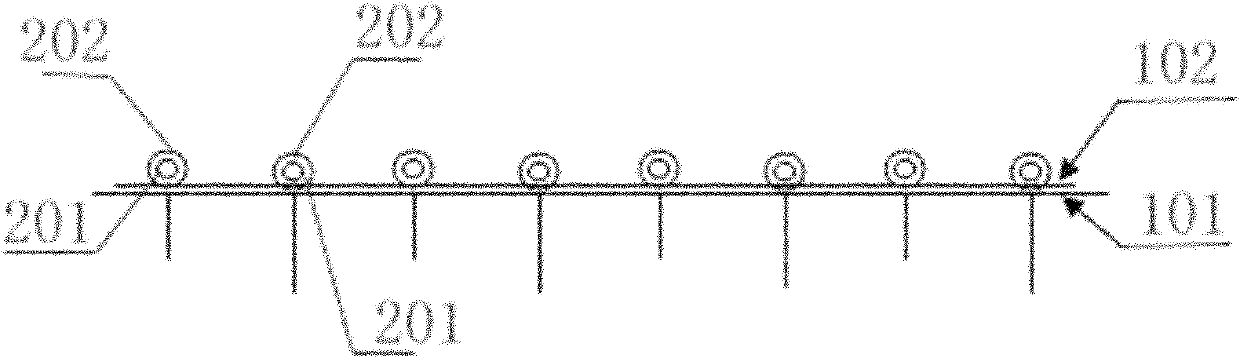

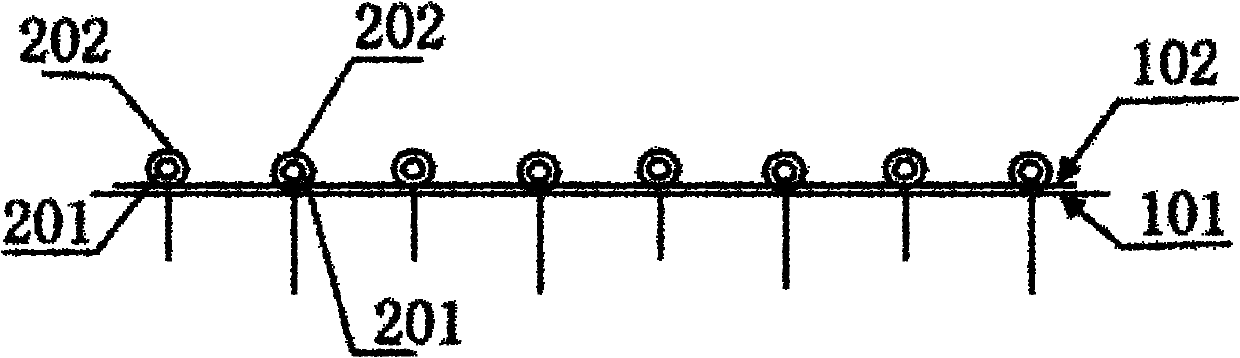

Structure of nylon polyurethane fiber sanding fabric and production method thereof

A production method, spandex technology, applied in fabric surface trimming, heating/cooling fabrics, textiles and papermaking, etc., can solve the problems of reduced quality stability, more repairs, long process, etc., to achieve stable quality and low repair rate , even sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Below in conjunction with embodiment, the production process of the present invention is compared with original production process.

[0027] Selected fabric name: 220G / M270D / 68Ftactel / 2+30D Lycra spandex jersey surface carbon sanding

[0028] Production technology of the present invention and the contrast of former production technology are as follows:

[0029] original craft

[0030] Weaving fabric: large circular machine 34 inches 24G weaving

[0031] Blank high temperature presetting: 190℃, overfeed 20%, speed 20m / min

[0032] Stitching: Prevents uneven dyeing from curling of the selvedge

[0033] Dyeing: Nylon dyed with acid dyes at 98°C*40 minutes

[0034] Post-processing + color fixation

[0035] fixed dry

[0036] The carbon sanding is as follows: Machine: Mario crosta made in Italy

[0037] Sanding roller: 1.2.3.4 The difference between the sanding rollers is 5.5 / 6 / 6.3 / 6.2

[0038] Cloth output speed: 6 m / min

[0039] Tension: 50%

[0040] Main speed: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com