Belt conveyer

A technology for belt conveyors and conveyor belts, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve problems such as limiting the scope of use of shovel conveyors, inability to flexibly change the conveying length, and complex design and structure of belt conveyors. , to achieve the effects of good flexibility of use, enhanced work adaptability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Shovel device:

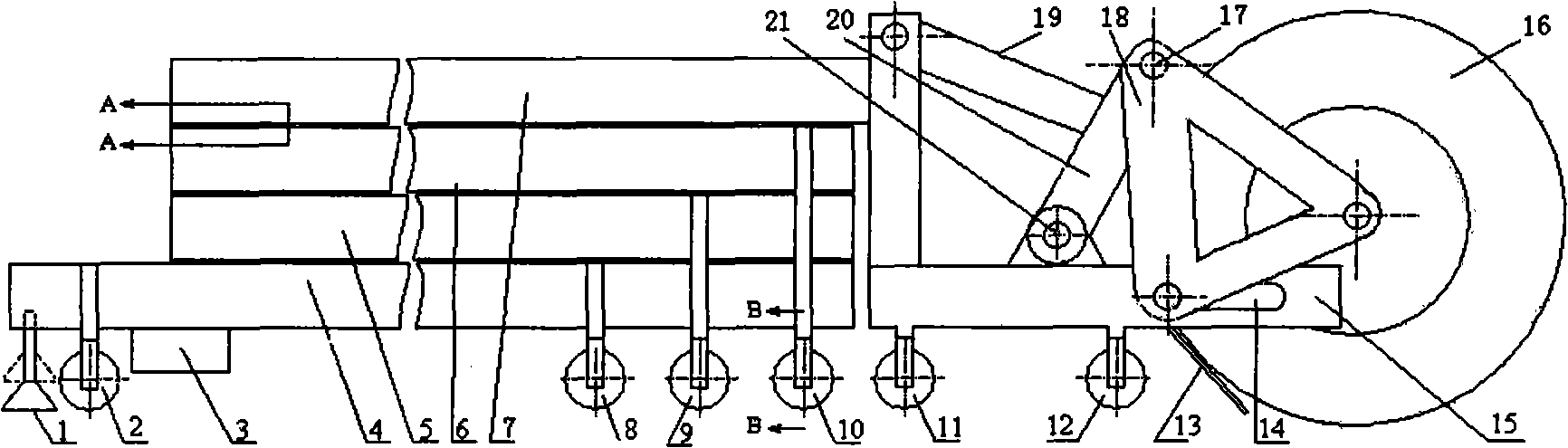

[0025] Such as figure 1 Shown: the shoveling device comprises a shovel bucket wheel 16, a flat push shovel 13, a support arm 20 and a tripod 18, the shovel bucket wheel 16 and the horizontal shovel 13 are installed on the tripod 18, and the tripod 18 is driven along the chute by a motor 14 rotates left and right around the rotary shaft 17, and the support arm 20 rotates left and right around the rotary shaft 21 to realize the lifting of the shovel bucket wheel 16 and the horizontal shovel 13.

