Dispensing machine and method for correcting position of dispensing needle

A calibration method and technology for dispensing machines, applied in the field of dispensing machines, can solve problems such as easy deviation, wrong dispensing path, affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

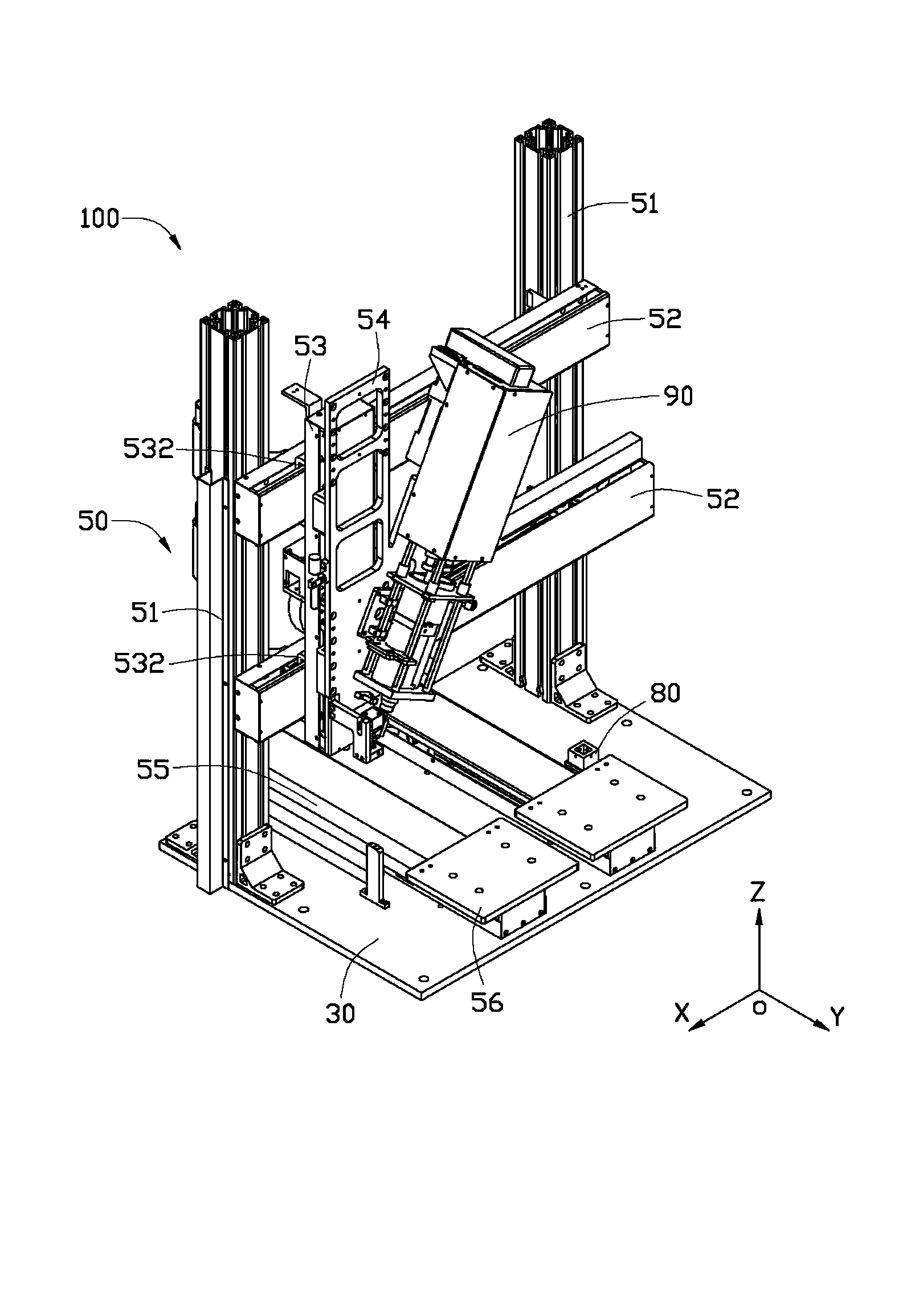

