Ultra-large type evanescent mould precision-casting shell manufacturing tool and shell manufacturing process thereof

A lost foam and super-large technology, applied in the field of investment casting, can solve the problems of castings that cannot be flipped flexibly, immediate sand hanging, mold shell deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

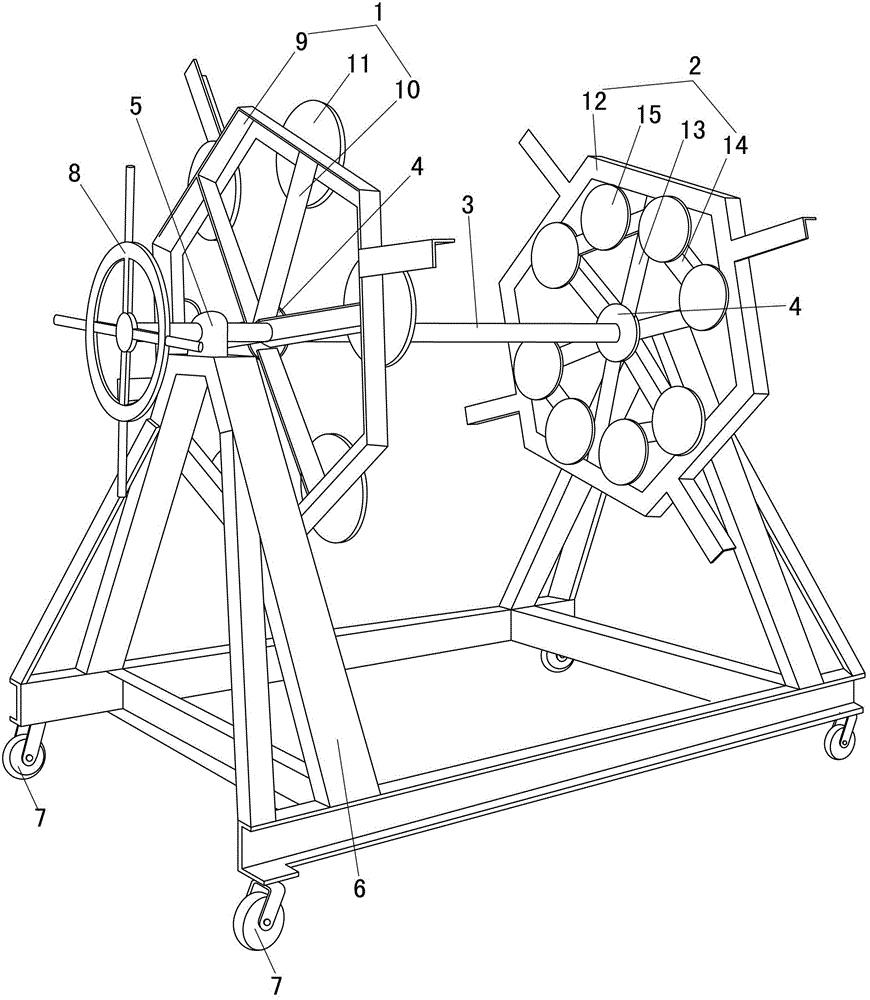

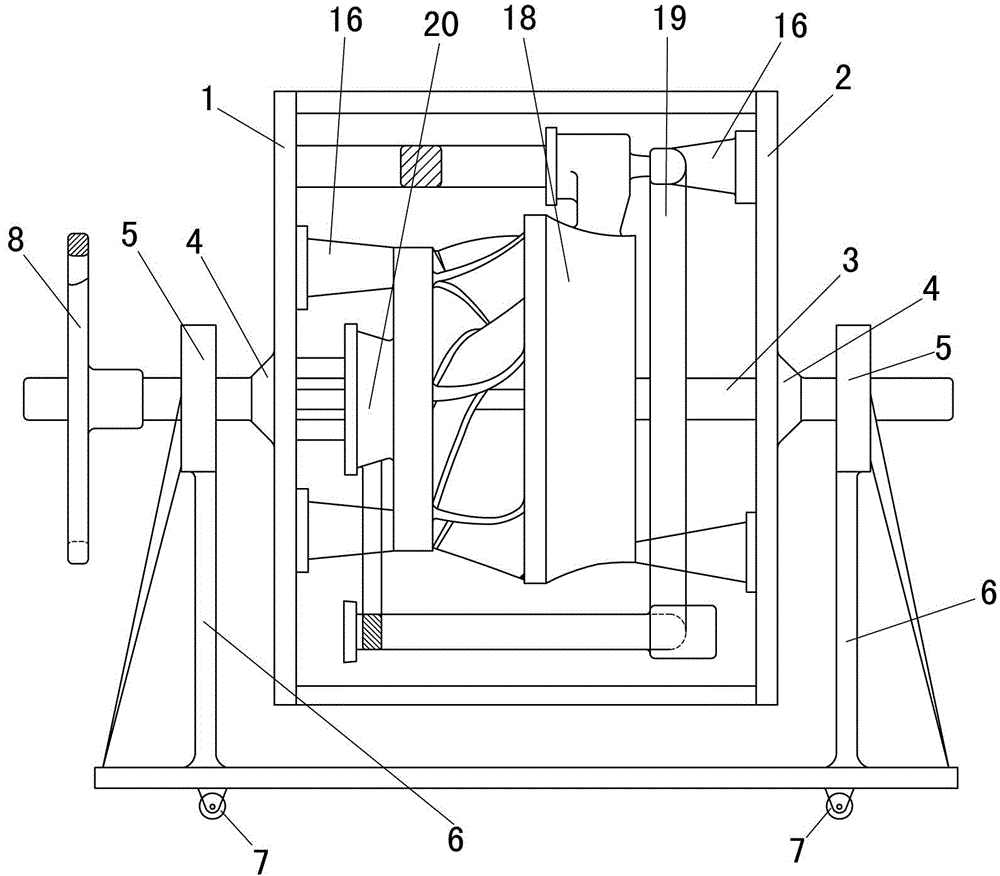

[0022] Such as figure 1 and figure 2 As shown, the ultra-large lost foam investment casting tooling of the present invention includes a first spoke structure 1 and a second spoke structure 2 . The first spoke structure 1 and the second spoke structure 2 are installed on the left and right parts of the main shaft 3 . The first spoke structure 1 comprises a hexagonal first frame 9 . Six first connecting plates 10 are welded in the first frame 9 . One end of each first connecting plate 10 is located at the center of the first frame 9 and welded together. The other end of each first connecting plate 10 is vertically welded to each side plate of the first frame 9 respectively. A first circular plate 11 is connected to the right side of the side plate connecting portion of each first connecting plate 1 and the first frame 9 . The second spoke structure 2 comprises a hexagonal second frame 12 . Six second connecting plates 13 are welded in the second frame 12, and one end of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com