Equipment and method for efficiently welding chips of double-interface intelligent cards

A dual-interface smart card and chip welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of long welding hours, affecting product quality, and prolonging welding time, so as to improve production efficiency and save auxiliary time , Improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

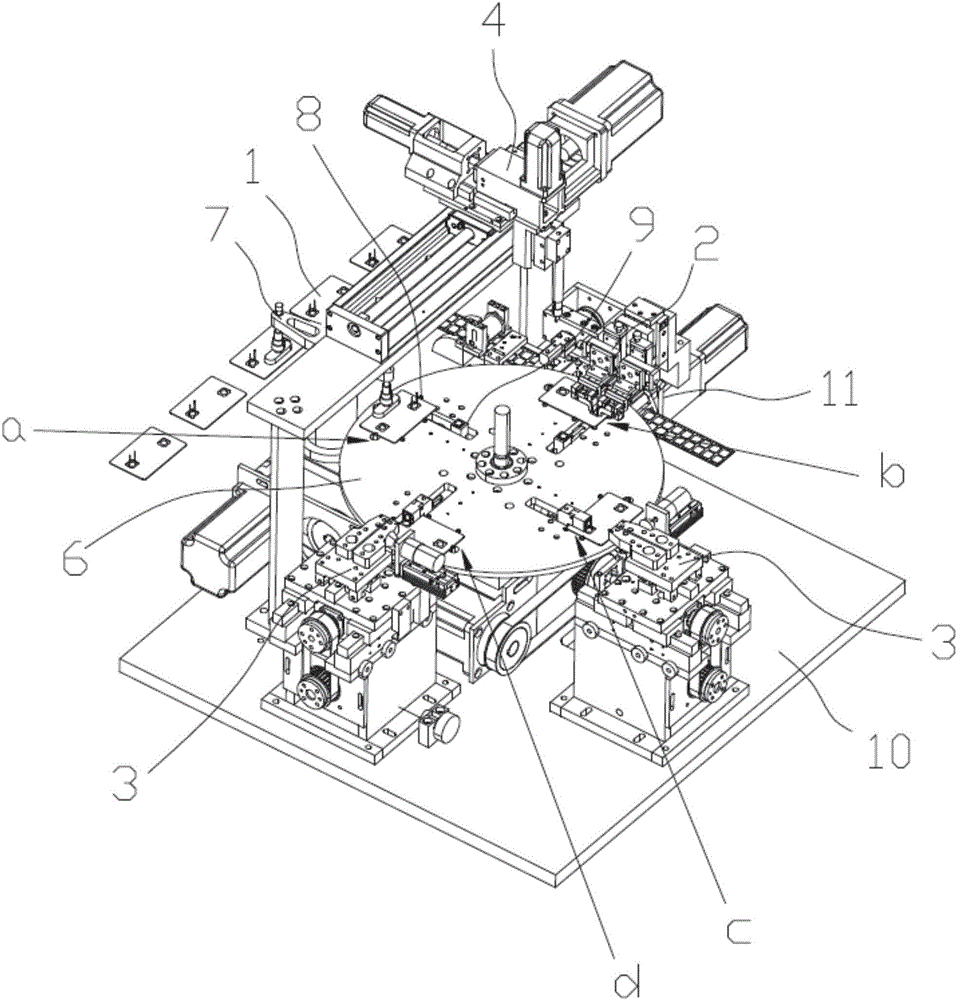

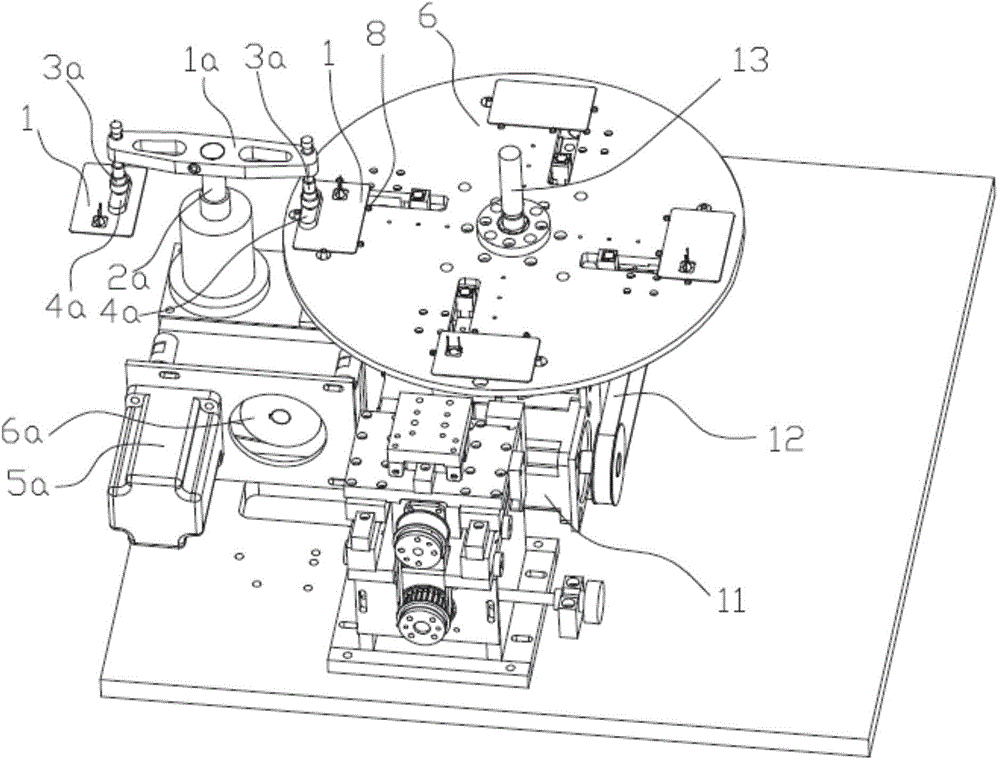

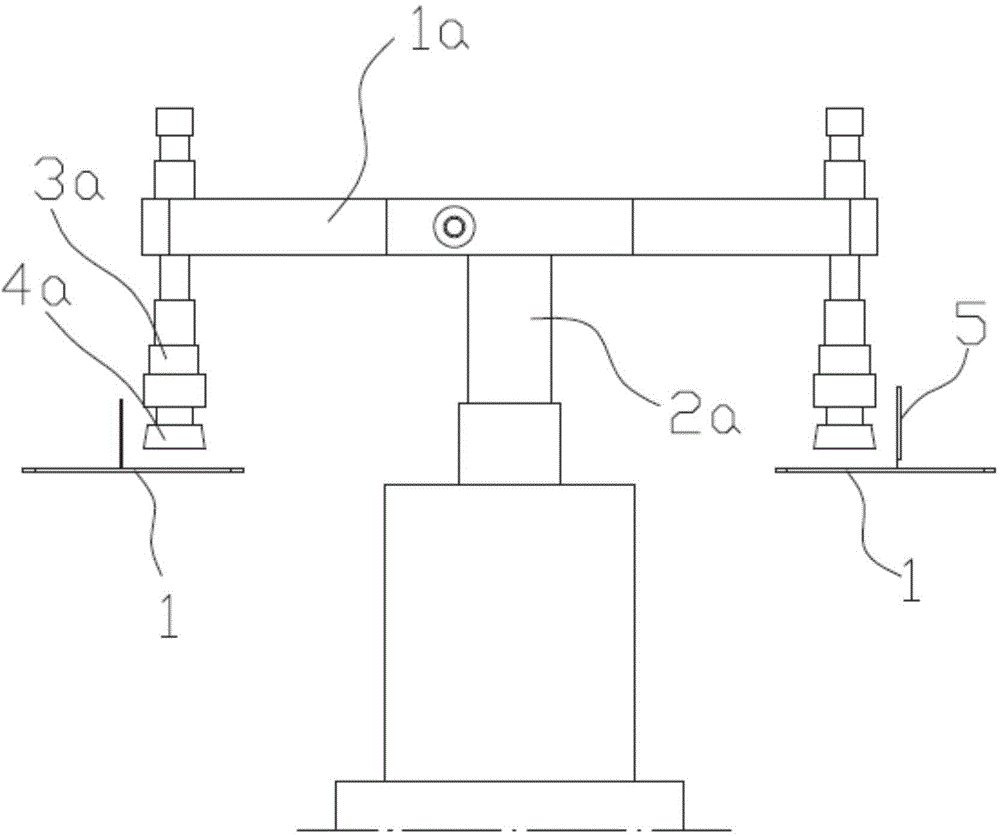

[0065] see figure 1 , the efficient dual-interface smart card chip welding equipment of the present invention includes the card transfer mechanism 7 that sends the card 1 to be welded to the card entry and exit station a and takes the welded card 1 out of the entry and exit station a, and transfers the chip 5 To the chip transfer mechanism 4 of the card in and out station a, the chip turning mechanism 9 that turns the chip 5 from the horizontal state into the vertical state, the antenna straightening device for correcting the verticality of the end of the antenna 11, two antenna ends and The chip 5 corresponds to a welding device for spot welding, a turntable 6 for intermittent precise parking, and a frame 10, wherein:

[0066] The turntable 6 is provided with four work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com