Fan framework machining machine

A technology for processing machines and fan bones, applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of time-consuming efficiency, increase production costs of enterprises, restrict enterprise development, etc., to ensure environmental sanitation, improve efficiency, and save labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

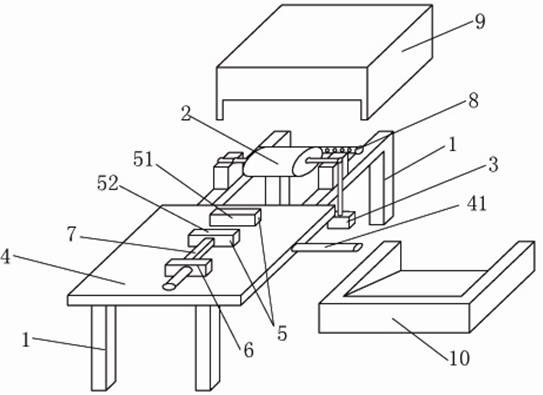

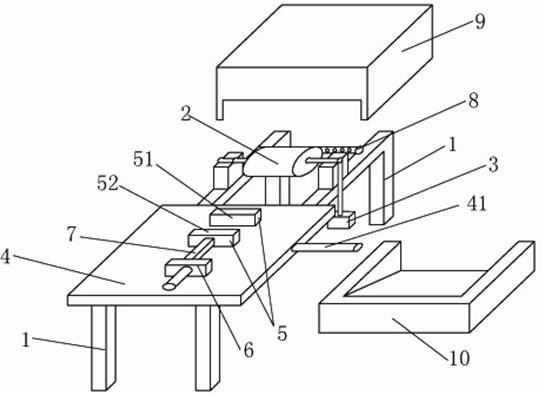

[0014] Combine below figure 1 Specific description embodiment:

[0015] A fan bone processing machine, comprising a frame 1, the frame 1 is provided with a grinding wheel 2, the grinding wheel 2 is connected with a motor 3, the frame 1 is movably connected with a slide plate 4, and the slide plate 4 A clamp 5 and a cylinder 6 are provided on it, the clamp 5 includes a fixed clamp 51 and a movable clamp 52, the movable clamp 52 is connected to the cylinder 6 through a push rod 7, and the clamp 5 can be approached under the push of the slide plate 4 The grinding wheel 2 reaches the bottom of the grinding wheel 2, and the frame 1 is provided with a water spray pipe 8 on one side of the grinding wheel 2.

[0016] Preferably, the grinding wheel 2 is provided with a protective cover 9 outside.

[0017] In a preferred manner, the sliding plate 4 is provided with a pull rod 41 .

[0018] Preferably, the frame 1 is provided with a drainage groove 10 below the grinding wheel 2 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com