Laser cutting tooling and laser cutting production line for soft-pack battery tabs

A technology of laser cutting and soft pack battery, applied in battery pack parts, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low work efficiency, low practicability, single function, etc. The effect of reducing workload and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

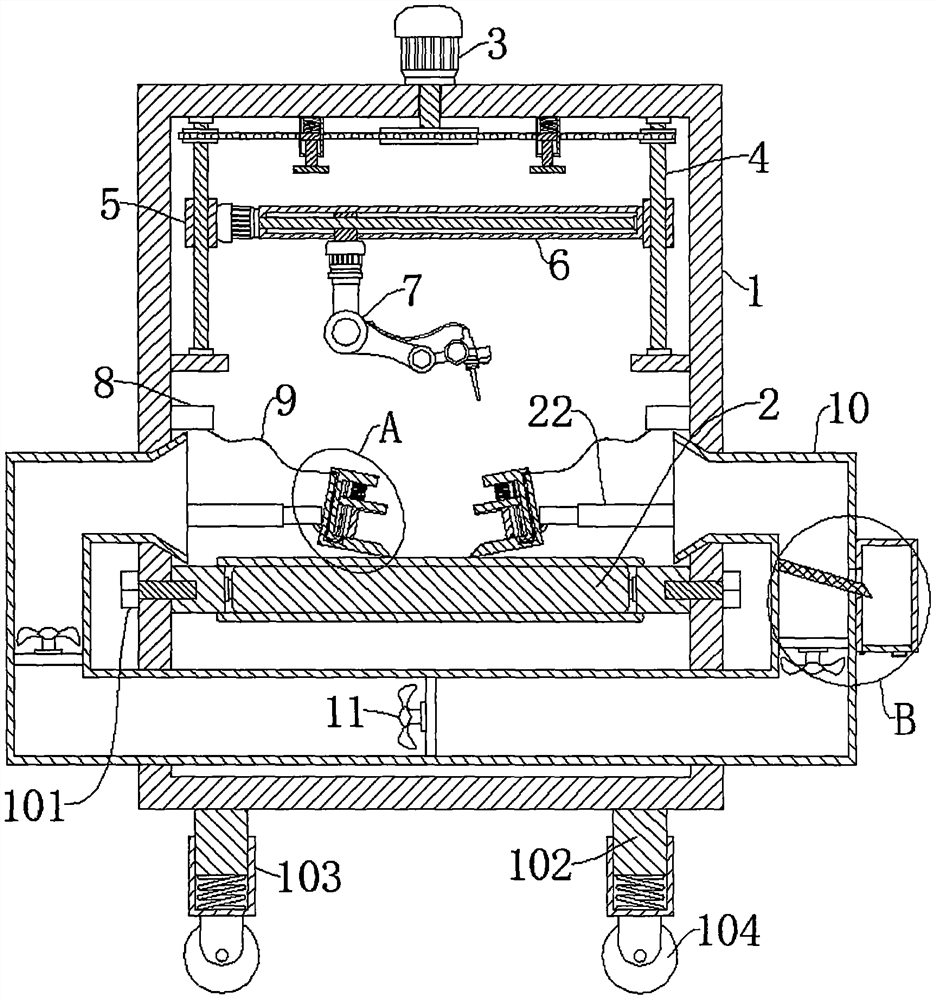

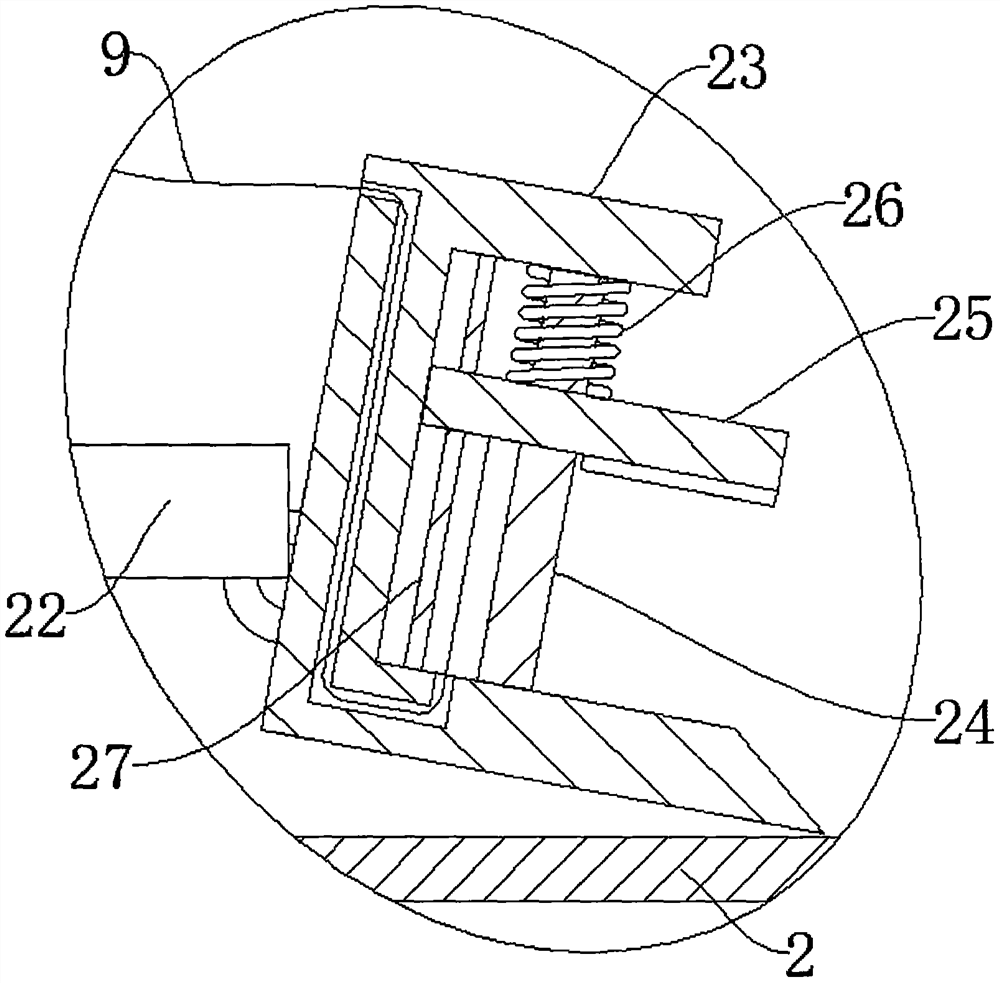

[0032] refer to Figure 1-8 , a laser cutting tool for soft-pack battery tabs, including a fixing frame 1, a transmission belt body 2, the fixing frame 1 is detachably connected to the transmission belt body 2 through bolts 101, and also includes: an arm-type laser cutting machine 7, set In the fixed frame 1; the driving mechanism, connected to the fixed frame 1, is used to drive the arm type laser cutting machine 7 to move; the electric push rod 22 is fixedly connected to the two sides of the fixed frame 1 close to the conveyor belt body 2; clamping mechanism, which is rotatably connected to the telescopic end of the electric push rod 22; the receiving block 8 is fixedly connected to both sides of the fixing frame 1; Fixed connection; the waste collection component is fixedly connected to the fixing frame 1, and is used to collect the waste generated by cutting.

[0033]When in use, the user first moves the tooling to the conveyor belt body 2, then fixes the fixing frame 1 t...

