Aluminum-titanium alloy material carbonization treatment equipment for aerospace satellite manufacturing

A technology of aluminum-titanium alloy and carbonization treatment, which is applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of time-consuming, laborious, cumbersome steps and danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A carbonization treatment equipment for aluminum-titanium alloy materials used in the manufacture of aerospace satellites, such as figure 1 with figure 2 As shown, it includes a base plate 1, a transport assembly 2, a carburizing mechanism 3 and an electromagnetic heating mechanism 4. The upper rear part of the base plate 1 is provided with a transport assembly 2, and the upper rear part of the base plate 1 is provided with a carburizing mechanism 3. The carburizing mechanism 3 Connected with the transport component 2, an electromagnetic heating mechanism 4 is provided in the left middle of the bottom plate 1, and the electromagnetic heating mechanism 4 cooperates with the transport component 2.

[0079] First, people put the aluminum-titanium alloy material in the electromagnetic heating mechanism 4, and pour the carbonizing liquid into the carburizing mechanism 3, so that the carburizing mechanism 3 continuously sprays the carbonizing liquid, and then turn on the ele...

Embodiment 2

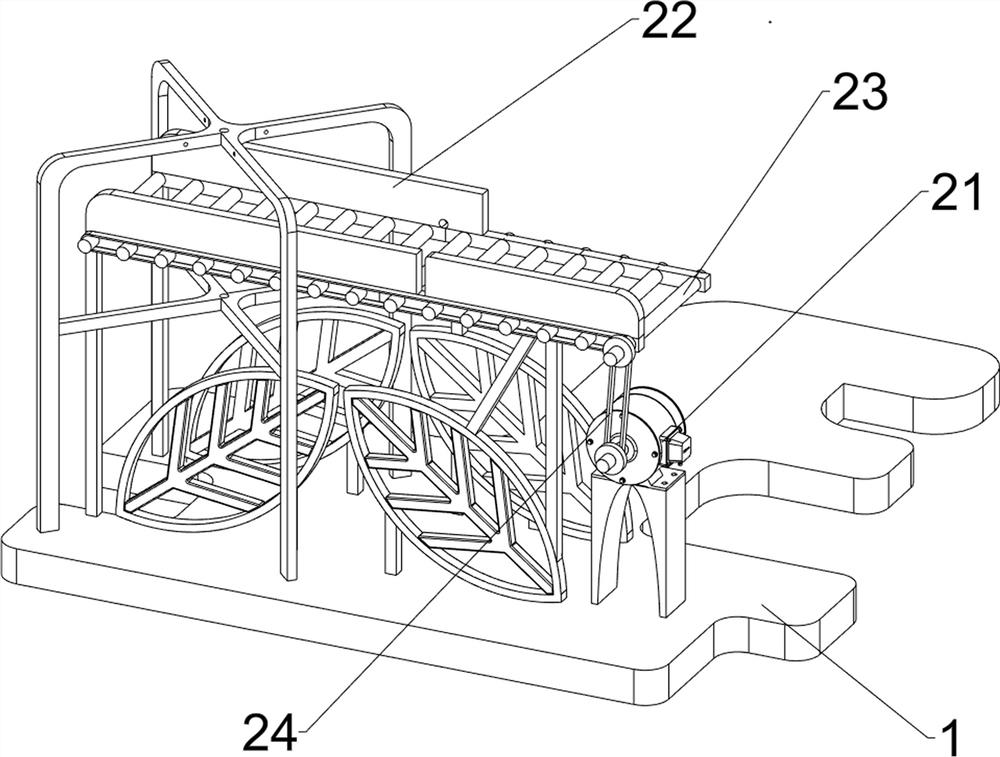

[0081] On the basis of Example 1, such as image 3 , Figure 4 with Figure 5 As shown, the transport assembly 2 includes a first servo motor 21, a material blocking plate 22, a transmission assembly 23 and a transmission assembly 24. The first servo motor 21 is installed on the left side of the upper rear part of the base plate 1, and the upper rear part of the base plate 1 is provided with two Block baffle plate 22, between the baffle plate 22 of front and back both sides is connected with transmission assembly 23 in a rotational manner, and is connected with transmission assembly 24 between the left side of transmission assembly 23 rear part and the output shaft of the first servo motor 21.

[0082] The heated aluminum-titanium alloy material slides from the electromagnetic heating mechanism 4 to the left part of the top side of the transmission assembly 23 due to gravity, and people start the first servo motor 21, and the output shaft of the first servo motor 21 rotates t...

