Automatic capping machine

A capping machine, automatic technology, applied to bottle/container caps, capping containers tightly with caps, bottle filling, etc., can solve the problems of slow packaging speed, leaky packaging, waste of human resources, etc., and reduce the defective rate of capping , Capping position is accurate, and the effect of capping efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

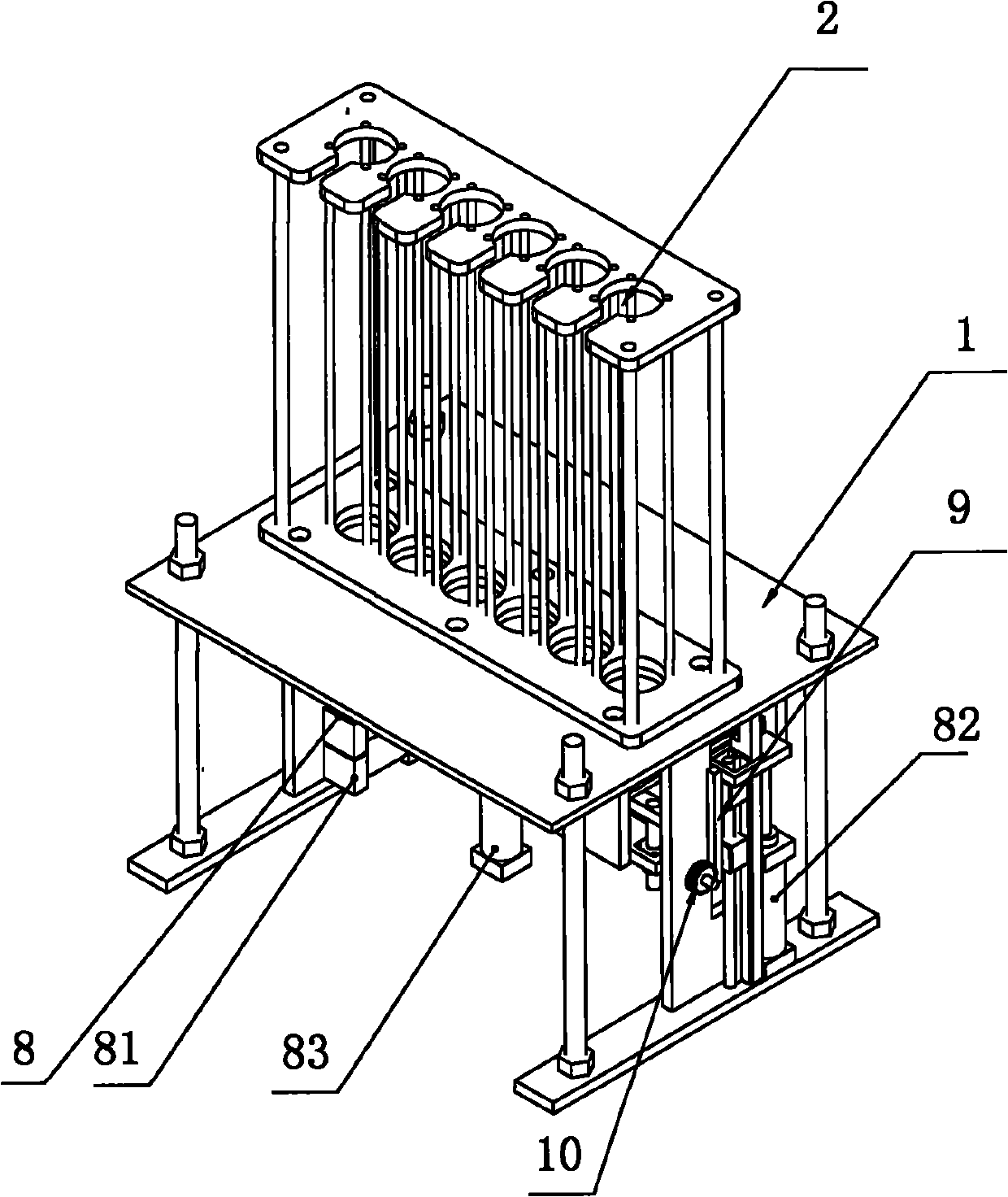

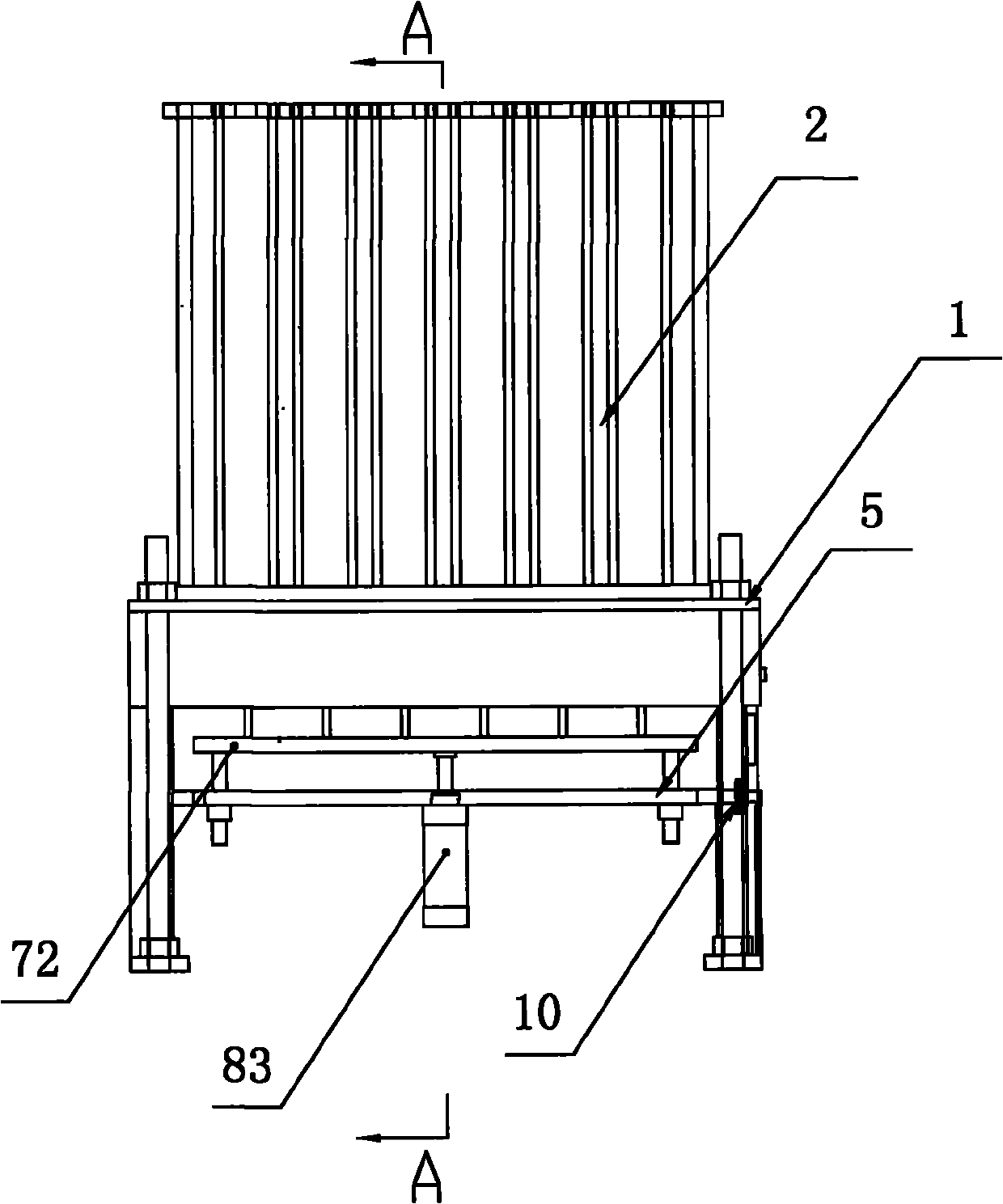

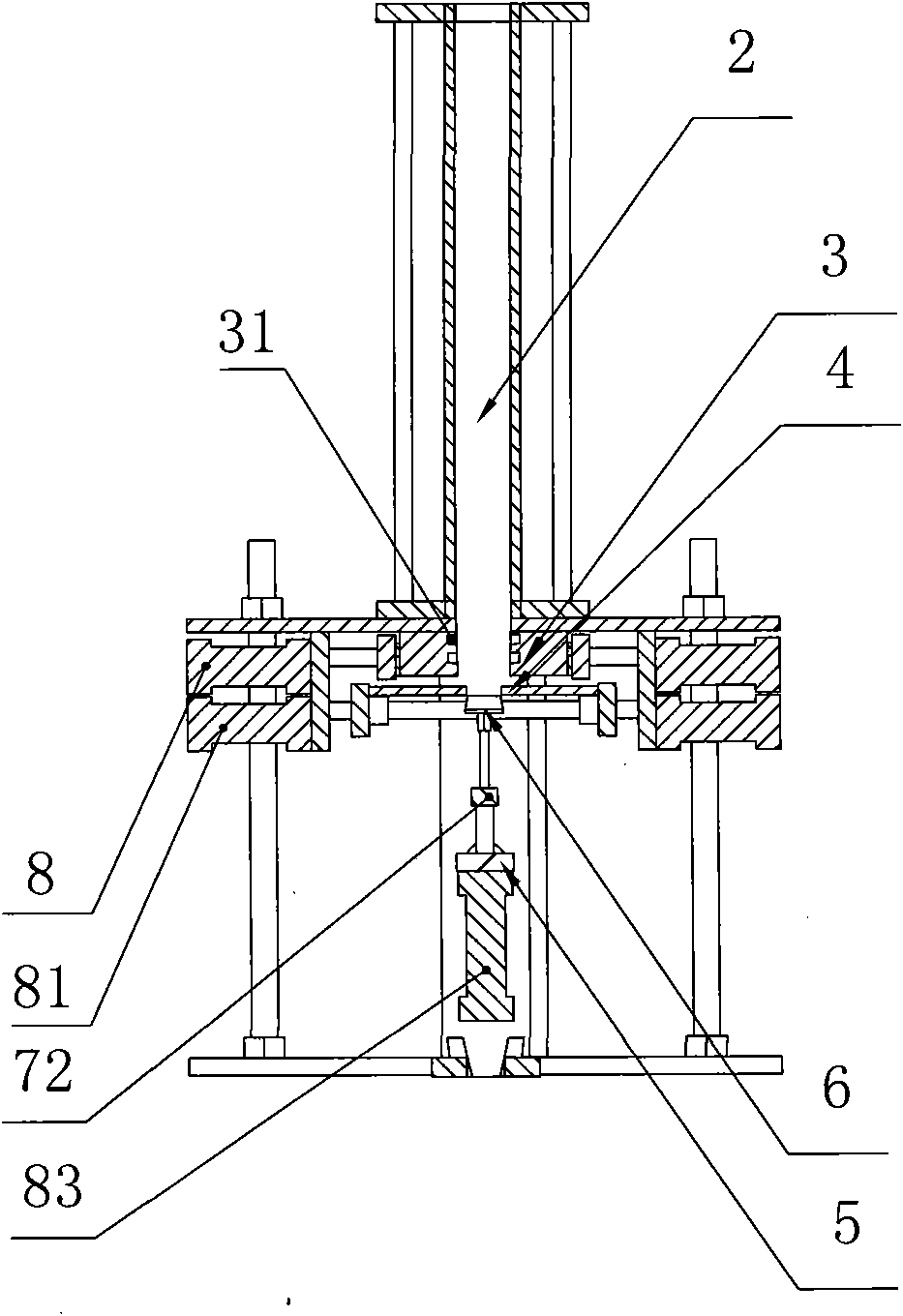

[0019] Embodiment: an automatic capping machine, including a frame 1, a placement channel 2, a first chuck 3, a second chuck 4, a suction cup holder 5 and a suction cup 6, based on the direction of use, at least one longitudinal direction has a setting The height of the placement channel 2 is fixed on the top of the frame 1, and the inside of the placement channel 2 can accommodate several axially overlapping cup covers. The cup covers can slide longitudinally along the placement channel 2. The initial state of the disk 3 is an open state, the first chuck is radially retractable and axially stopped and positioned on the frame 1 at the lower end of the placement channel 2, and the initial state of the second chuck 4 that is consistent with the number of placement channels 2 is a contracted state , the second chuck can be radially opened and the axial stopper is positioned on the frame 1 at a set distance below the first chuck 3, and the axis lines of the first and second chucks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com