High-precision film cutting device for film production

A high-precision, membrane device technology, applied in metal processing and other directions, can solve problems such as deformation and rapid rise, and achieve the effect of convenient operation, reasonable structure, and prevention of deformation of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

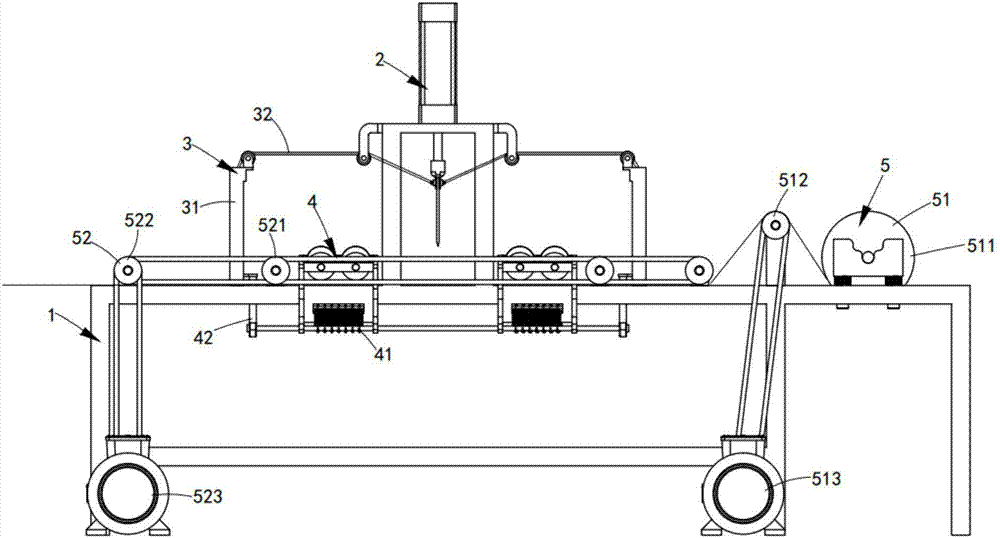

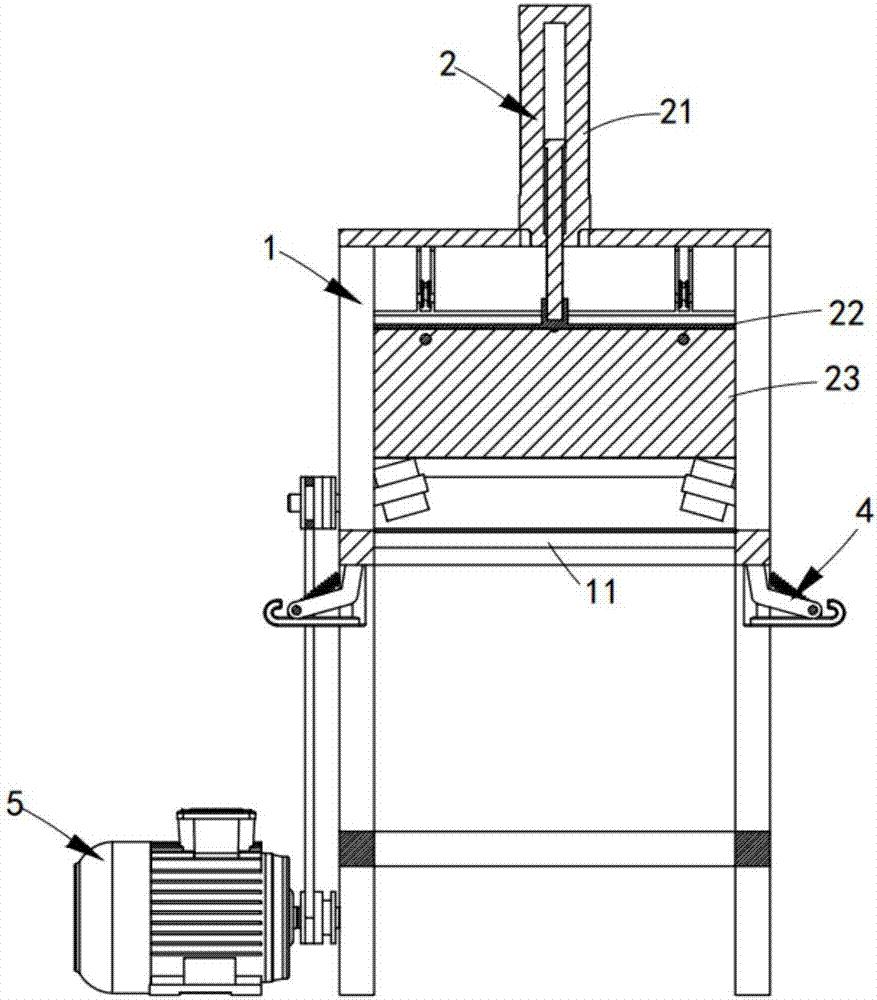

[0059] Such as figure 1 Shown is a high-precision film cutting device for film production, including a frame 1, and also includes:

