Injection mold with insert assembling structure

An injection mold and insert technology, applied in the coating and other directions, can solve the problems of insert coverage and complex structure, and achieve the effect of improving the qualification rate of plastic parts and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

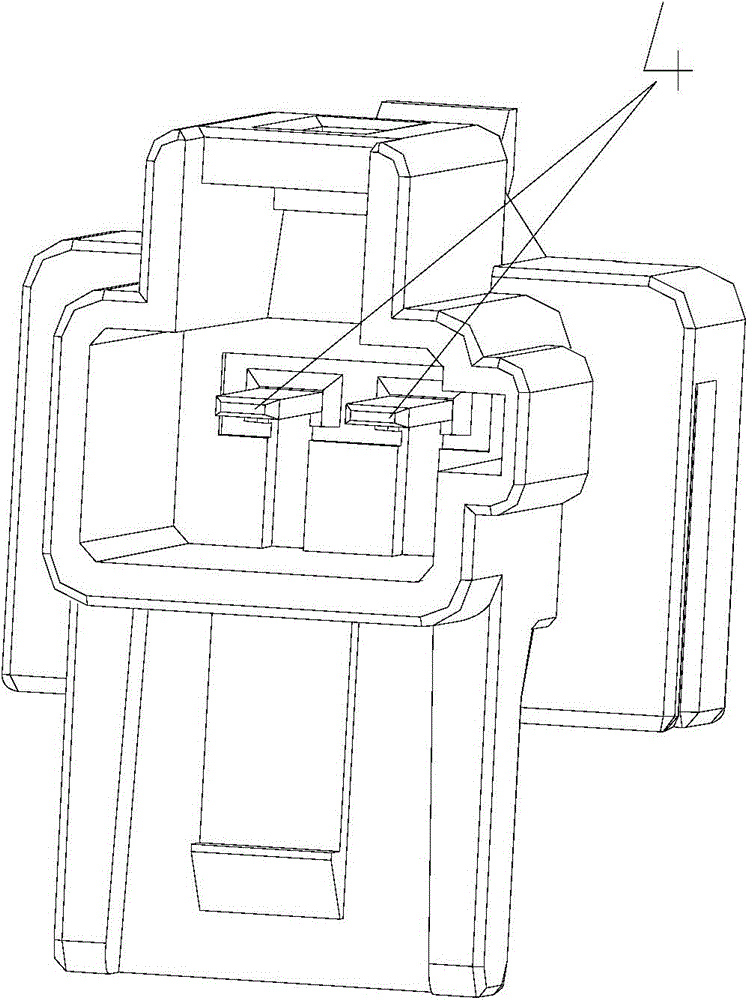

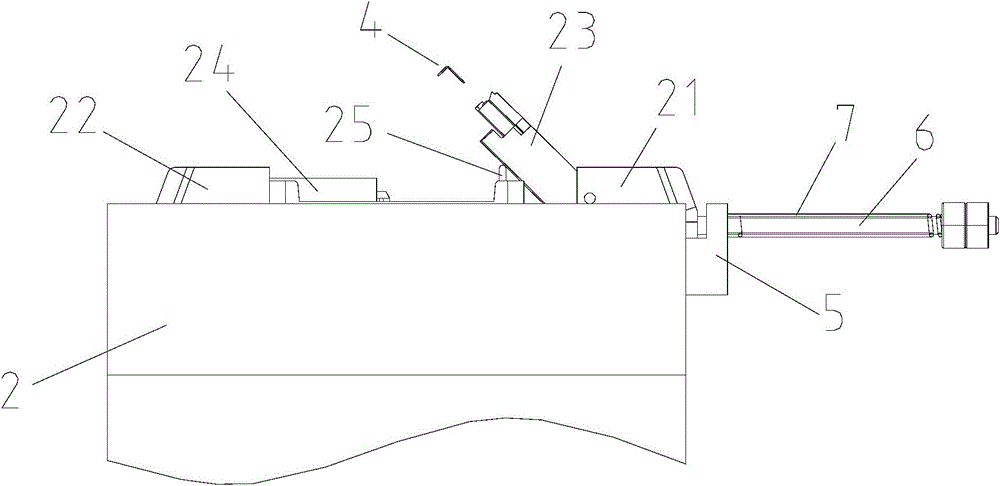

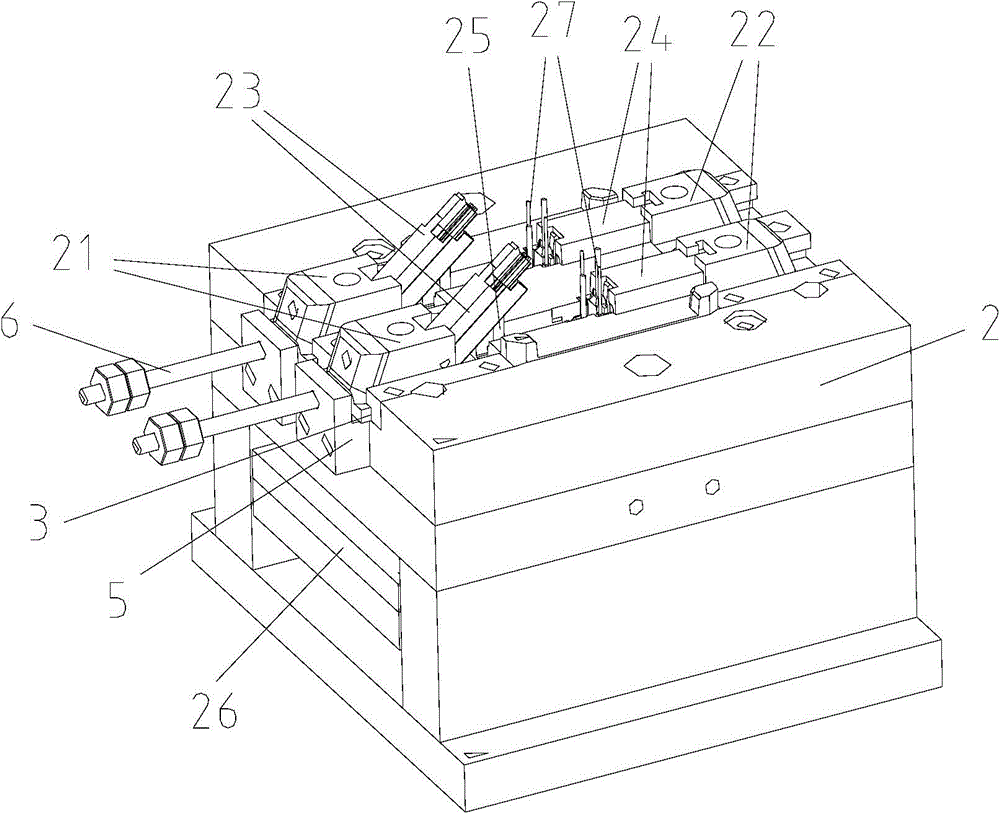

[0016] Examples, please refer to Figures 1 to 4 , an injection mold with an insert structure, including a fixed mold 1 and a movable mold 2, wherein the fixed mold 1 is equipped with a first slanted guide post 11 and a second slanted guide post 12, the first slanted guide post 11 and The second inclined guide column 12 is set in the shape of "eight"; the movable mold 2 is provided with a guide chute 3, and the first slider 21 and the second slider 22 are arranged in the guide chute 3; the first slider 21 is provided with a side core 23 for assembling the insert 4 and a first through hole matched with the first inclined guide post 11, and the second slider 22 is provided with a movable mold core 24 matched with the side core 23 And the second through hole matched with the second oblique guide post 12 .

[0017] Further, the movable mold 2 also includes a needle face plate 26 on which a group of unloading rods 27 is installed. The side core 23 is hinged to the first slider 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com