Patents

Literature

64results about How to "Reduced chance of wrinkling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

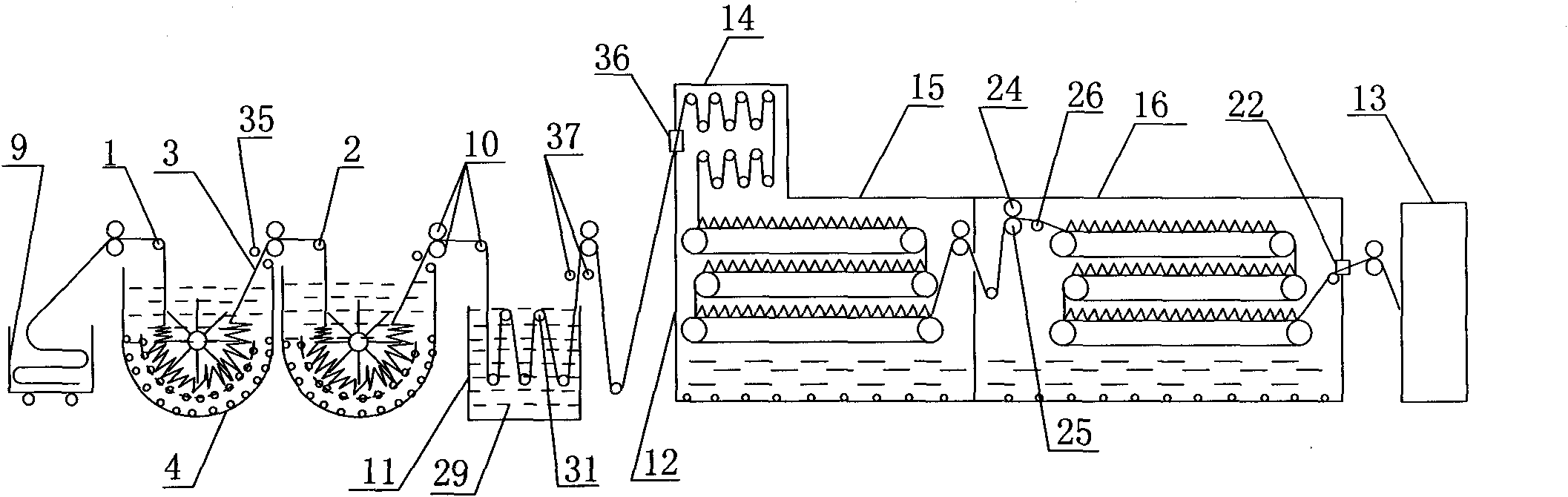

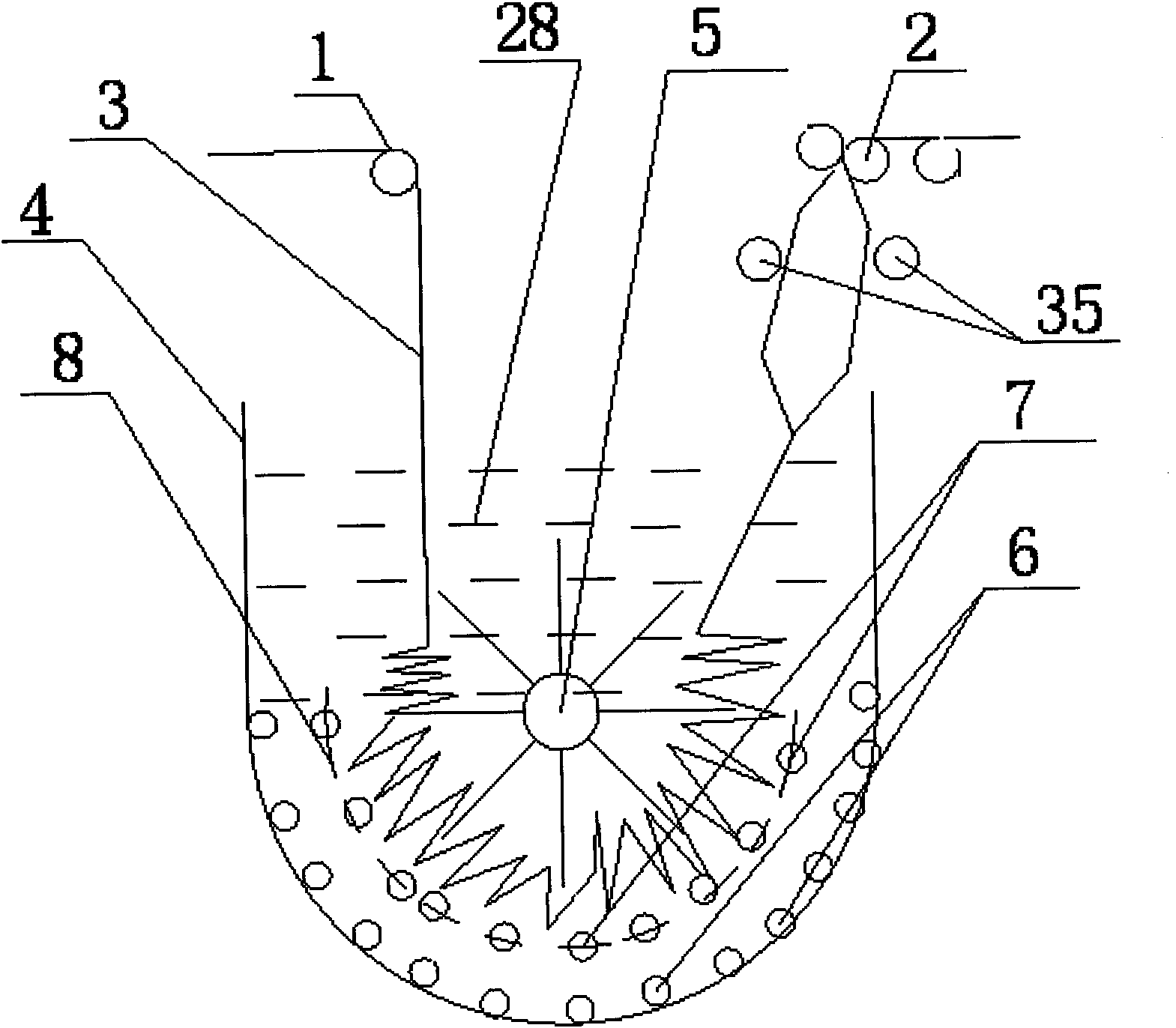

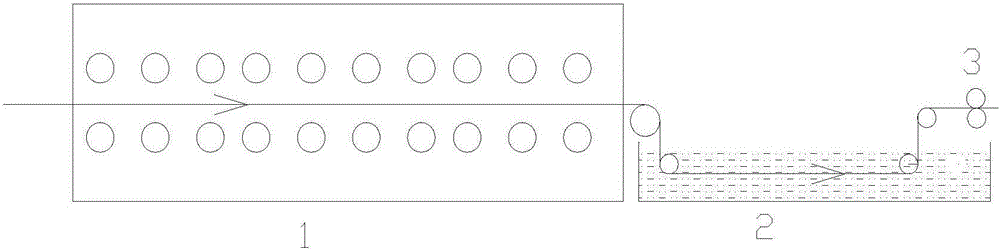

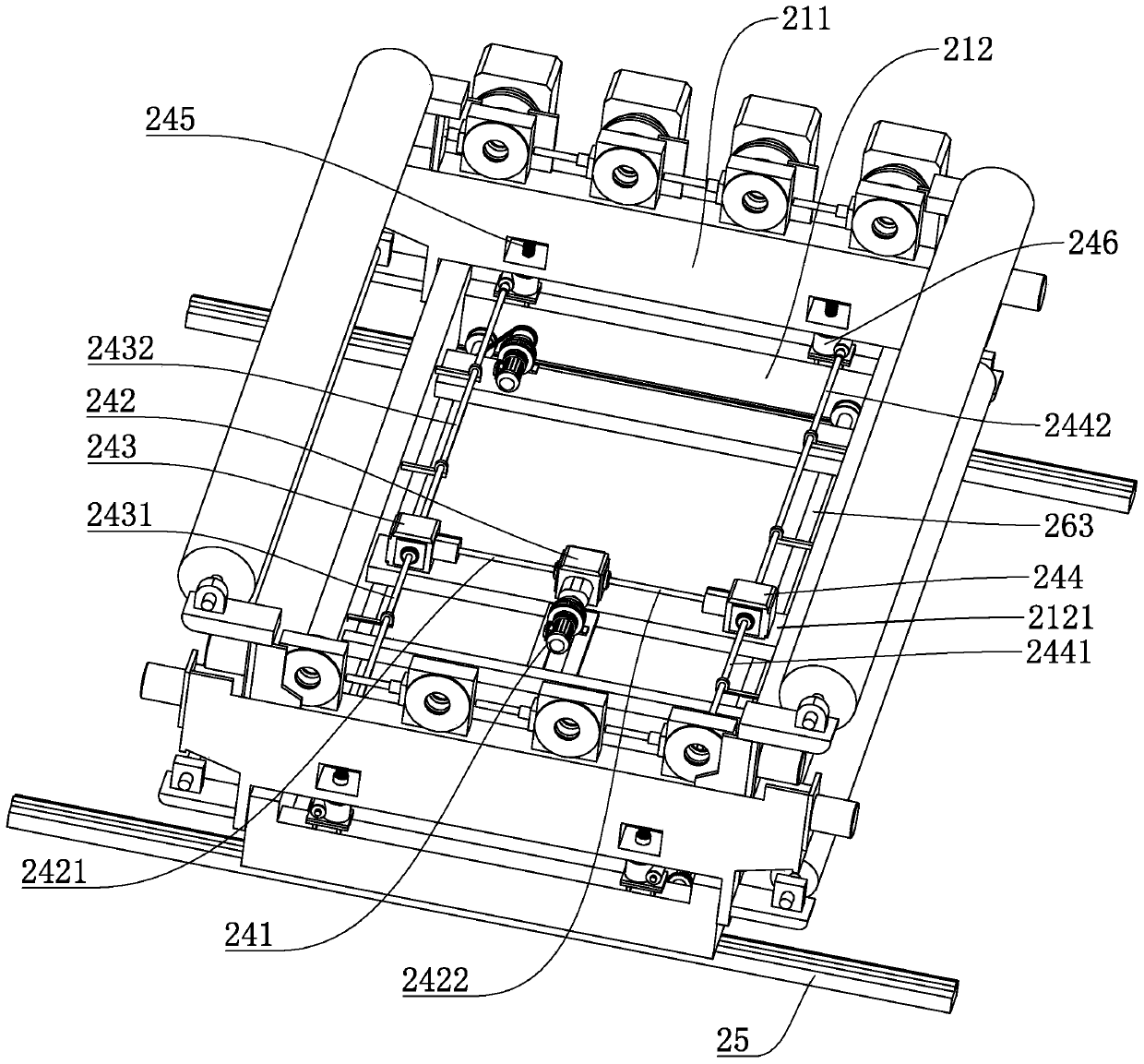

Crease prevention device for scouring and bleaching equipment, scouring and bleaching equipment and crease prevention method

ActiveCN101768845ALess chance of wrinklingImprove processing efficiencyTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringTextile

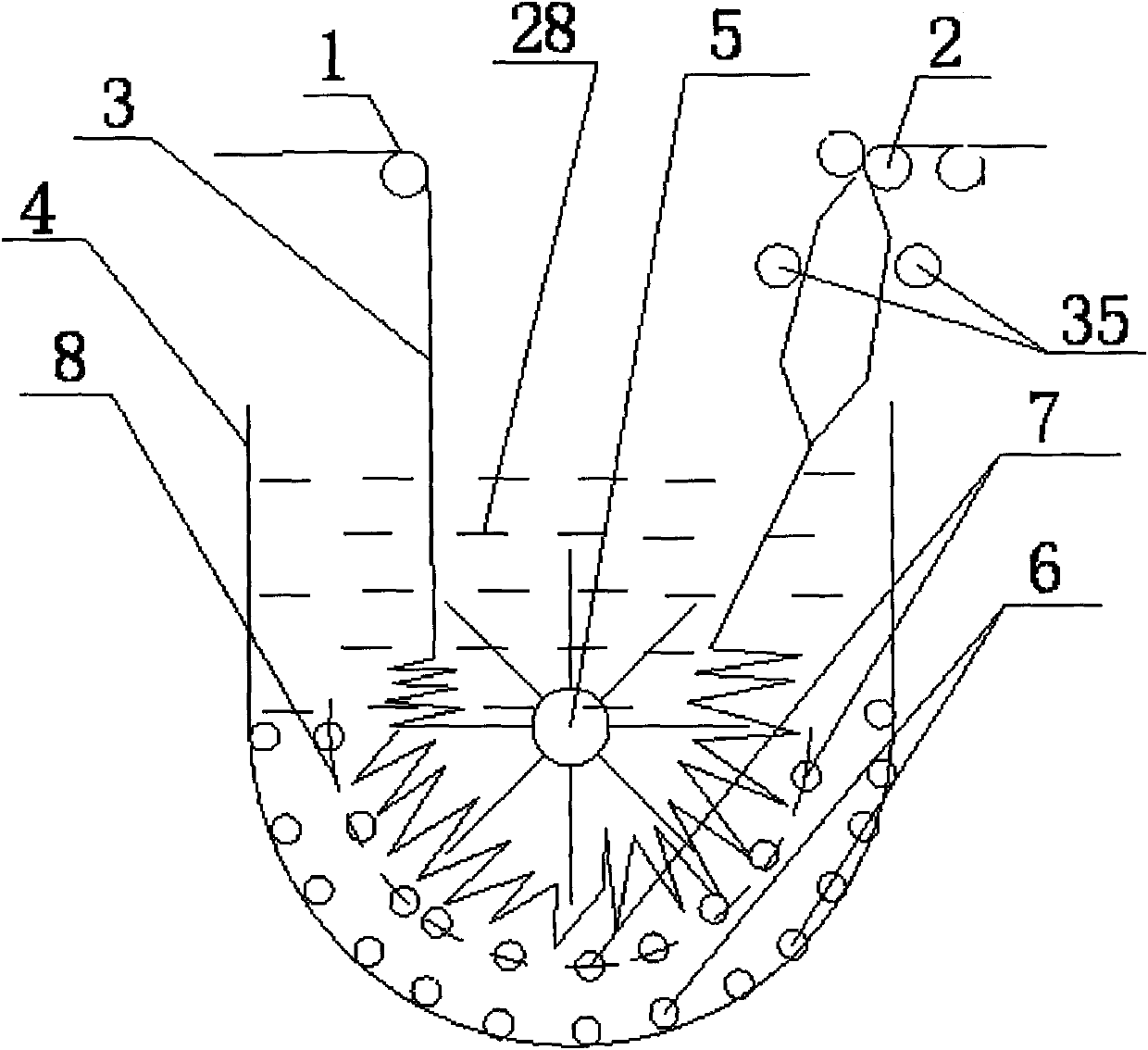

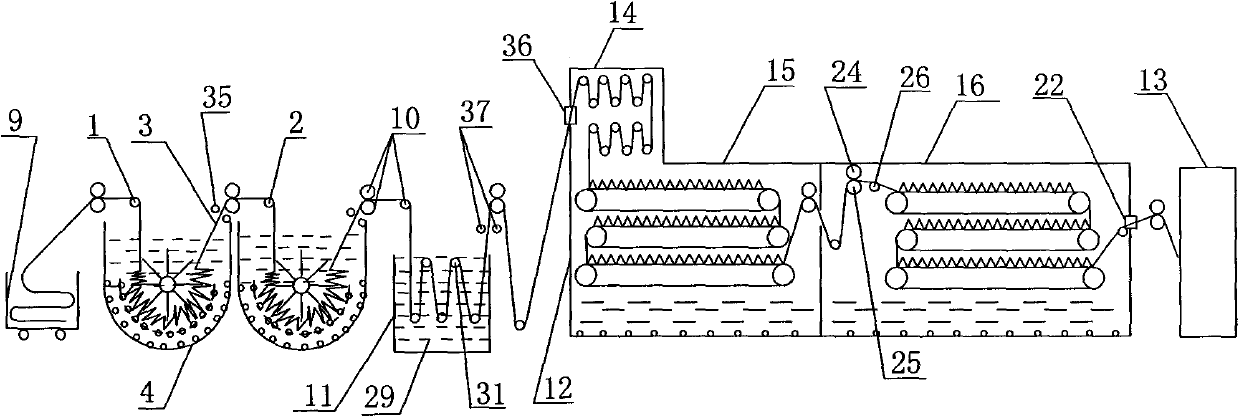

The invention discloses a crease prevention device for scouring and bleaching equipment, scouring and bleaching equipment and a crease prevention method; a fabric is led in a fabric soaking vessel by a fabric lead-in roller; the fabric enters in hot water of the fabric soaking vessel and hot water flows through the fabric continuously under the condition that the fabric is in a loose state; the fabric in the fabric soaking vessel is led out to the next procedure by a fabric lead-out roller; the crease prevention device is arranged in the scouring and bleaching equipment, and the fabric is processed according to the process flows; in the invention, the fabric is fully self-swelled in the crease prevention device, the crease ratio of cotton knitted textile is reduced, the flatness of the cotton knitted textile is kept; in addition, the crease prevention device and a steam box in the scouring and bleaching equipment are improved, the fabric passes through a fabric trolley, an immersion device, the steam box and a rinsing machine sequentially by a delivery mechanism, so as to realize continuous processing and greatly improve the processing efficiency; under the condition of low cost operation, the fabric with no crease, high planeness, high whiteness and high capillary effect can be processed continuously.