Embodiment 3

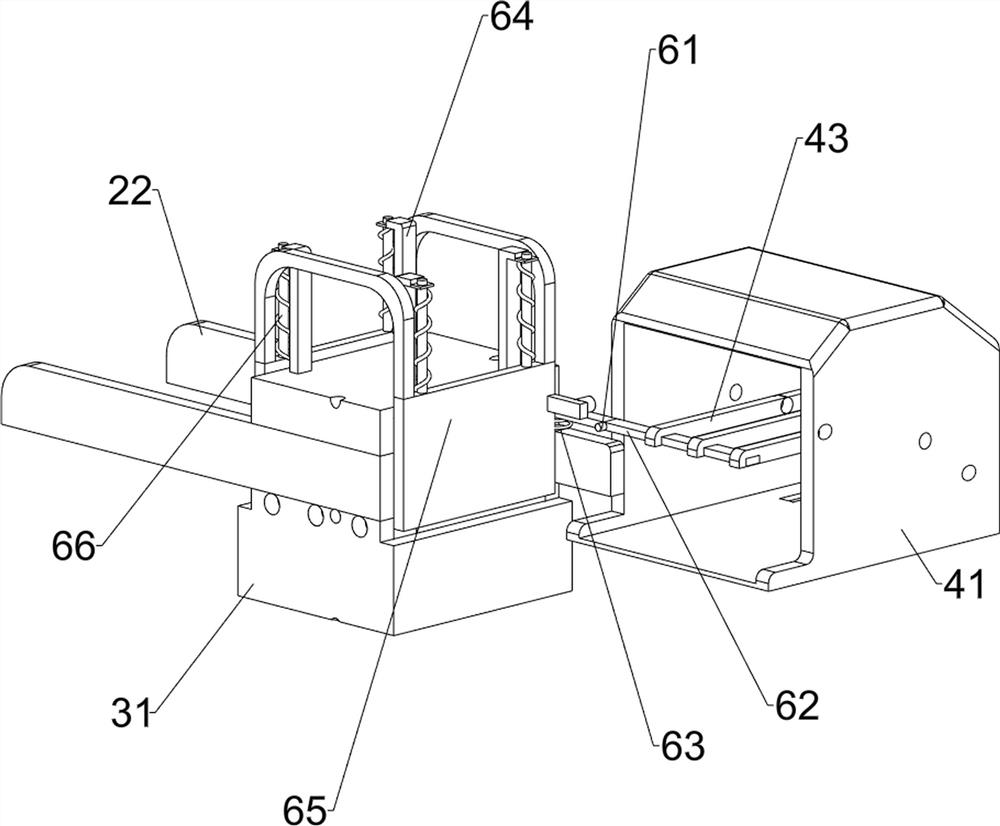

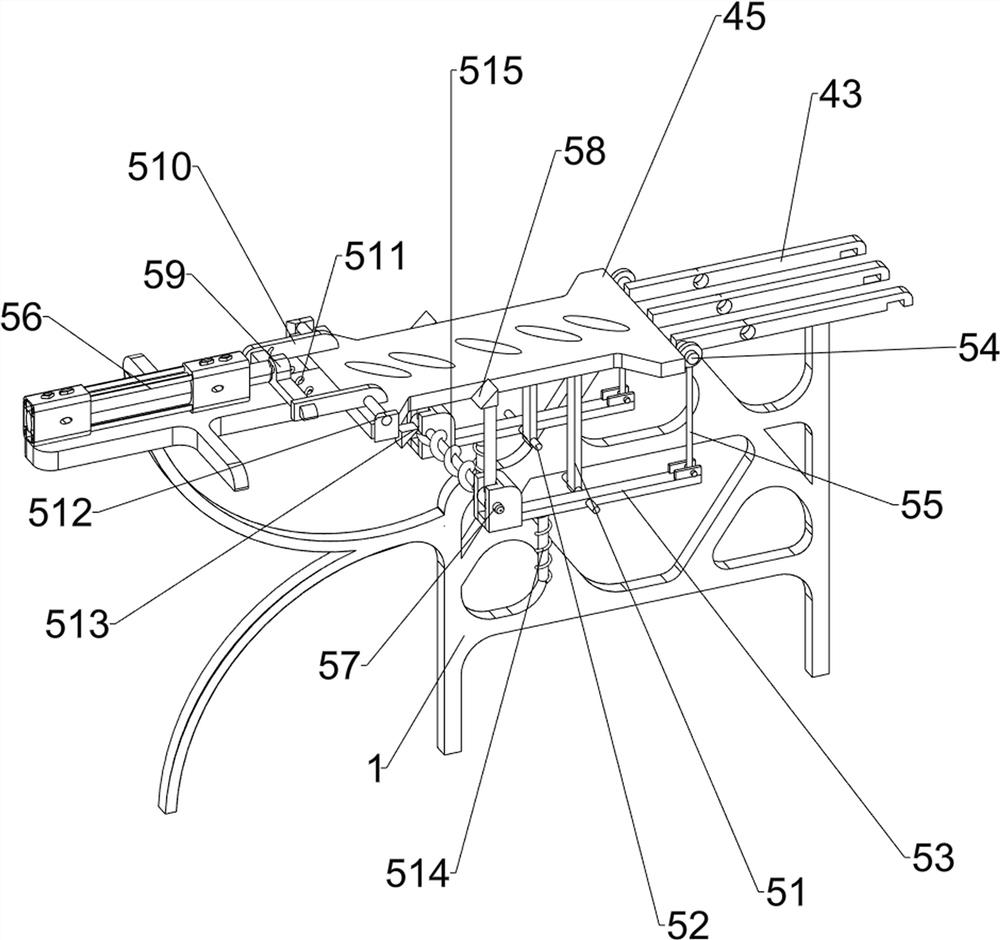

[0088] On the basis of Example 2, such as figure 1 , figure 2 , Image 6 , Figure 7 with Figure 8 As shown, also include pinch mechanism 5, pinch mechanism 5 includes fixed block 51, first rotating rod 52, first pry plate 53, second rotating rod 54, connecting rod 55, cylinder 56, fixed rotating rod 57 , the first wedge-shaped block 58, the push block 59, the clamp block 510, the second spring 511, the second wedge-shaped block 512, the third wedge-shaped block 513, the first elastic assembly 514 and the third spring 515, behind the bottom side of the material holding plate 45 The left and right sides of the part are all provided with fixed blocks 51, and the inner sides of the fixed blocks 51 bottoms on the left and right sides are all rotatably provided with first rotating rods 52, and the first rotating rods 52 on the left and right sides are all provided with first skid plates 53, The first elastic assembly 514 is connected between the bottom side front part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com