Medical alcohol boxing and packaging device

An alcohol and cartoning technology, applied in the directions of packaging, transportation and packaging, application, etc., can solve the problems of volatile and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A medical alcohol packing device, such as figure 1 As shown, it includes a workbench 1, a mounting frame 2, a feed port 3, a feeding mechanism 4 and a first unloading mechanism 5, and two workbenches 1 are placed on the ground, and two workbenches 1 are provided with mounting frames. 2. There is a feeding port 3 between the upper sides of the two installation frames 2, a feeding mechanism 4 is provided between the middle parts of the two workbenches 1, and a The first blanking mechanism 5.

[0068] When people need to box and package medical alcohol, people place the alcohol box on the feeding mechanism 4 from the feed port 3, and place the alcohol barrel next to the workbench 1 on the left side, so that the first unloading mechanism 5 is located In the alcohol barrel, at this time, people will open the feeding mechanism 4, so that the feeding mechanism 4 drives the alcohol box to move. When the alcohol box moves below the first feeding mechanism 5, the feeding mechani...

Embodiment 2

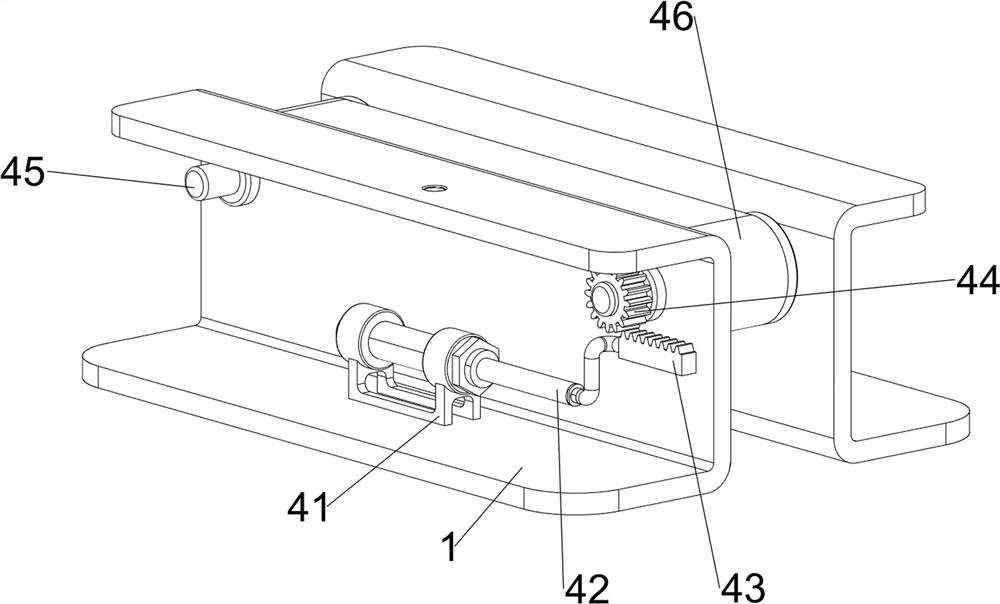

[0070] On the basis of Example 1, such as figure 2 As shown, the feeding mechanism 4 includes a cylinder 41, a push rod 42, a rack 43, a gear 44, a first rotating shaft 45 and a belt assembly 46, the workbench 1 on the left side is provided with a cylinder 41, and the piston rod of the cylinder 41 is connected with a Push rod 42, rack 43 is arranged on push rod 42, first rotating shaft 45 is arranged on the front and rear sides between the two workbenches 1, and belt assembly 46 is wound between the two first rotating shafts 45, the front side The left part of the first rotating shaft 45 is provided with a gear 44, and the gear 44 is meshed with the rack 43.

[0071] When the alcohol box is placed on the belt assembly 46 through the feed port 3, people will open the cylinder 41, so that the piston rod of the cylinder 41 drives the push rod 42 to move, and when the piston rod of the cylinder 41 drives the push rod 42 to move to the side, Make the rack 43 move to the front sid...