Owner:QINGDAO UNIV

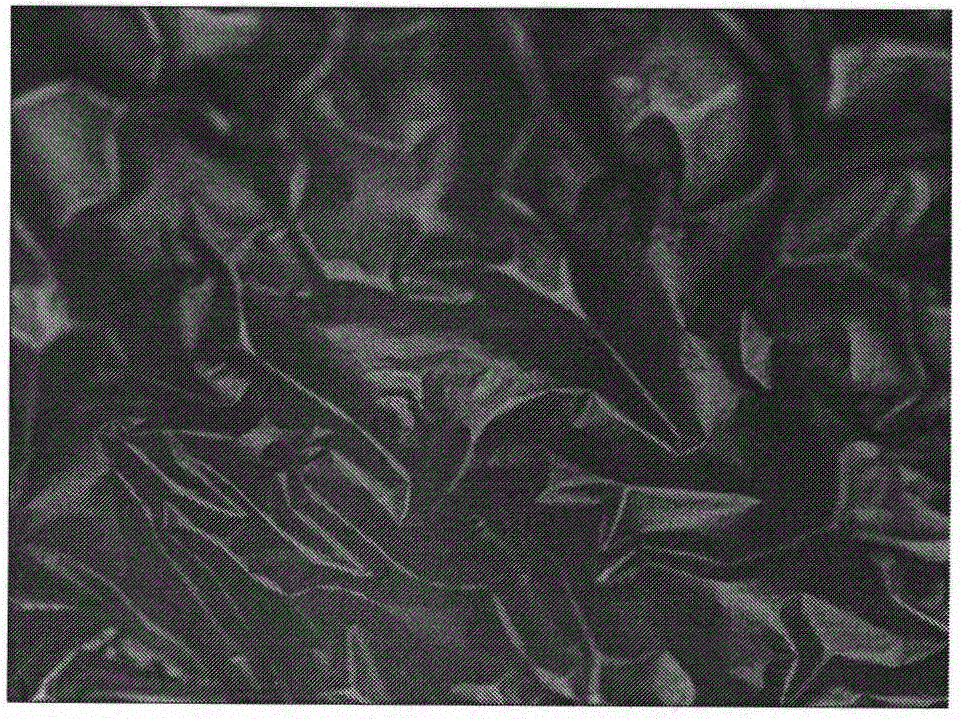

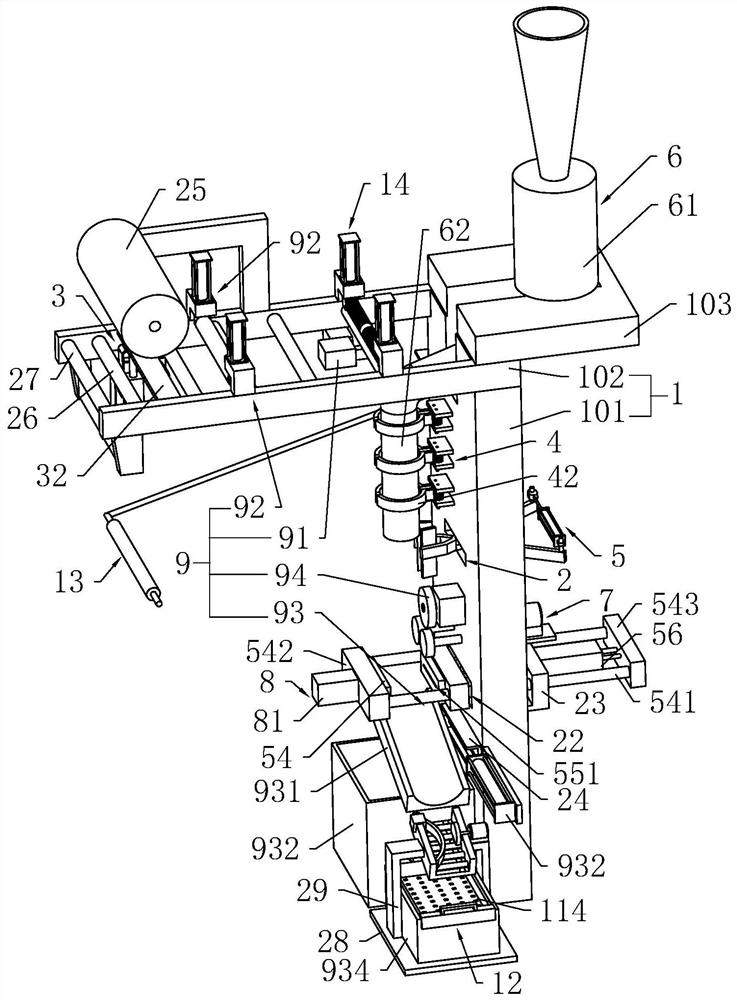

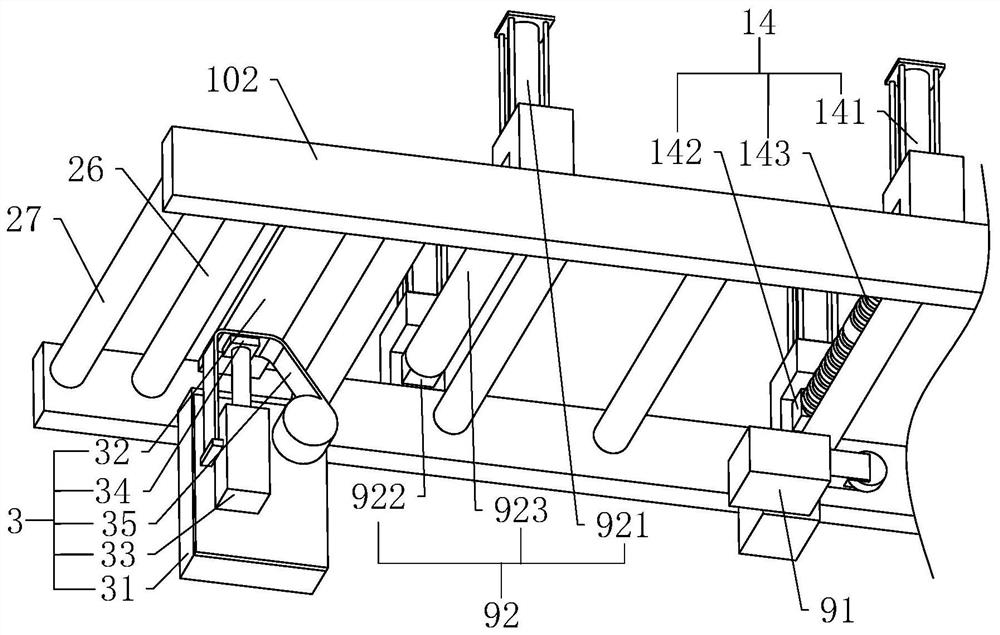

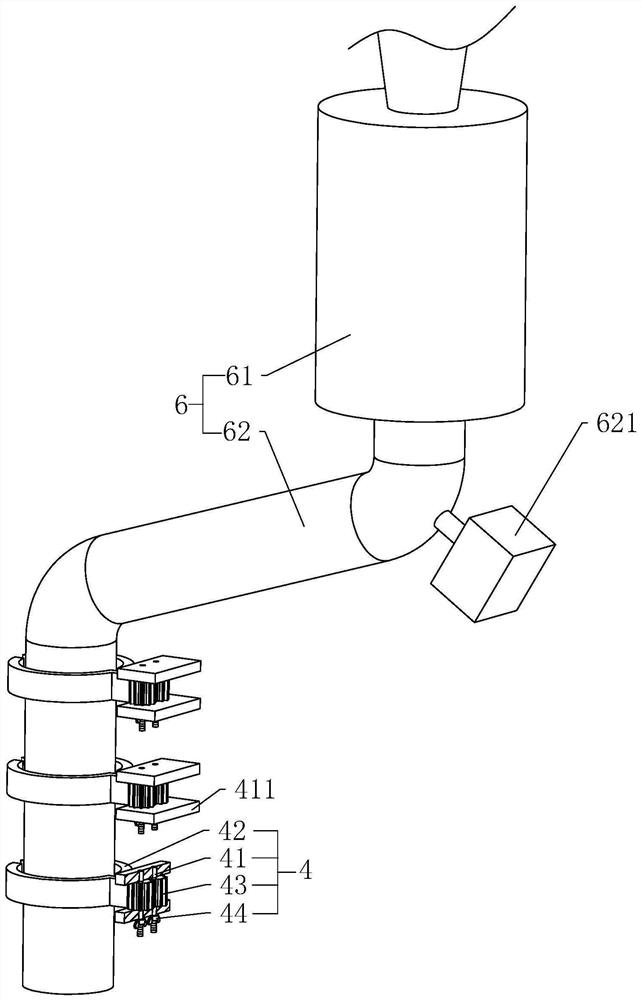

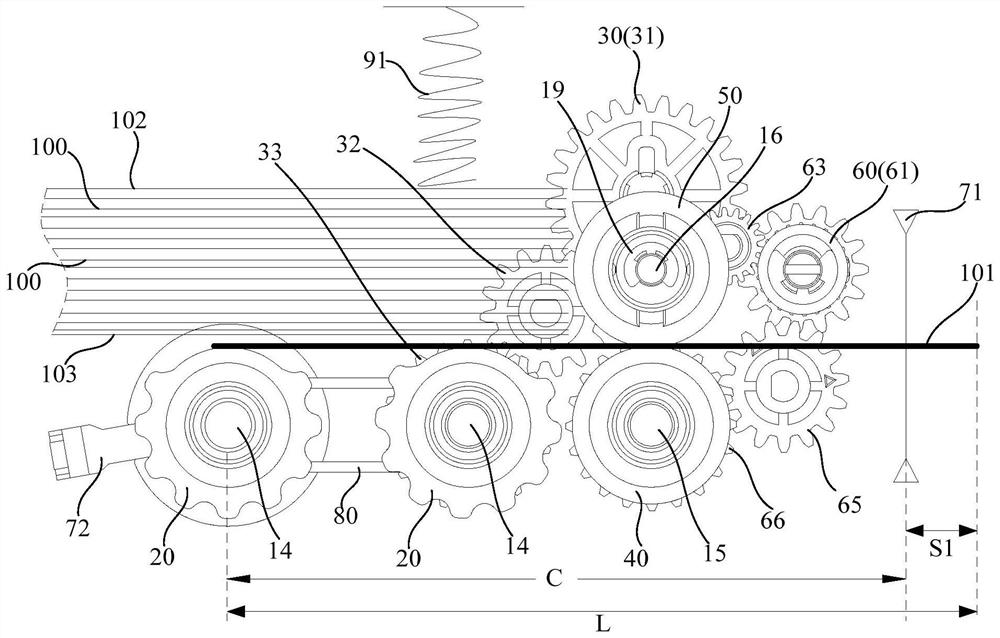

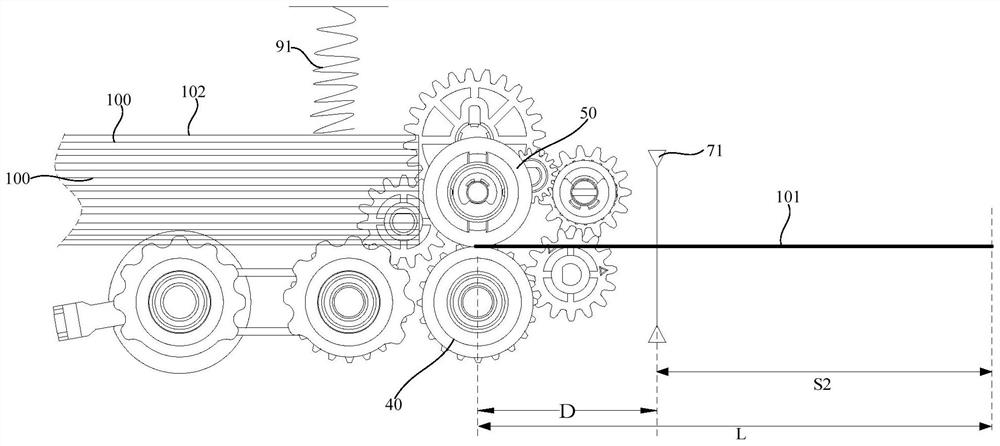

Steam box used for scouring and bleaching equipment, scouring and bleaching equipment and steaming method

ActiveCN101781837AImprove flatnessHigh whitenessTextile treatment containersTextile treatment machine arrangementsEngineeringStretch rate

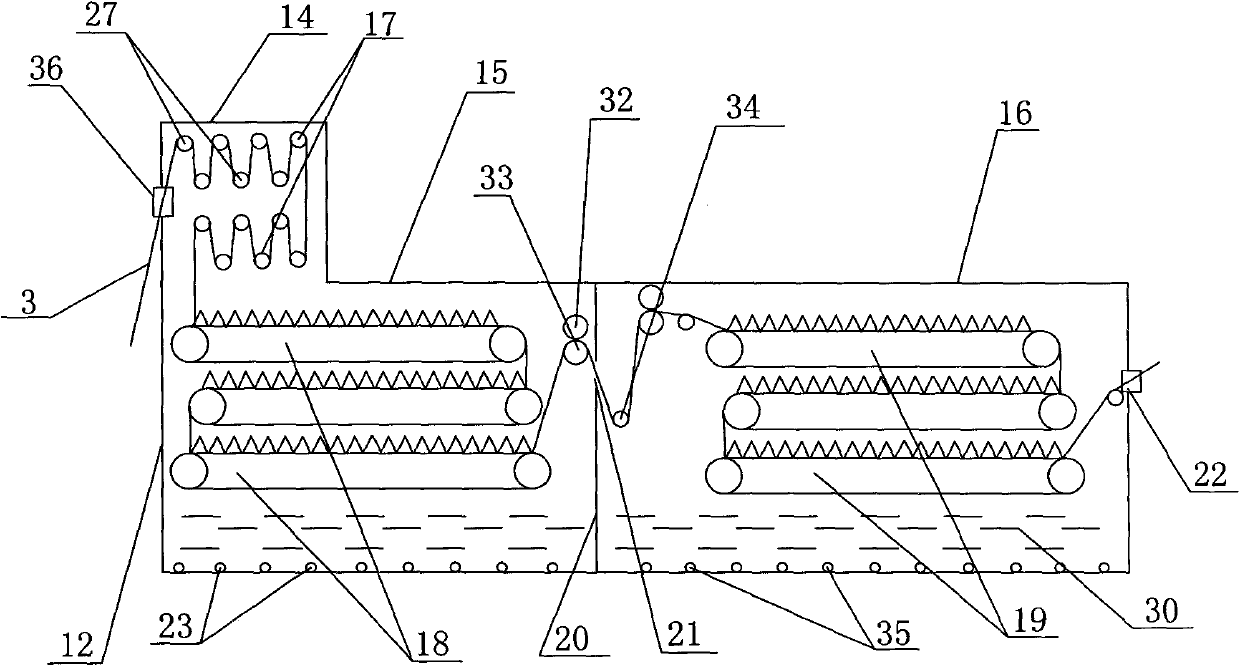

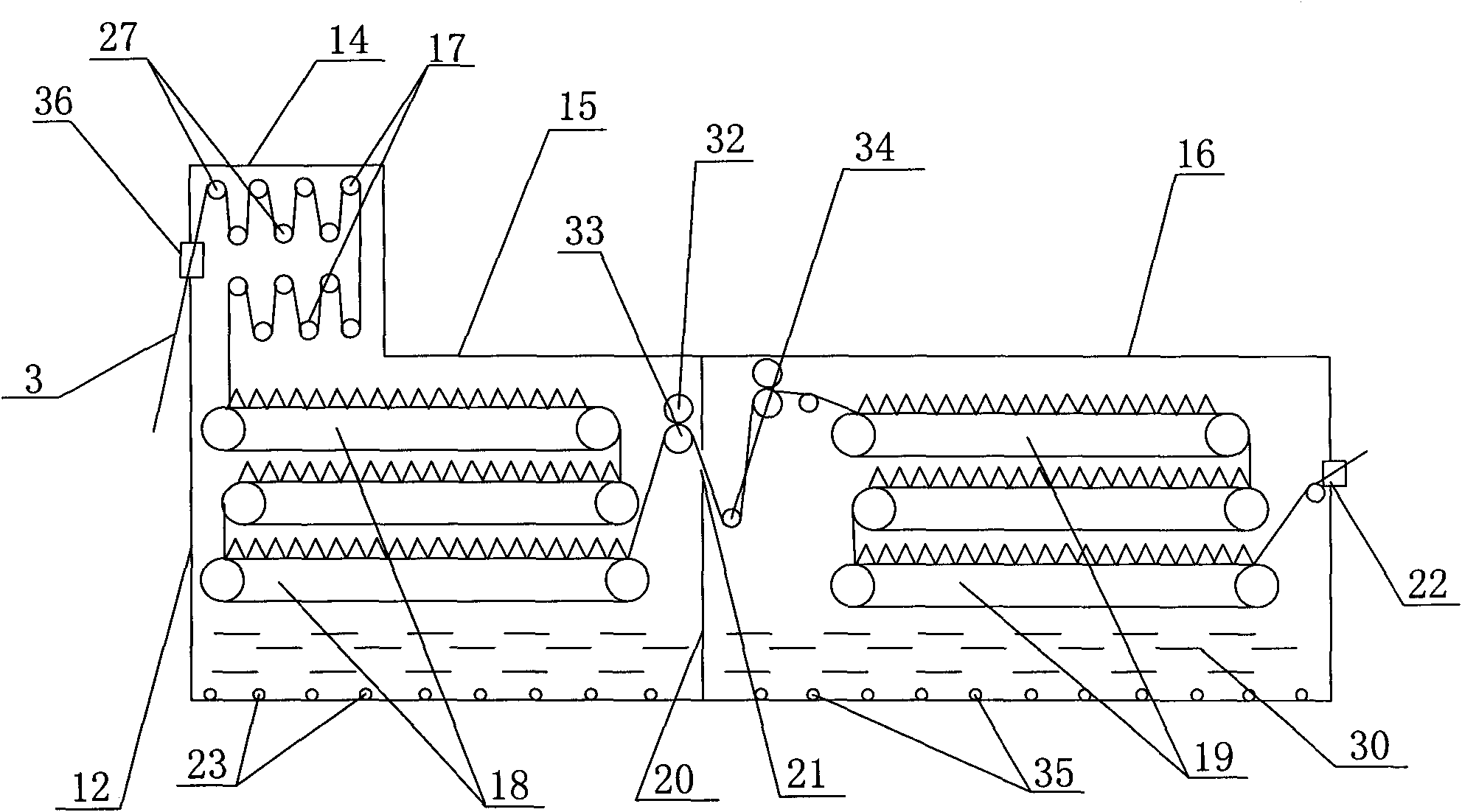

The invention discloses a steam box used for scouring and bleaching equipment, scouring and bleaching equipment and a steaming method. The steam box comprises a preheating zone, a first temperature zone and a second temperature zone; a steam box guide roller used for transmitting fabrics is arranged in the preheating zone; a first crawler belt set and a second crawler belt set are respectively arranged in the first temperature zone and the second temperature zone; the transmission directions of adjacent crawler belts in the first crawler belt set and the second crawler belt set are opposite; the crawler belts are staggered in parallel to form the continuous transmission of the fabrics, thereby enabling the fabrics to be stacked on the crawler belts and continuously transmitted; the steam box is arranged in the scouring and bleaching equipment and treats the fabrics according to certain process flows. The invention thoroughly solves the problems that the scouring and bleaching effect is not ideal, the cloth cover evenness of the fabrics is poorer, the dimensional stability is poor because the textile stretch rate is overlarge, the effects of energy saving and consumption reducing are not ideal and the like, thereby continuously producing the fabrics with high evenness, high whiteness and high capillary effect but without creases.

