Automatic film covering machine for barreled printing ink

A laminating machine and automatic technology, applied in the direction of decorative covering, protective/decorative covering, packaging, etc., can solve the problems of ink surface oxidation and agglomeration, ink quality impact, low work efficiency, etc., to protect the health of the body , reduce the contact between personnel and ink, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

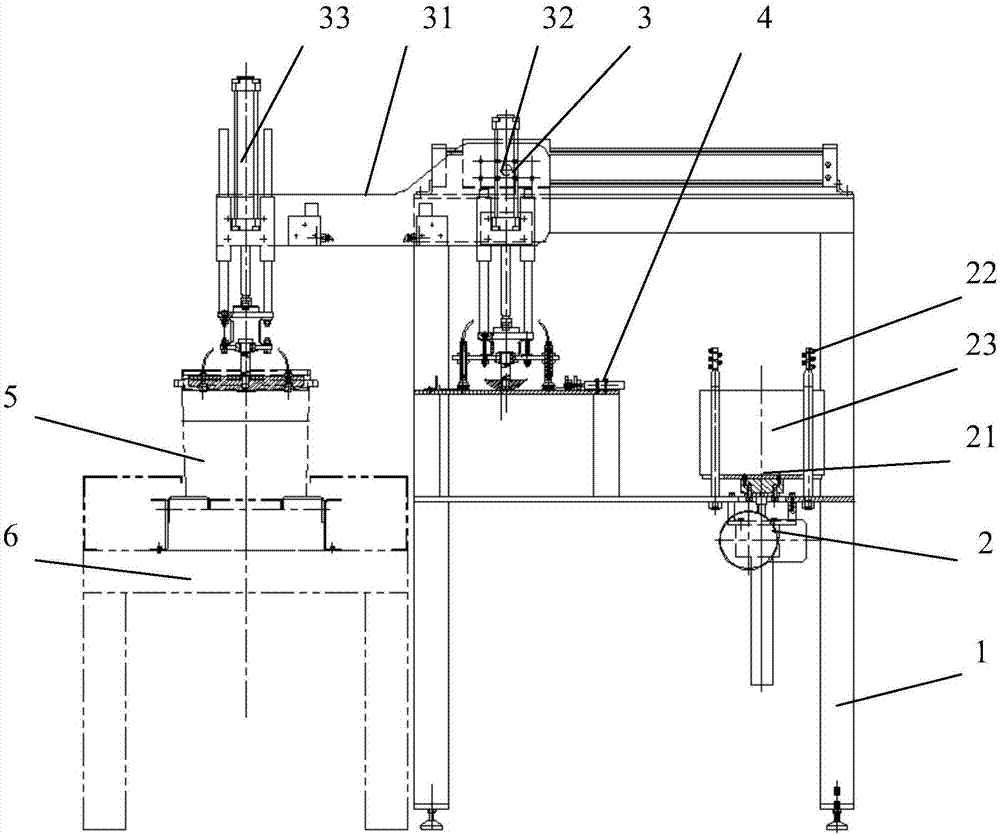

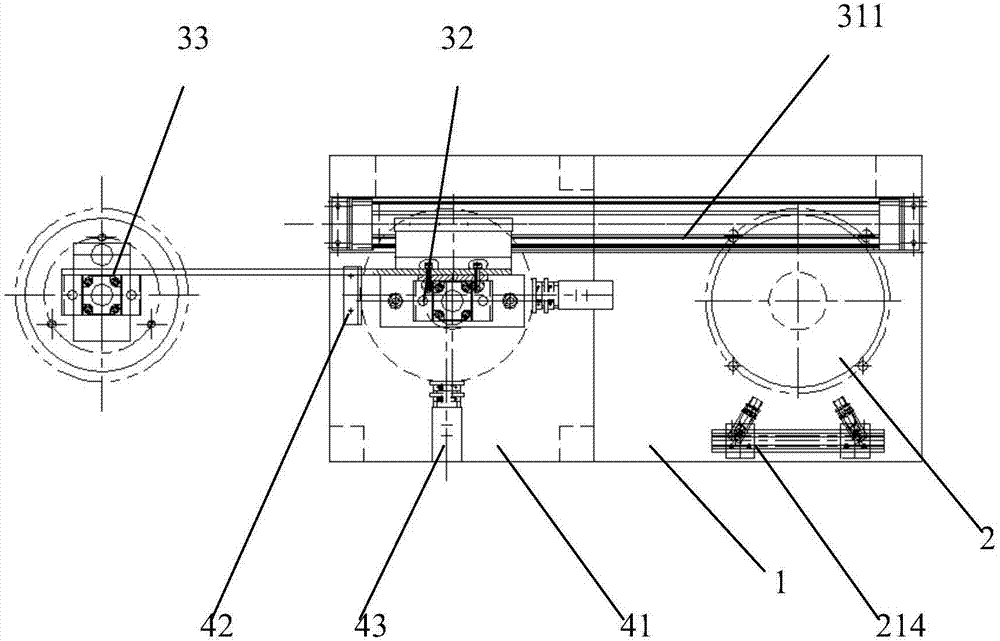

[0016] Such as figure 1 , figure 2 As shown, an automatic capping film device for barreled ink includes a frame 1, a plastic film automatic jacking mechanism 2, a moving film releasing