A splitting and shearing machine for processing the protective cover of the steel belt of the transmitting antenna

A technology of transmitting antenna and protective cover, applied in the field of machinery, can solve the problems of limited cutting thickness, inconvenient tool change, waste of time, etc., achieve the effect of convenient tool change, improve cutting efficiency, and prevent movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

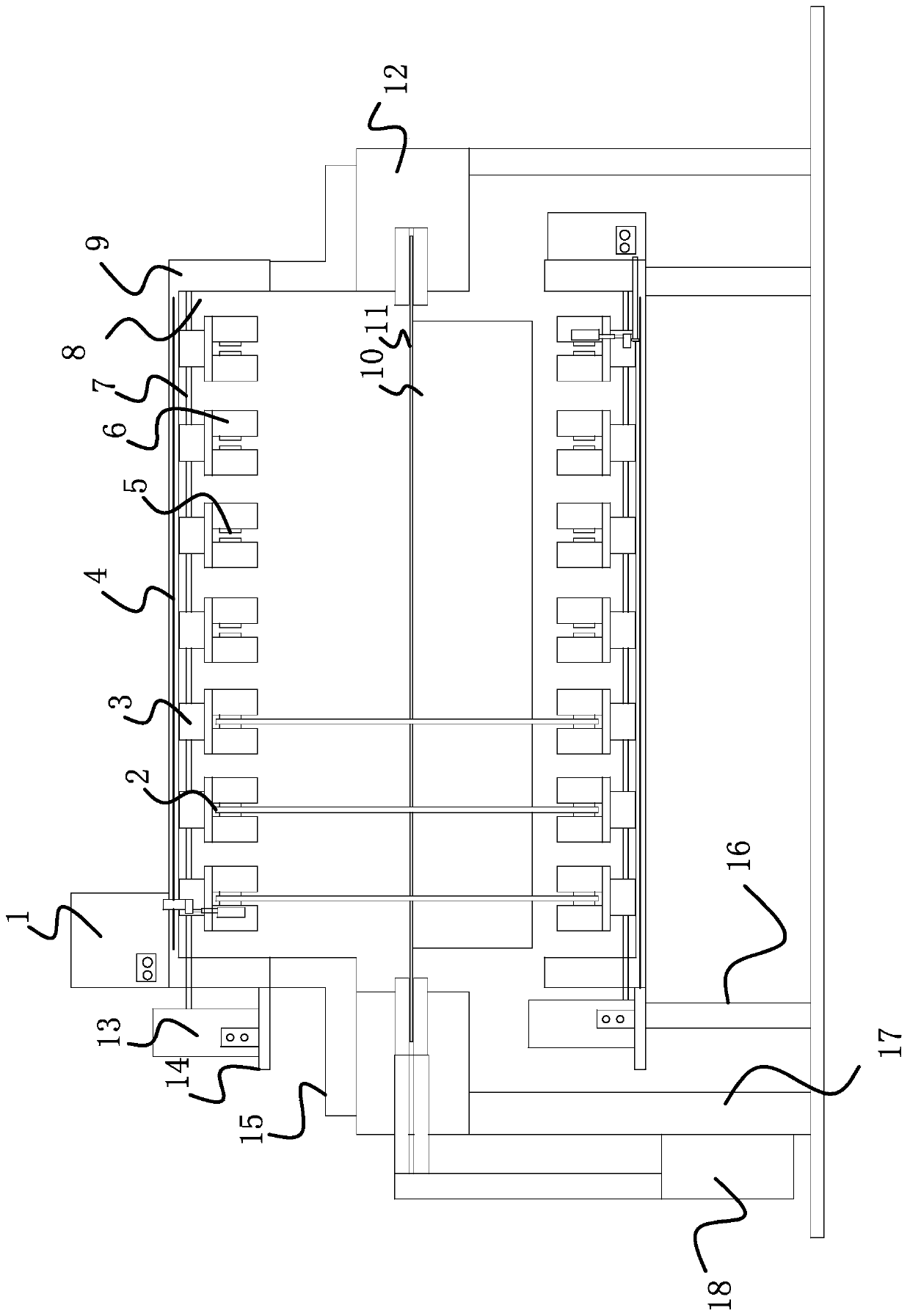

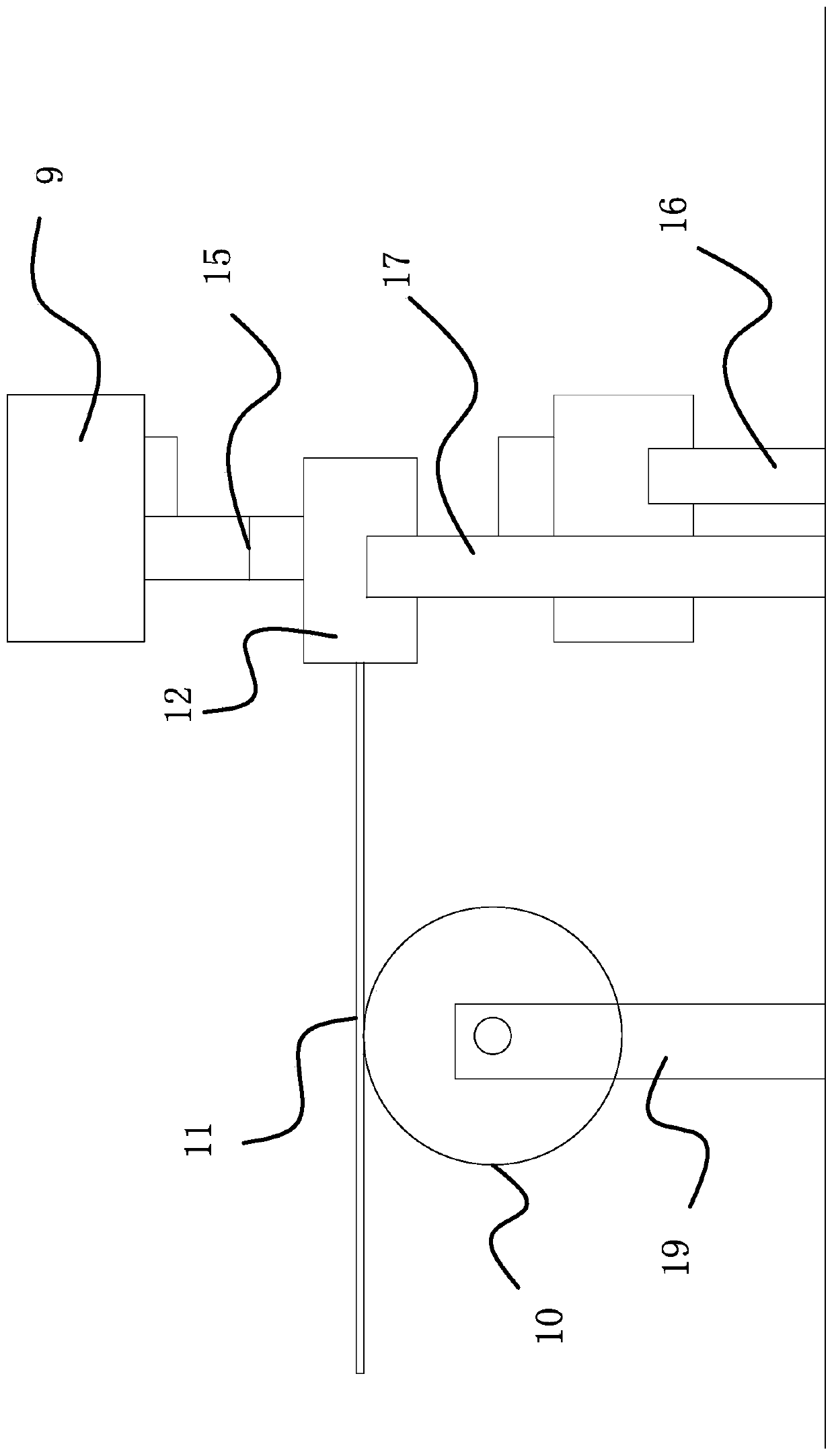

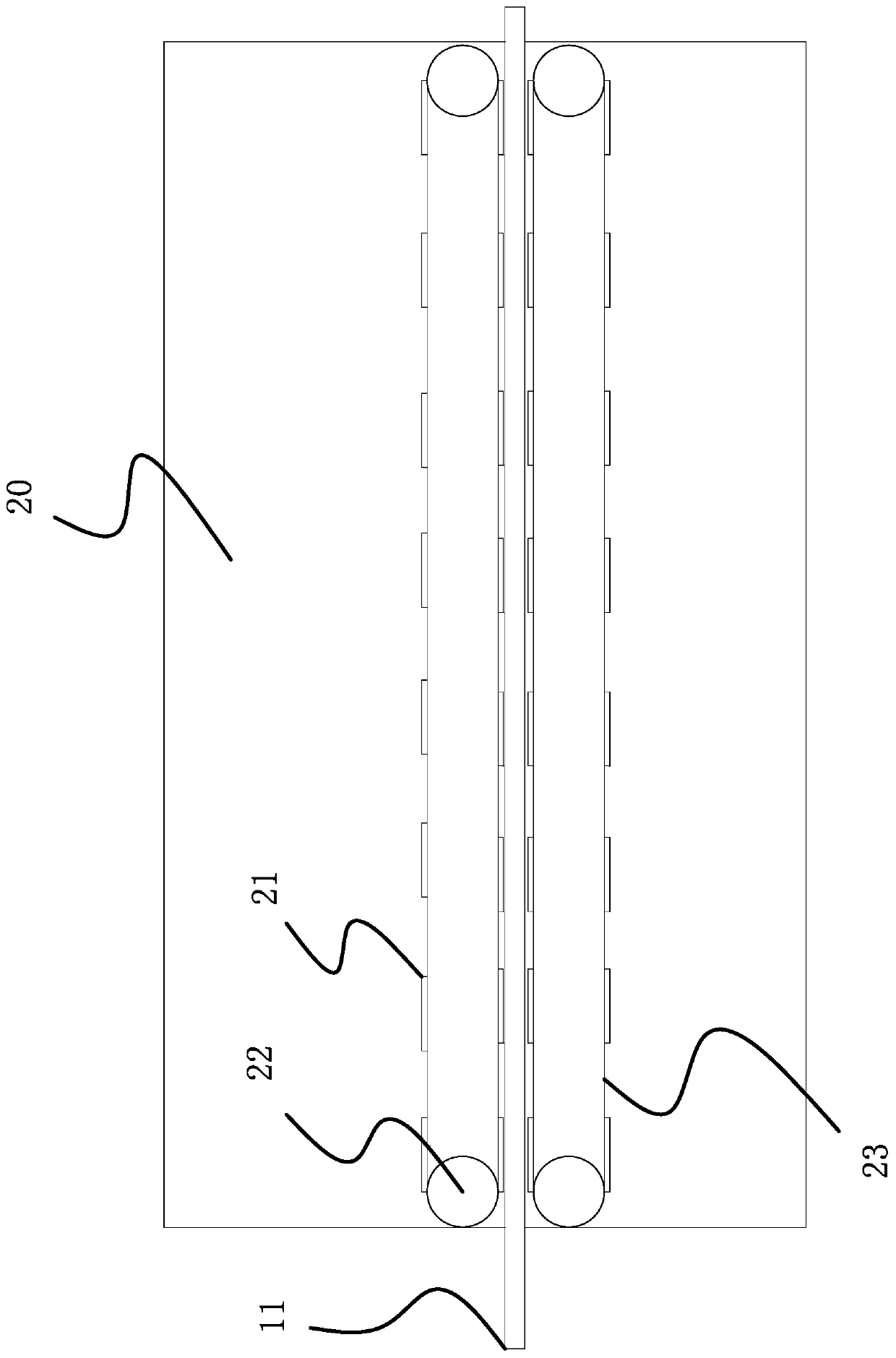

[0028] Such as figure 1 , figure 2 , Figure 4 and Figure 6 As shown, a cutting machine for processing the protective sleeve of the transmitting antenna steel band, it includes a knife group mechanism, a traction mechanism 12 and a feed roller 10, and it is characterized in that the knife group mechanism includes a circular saw blade 2, a motor, a hydraulic pressure Pump 13, hydraulic fixed roller 7 and knife group seat 9, knife group seat 9 has two sets, is mirror image setting up and down, has some clamping parts 6 and sliding part 3 on the knife group seat 9, knife group seat 9 is square, knife group There is a mounting plate 14 on the outer side of the group seat 9, a scale line 4 is provided on the outside of the knife group seat 9, a strip groove 8 is provided at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com