Owner:QINGDAO UNIV

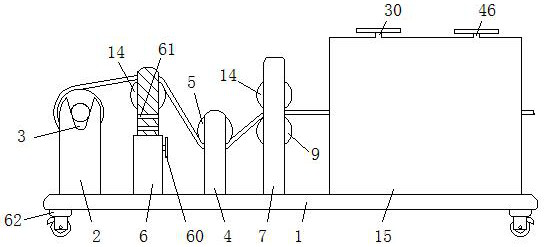

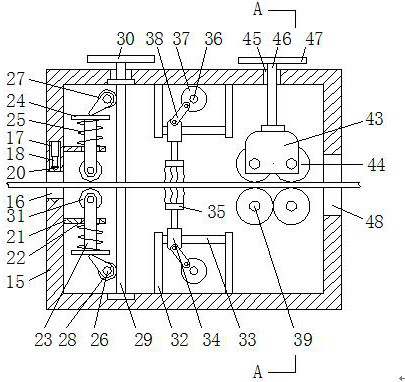

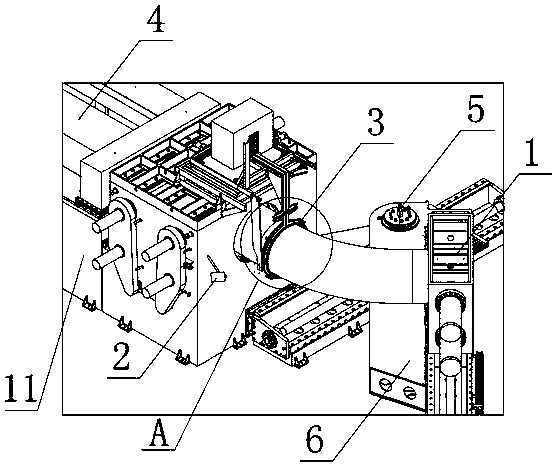

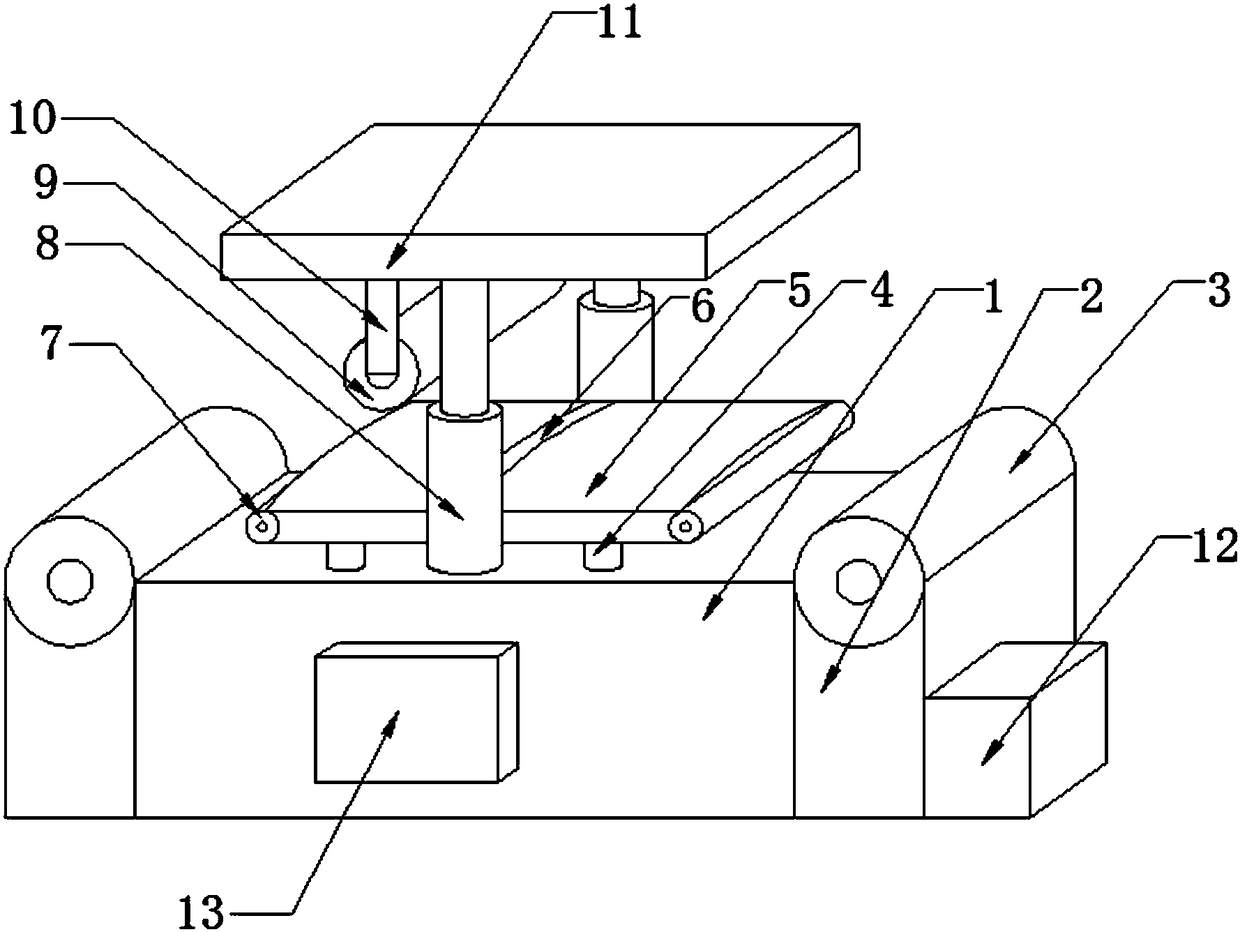

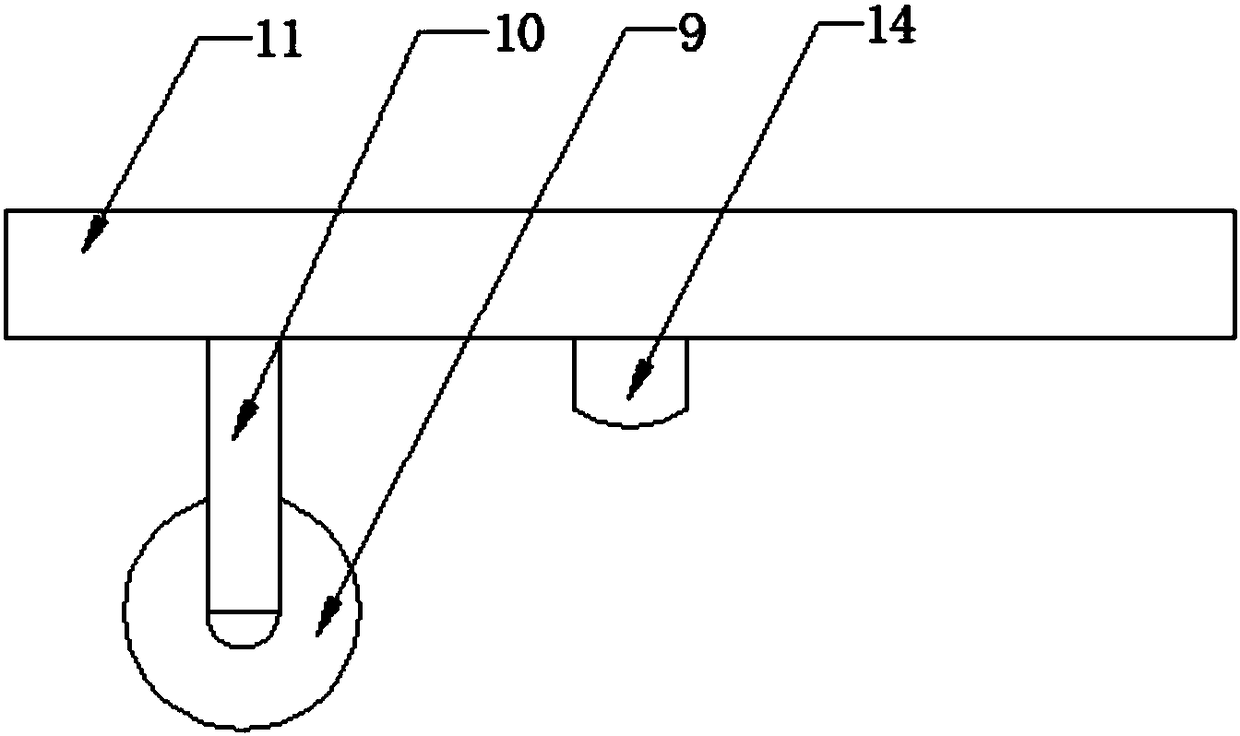

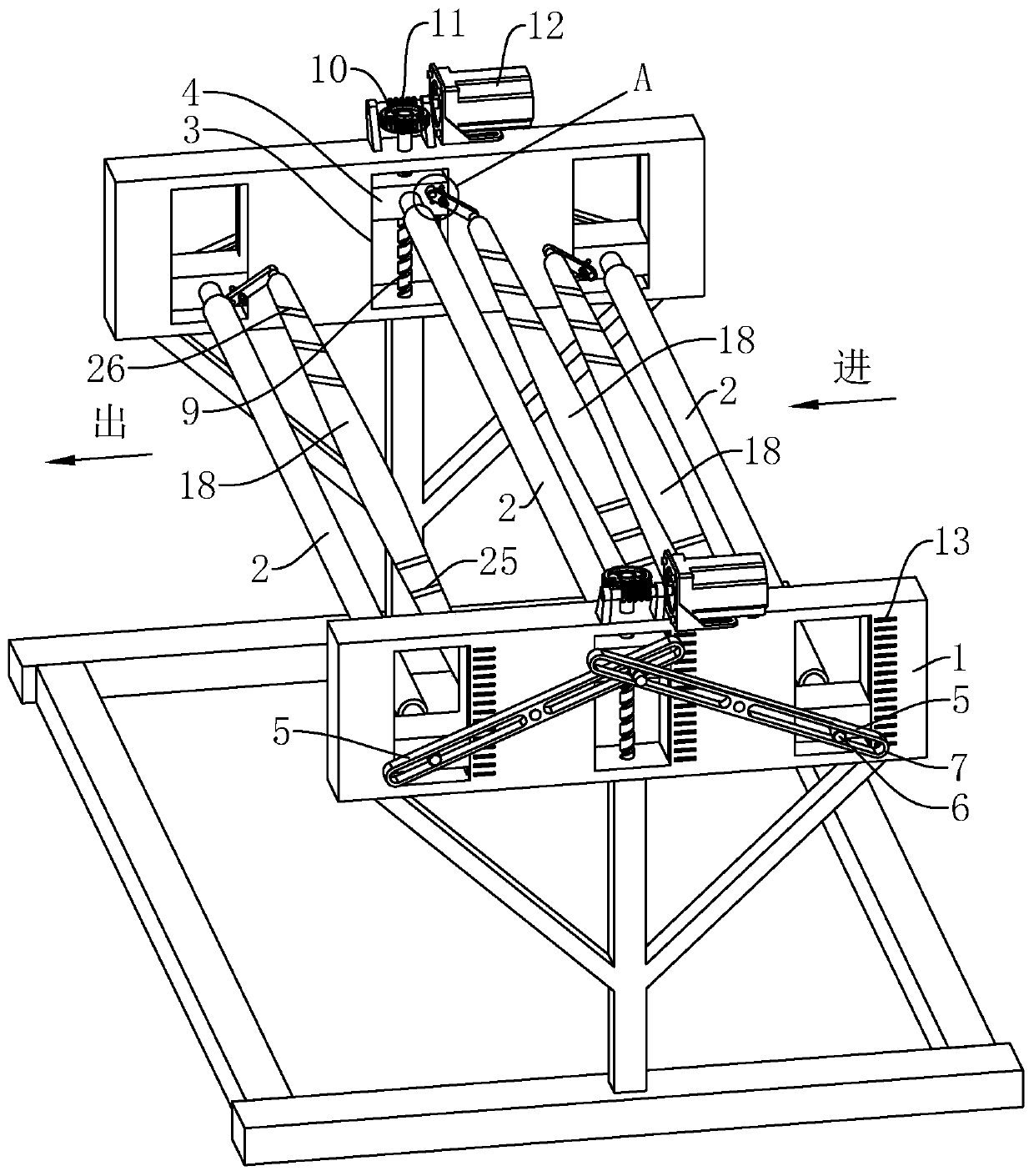

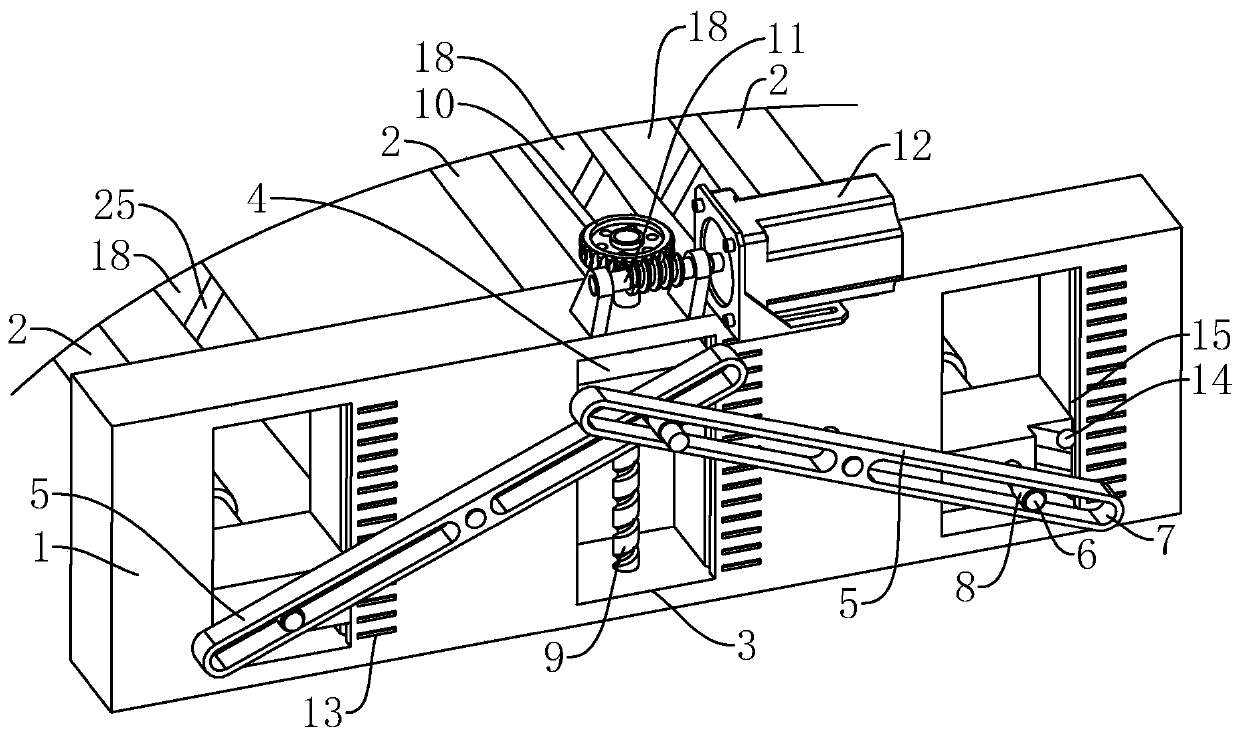

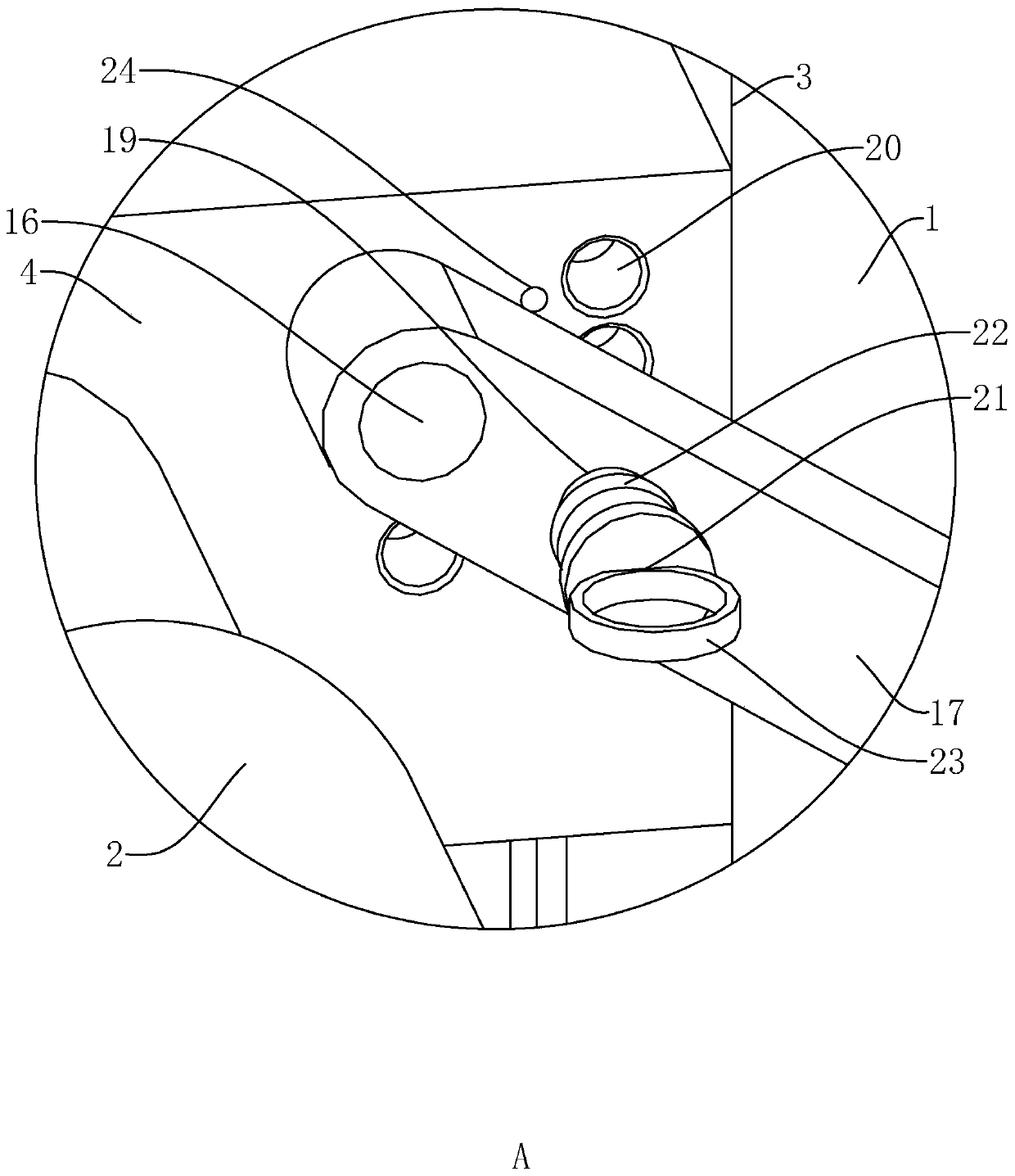

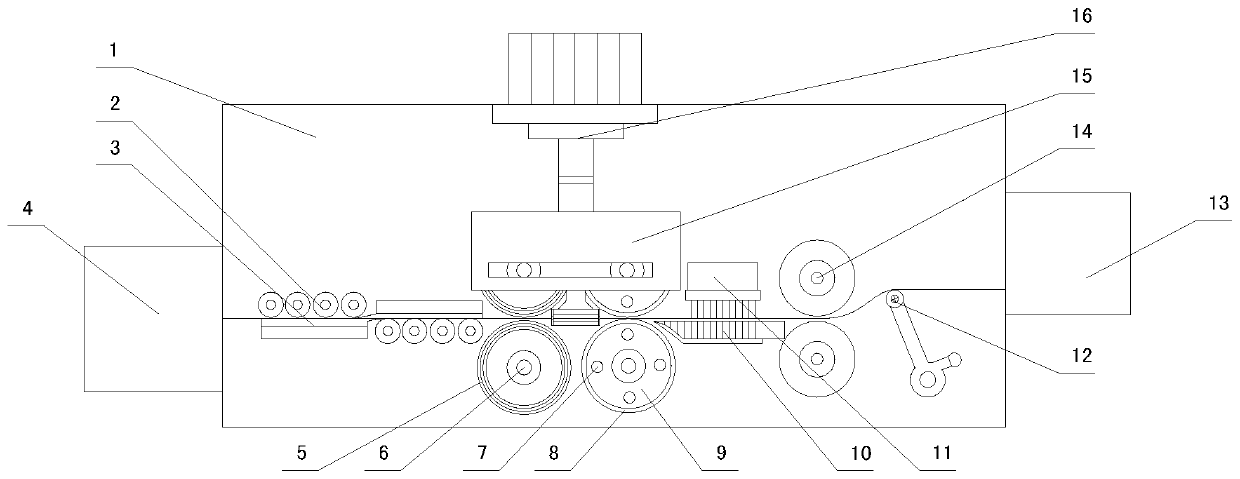

Spinning machine discharging mechanism with tailoring structure

ActiveCN111648009AReduced chance of wrinklingImprove applicabilityMechanical cleaningPressure cleaningTextile technologySpinning

The invention relates to the technical field of spinning, in particular to a spinning machine discharging mechanism with a tailoring structure. A base is included. The upper end of the base is sequentially fixedly connected with two support columns, a tensioning device, a first framework, a conveying device and a box from left to right. The upper portion and the lower portion of the left side of the inner wall of the box are symmetrically fixedly connected with second connecting plates. The second connecting plates are provided with through grooves. Movable