Pretreatment device and soil remediation method using same

A pretreatment device and soil technology, applied in the field of soil remediation, can solve the problems of workers' health hazards, noise pollution, energy consumption, etc., and achieve the effects of comprehensive and thorough restoration, improved quality, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0068] Embodiment two: a kind of pretreatment device and the soil remediation method using this device, and the difference of embodiment one is, comprise the following several steps:

[0069] Step 1: Use multi-point sampling method to investigate, measure and evaluate the polluted soil;

[0070] Step 2: Dig out the polluted soil, pave the excavated soil to a thickness of 3cm-5cm, and spray the excavated soil with water at a rate of 1L / ㎥. Then it is dried, the drying temperature is controlled at 80°C, and the drying time is controlled at 2h. After drying, it is left to stand for 40min to keep the soil humidity at 60%;

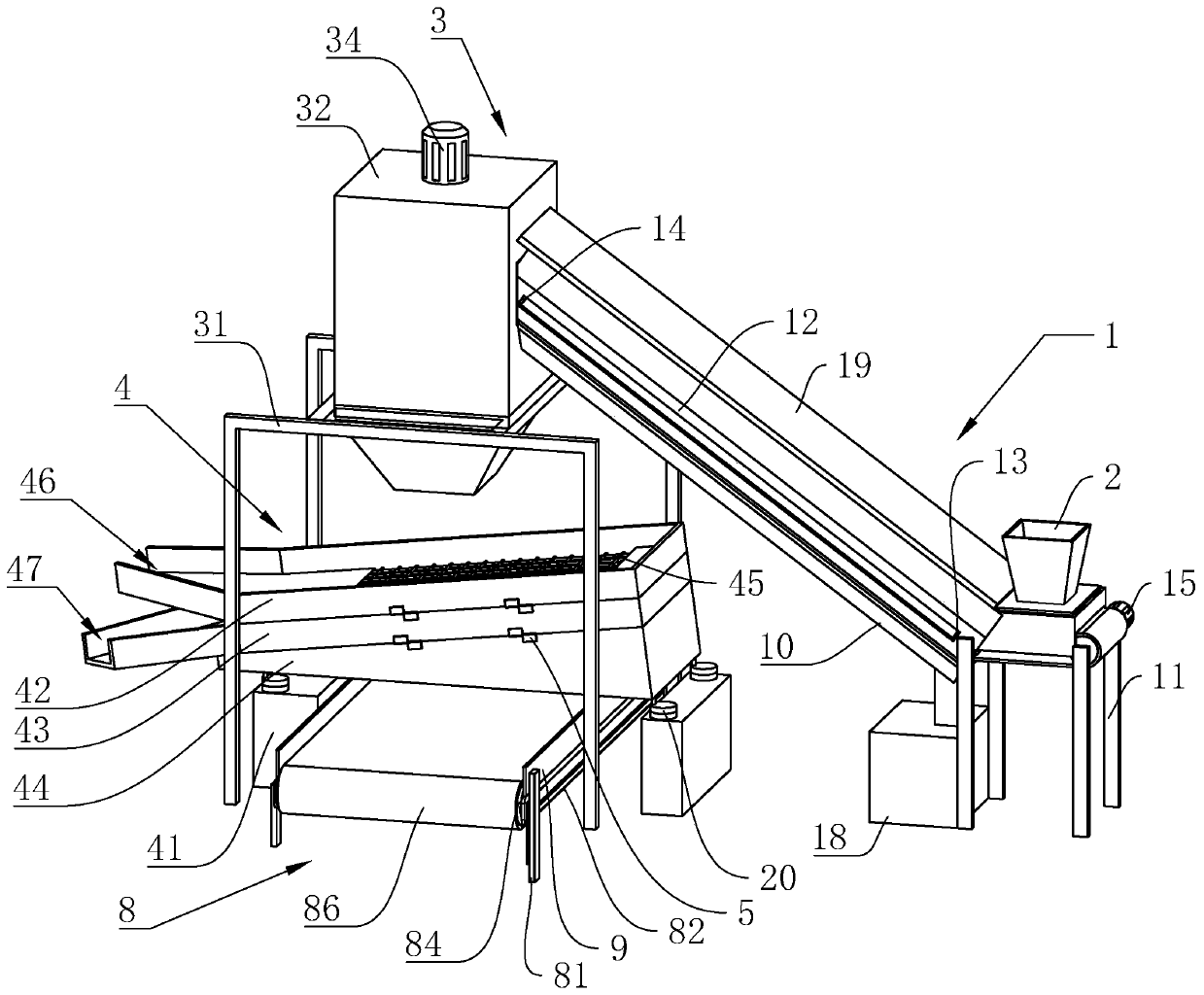

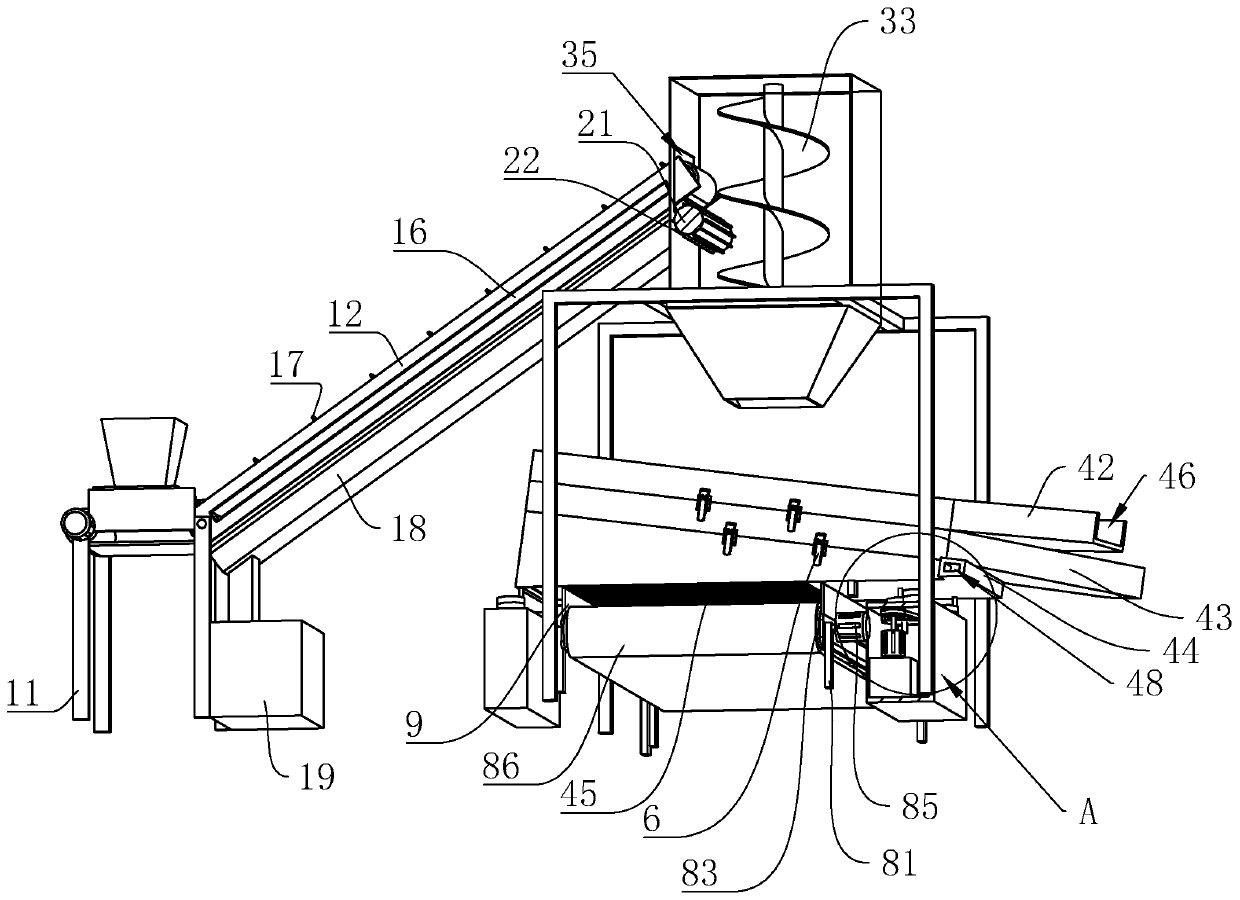

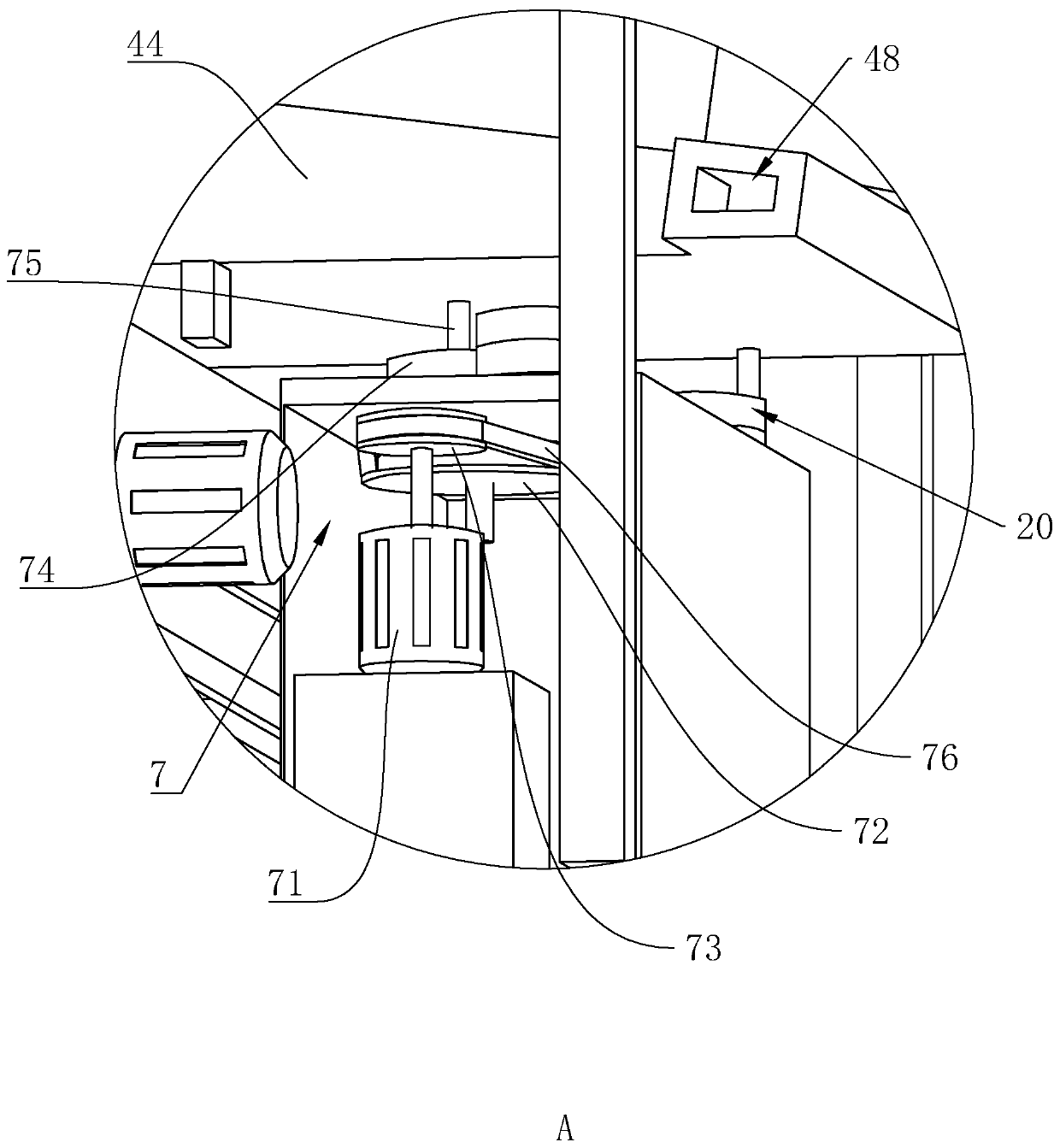

[0071] Step 3: Use the slope feeding mechanism 1 to transport the soil into the crushing cylinder 32, the crushing blade 33 in the crushing cylinder 32 crushes the soil, the speed of the crushing blade 33 is controlled at 800rpm, and the crushed soil falls to the screening mechanism 4, the eccentric structure 7 drives the first sieve plate 42, the second sieve ...

Embodiment 3

[0075] Embodiment three: a kind of pretreatment device and the soil remediation method using this device, and the difference of embodiment one is, comprise the following several steps:

[0076] Step 1: Use multi-point sampling method to investigate, measure and evaluate the polluted soil;

[0077] Step 2: Dig out the polluted soil, pave the excavated soil to a thickness of 4cm, and spray the excavated soil with water at a rate of 0.8L / ㎥, after spraying Dry it, the drying temperature is controlled at 70°C, and the drying time is controlled at 1.5h. After drying, let it stand for 35min to keep the soil humidity at 55%;

[0078] Step 3: Use the slope feeding mechanism 1 to transport the soil into the crushing cylinder 32, the crushing blade 33 in the crushing cylinder 32 crushes the soil, the speed of the crushing blade 33 is controlled at 700rpm, and the crushed soil falls to the screening mechanism 4, the eccentric structure 7 drives the first sieve plate 42, the second sieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com