Nylon rope separating device for constructional engineering

A separation device, construction engineering technology, applied in metal processing and other directions, can solve the problems of complicated manual cutting process, low work efficiency and high nylon strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is realized through the following technical solutions:

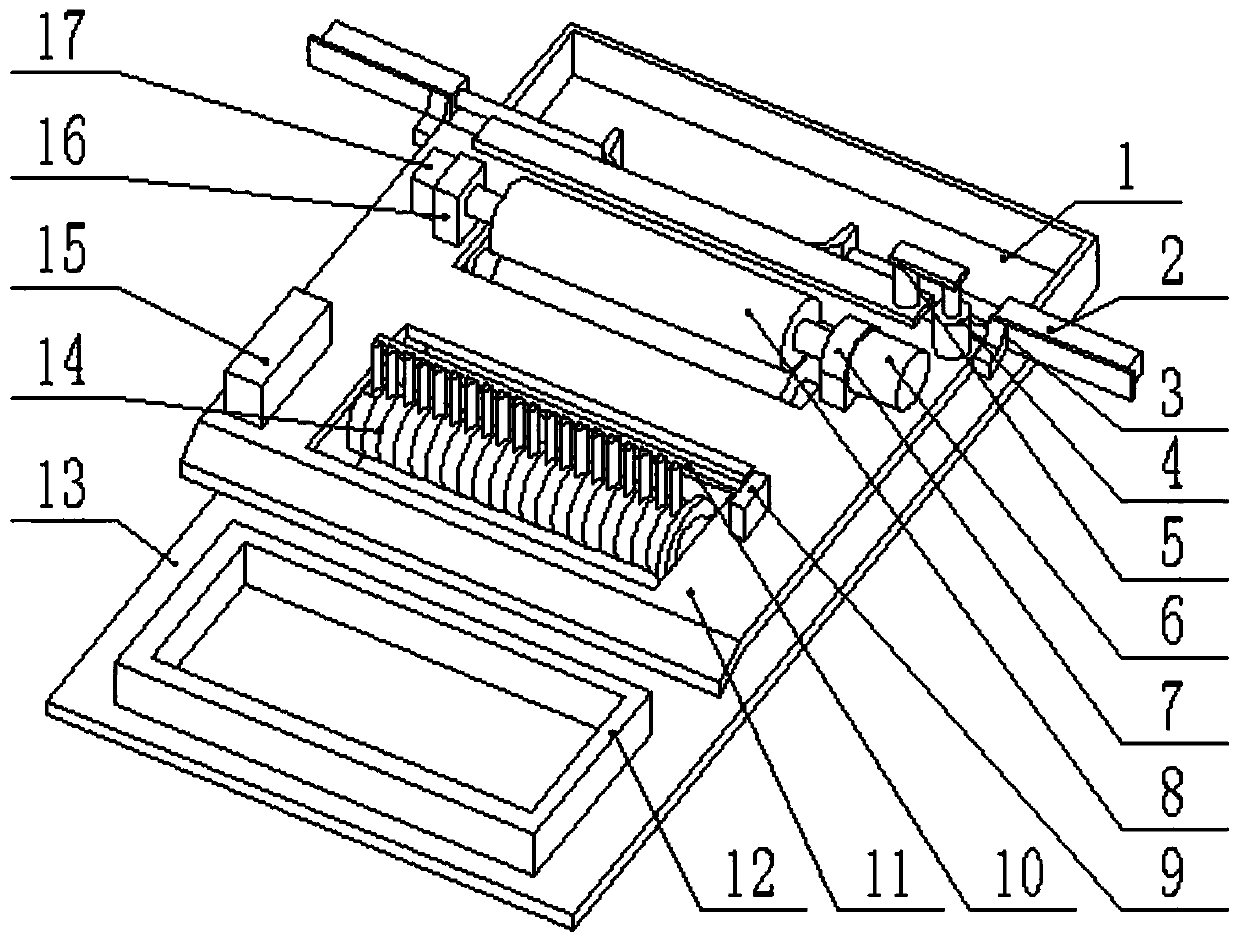

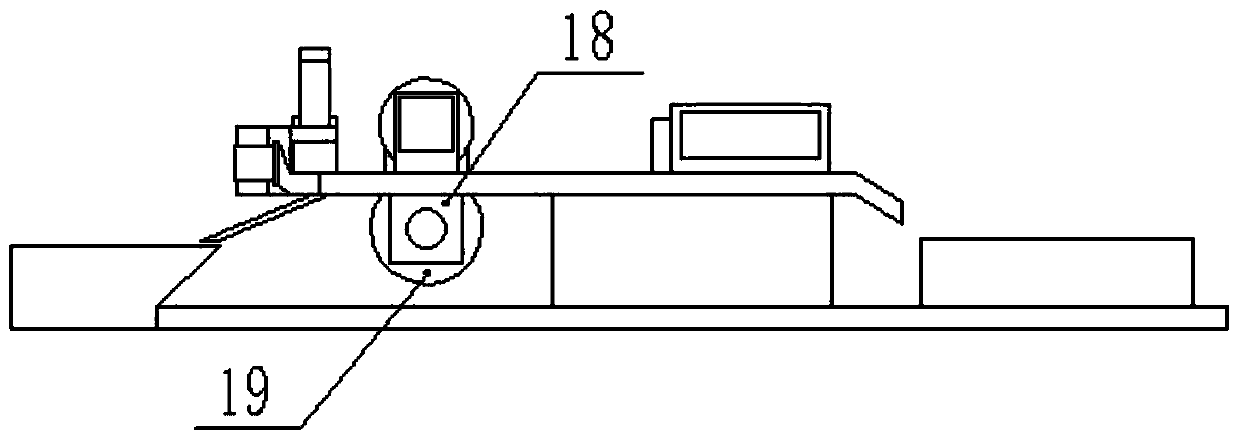

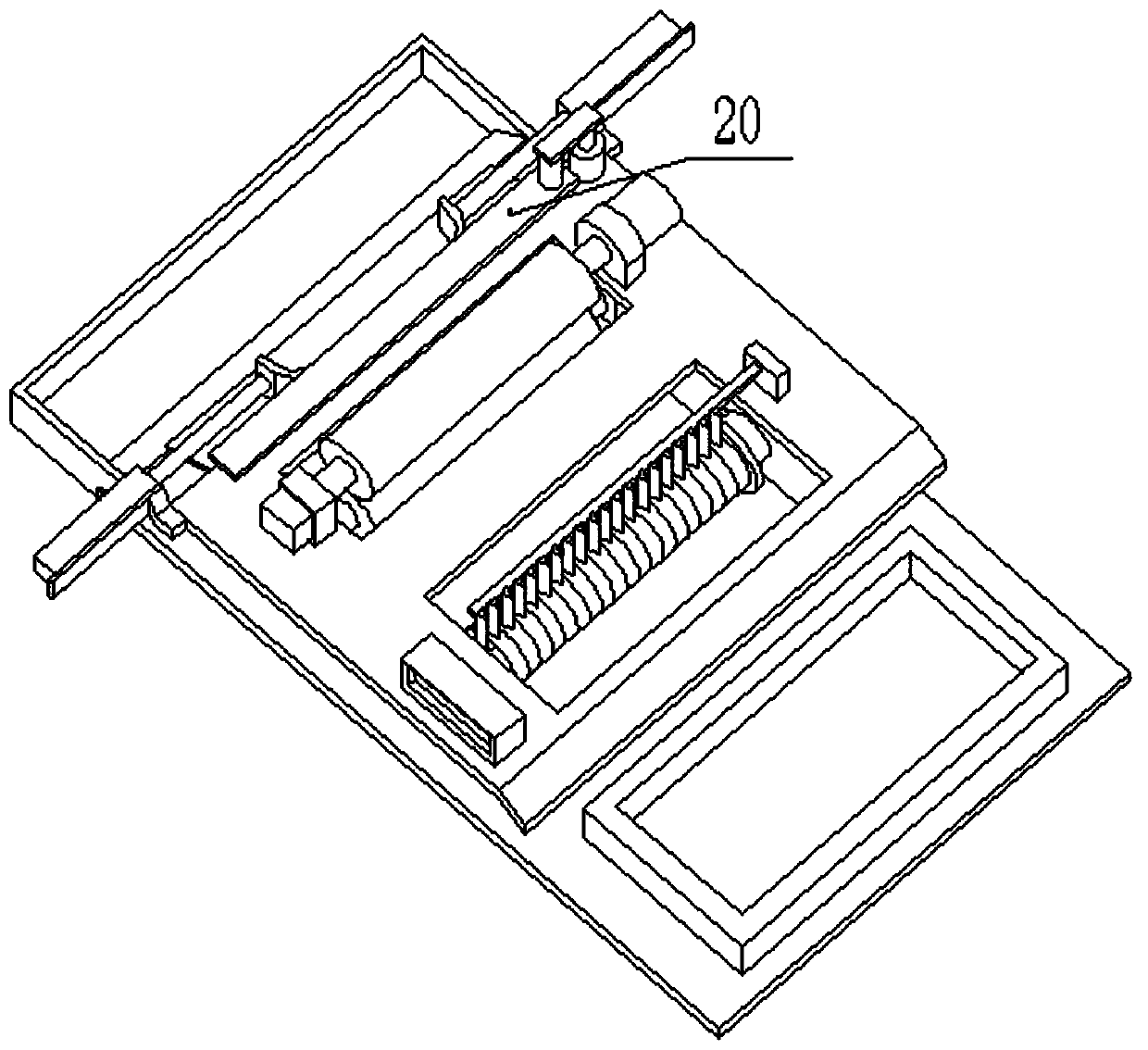

[0020] A nylon rope separation device for construction engineering, including a finished product box 1, an electromagnet 2, an electromagnet base 3, a hydraulic cylinder 4, a first bracket 5, a motor 6, a motor base 7, a driving wheel 8, and a second bracket 9 , limit support 10, workbench 11, storage box 12, base 13, dividing device 14, controller 15, the 3rd support 16, encoder 17, the 4th support 18, driven wheel 19, pressing support 20 and cutting Knife 21, the finished product box 1 is installed on the rear side of the base 13, which is located at the rear of the cutting knife 21, and is used to store the cut nylon rope. The electromagnet 2 has two, which are fixed on the electromagnet base 3 , used to drive the cutting knife 21 to cut off the nylon rope. The electromagnet base 3 is fixed on the left and right ends of the rear side of the workbench 11, and there are two in number. The hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com