rods are movably connected in the through grooves. The opposite sides of the two movable rods are fixedly connected with movable plates. Rotation shafts are symmetrically and rotationally connected between the left portions of the frontside and the rear side of the inner wall of the box. Worm gears are fixedly in cup joint to the rear sides of the outer portions of the rotation shafts. Worms engaged with the worm gears are rotationally connected between the upper end and the lower end of the inner wall of the box. By means of the spinning machine discharging mechanism, wrinkles of cloth in the conveying process can be avoided,dust on the cloth is removed, practicability and functionality of the device are greatly improved, and the spinning machine discharging mechanism is worthy of popularization and usage.

Owner:嘉兴如运建筑科技有限公司

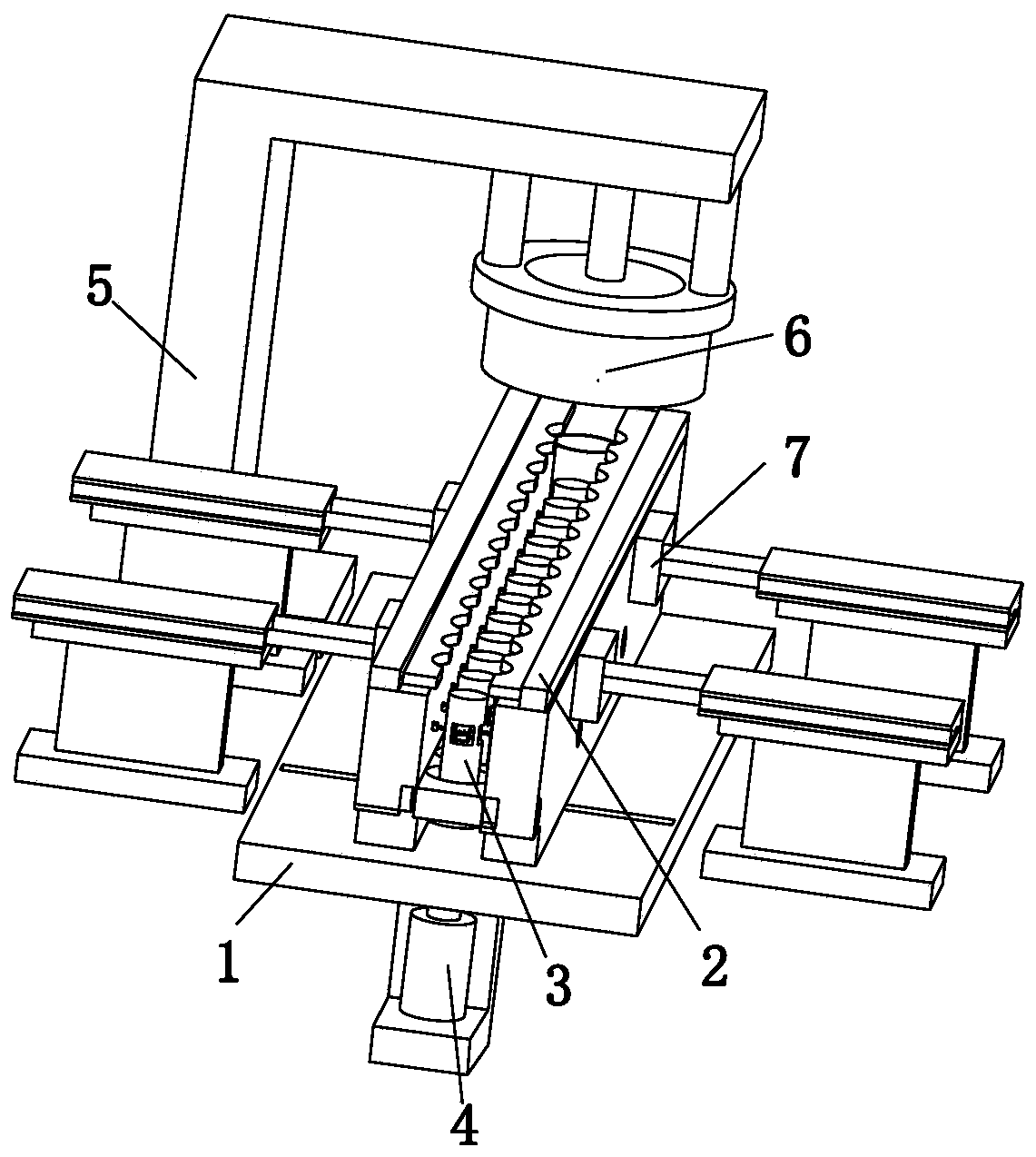

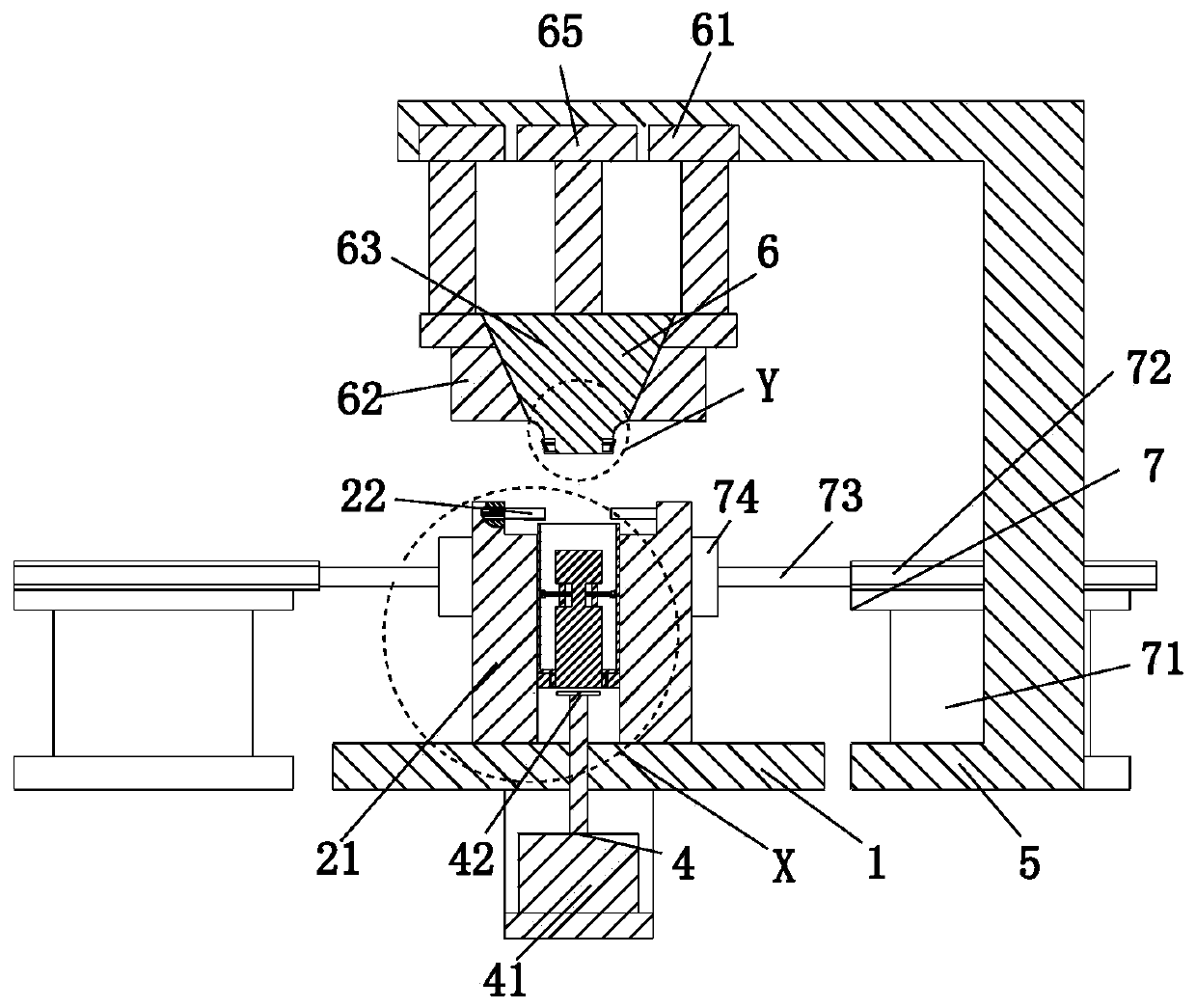

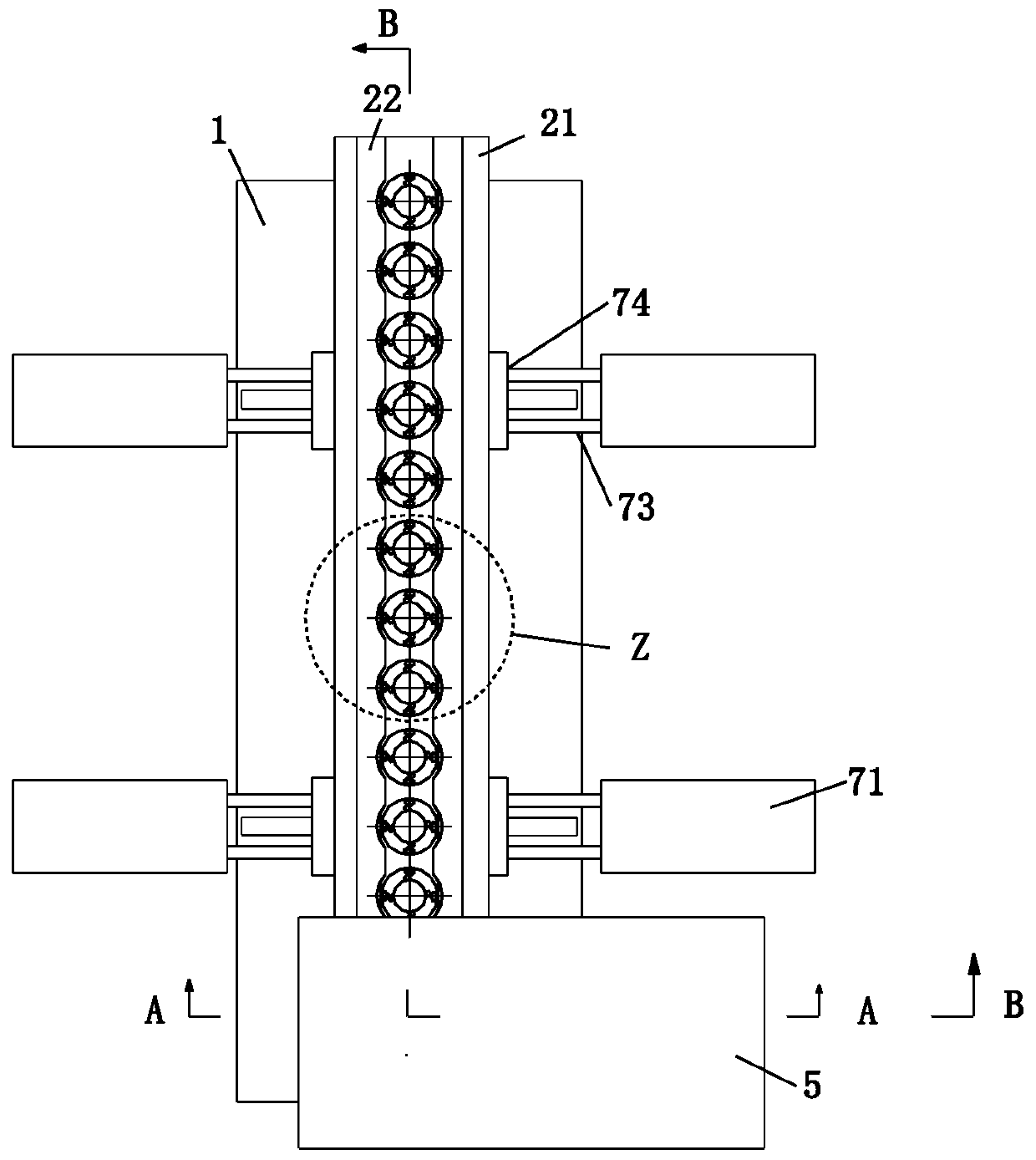

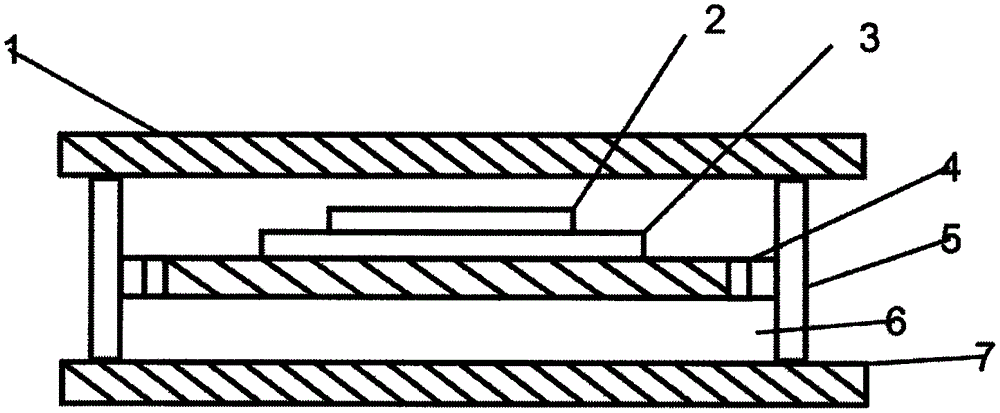

Hardware product hemming stamping die

ActiveCN110421089AReduce shakingReduce wrinklesShaping toolsMetal-working feeding devicesWrinkle skinPunching

