Grinding machine with automatic positioning and fine adjusting functions

An automatic positioning and positioning technology, which is used in grinding machines, control of workpiece feed motion, and machine tools designed for grinding workpiece rotating surfaces. , to achieve the effect of no deviation, improving quality and maintaining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

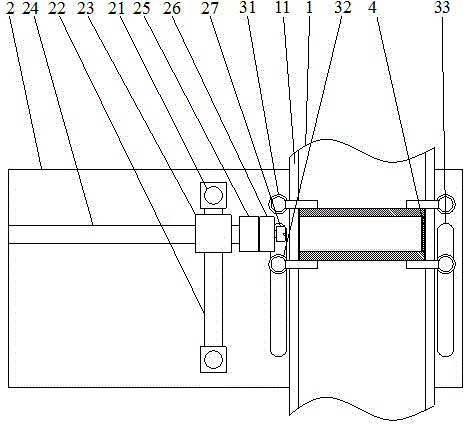

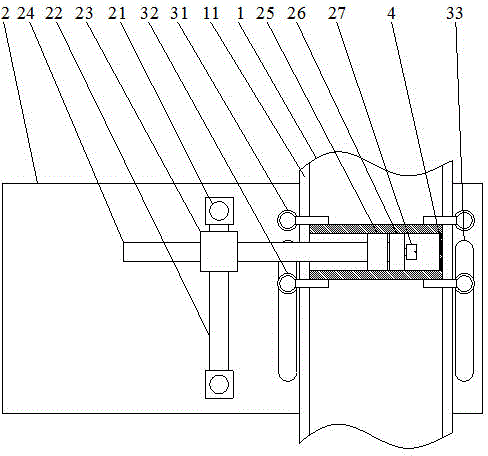

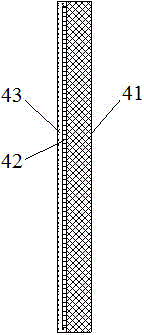

[0015] Such as Figure 1 to Figure 4 As shown, a grinding machine for automatic positioning and fine-tuning, it includes an operation table 1 and a grinder table 2 arranged under the operation table 1; the operation table 1 is an assembly line; the two sides of the assembly line are provided with limiting plates 11 Two Z-axis CNC slide rails 21 are erected on the grinder table 2 on the left side of the operation table 1; two Y-axis CNC slide rails 22 are arranged between the two Z-axis CNC slide rails 21; Numerical control slider 23 is pierced on the axis numerical control slide rail 22; X-axis slider 24 is pierced from left to right on the numerical control slider 23; the right side of the X-axis slider 24 is connected with fine frost Wheel 25, coarse grinding wheel 26 and infrared beam emitter 27; the two sides of described operating platform 1 are provided with fixed rotatable stop bar 31, mobile rotatable stop bar 32 and the slide for moving rotatable stop bar 32 to move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com