Loading device for calibrating displacement sensor, and calibration method

A displacement sensor and loading device technology, applied in the direction of using electrical devices, measuring devices, instruments, etc., can solve problems such as large errors, few measurement points, and inability to meet the calibration requirements of displacement sensors of different types and ranges, and achieve rapid data processing Intuitive, compact and reasonable effect of position setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

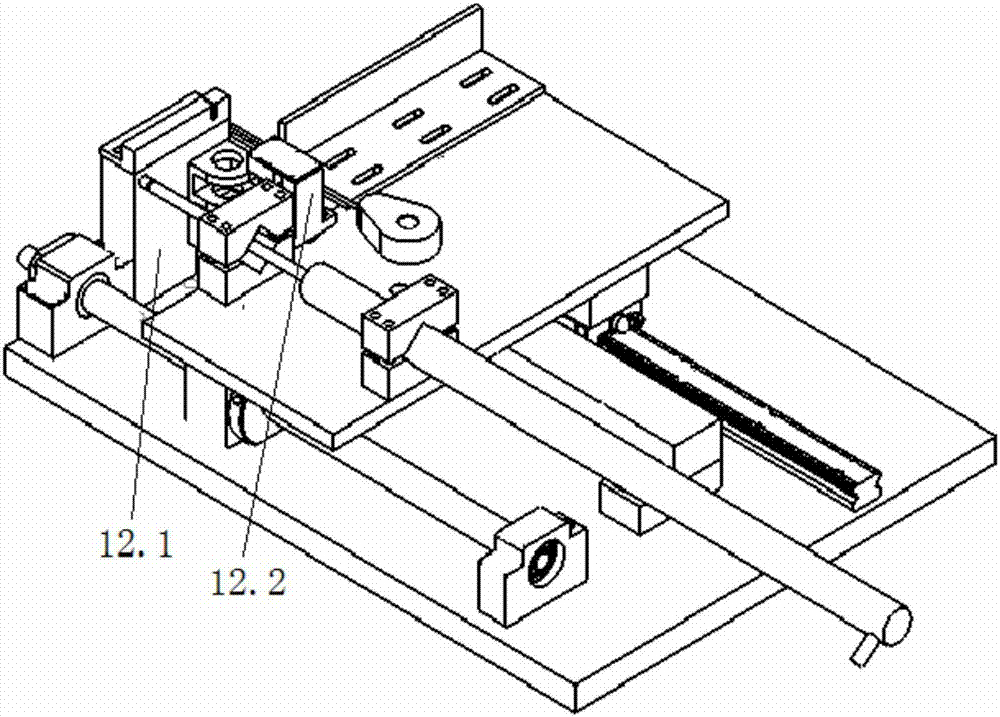

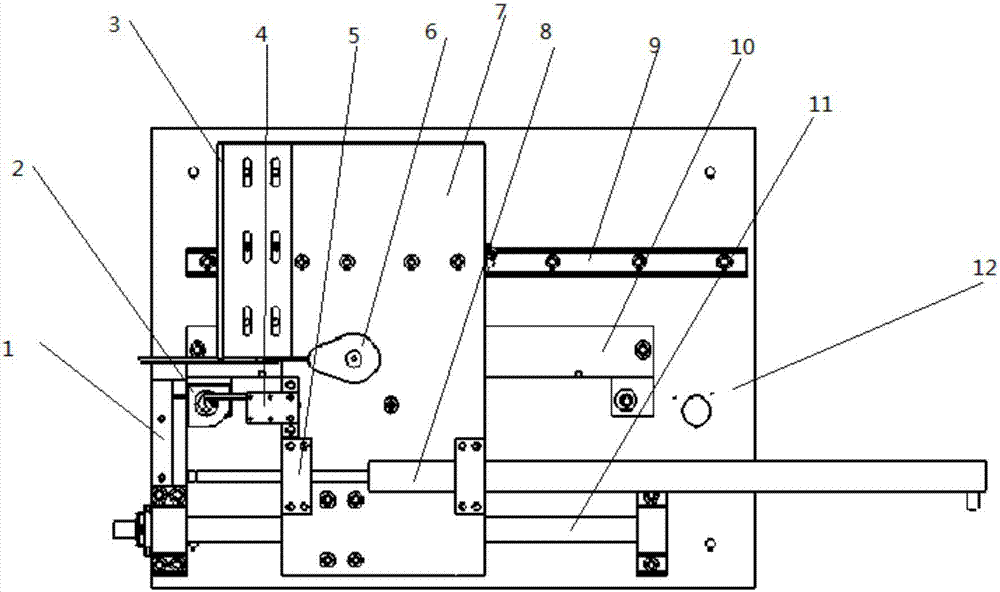

[0038] The loading device for calibration of the displacement sensor of the present invention is as figure 1 (Some details of which are not in the figure 1 Shown in , such as the mounting holes on the movable plate 7, etc., please refer to the detailed structure of the parts not shown figure 2 ) and 2, including a base plate 12, the loading device is fixed on the work table through the base plate 12, which reduces the accidental error caused by position offset during the calibration process. For convenience of description, the present invention uses figure 2 The left direction shown is the rear, and the right direction is the front (the front and rear direction is the moving direction of movable plate 7); image 3 The bottom of the page shown is left and the top of the page is shown right.

[0039] On the upper surface of the base 12, a ball screw 11, a grating ruler 10 and a linear guide 9 are arranged in parallel in sequence from left to right, and the three should be h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com