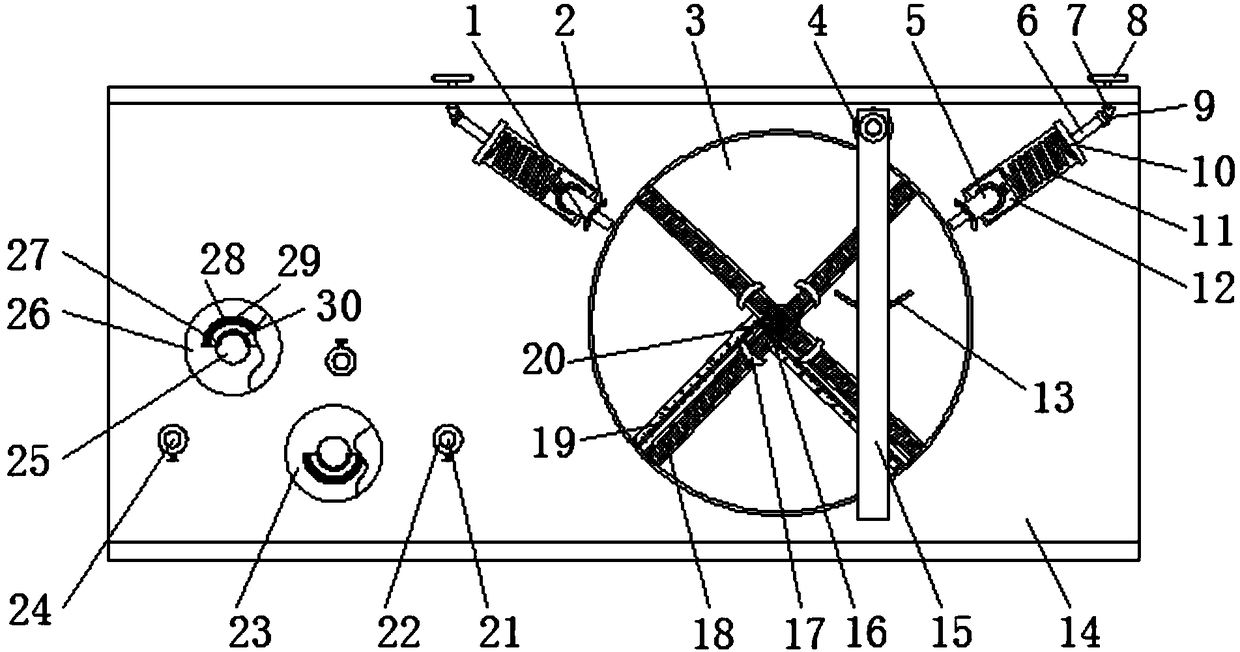

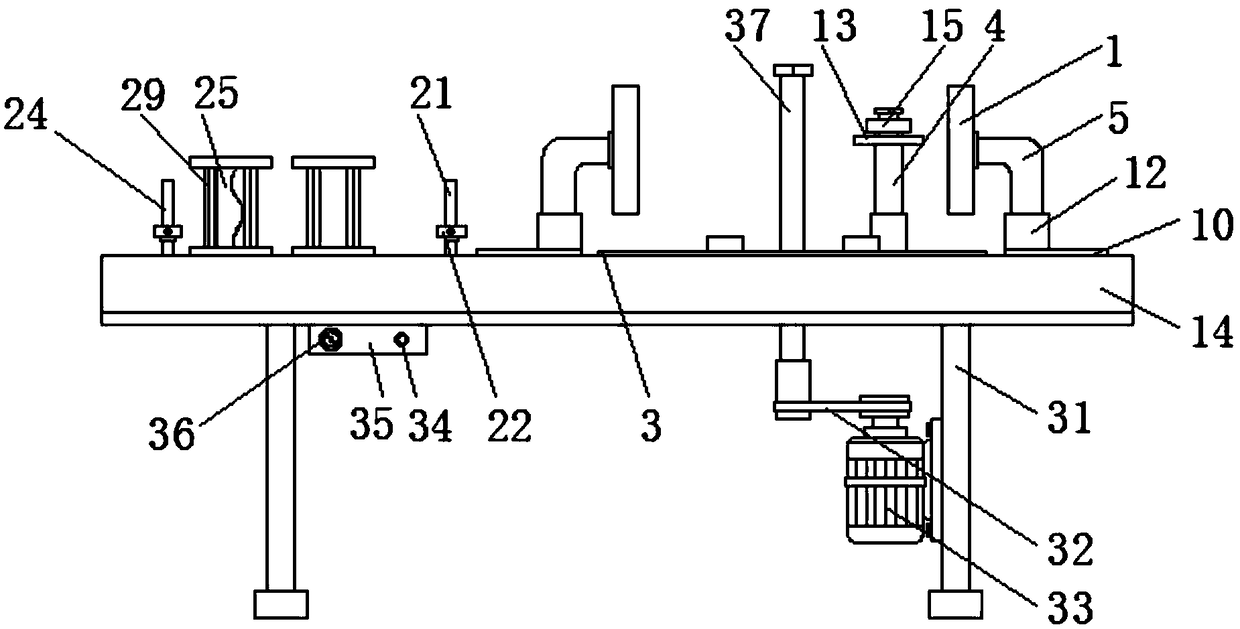

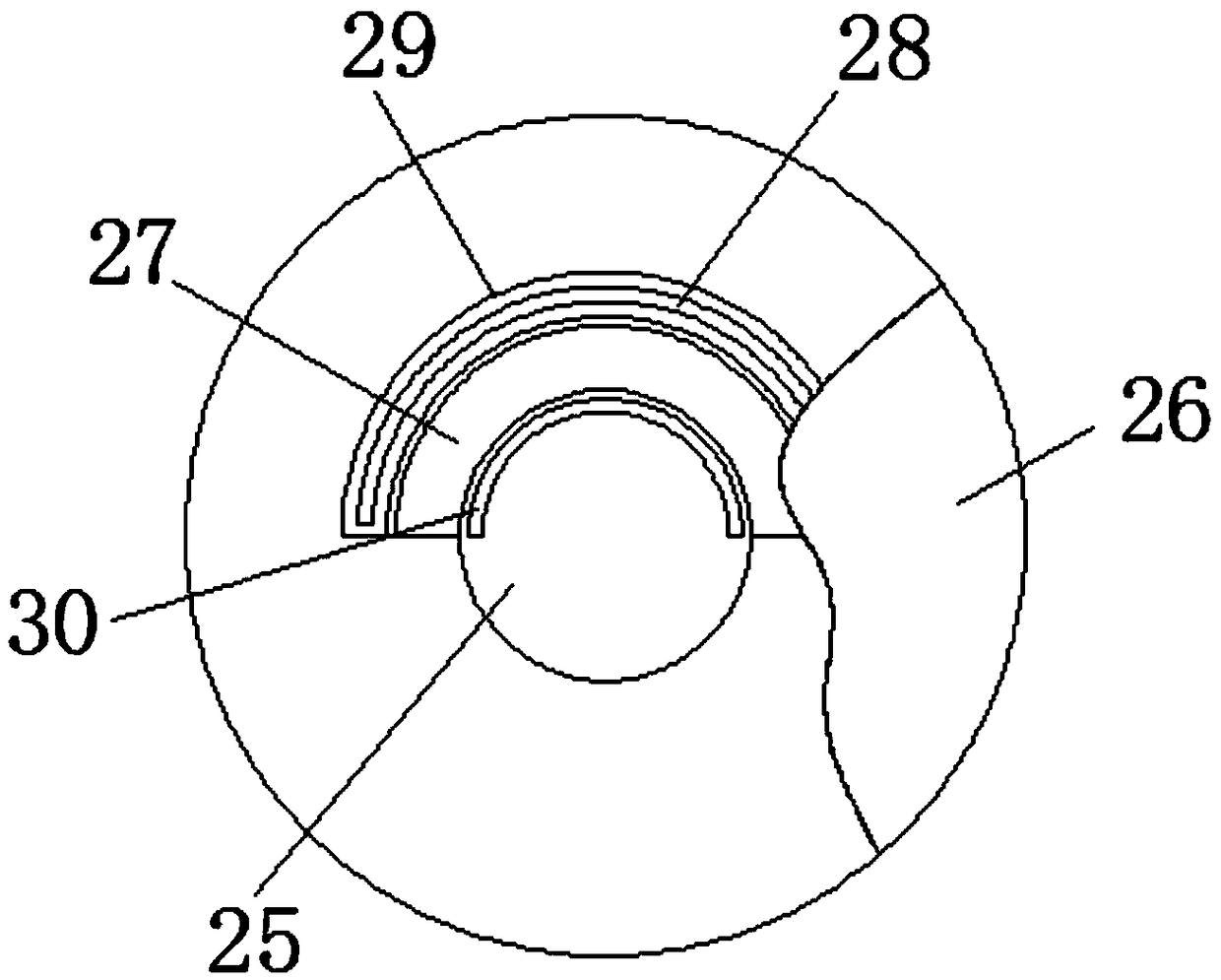

The invention relates to a hardware product hemming stamping die. The hardware product hemming stamping die comprises a workbench, two attaching devices, a limiting device, an ejection device, a U-shaped frame, a stamping device and four clamping devices, wherein the attaching devices are symmetrically arranged on the upper end surface of the workbench in a bilateral symmetry mode, the two clamping devices are connected by the limiting device, the ejection device is arranged behind the lower end of the workbench, the clamping devices are symmetrically arranged on the left side and the right side of the workbench, the U-shaped frame is installed at the front end of the right side of the workbench, and the stamping device is installed on the lower end surface of the U-shaped frame. The hardware product hemming stamping die can solve the problems that when an existing iron sheet is punched, the iron sheet can be directly placed into a clamping groove, and a fixing device is not arranged in the clamping groove, and during stamping, wrinkles can be generated between the iron sheets in the punching process, the iron sheet can also shake, stamping deviation is avoided, and hemming is noteasy to form, and meanwhile, an existing external rigid clamping device and an iron sheet contact part are easy to deform.

Owner:武汉普泰金属制造技术有限公司

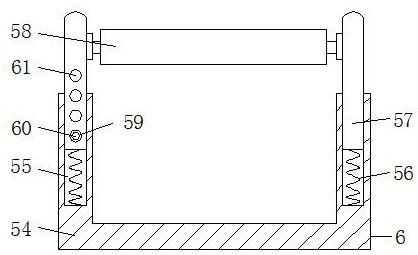

Belt winding machine for textile manufacturing

ActiveCN108423460AAccurately grasp the distanceImprove fixed applicabilityHeating/cooling textile fabricsWebs handlingWinding machineTextile manufacturing

The invention discloses a belt winding machine for textile manufacturing, the belt winding machine comprising a working platform, wherein support legs and an electric cabinet are fixedly connected tothe bottom of the working platform by bolts, the support legs are located on one side of the electric cabinet, a motor is fixed and connected to the outer wall of one side of one support leg by a bolt, a rotary table is in transmission connection to one end of the motor by a belt pulley set, second screw rods are mounted in the rotary table, a fourth bevel gear is welded to one ends of the secondscrew rods, clamping plates are in screwing connection to the second screw rods by threads, and a center pipe is welded to the center position of the top of the rotary table. According to the belt winding machine for textile manufacturing, the four clamping plates can fix cylinders with different diameters, the rolling radius can be adjusted as required while the fixing applicability is improved,the packing, storing and transporting requirements can be conveniently met, besides, calibrated scales are arranged on the rotary table so that the distance from the clamping plates to the center pipecan be accurately grasped, the rolling radius can be accurately grasped, and the rolling accuracy is improved.

Owner:山东滨州丰腾化纤绳网有限公司

True blind hole circuit board making process

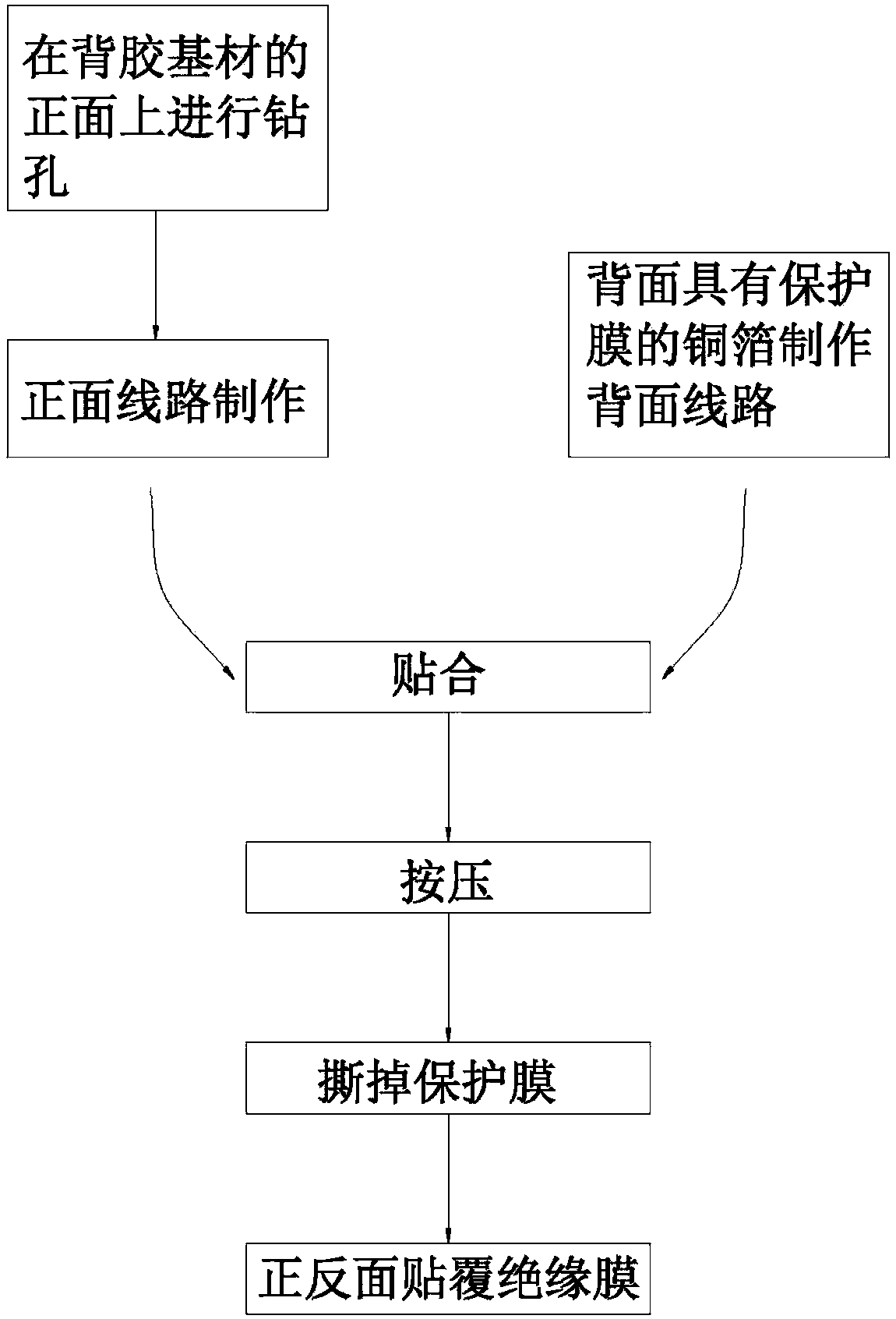

InactiveCN108184313AReduce the chance of wrinklingSimple processMultilayer circuit manufactureTectorial membraneEtching

The invention discloses a true blind hole circuit board making process. The process comprises steps that (1), drilling on a front side of a gum base material is carried out, and front side circuit making is carried out; (2), back etching of a copper foil having a protection film on the back side is carried out to make a back side circuit; (3), a back side of the gum base material and a front sideof the copper foil are bonded; (4), the gum base material and the copper foil which are bonded are pressed to synthesize a board body; (5), the protection film on the copper foil is torn; and (6), insulation films are pasted on front and back sides of the board body. The process is advantaged in that the process is simple, the circuits at the back and front sides are produced simultaneously, bonding is then carried out, the integral process steps are effectively and integrally simplified, the production period is greatly shortened, production efficiency is improved, manpower and material resources are effectively saved, production cost is reduced, the back side of the copper foil is supported through employing the protection film, the wrinkle rate of the copper foil is effectively reduced,the yield is improved, product quality is guaranteed, and wide popularization and application are facilitated.

