Lifting gear of cap whirling machine

A lifting device and capping machine technology, which is applied in the direction of capping containers tightly with caps, packaging, threaded bottle caps, etc., can solve the problems of not ideally meeting the packaging requirements of screw caps, errors, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

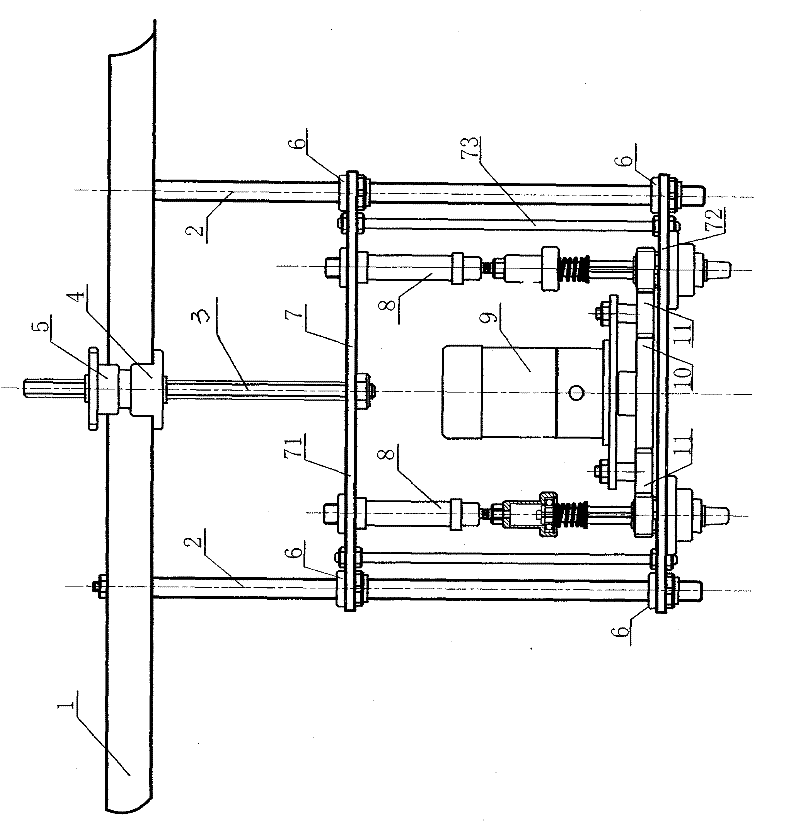

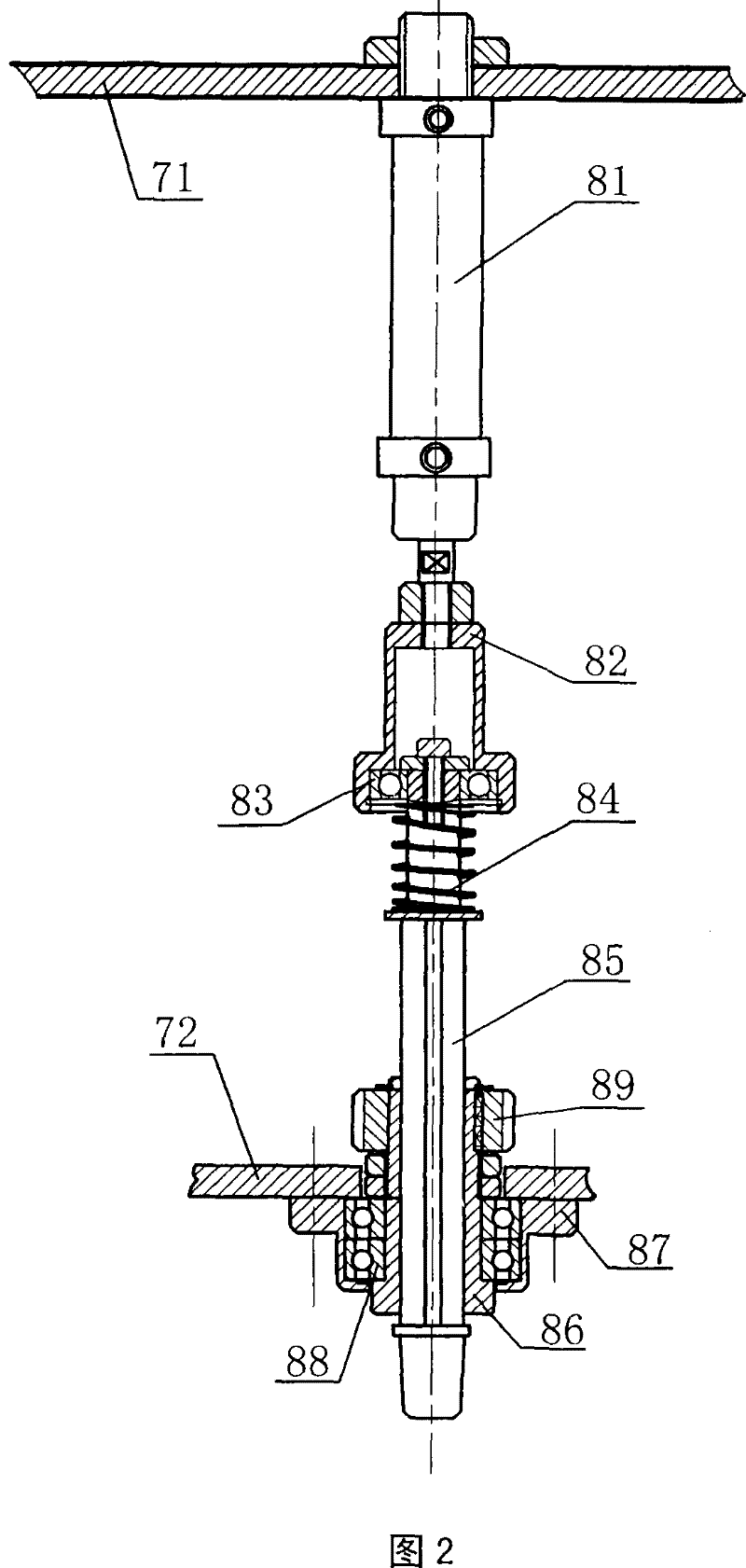

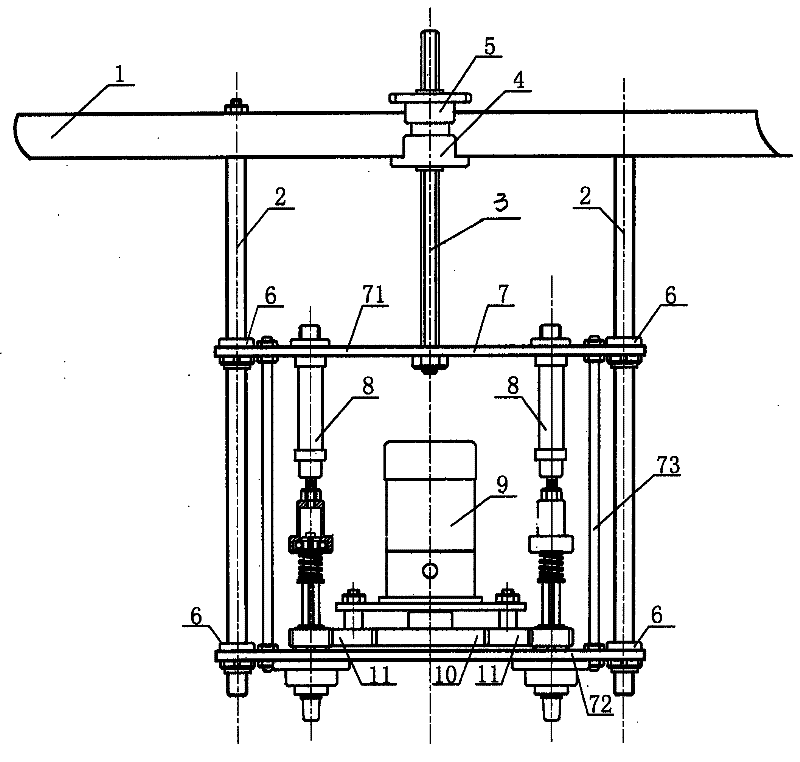

[0015] The cylinder telescopic capping device of the capping machine of the present invention includes a beam 1, a guide column 2, a lifting screw 3, a nut seat 4, an adjusting hand wheel 5, a sliding sleeve 6, a support frame 7, and two rotating telescopic parts 8 , motor 9, motor gear 10 and bridge gear 11, beam 1 is fixed on the frame by two guide columns 2; support frame 7 is made up of upper slide plate 71, lower slide plate 72, fixed rod 73, upper slide plate 71 and lower slide plate 72 is connected into a frame structure by two fixed rods 73, and the support frame 7 is set on the two guide posts 2 through four sliding sleeves 6 installed on the upper slide plate 71 and the lower slide plate 72, and the lifting screw rod 3 passes through and is fixed on the The nut seat 4 on the crossbeam 1, the lower end of the lifting screw 3 is fixed on the support frame 7, and the rotation adjustment handwheel 5 can make the support frame lift; The spring 84, the lifting rotating rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com