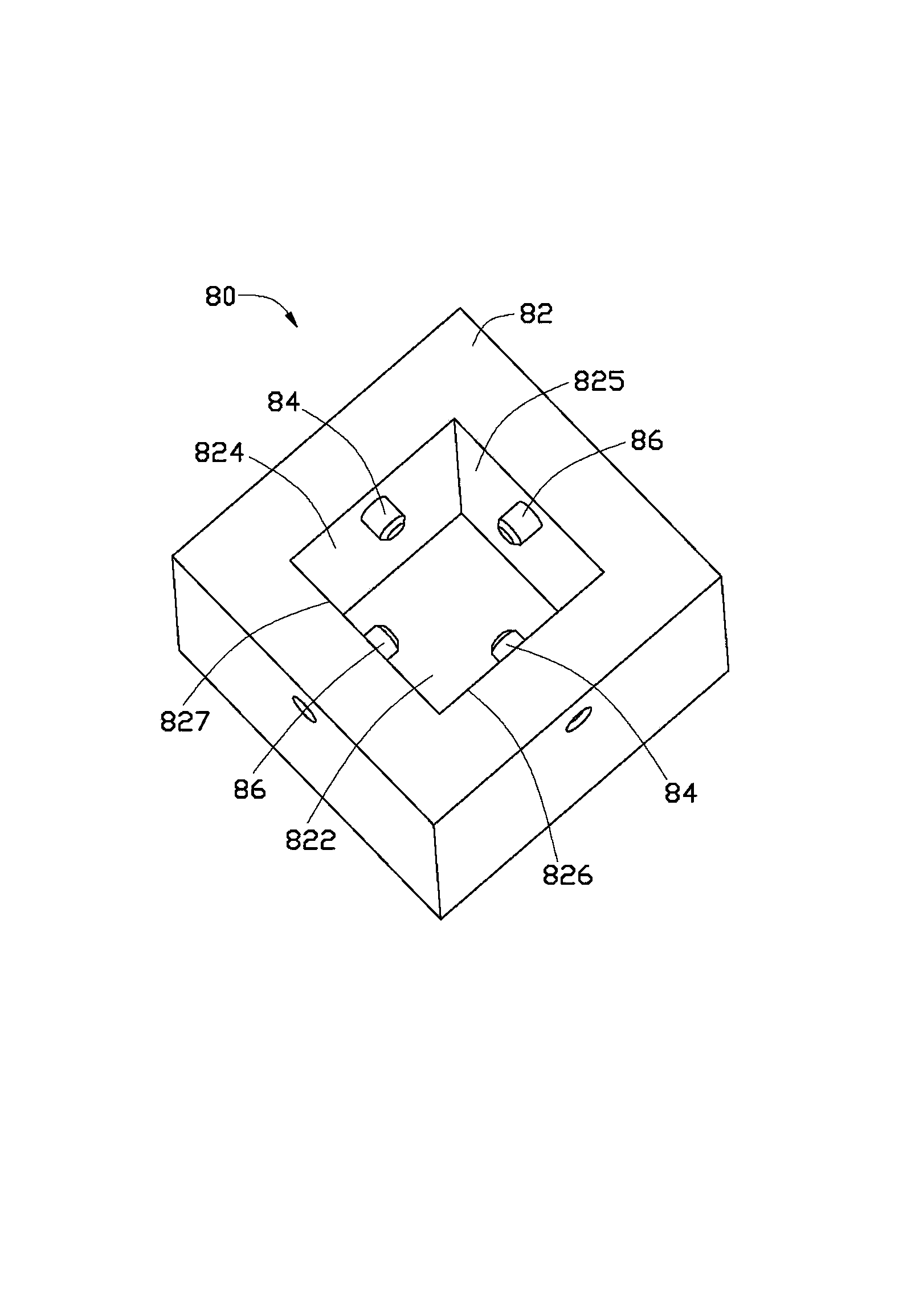

[0016] see figure 1 , a preferred embodiment of the present invention provides a glue dispenser 100 for dispensing various products (such as mobile phone casings). The dispenser 100 includes a base 30 , a moving component 50 , a sensing component 80 and a dispensing component 90 .