Owner:东莞市天晖电子材料科技有限公司

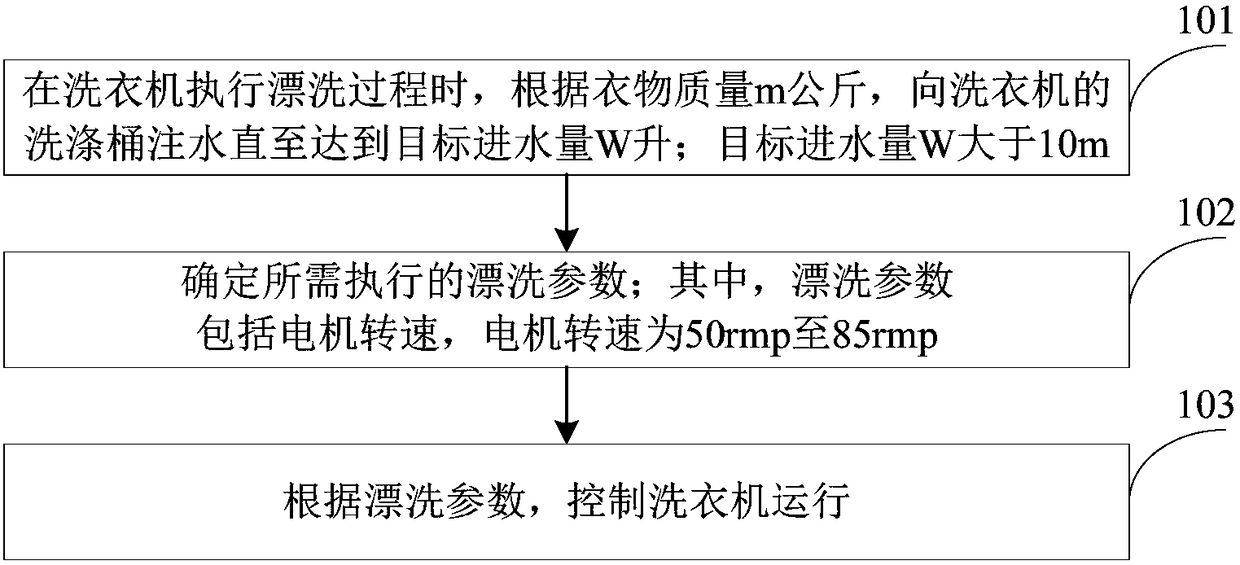

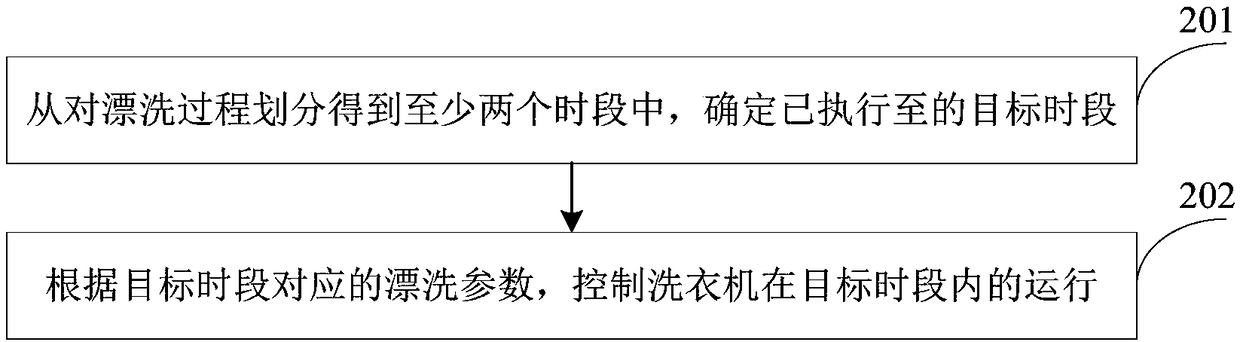

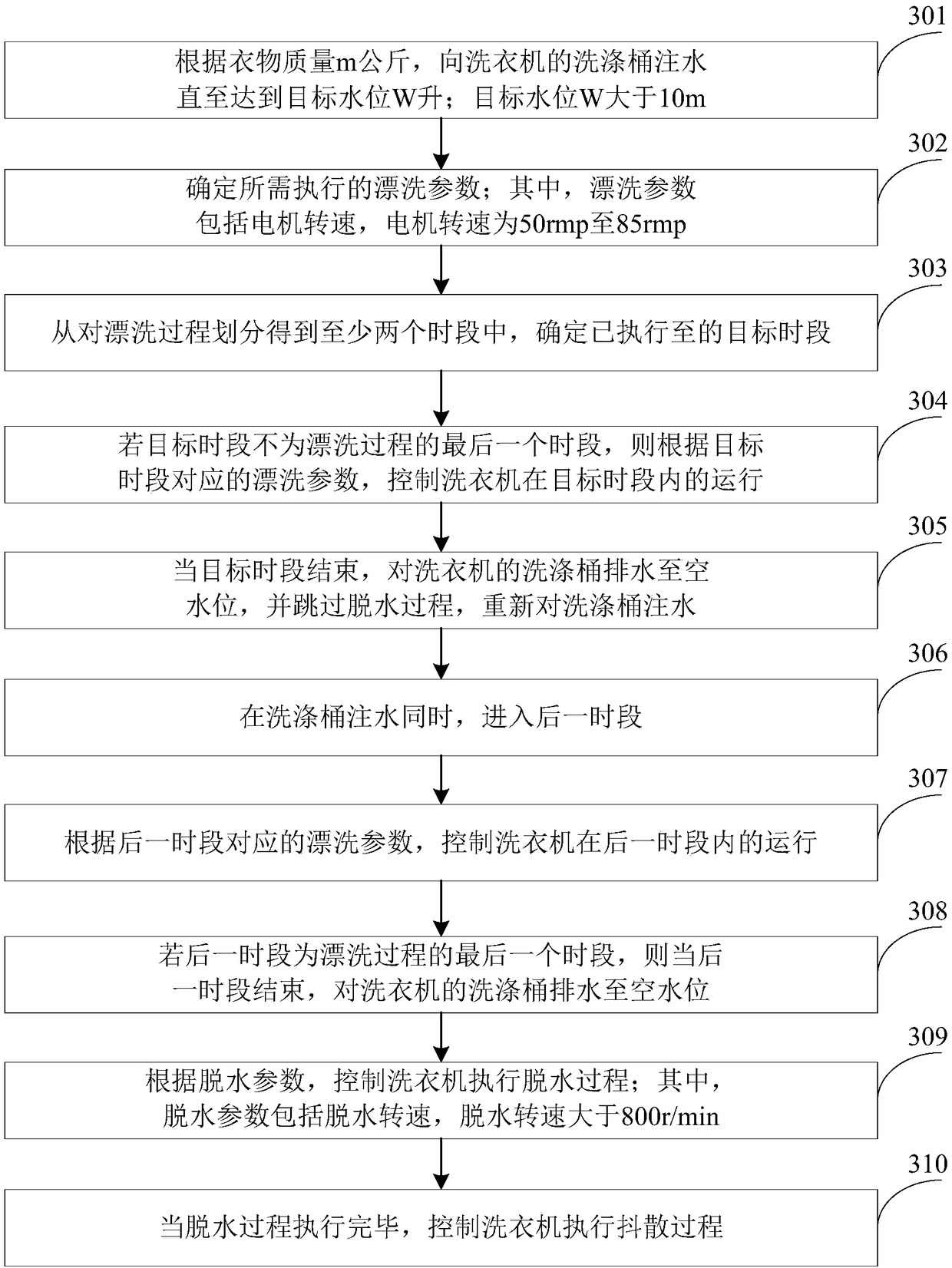

Washing machine control method and device

PendingCN109505091AReduced chance of wrinklingReduce wrinklesControl devices for washing apparatusTextiles and paperWrinkleLaundry

The invention provides a washing machine control method and device. When a washing machine executes a rinsing process, on one hand, water is injected into a wash tub of the washing machine until the target water inlet amount W L is reached, wherein the target water inlet W is greater than 10 m, and the water intake is increased compared with the prior art; on the other hand, the motor speed is controlled from 50 rpm to 85 rpm, and the motor speed is also increased compared with the prior art. According to the method, the motor speed is increased while the water intake is increased, the rinsingeffect similar to yarn washing in water is achieved in the laundry rinsing process, and the probability of wrinkles in the laundry is reduced. In addition, the water intake is increased, stains wrapped in the laundry can be dissolved while a detergent adsorbed on the laundry is dissolved, and the effect of secondary washing is achieved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

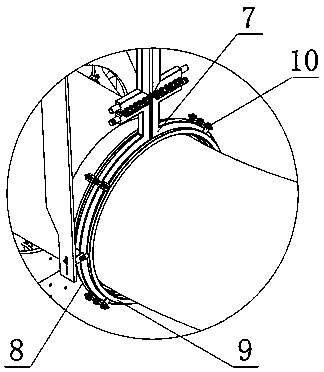

Intermediate-frequency pipe bending machine

The invention discloses an intermediate-frequency pipe bending machine which comprises a rack used for storing pre-bent steel pipes. A three-ring heating and cooling coil set is arranged at the frontend of the rack, wherein the three-ring heating and cooling coil set is used for being arranged on to-be-heated parts of the steel pipes in a sleeving manner and heats and cools the parts. The three-ring heating and cooling coil set comprises a heating coil, an air jetting coil and a cooling coil, wherein the air jetting coil and the cooling coil are arranged on the two sides of the heating coil correspondingly. The heating coil, the air jetting coil and the cooling coil are detachably connected into one through an adjusting assembly. The adjusting assembly can adjust the axial interval amongthe three coils so as to adjust the red strip size after the steel pipes are heated. The machine can achieve the purposes of controlling steel pipe heating red strips uniformly and controlling the temperature accurately, the phenomena of the wrinkle rate, the ovality and the like can be reduced, and the bending quality and the bending precision of intermediate-frequency bent pipes are enhanced. The needs of industries of aerospace, nuclear industry, petrochemical industry, ship building, electricity, vessel manufacturing, steel structures and the like for a larger number of intermediate-frequency hot-bent pipelines are met.

Owner:株洲双菱科技有限公司

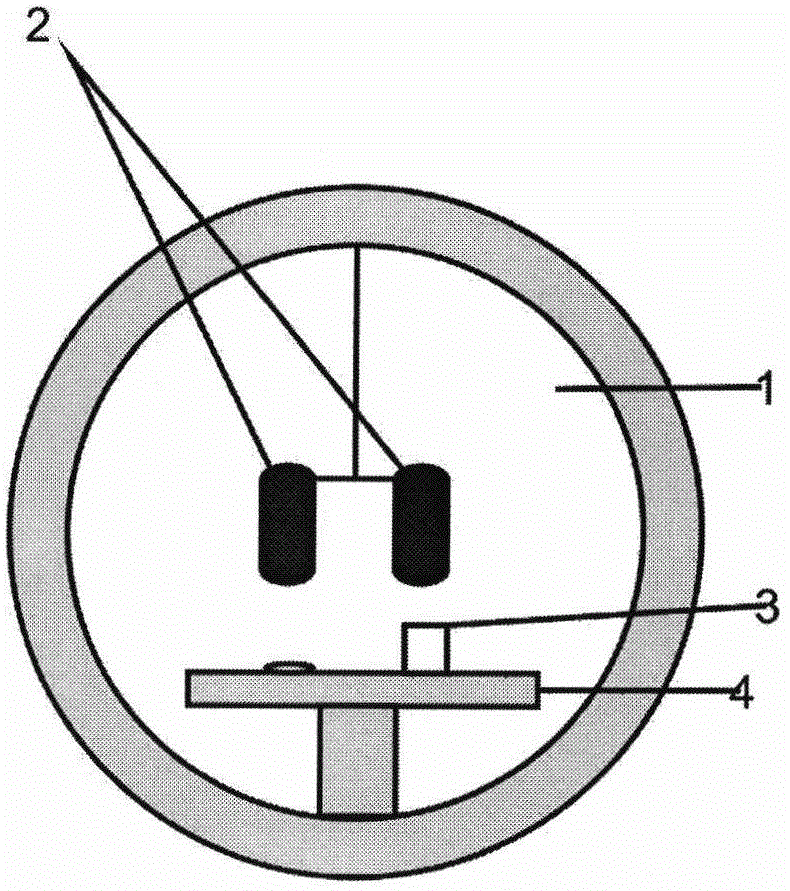

Liquid phase substrate deposition metal film separation device

ActiveCN105671510AWill not oxidizeReduced effectVacuum evaporation coatingSputtering coatingThin layerEngineering

The invention belongs to a magnetron sputtering technology, and particularly relates to a liquid phase substrate deposition metal film separation device.The liquid phase substrate deposition metal film separation device is characterized in that a head cover can conveniently open and seal an opening, a base seals the bottom of a drum, a partition plate with holes is fixed at the middle position of the drum, the middle of the partition plate with the holes is coated with a dimethyl silicone oil thin layer, and the metal film is deposited on the upper portion of the dimethyl silicone oil thin layer.The liquid phase substrate deposition metal film separation device has the advantages that the metal film formed after the magnetron sputtering process can be obtained in a vacuum environment and cannot be oxidized; by means of a constant temperature environment, the action of internal stress of silicon oil on the metal film is reduced, and corrugation of the metal film cannot occur.

Owner:CHINA JILIANG UNIV

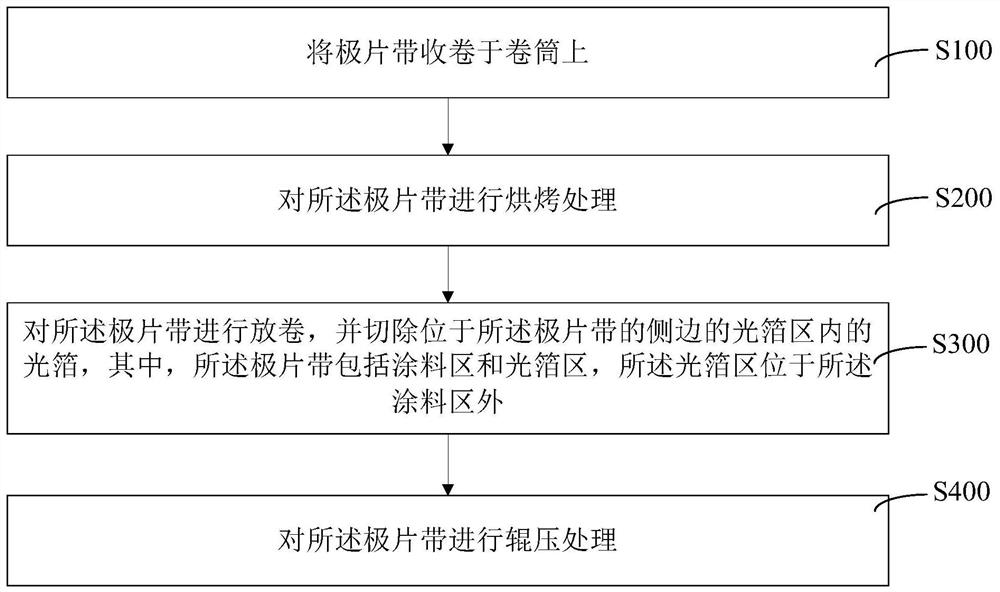

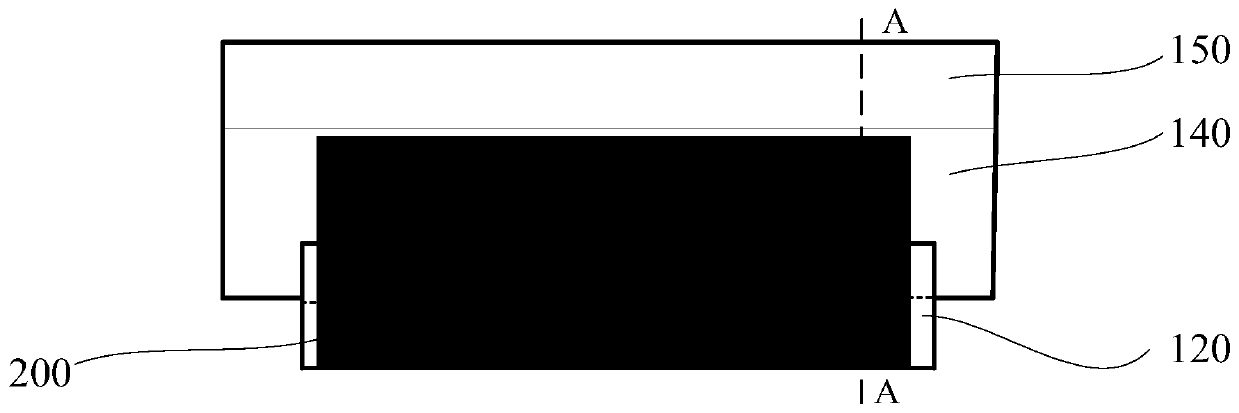

Method and equipment for treating side wrinkles of pole piece

ActiveCN111916677AGuaranteed stress reliefConsistent thicknessElectrode rolling/calenderingSecondary cellsEngineeringMechanical engineering

The invention provides a method and equipment for treating wrinkles on the side edge of a pole piece. The method comprises the following steps: winding a pole piece belt on a winding drum; carrying out baking treatment on the pole piece belt; unreeling the pole piece belt, and cutting light foil located in a light foil area on the side edge of the pole piece belt, wherein the pole piece belt comprises a coating area and a light foil area, and the light foil area is located outside the coating area; and carrying out rolling treatment on the pole piece belt. Before the pole piece belt is rolled,the pole piece belt is wound, the wound pole piece belt is baked, the stress release of the two sides of the pole piece belt is guaranteed, and then smooth foils on the side edges of the pole piece belt are cut off, so the thickness of the side edges of the pole piece belt is consistent, and therefore the ductility of the side edges of the pole piece belt is consistent; therefore, when the pole piece belt is stripped, the side edge of the pole piece belt is uniformly stressed, the flatness of the side edge of the pole piece belt is improved, and the probability of wrinkles of the pole piece belt is reduced.

