Optical glass lifting type cutting equipment

A technology of cutting equipment and optical glass, applied in glass manufacturing equipment, glass cutting device, stone processing equipment and other directions, can solve the problem of increasing cutting cost, and achieve the effect of good stability, strong practicability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

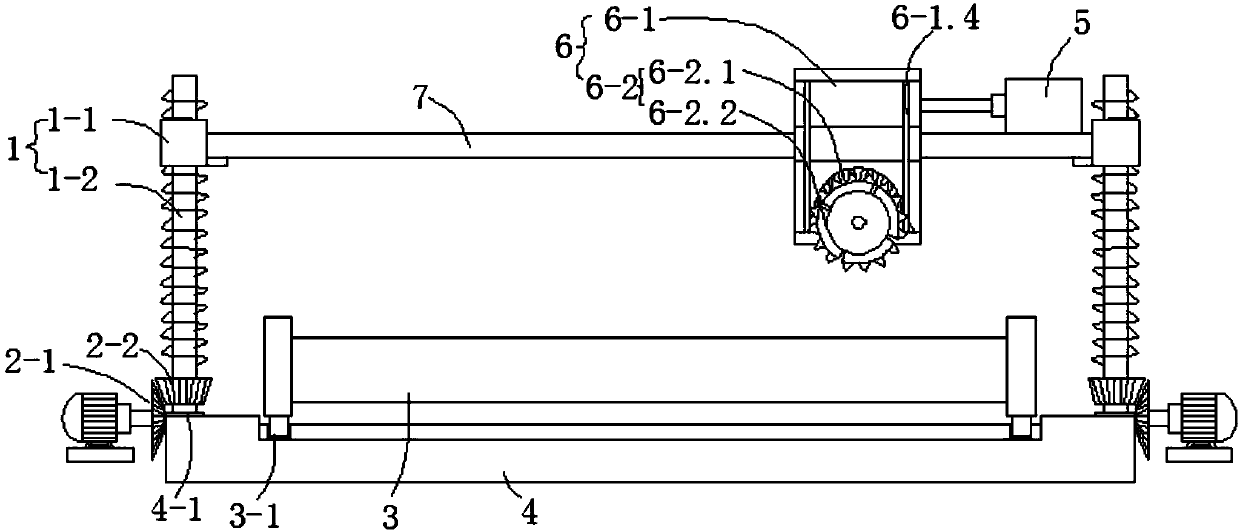

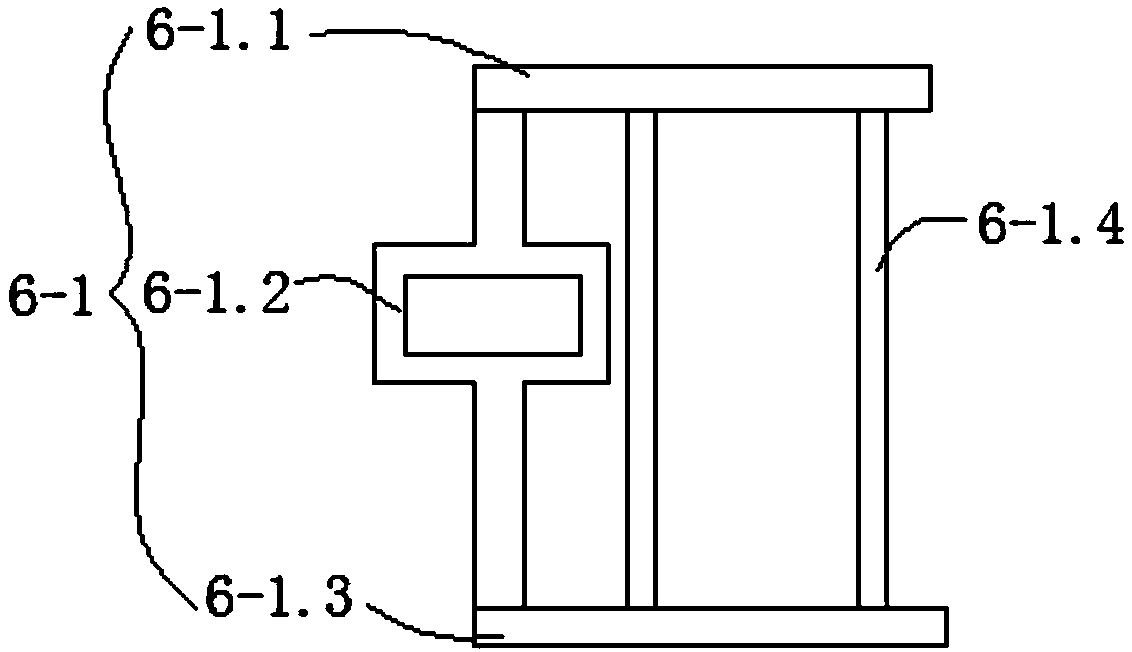

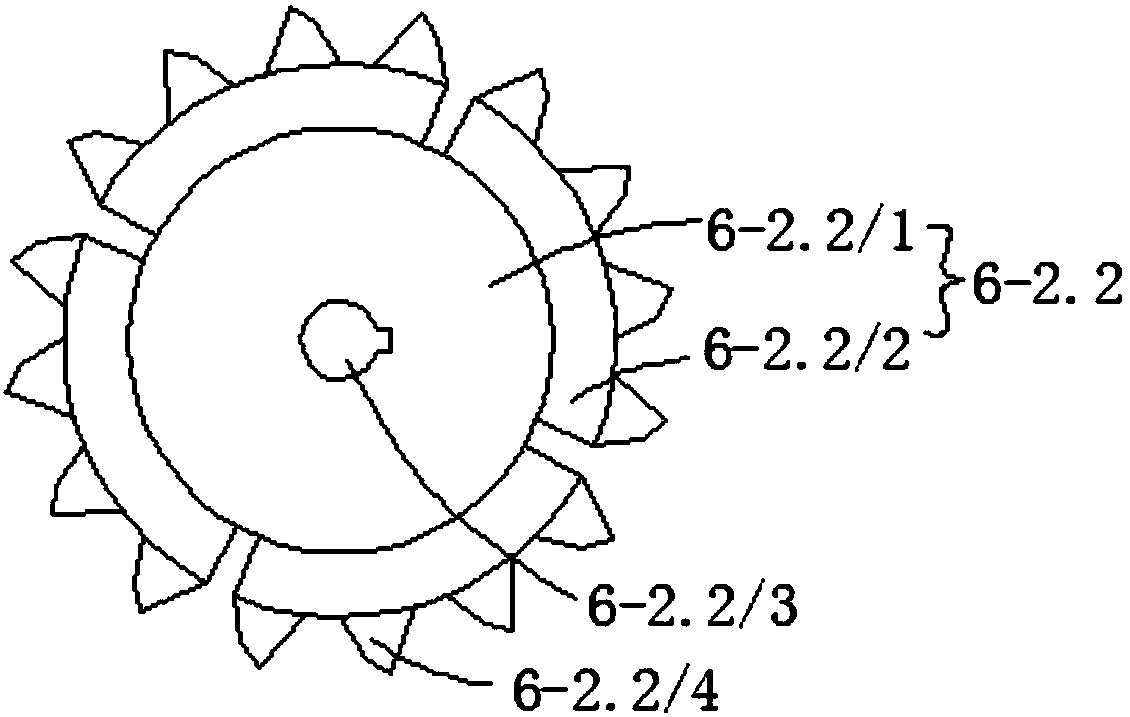

[0016] Such as Figure 1 to Figure 3 As shown, this embodiment provides a lifting cutting device for optical glass, including a base 4 and a cutting mechanism 6, characterized in that: the base 4 is provided with a movable cutting base 3, and the bottom of the movable cutting base 3 is symmetrically arranged There are two pulley sets 3-1, the base 4 is provided with two guide rails respectively adapted to the two pulley sets 3-1, and two lifting mechanisms 1 with the same structure are symmetrically provided on both sides of the mobile cutting base 3 on the base 4, two lifting mechanisms A horizontal support plate 7 is connected between the mechanism 1, one end of the horizontal support plate 7 is provided with a telescopic cylinder 5, the cutting mechanism 6 includes a mounting frame 6-1 and a cutting assembly 6-2, and the mounting frame 6-1 includes an upper horizontal plate 6- 1.1. The lower horizontal plate 6-1.3 and the connecting part 6-1.2 connecting the upper horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com