[0060] Film cutting mechanism 2, said film cutting mechanism 2 is arranged on the middle part of frame 1, and it is used for cutting film;

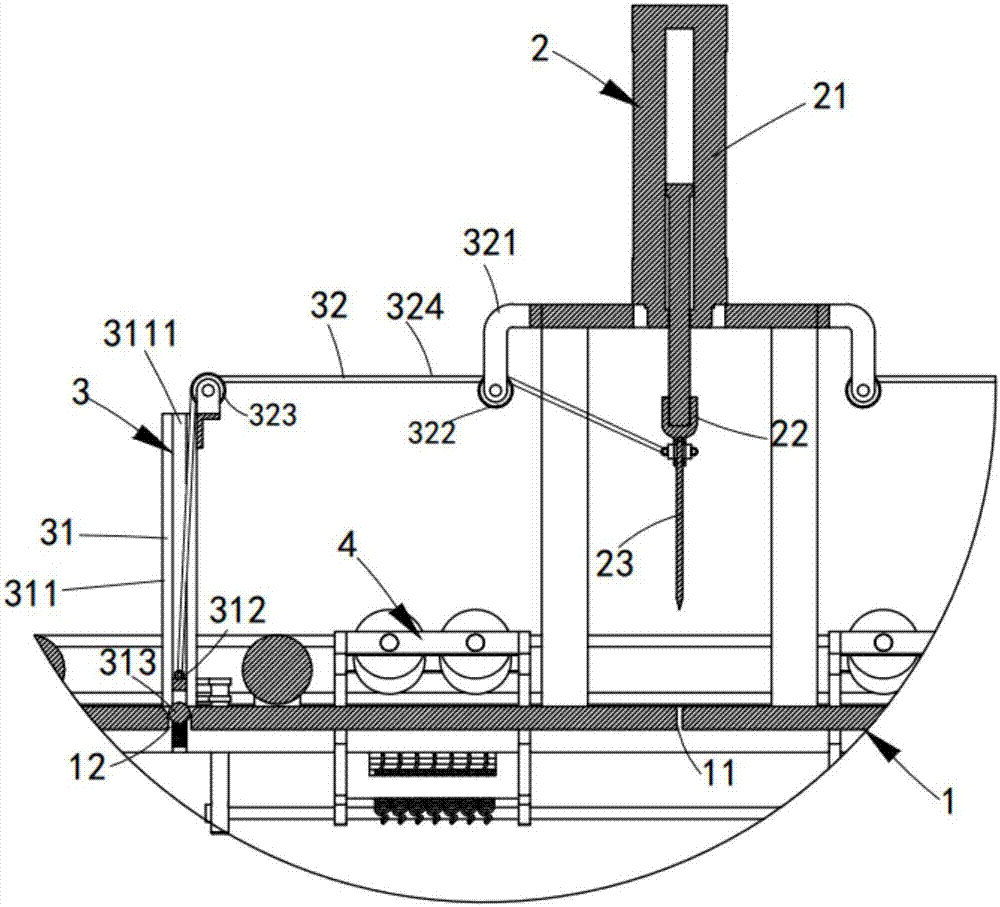

[0061] Buffer mechanism 3, the buffer mechanism 3 is fixedly arranged on the frame 1, it is symmetrically arranged on both sides of the described film cutting mechanism 2, and it is connected with the upper end of the film cutting mechanism 2, the buffer mechanism 3 includes buffer Component 31 and connecting component 32;

[0062] A crimping mechanism 4, the crimping mechanism 4 is symmetrically arranged between the buffer mechanism 3 and the film cutting mechanism 2, and its rotation is arranged at the front and rear edges of the frame 1, and the crimping mechanism 4 is used for film The two sides of the crimping mechanism 4 include a crimping assembly 41 and a toggle assembly 42;

[0063] Conveying mec...

Embodiment 2

[0111] Figure 7 It is a structural schematic diagram of Embodiment 2 of a high-precision film cutting device for film production of the present invention; as Figure 6 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0112] Such as Figure 7 As shown, a high-precision film cutting device for film production, the bottom of the chute 3111 is provided with a buffer spring 314 , and the buffer spring 314 is located below the buffer seat 312 .

[0113] It should be noted that the buffer assembly 31 presses down the film by its own gravity, so that the film forms a buffer section, so as to avoid damage to the film due to its own gravity when the buffer assembly 31 is pressed down. A buffer spring 314 is arranged at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com