Owner:MEIZHOU LIANGNENG NEW ENERGY SCI & TECHCO

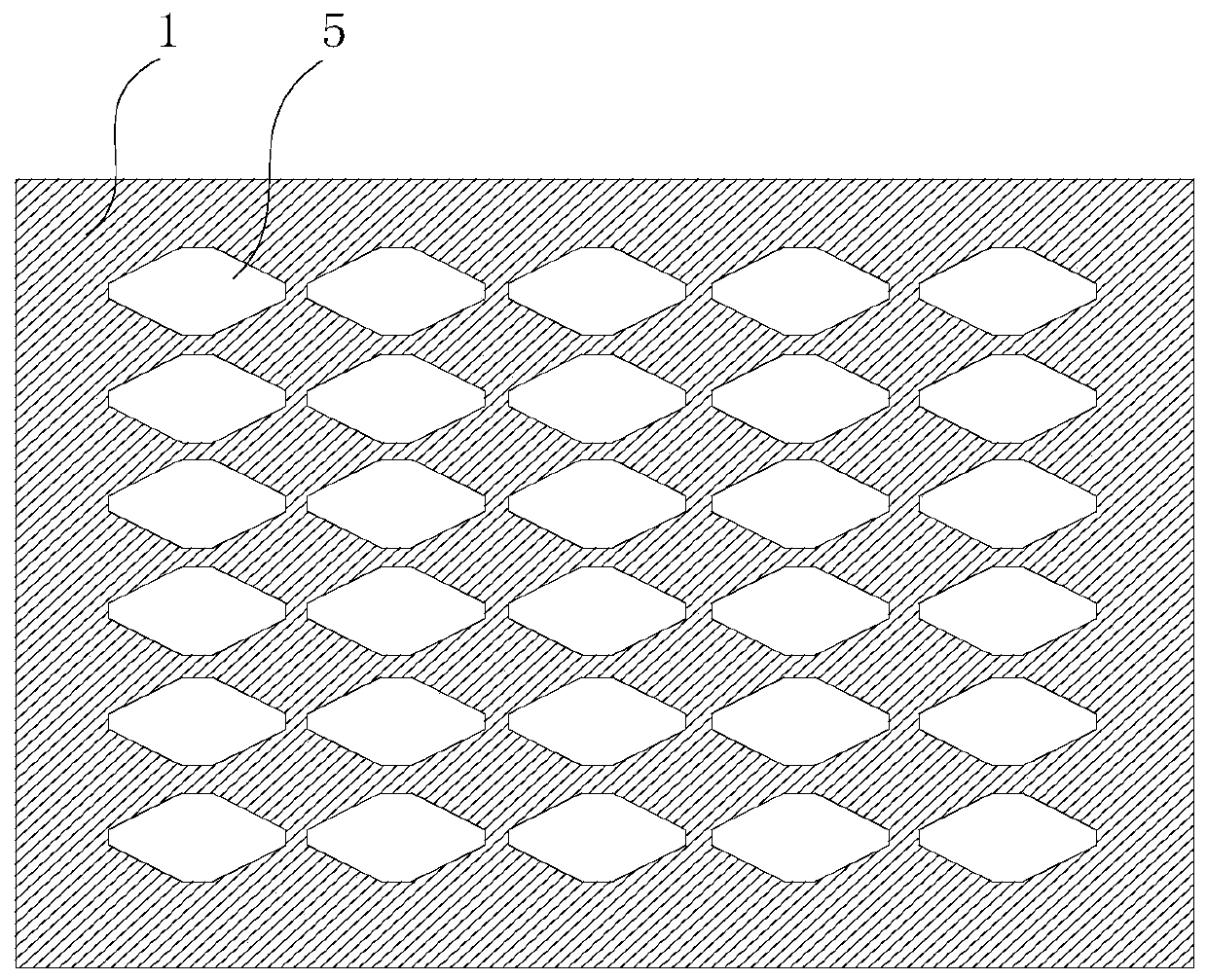

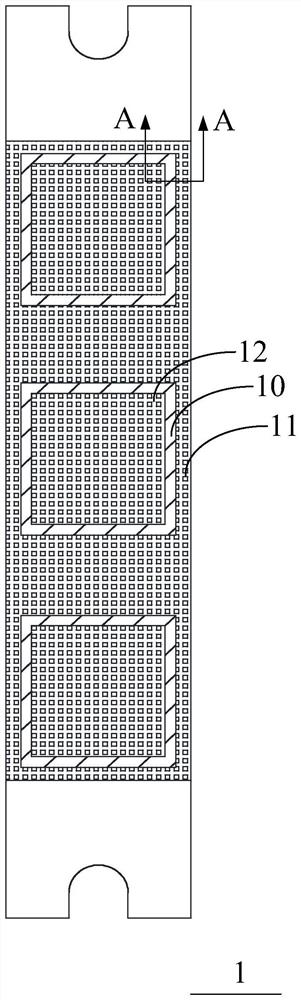

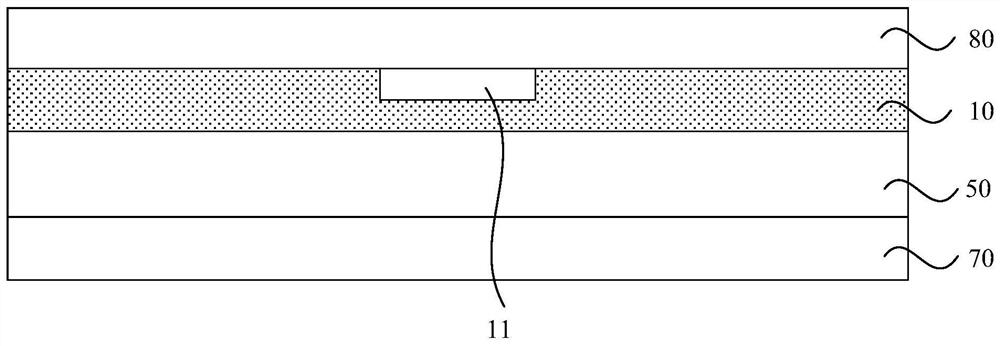

Mask plate and pixel structure

ActiveCN110578112AReduce the difficulty of manufacturing processReduced chance of wrinklingLiquid surface applicatorsVacuum evaporation coatingEngineering

The invention discloses a mask plate and a pixel structure. The mask plate includes a mask opening for making sub-pixel in a pixel opening of a display panel, the area of the mask opening is greater than that of the corresponding pixel opening, the pixel opening includes one or more inward concave curved edges, the mask opening includes one or more mask edges, the one or more mask edges correspondto the one or more curved edges, and the curvature of each mask edge is less than that of the corresponding curved edge. According to the mask plate disclosed by the invention, the mask opening is enlarged in non-equal proportion relative to the corresponding pixel opening, the sizes of the mask opening at different positions of the mask plate can be adjusted within a process allowance, the situation that the mask edges of the mask opening are made into the inward concave curved edges is avoided, the preparation technology difficulty of the mask opening of the mask plate is reduced, and thusthe prepared mask plate with the pixel structure of the curved edges can be mass-produced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

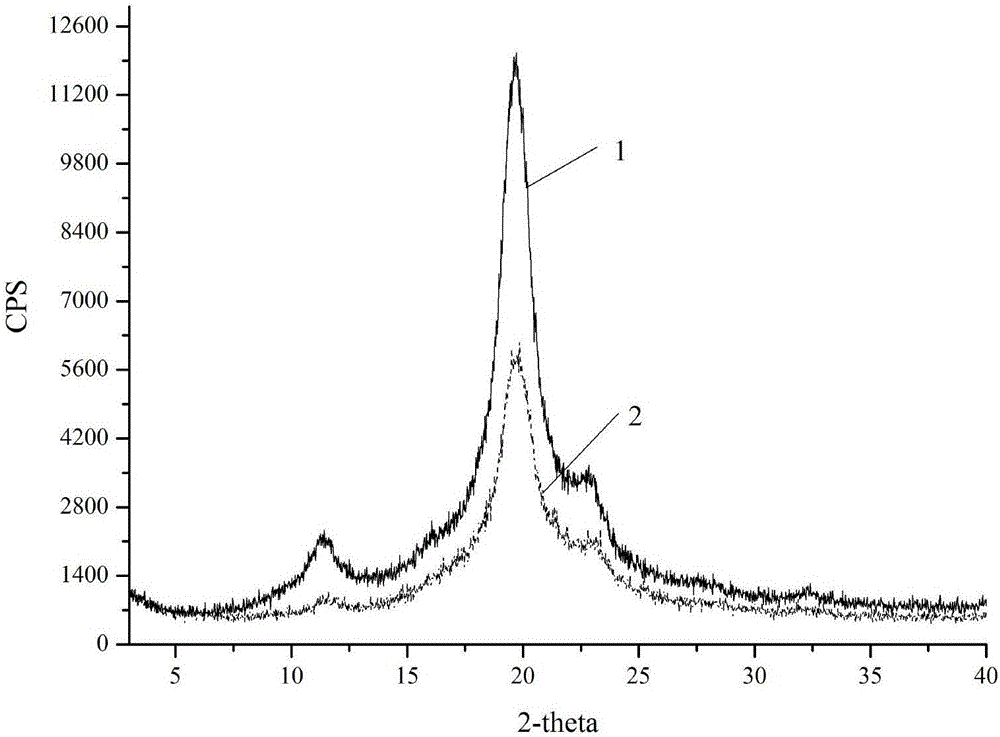

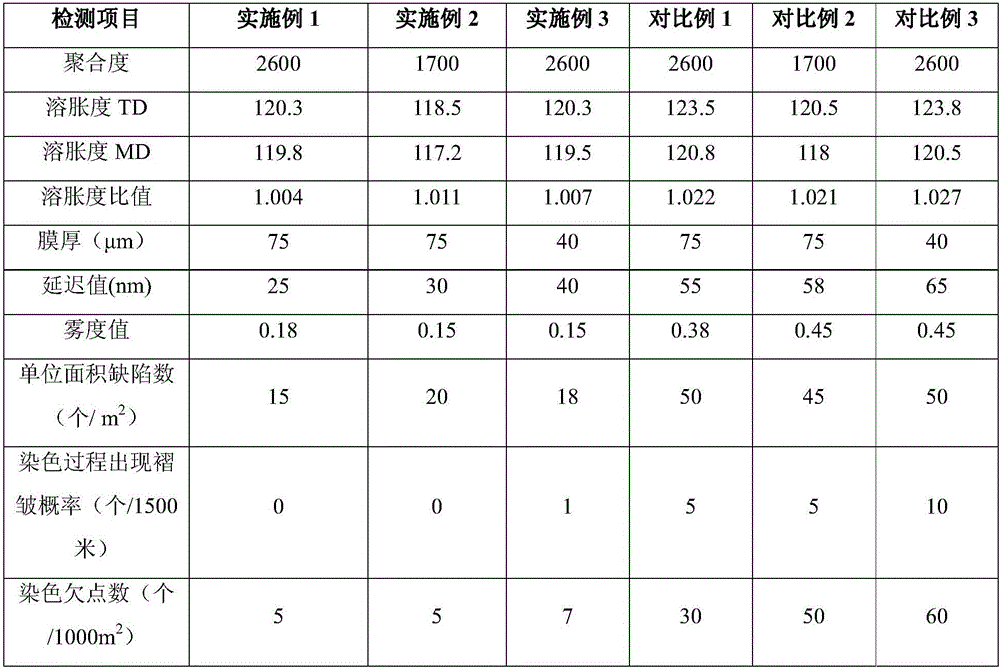

Heat treatment method of polyvinyl alcohol optical film

ActiveCN105738977AEliminate unevennessHorizontal and vertical shrinkage is the samePolarising elementsPolarizerSwelling capacity

The invention discloses a heat treatment method of a polyvinyl alcohol optical film. The heat treatment method is characterized in that heat treatment is performed on the polyvinyl alcohol optical film in manners of hot air treatment and silicone oil bath treatment; the temperature of hot air treatment is 40-100 DEG C and the time lasts for 1-5 minutes and temperature of silicone oil bath treatment is 50-150 DEG C and the time lasts for 1-5 minutes. According to the polyvinyl alcohol optical film product obtained through the method of the invention, swelling capacities in a TD direction and an MD direction are 121-118% and 120-117%; a ratio of TD / MD is 1.007-1.01; a central phase difference in the width direction of the film is 25-40nm; and a haze value is smaller than or equal with 0.2. After swelling and dyeing of a base film, wrinkle probability which is generated after 3-5 times of stretching is remarkably reduced, and the number of insufficient-dyed points on a prepared polarizing film is smaller than or equal with 7 per 1000m<2>. Yield and use performance of a polarizer are greatly improved.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD

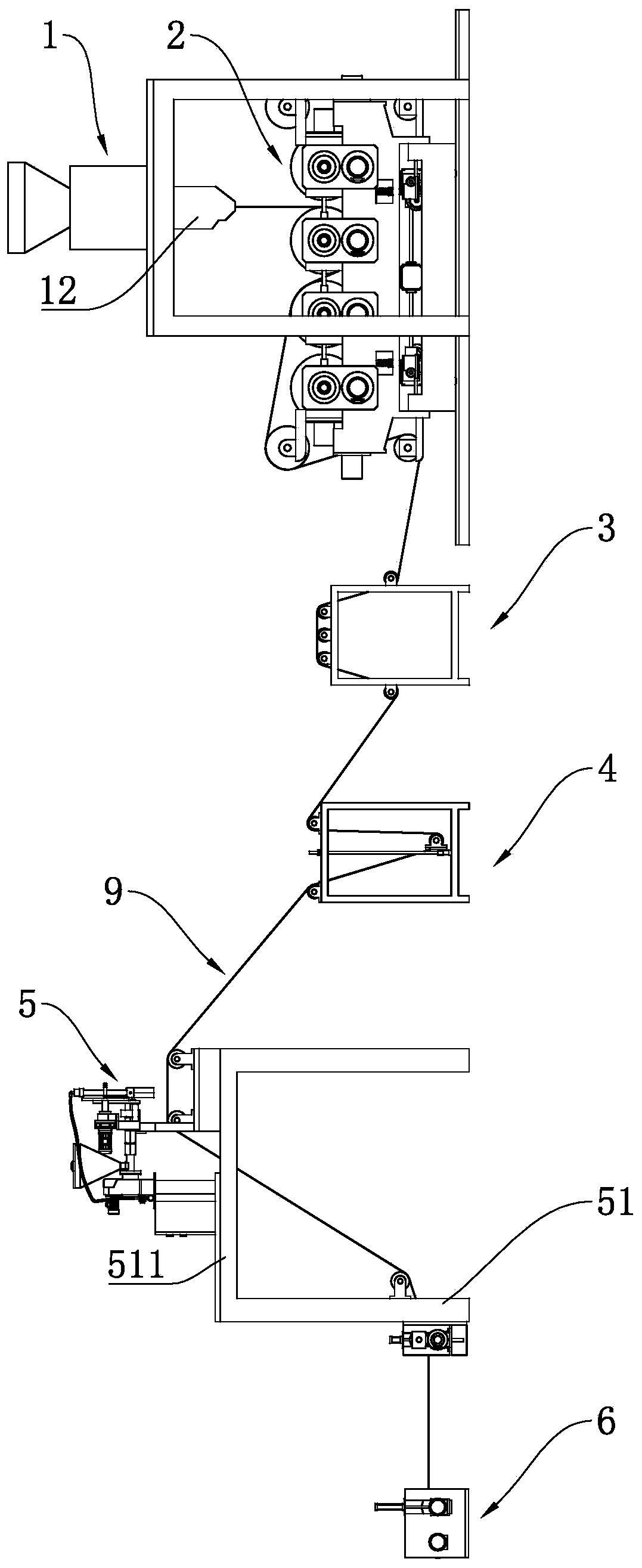

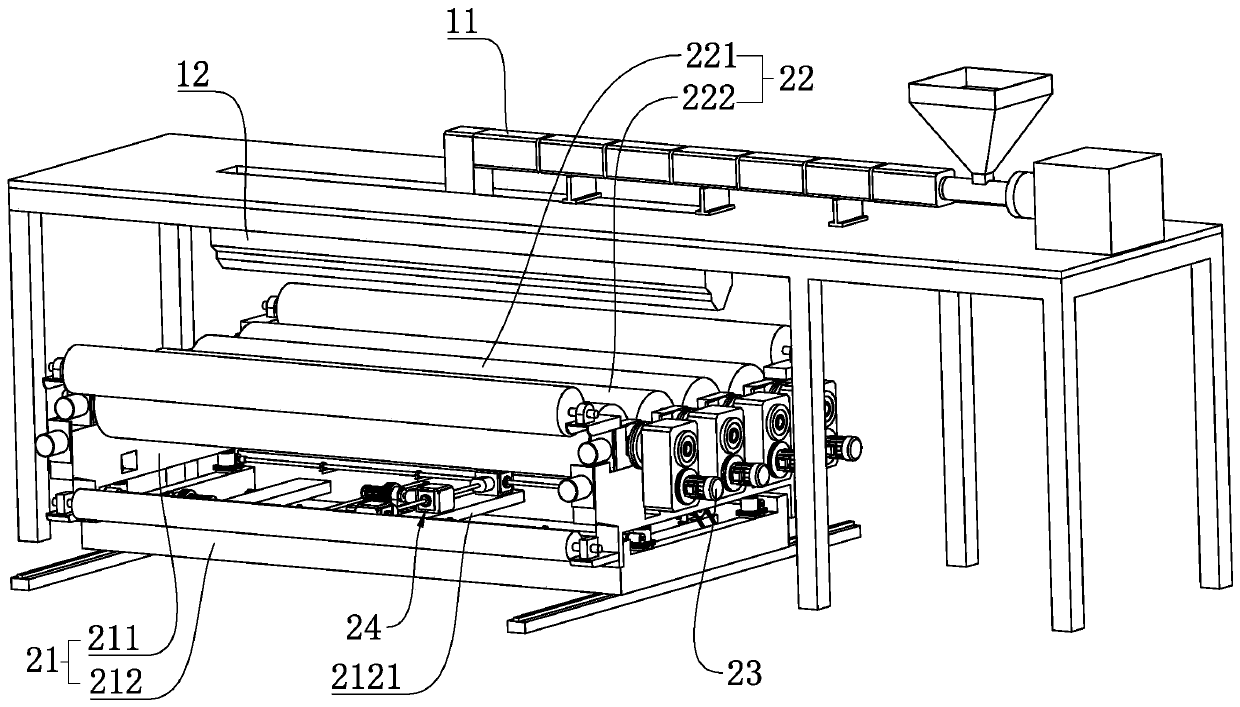

Secondary spray roughing device, and production line and process for textured geomembrane

PendingCN111546674AImprove flatnessReduced chance of wrinklingMovable spraying apparatusFlat articlesProduction lineSoil science

The invention relates to a secondary spray roughing device, and a production line and process for a textured geomembrane. The secondary spray roughing device comprises a rack, an extrusion die head, aswing mechanism and a spray roughing mechanism, and the spray roughing mechanism is rotatably connected and communicates with the extrusion die head; the spray roughing mechanism is driven by the swing mechanism to swing; the spray roughing mechanism is provided with an elastic piece, and one end of the elastic piece is connected with the spray roughing mechanism; the other end of the elastic piece is connected with the rack; the production line for the textured geomembrane is provided with a plate extruding device, a calendering device, a transmission device, a geomembrane storage device, the secondary spray roughing device and a winding device; and the production process for the textured geomembrane comprises the steps of ingredient mixing, extrusion, calendering, transfer, geomembranestorage, online secondary spray roughing, winding and cutoff. According to the secondary spray roughing device, and the production line and process for the textured geomembrane, the online spray-coating and secondary spray roughing can be achieved on the production line for the geomembrane; not only can the shortcomings of poor adhesion force and small friction coefficient of spray roughing materials on the geomembrane surface can be avoided, but also the effects of one-step forming and uniform textured surfaces of a geomembrane product with a single textured surface or double textured surfaces can be achieved.

