SLS (selective laser sintering) double-roller powder spreading device

A powder spreading device and laser sintering technology, which is applied in the direction of improving process efficiency and energy efficiency, and can solve problems such as limited equipment space saving, complex device structure, and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

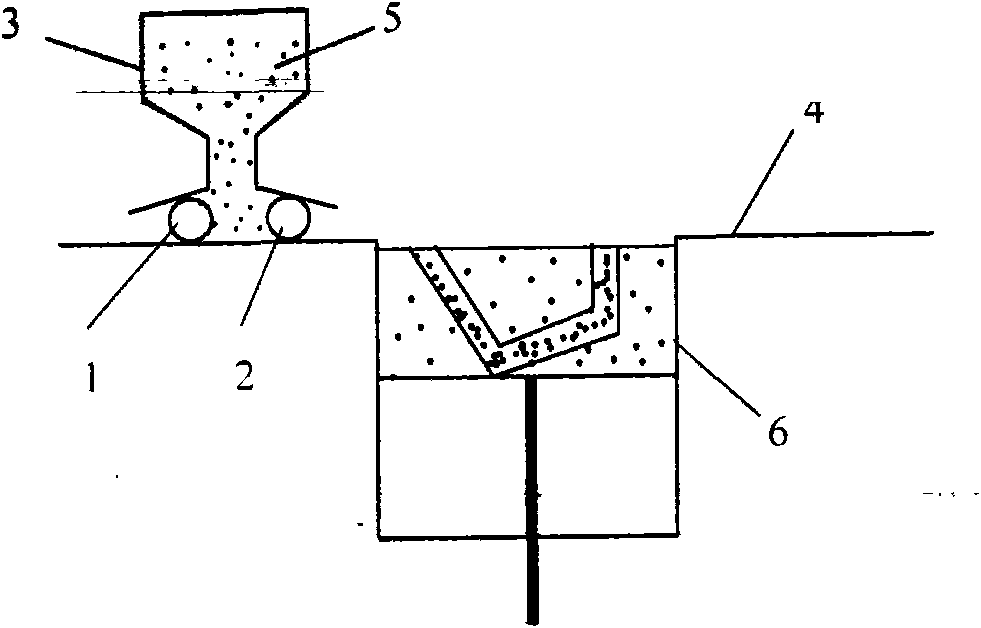

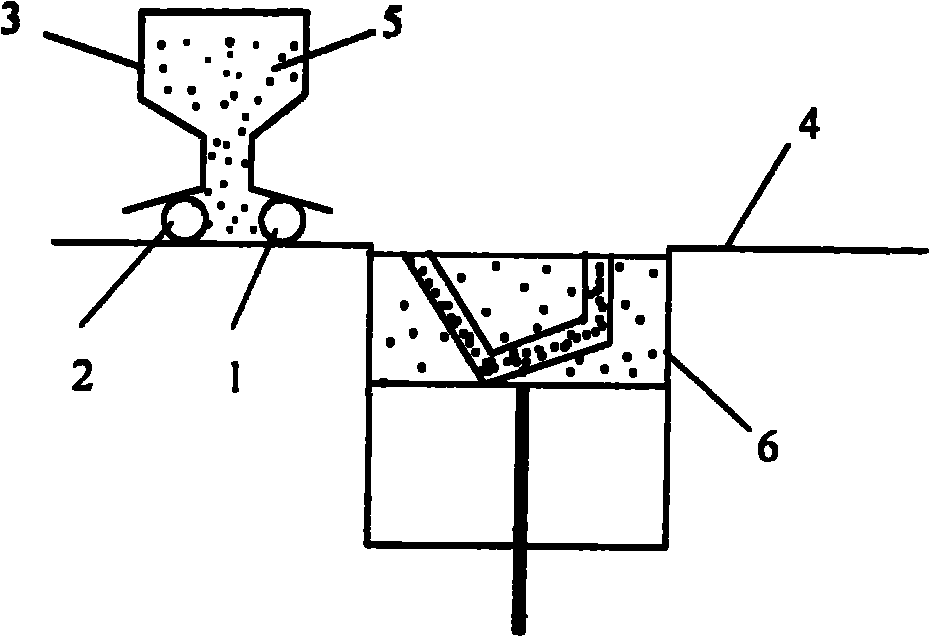

[0009] As shown in the accompanying drawings, the present invention includes a powder storage cylinder (3), two parallel powder spreading rollers: a left powder spreading roller (1) and a right powder spreading roller (2), and the powder spreading device and the king's table (4 ) to form a closed system, the powder storage cylinder (3) is a cylinder body with an open bottom, fixed on two parallel powder spreading rollers (1 and 2), and can move synchronously with the powder spreading rollers, and the powder spreading powder (5) is stored In the closed system formed by the device and the work surface (4). The double-roller powder spreading device moves from the left side of the working cylinder (6) to the right side of the working cylinder (6), the right powder spreading roller (2) compacts the upper layer of powder, and the left powder spreading roller (1) compresses the powder spreading powder ( 5) Spread evenly on the work surface (4). The powder spreading device runs to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com