Embodiment 2

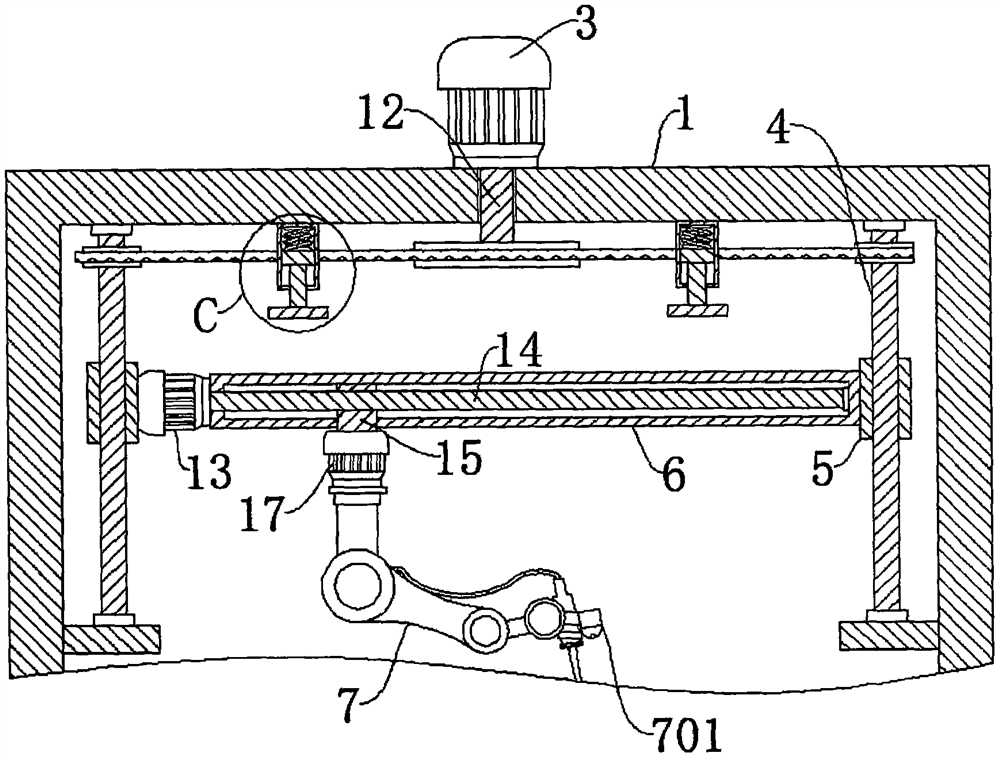

[0035] refer to figure 1 , figure 2 and Figure 8 , a laser cutting tool for the tabs of a soft-pack battery, which is basically the same as the embodiment 1, and further: the driving mechanism includes a first motor 3, an output shaft 12, a screw 4, a first moving block 5, and a second motor. 13. The moving plate 6, the threaded rod 14, the first motor 3 is fixedly connected to the upper end of the fixing frame 1, the output shaft 12 is fixedly connected to the output end of the first motor 3, and the end of the output shaft 12 away from the first motor 3 runs through the fixed frame. The frame 1 is fixedly connected with a first gear, the screw rod 4 is rotatably connected to the inner two sides of the fixed frame 1, the screw rod 4 is fixedly connected with a second gear, the first gear and the second gear are connected by a chain, and the first move The block 5 is rotatably connected with the screw rod 4 through threads, the moving plate 6 is fixedly connected between t...

Embodiment 3

[0037] refer to figure 2 and Figure 5 , a laser cutting tool for the tabs of a soft-pack battery, which is basically the same as Embodiment 1, and further is: a sleeve 18 is fixedly connected to one end of the fixing frame 1 close to the moving plate 6, and a buffer spring is fixedly connected to the sleeve 18 21. A moving rod 19 is slidably connected in the sleeve 18, and a buffer plate 20 is provided at one end of the sleeve 18 close to the moving plate 6. The two ends of the moving rod 19 are respectively fixedly connected with the buffer spring 21 and the buffer plate 20, through the buffer plate 20 . The setting of the buffer spring 21 can play a buffering and protection role for the driving mechanism when driving the arm-type laser cutting machine 7 to move upward, and prevent the moving plate 6 in the driving mechanism from rising too much and interacting with the first gear and the second gear. Wear, so that the driving mechanism is damaged, and the service life of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com