[0026] 2. Walking mechanism

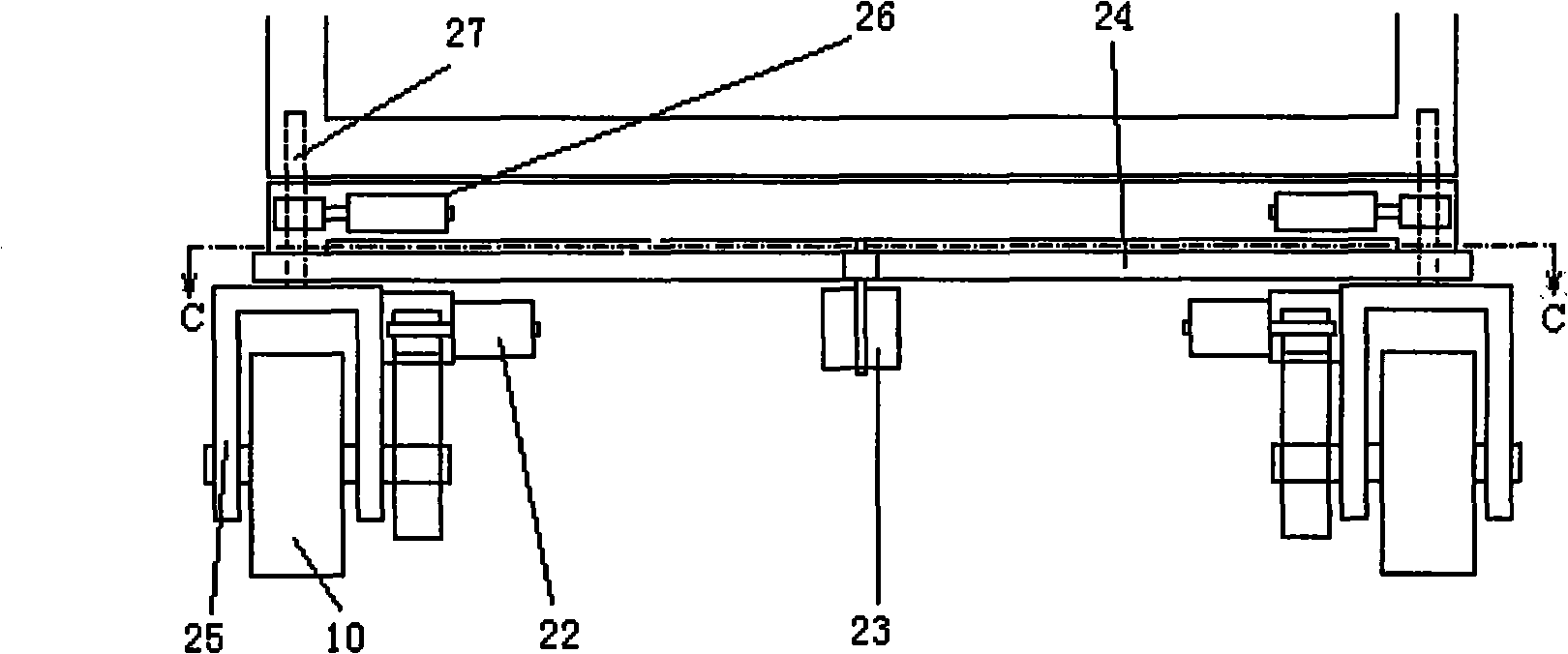

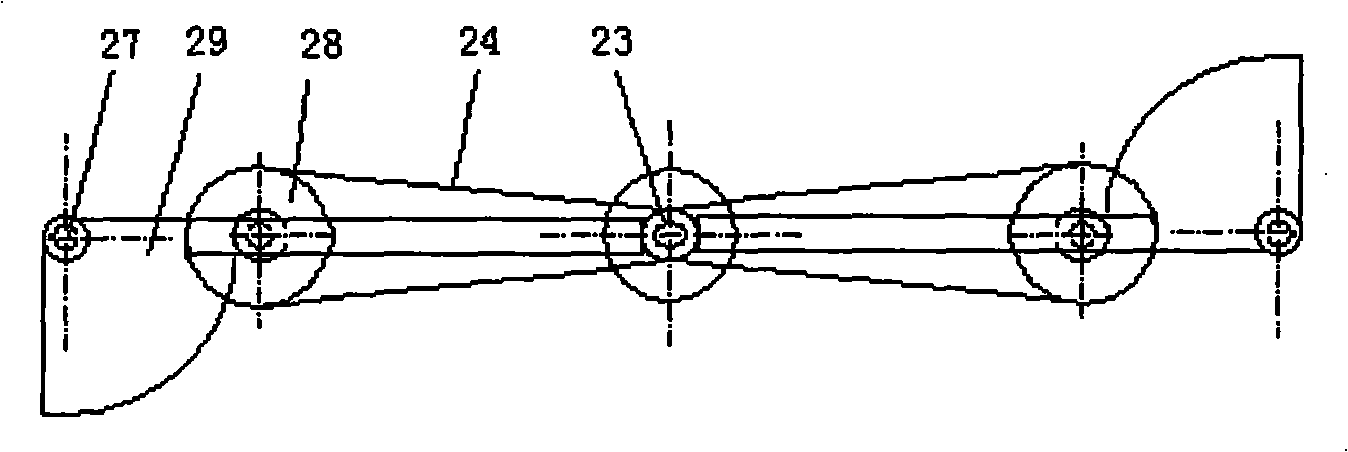

[0027] Such as figure 2 As shown, the running gear is steerable and its structure is symmetrical. The steering is driven by the driving motor 23 through the transmission chain 24 of the gear mechanism to drive the support 25 of the walking support wheel 10 to rotate around the rotary positioning shaft 27 to realize the steering. The driving supporting wheel is driven by the driving motor 22 through the gear, and the combination o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com