Embodiment 3

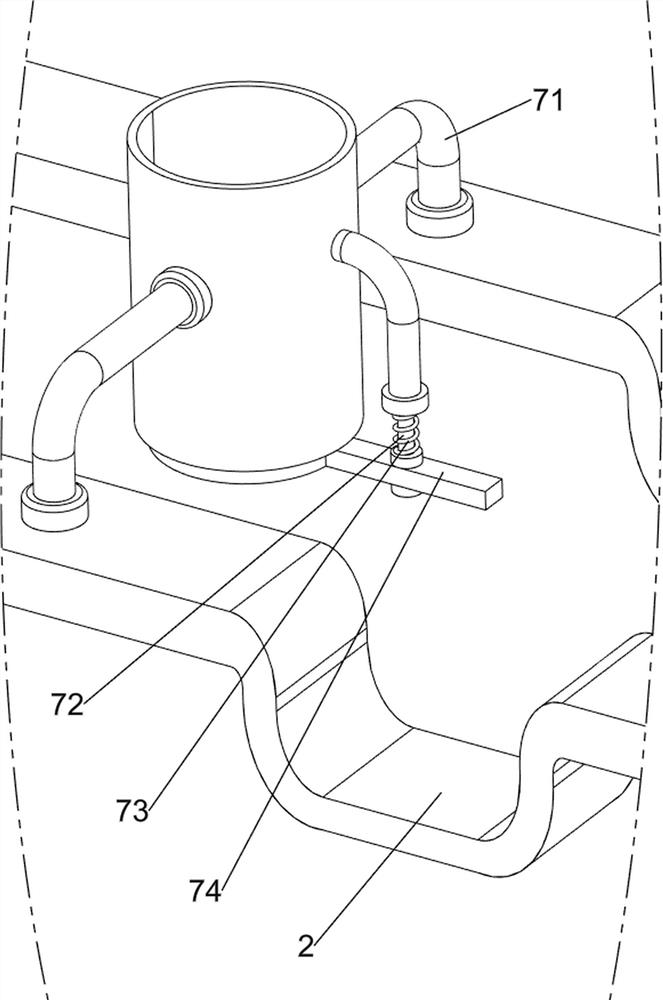

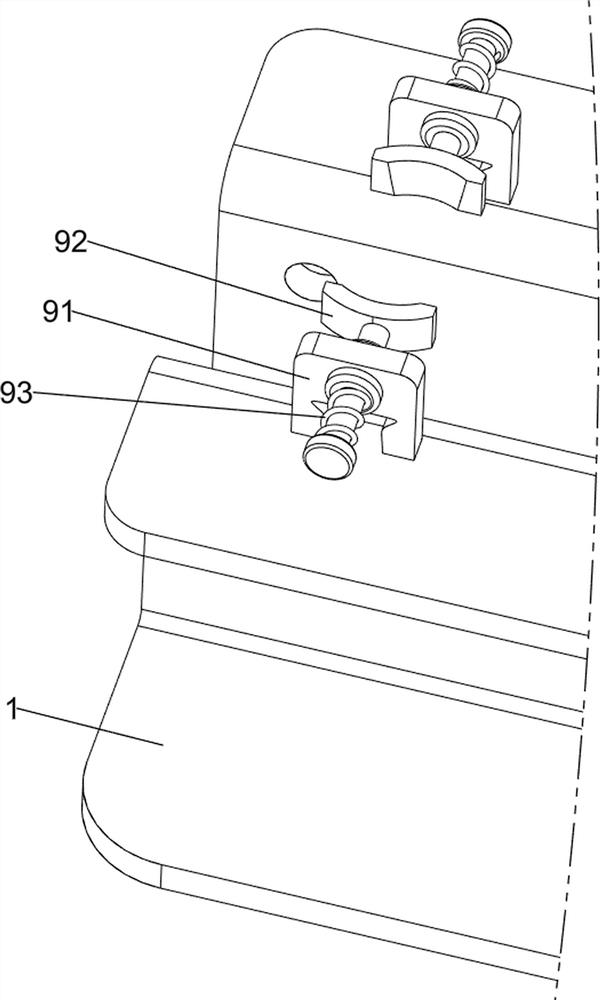

[0073] On the basis of Example 2, such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the first unloading mechanism 5 includes a feed pipe 51, a valve body 52, a movable block 53, a first spring 54, a connecting block 55, a first slide bar 56 and a second spring 57, and the left side of the workbench 1 A first slide bar 56 is provided in the middle of the upper left part, and a connecting block 55 is slidably arranged on the first slide bar 56. A second spring 57 is sleeved on the first slide bar 56, and the two ends of the second spring 57 are connected with the connecting block 55 respectively. Connected with the first slide bar 56, the upper middle part of the workbench 1 on the left side is provided with a movable block 53, and a valve body 52 is slidingly arranged on the movable block 53. The first spring 54 is connected with the valve body 52 and the movable block 53 , the left and right ends of the valve body 52 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com