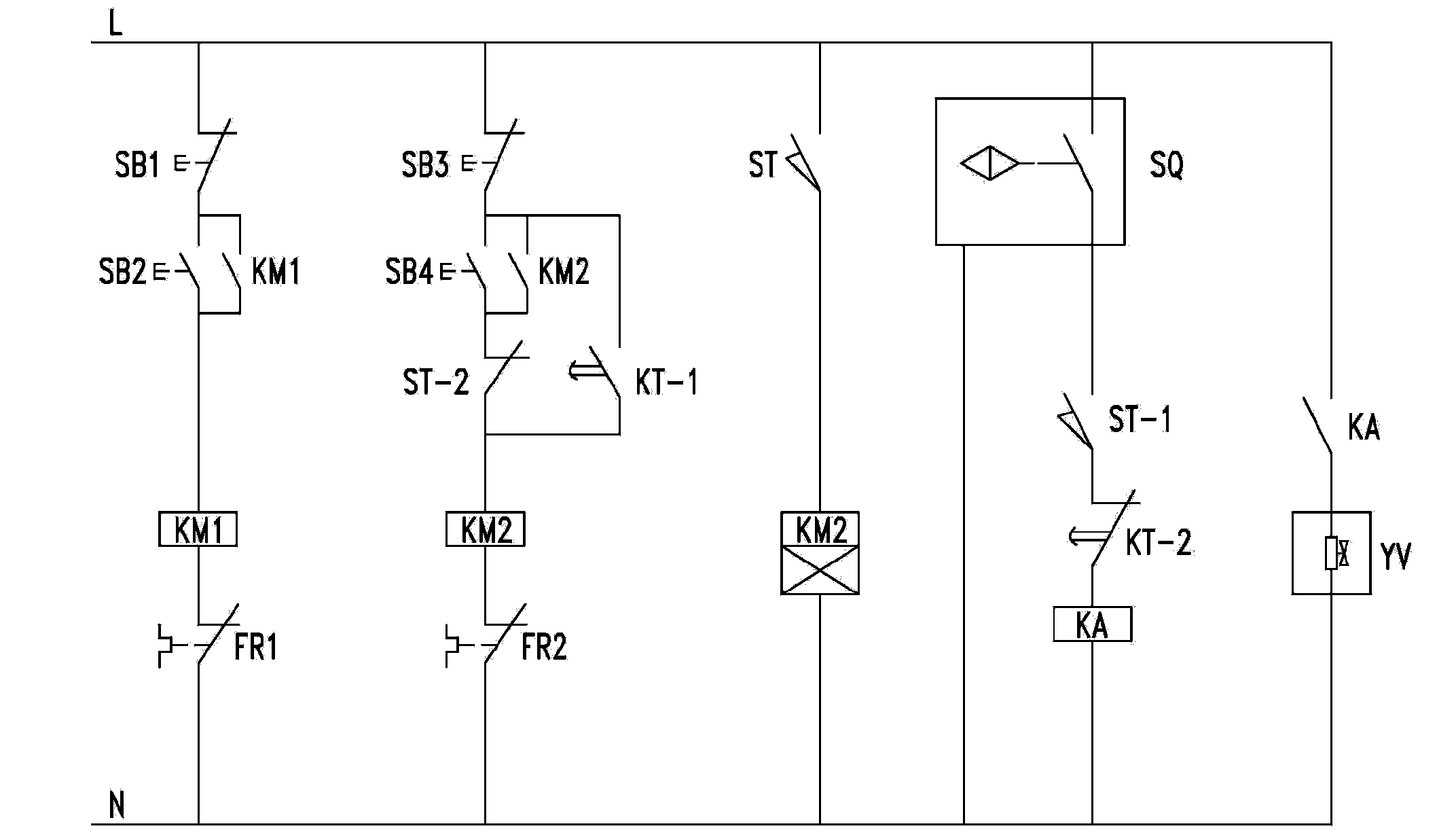

[0019] In this embodiment, in order to realize the operation of automatically sealing the sealant barrel, at least one induction iron 9 needs to be set on the above-mentioned rotating disk 2, and it is set on the position corresponding to the above-mentioned induction iron 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com