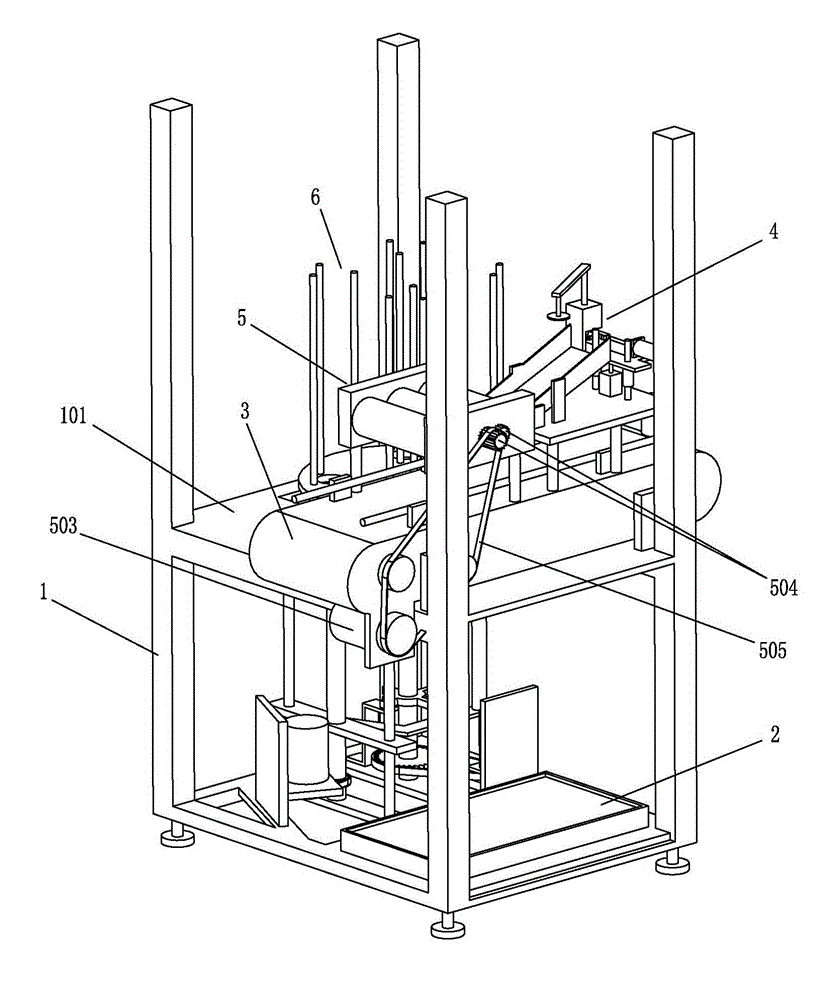

Automatic capping packaging machine

A packaging machine, automatic technology, applied in packaging, transportation and packaging, bottle/container caps, etc., can solve problems such as low production efficiency, and achieve the effects of short capping time, reduced production costs, and simple working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