mechanism 3 and an intermediate positioning mechanism 4, and the frame 1 can adopt the prior art Known technology, such as racks made of steel. Described intermediate positioning mechanism 4 is installed on the frame 1, and intermediate positioning mechanism 4 comprises centering platform 41 installed on the frame, centering positioning seat 42 and centering cylinder 43, and two centering cylinders 43 act successively to The plastic film is pushed toward the centering and positioning seat 42 to complete the centering and positioning of a single plastic film.

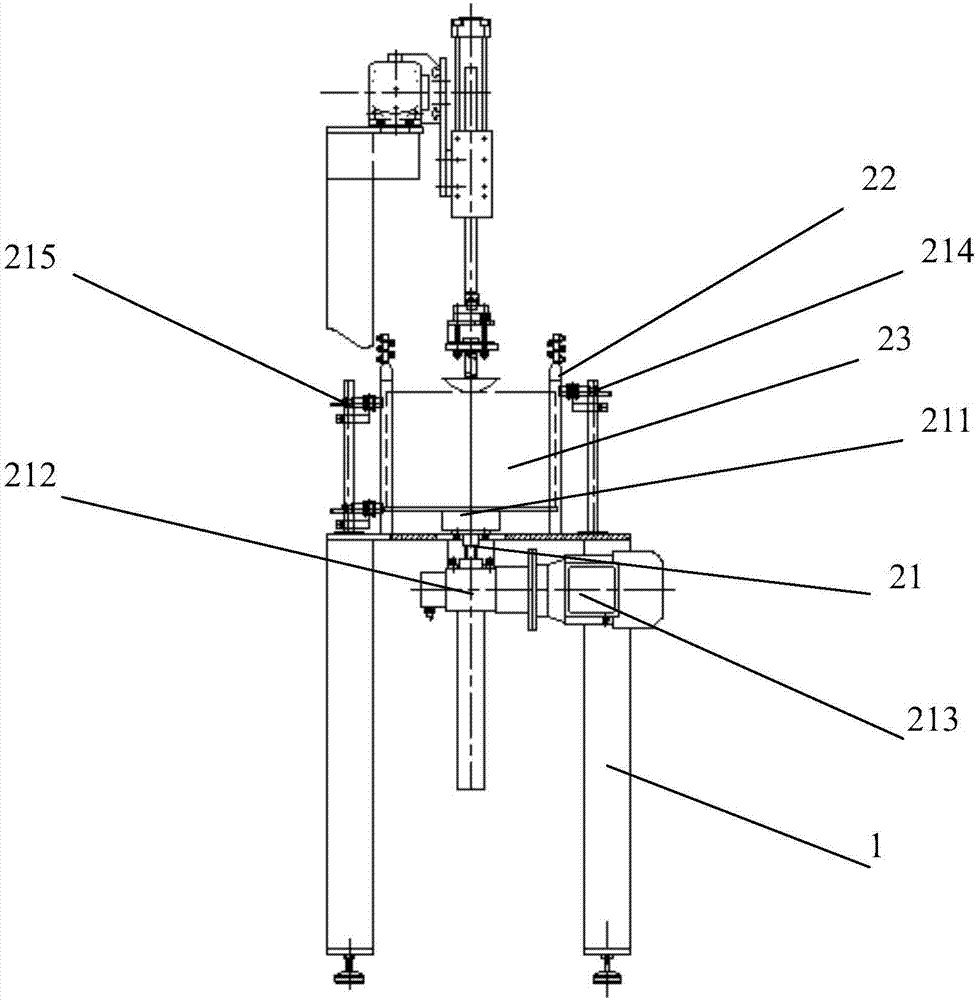

[0017] Such as image 3 The plastic film automatic ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com