Automatic ink supply system for printing machine

A printing machine, automatic technology, applied in the direction of printing machines, printing, general parts of printing machinery, etc., can solve the problems of working environment impact, overflowing ink cartridges, waste, etc., and achieve the effect of cleaning the working environment, avoiding fluctuations, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

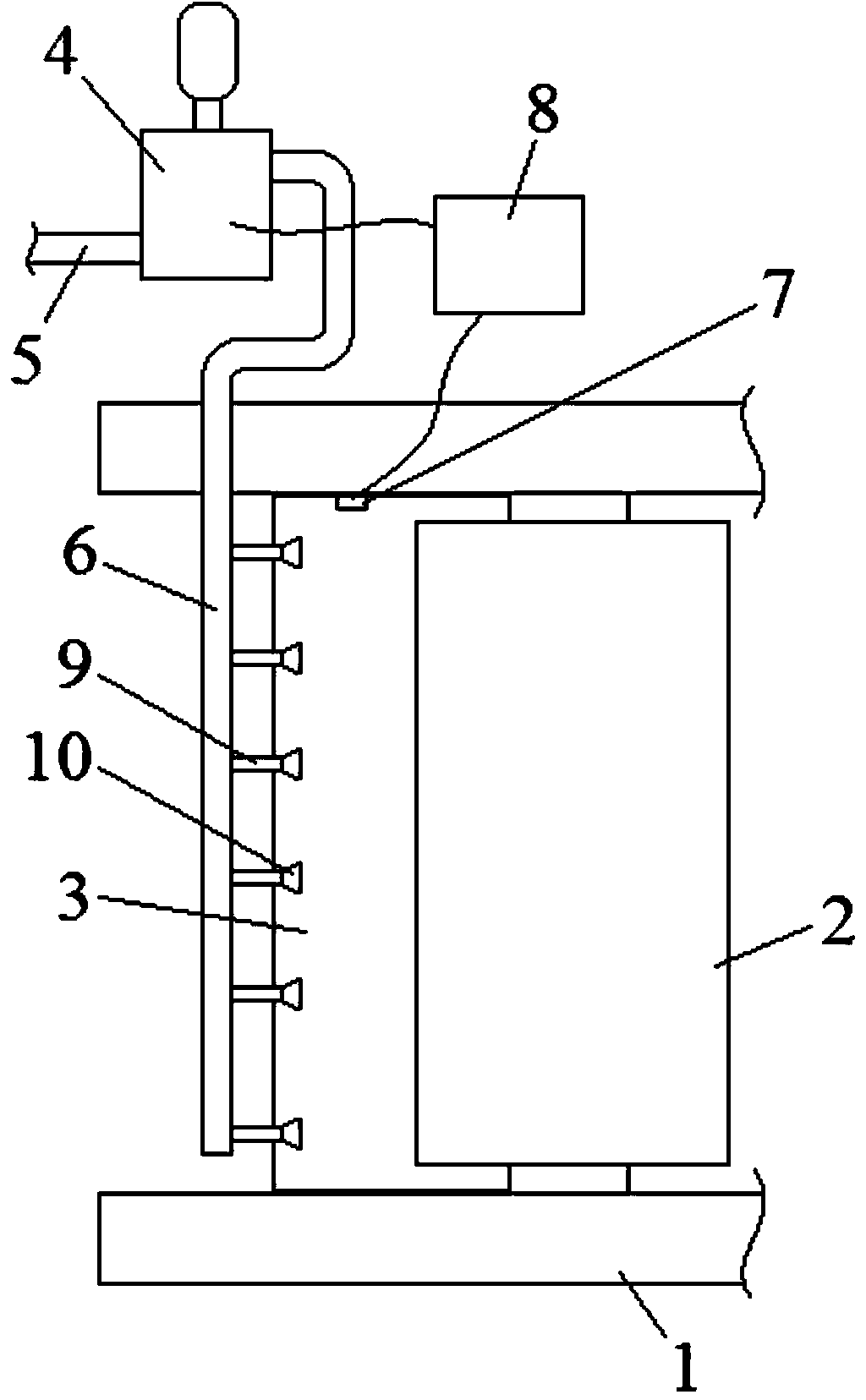

[0011] see figure 1 , an automatic ink supply system for a printing machine, including a printing roller set 2 rotatably mounted on a printing machine frame 1, an ink cartridge 3 is fixedly installed below the printing roller set 2 on the printing machine frame 1, and the printing machine The outer side of frame 1 is provided with ink supply pump 4, is respectively connected with inlet and outlet ink tube 5,6 on the ink supply pump 4, and liquid level sensor 7 is installed in the ink box 3, and liquid level sensor 7 communicates with ink supply through controller 8. The pump 4 is electrically connected; the front side of the ink cartridge 3 is respectively provided with a plurality of openings, and the front end of the ink outlet pipe 6 extends to the front of the ink cartridge 3, and one side of the front end of the ink outlet pipe 6 is respectively connected with a plurality of branch pipes 9. The front ends of the branch pipes 9 respectively pass through a plurality of open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com