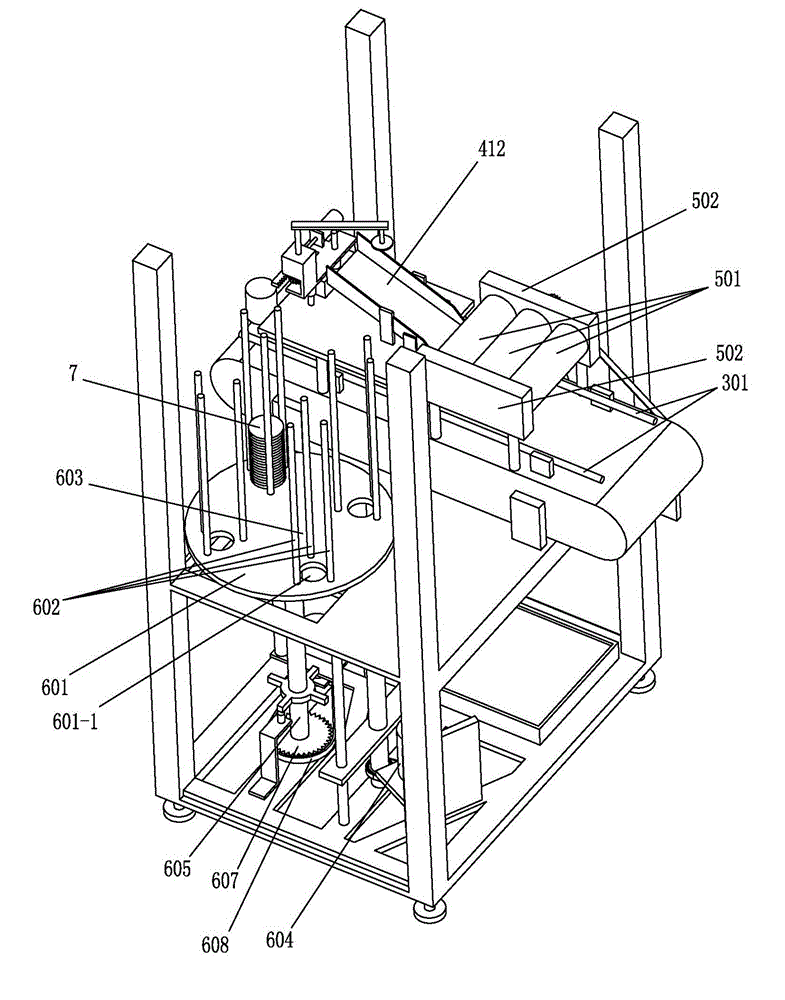

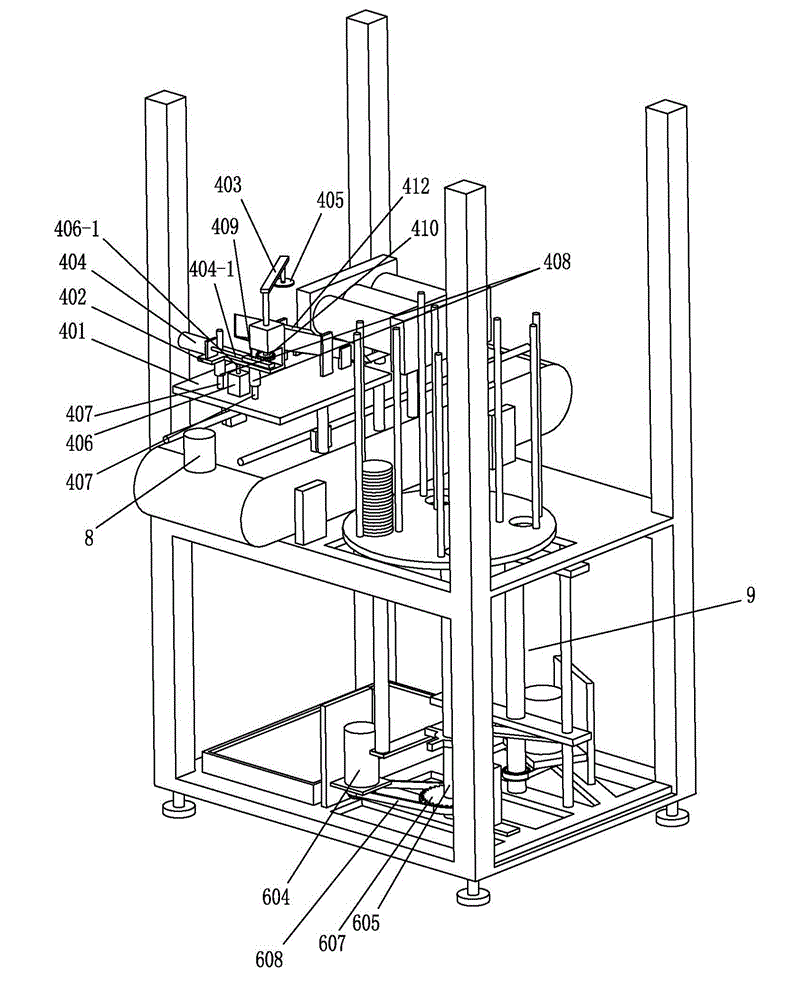

[0027] Described lifting device 9 is made up of lifting screw mandrel 901, lifting guide rod 902, lifting motor 903 and lifting guide plate 904, and lifting motor 903 is connected with runner 906 at the bottom end of lifting screw mandrel 901 by belt or chain 905, and lifting guide plate 904 Sleeved on the lifting screw rod 901, the two ends of the lifting guide plate 904 are guided and slidably connected with the two lifting guide rods 902, and the bottom end of the lifting mandrel 606 is fixedly connected to the lifting guide plate 904 through the connecting plate 907; the lifting guide plate 904 is connected by the lifting wire The positive rotation and reverse rotation of the rod 901 realizes up and down lifting, and the bottom end of the lifting jack 606 is connected with the lifting guide plate 904 through the connecting plate 907, so that the lifting guide plate 904 drives the lifting jack 606 to realize the up and down lifting. For the stability of the lifting device 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com