Equipment for processing plastic bottle cap by extrusion compression molding

A technology of molding processing and bottle caps, which is applied to household components, household appliances, and other household appliances, and can solve problems such as uneven extrusion, incomplete stripping, and mold sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

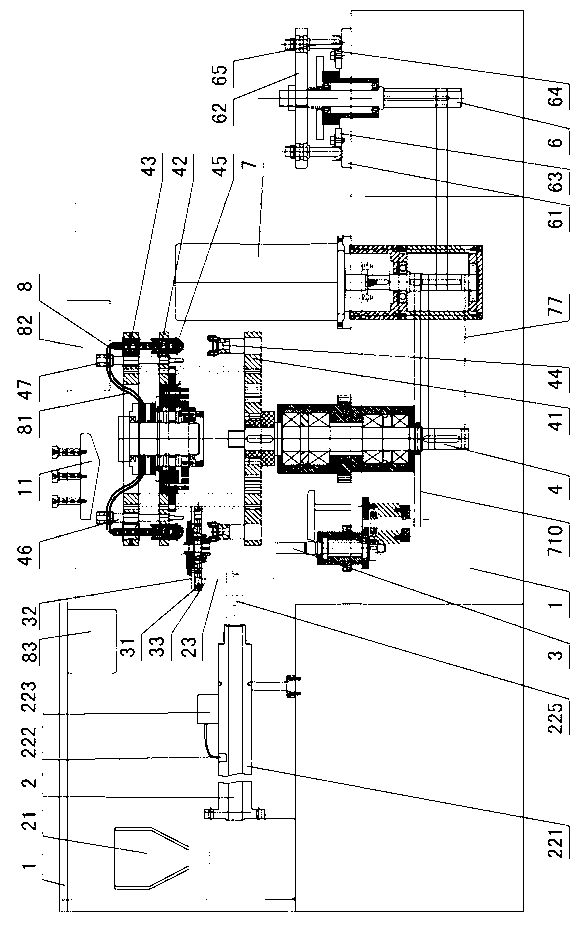

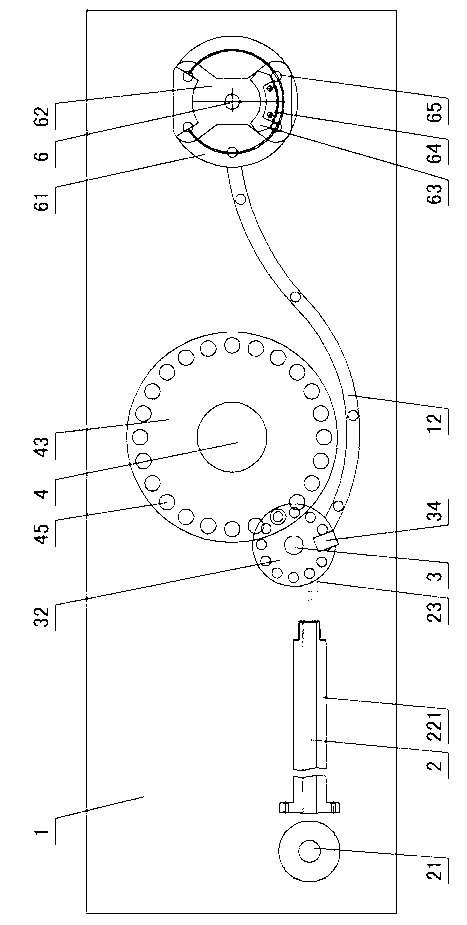

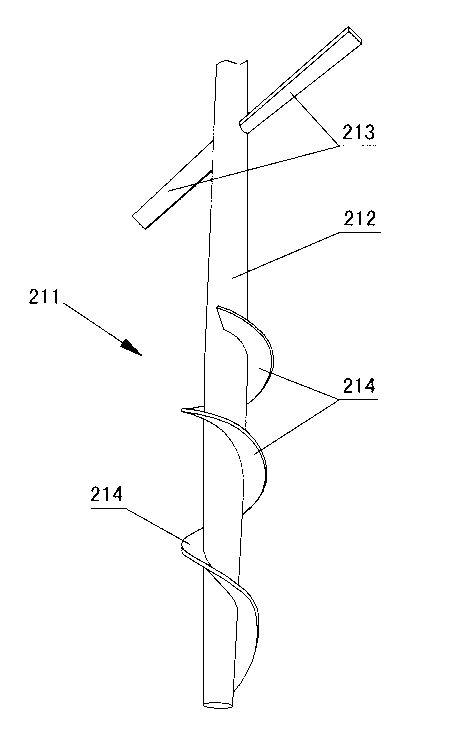

[0015] The present invention relates to a kind of equipment of extruding molding processing plastic bottle cap, such as figure 1 — Figure 8 As shown, it is characterized in that it includes a frame 1, and an extrusion mechanism, a scraping and feeding mechanism, a molded cap mechanism, a demoulding mechanism, a ring cutting mechanism and a thermal insulation and dehumidification system are installed on the frame, and the extrusion mechanism includes a feed Bucket 21, barrel 2 and extrusion port 23, reinforced feeding screw 211 is installed in the feeding hopper, the reinforced feeding screw includes material roller 212, the material roller is driven to rotate by the motor, and the left and right two stirring material rollers are formed on the material roller Rod 213 and extruding blade 214, the diameter of the two ends of the material roller 212 is smaller than the diameter of the middle part, and an extruding sheet 214 is formed on the outer wall of the middle part of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com