Continuous finishing apparatus for slide fastener

一种加工装置、拉链的技术,应用在末道加工拉链的末道加工装置领域,能够解决提高处理速度末道加工时间困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

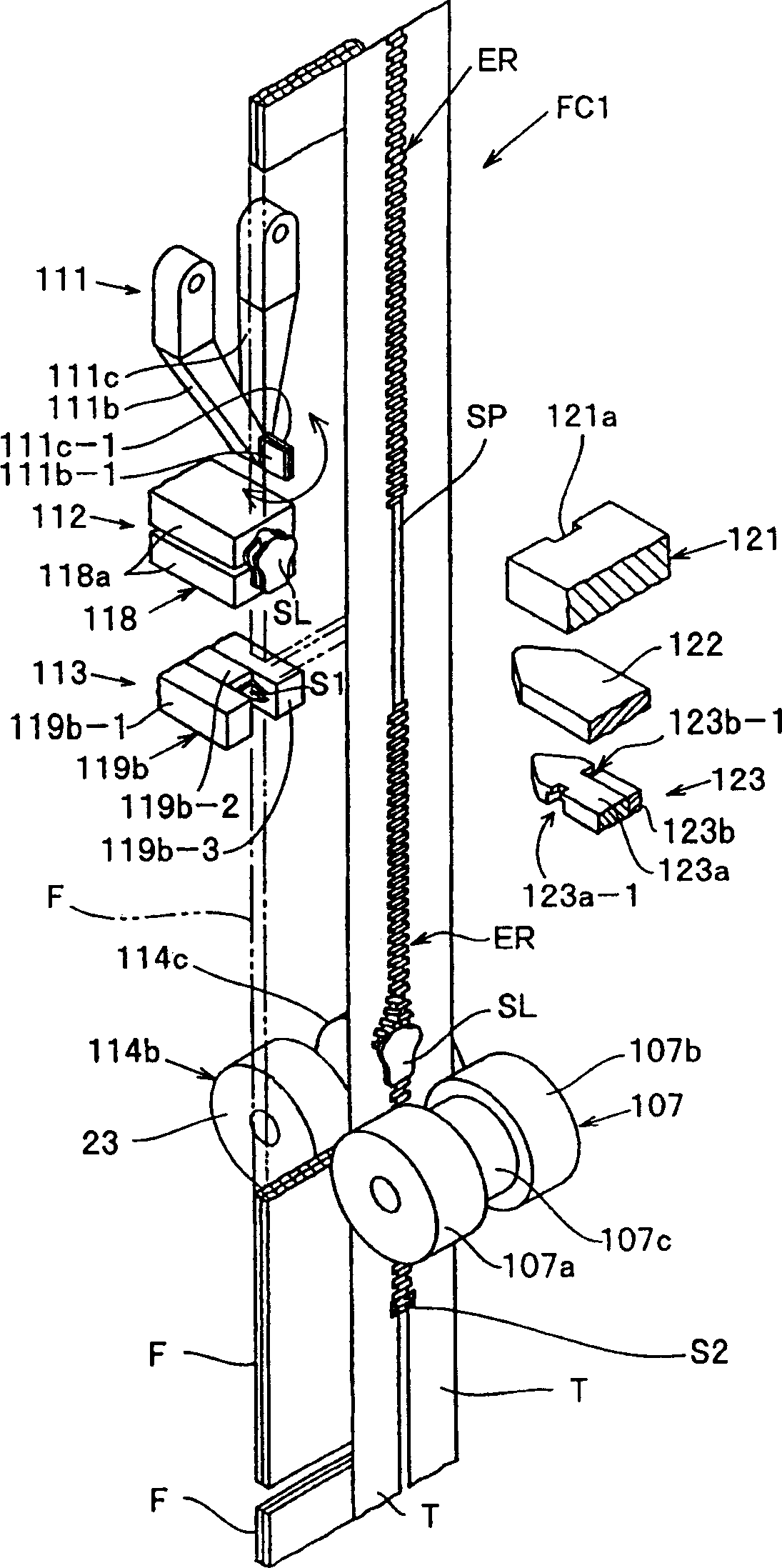

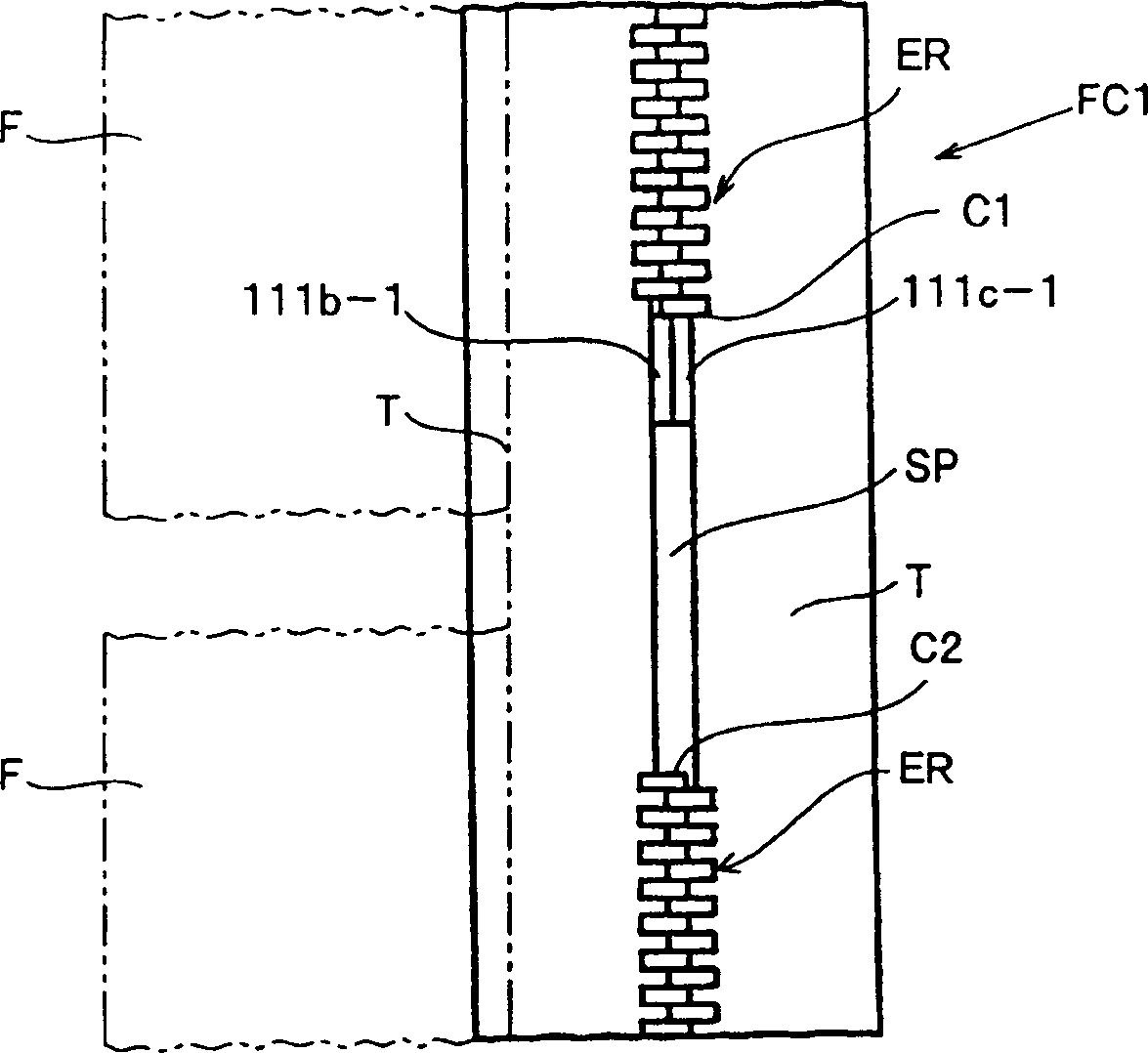

[0048] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

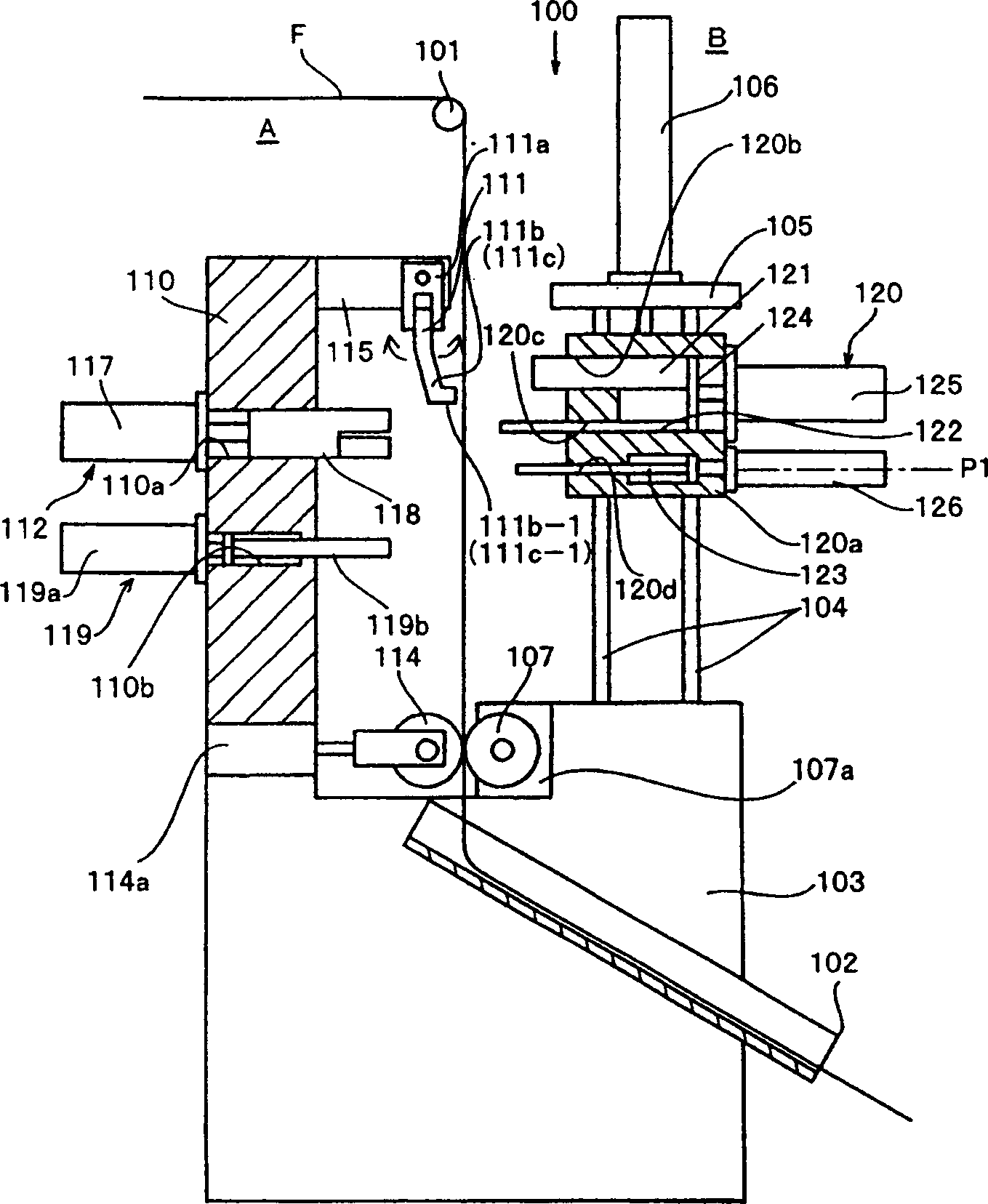

[0049] figure 1 It is a structural diagram schematically describing a typical embodiment of the continuous finishing device for slide fasteners according to the present invention.

[0050] As shown in this figure, according to the present embodiment, the fastener tape FC is conveyed horizontally from the previous step, turned by 90° by the first guide roller 101 located above the finishing device 100 of the present invention, and then conveyed vertically downward. . Thereafter, the fastener tape is discharged from the device along the discharge channel 102 located immediately below. However, the continuous finishing apparatus of the present invention can continuously perform all finishing processes while the fastener tape FC is conveyed horizontally along the fastener tape conveying path.

[0051] According to the present embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com