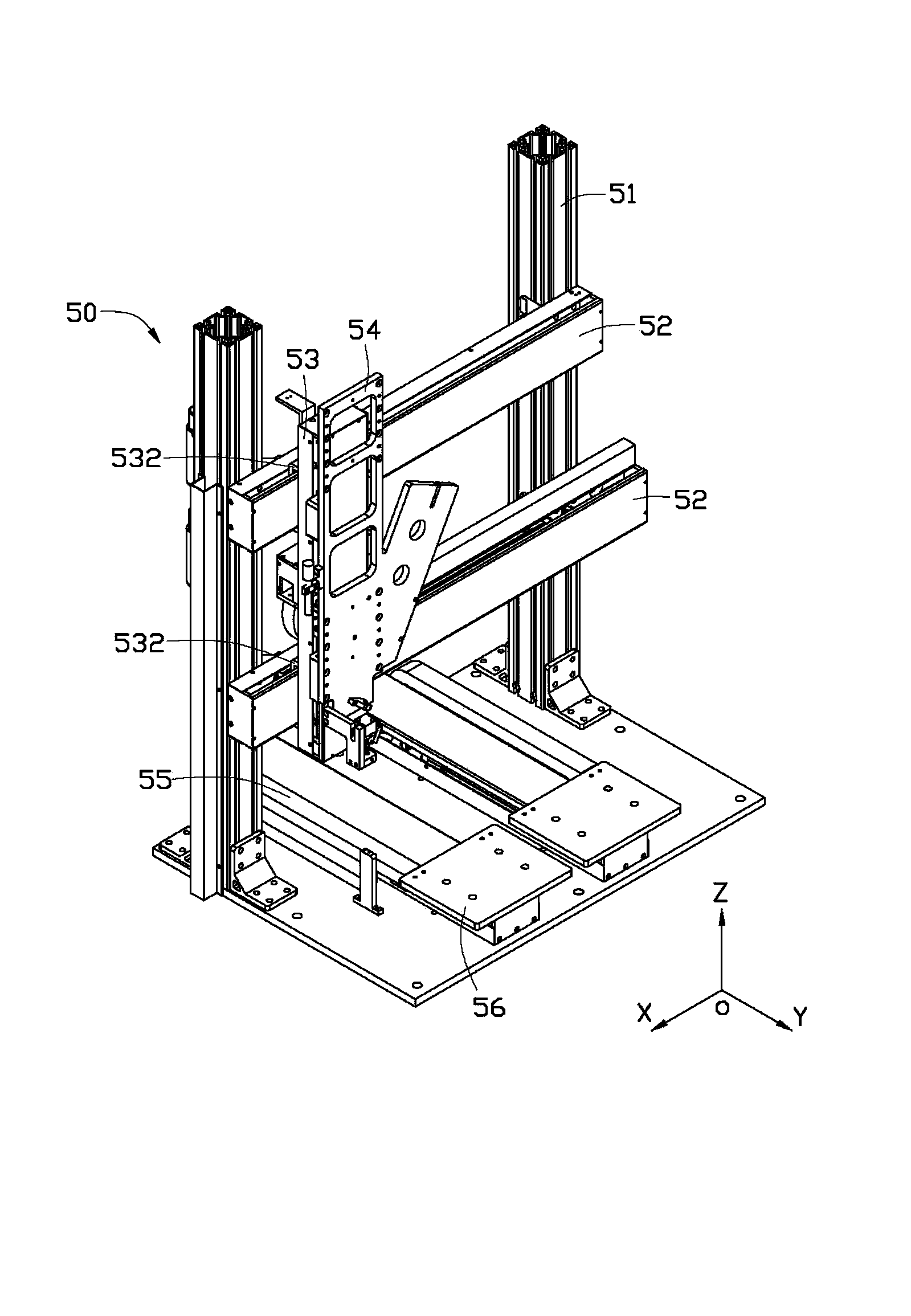

[0017] see figure 2 , the moving assembly 50 is disposed on the base 30 and is used to drive the dispensing assembly 90 to move in the directions of the X-axis, Y-axis and Z-axis. The moving assembly 50 includes two cylinders 51 , two fixing plates 52 , a connecting plate 53 , a sliding plate 54 , two guiding plates 55 and two carrying platforms 56 . The two cylinders 51 are vertically disposed on the base 30 , and the two fixing plates 52 are parallelly disposed on the two cylinders 51 . The connecting plate 53 is slidably arranged on the two fixing plates 52. In this embodiment, two sets of guide rails 532 are arranged on the connecting plate 53, and each set of guide rails 532 is assembled o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com