Owner:常州新达力塑料机械有限公司

Powder packaging machine

ActiveCN111605818AImprove packaging qualityReduced chance of wrinklingWrapper twisting/gatheringPackaging automatic controlStructural engineeringElectrical and Electronics engineering

The invention relates to a powder packaging machine and relates to the technical field of packaging machines. The powder packaging machine comprises a rack. A sorting mechanism is arranged on the rack. The sorting mechanism comprises a tension detection part, a thrust device, a collecting device and a meter counting wheel. The tension detection part is arranged on the rack and is used for detecting the pressure on a packaging bag. The thrust device is arranged on the rack. The thrust device comprises a thrust air cylinder, a thrust seat and a thrust roller. The collecting device is arranged onthe rack and comprises a sliding way, a collecting box, a drive air cylinder and a collecting box. The meter counting wheel is arranged on the rack. By means of the powder packaging machine, when thepackaging bag is stuck, the tension detection part controls the sliding way to move, meanwhile, the thrust roller moves to make the packaging bag tend to be flat, and therefore the packaging bag moves into the collecting box to be collected; and meanwhile, the tension detection par triggers a signal to control the sliding way to get away from a cut-off mechanism, the packaging bag which is cut off falls into the collecting box, and the packaging quality of the packaging machine is improved.

Owner:浙江美生日化用品有限公司

Cotton spinning and weaving processing technology with anti-folding function

InactiveCN109137218AWith anti-wrinkle functionEasy to useDyeing processWoven fabricsWoven fabricPetroleum

The invention discloses a cotton spinning and weaving processing technology with an anti-folding function. The technology comprises the following steps of scattering cotton materials in a cotton opening machine to loosen the compacted cotton material into smaller cotton pieces or cotton bundles; making a polyester raw material or a polyester chip raw material extracted from petroleum into a polyester staple fiber; making a nylon raw material into a nylon staple fiber; pouring the cotton raw material after impurity removing, the polyester staple fiber and the nylon staple fiber into a drawing frame to carry out mixing processing so as to form a spun yarn; putting yarn sheets drawn from warps and weft yarns on a weaving machine to carry out weaving; weaving a conductive fiber into a fabric formed through weaving the warps and the weft yarns at equal intervals; and carrying out desizing, scouring and bleaching on a woven fabric through an enzyme, an acid and an oxidizing agent, and carrying out dip dyeing and coloring on a textile in a dye vat. By using the cotton spinning and weaving processing technology with the anti-folding function, problems that a cotton woven fabric is easy tofold, and is easy to shrink after washing so that usage is affected and static electricity is easy to generate can be effectively solved.

Owner:刘福芳

Large-curvature variable-section titanium alloy skin one-step hot-press forming die

The invention provides a large-curvature variable-section titanium alloy skin one-step hot-press forming die, and belongs to the technical field of titanium alloy material forming. The die only consists of a male die and a female die, and no blank holder is arranged in the middle layer. A blank is arranged on the outer side of the male die, a profile area is arranged in the male die, and the height of the profile area is lower than that of the blank on the outer side. The die is suitable for one-step hot pressing forming of large-curvature variable-section titanium alloy skin. The die has theadvantages of improving the forming efficiency of large-curvature variable-section titanium alloy parts and the like.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

Cloth pressing device for weaving machine with adjustable tensioning degree

InactiveCN108360203AReduce light intensityReduce light transmissionInspecting textilesTextile shapingEngineeringMechanical engineering

The invention discloses a cloth pressing device for a weaving machine with the adjustable tensioning degree. The cloth pressing device comprises a base, wherein support seats are fixedly arranged at two ends of the base; the top ends of the two support seats are in rotation connection with a transmission roller through a rotating shaft; the top end of the base is fixedly connected with the four edge and corner positions of the bottom end of a bottom plate through four first electric telescopic rods. According to the scheme, through the arrangement of the detection device, in the cloth transmission process, a photosensitive switch is matched with an illumination lamp; the light transmission degree of the cloth is detected; when the cloth generates drapes, the photosensitive switch is switched off; the warning device gives out alarm; the bottom plate is made into a circular arc shape; the tensioning force formed among all positions of the cloth is poor; the cloth drape occurring possibility is reduced; through the arrangement of the first electric telescopic rod and the second electric telescopic rod, the height of the bottom plate is regulated through the first electric telescopic rod; the cloth is subjected to tensioning force regulation; the second electric telescopic rod is used for regulating the distance between the press roller and the bottom plate, so that the material feeding is convenient.

Owner:安吉美庭纺织品贸易有限公司

Air bubble film tensioning device

ActiveCN110950137ALess bendingReduced chance of wrinklingWebs handlingEngineeringMechanical engineering

The invention relates to an air bubble film tensioning device which comprises two mounting plates and multiple first tensioning rollers. First through grooves are vertically formed in the two mountingplates. Sliding blocks slide in the first through grooves, and the two ends of the first tensioning rollers are rotationally connected to the opposite sliding blocks on the two sides. A drive mechanism is arranged on the mounting plates and comprises linkage rods rotationally connected to the mounting plates and located between the two sliding blocks, second through grooves formed in the two endsof the linkage rod correspondingly, connecting rods arranged on the sliding blocks and a lifting assembly arranged on the mounting plates, wherein one end of each connecting rod is embedded in the corresponding second through groove. Connecting plates are arranged on the opposite sliding blocks on the two sides, second tensioning rollers are rotationally connected between the two connecting plates, and the cross sections of the second tensioning rollers are gradually enlarged from the two sides to the middles in the axial direction of the second tensioning rollers. By means of the scheme, airbubble films can be stretched and tensioned in the length direction and the width direction of the air bubble films at the same time, and the air bubble films can be flatly and compactly wound on winding rollers.

Owner:杭州朔骅包装有限公司

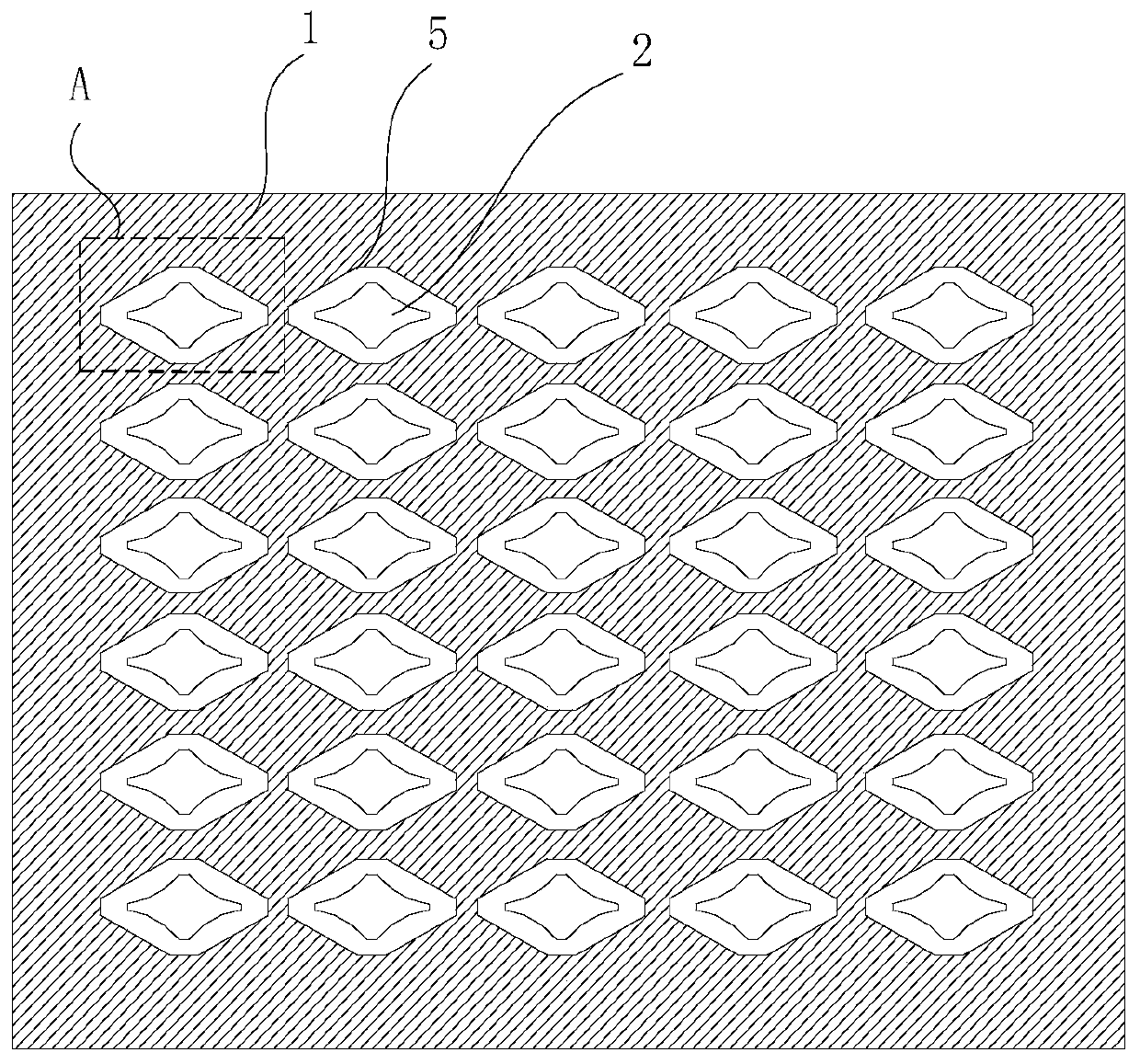

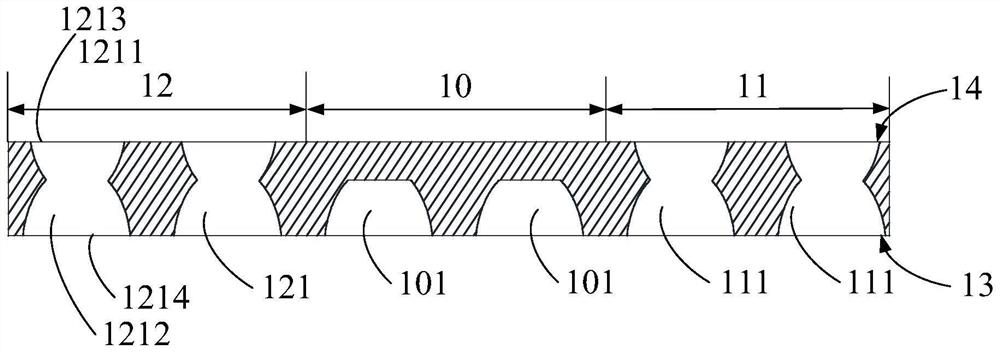

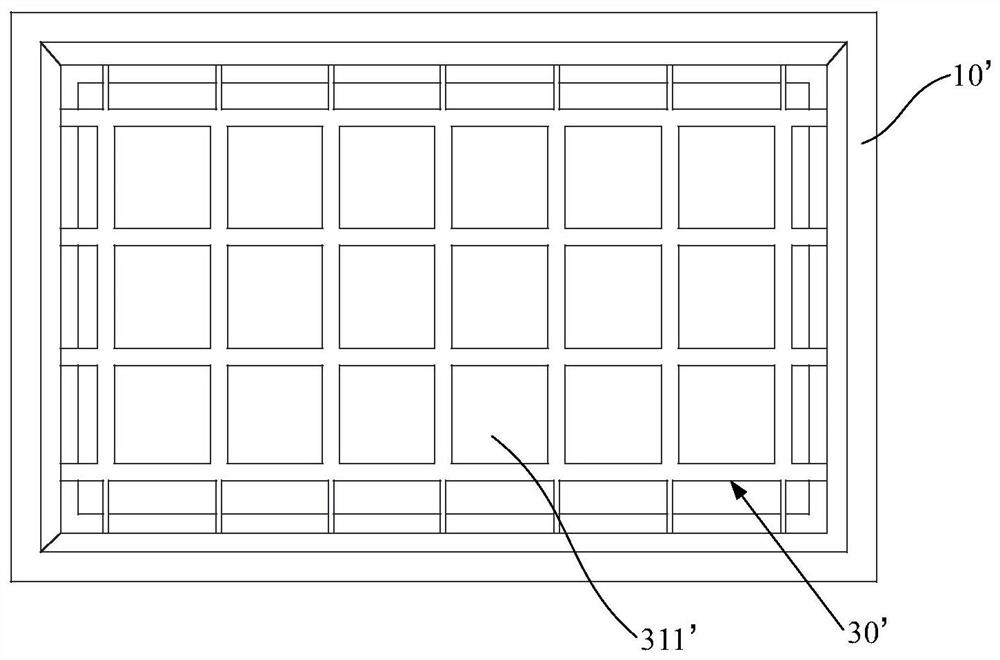

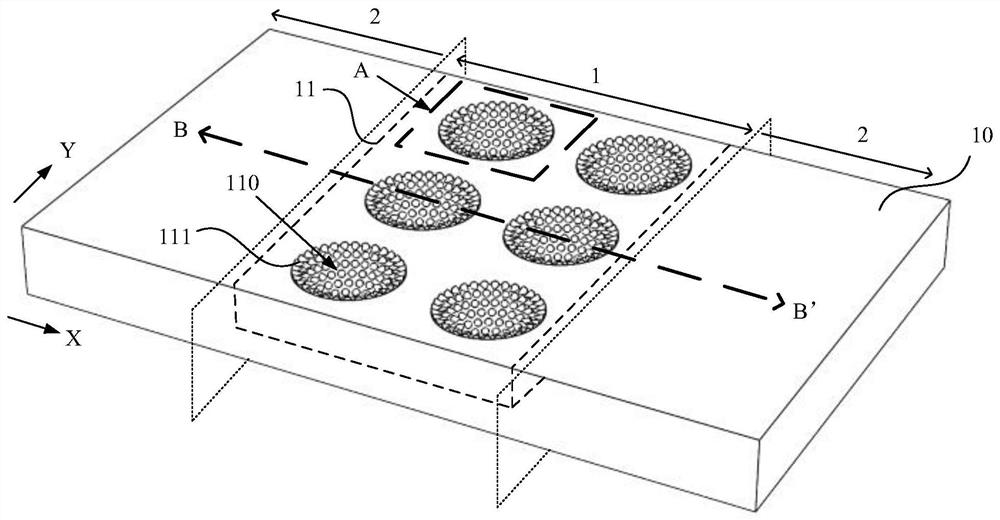

Precise mask plate and mask plate

PendingCN114032499AReduce wrinklesReduced chance of wrinklingSolid-state devicesVacuum evaporation coatingEdge regionEngineering

The invention discloses a precise mask plate and a mask plate. The precise mask plate comprises a mask plate body which comprises at least one evaporation area, a shielding area at least partially surrounding the evaporation area and an edge area surrounding the evaporation area and the shielding area, wherein the evaporation area comprises a plurality of precise evaporation holes, the edge area comprises a plurality of edge area openings, and the shielding area comprises a plurality of grooves. According to the precise mask plate provided by the invention, due to the fact that the supporting strength difference of the shielding area, the edge area and the evaporation areas is small, the stress difference borne by all the areas can be reduced in the net stretching process of the precise mask plate, the probability that the precise mask plate is wrinkled after net stretching is reduced, and the product yield is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Display device

ActiveCN109890129ASmall reboundImprove qualityPrinted circuit detailsNon-linear opticsFlexible electronicsElectricity

The application provides a display device for reducing bounciness of a FPC (Flexible Printed Circuit). The display device comprises a display panel, a FPC board and a conduction part, wherein the display panel comprises a driving chip; the FPC board comprises a main body part and a projection part; the main body part comprises a binding region; the binding region comprises a plurality of golden fingers arranged along a first direction; the FPC board is electrically connected with the driving chip by the binding region; the projection part is arranged at at least one side edge of the main bodypart and comprises exposed copper; and the conduction part at least partially covers the driving chip and is grounded by the exposed copper.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

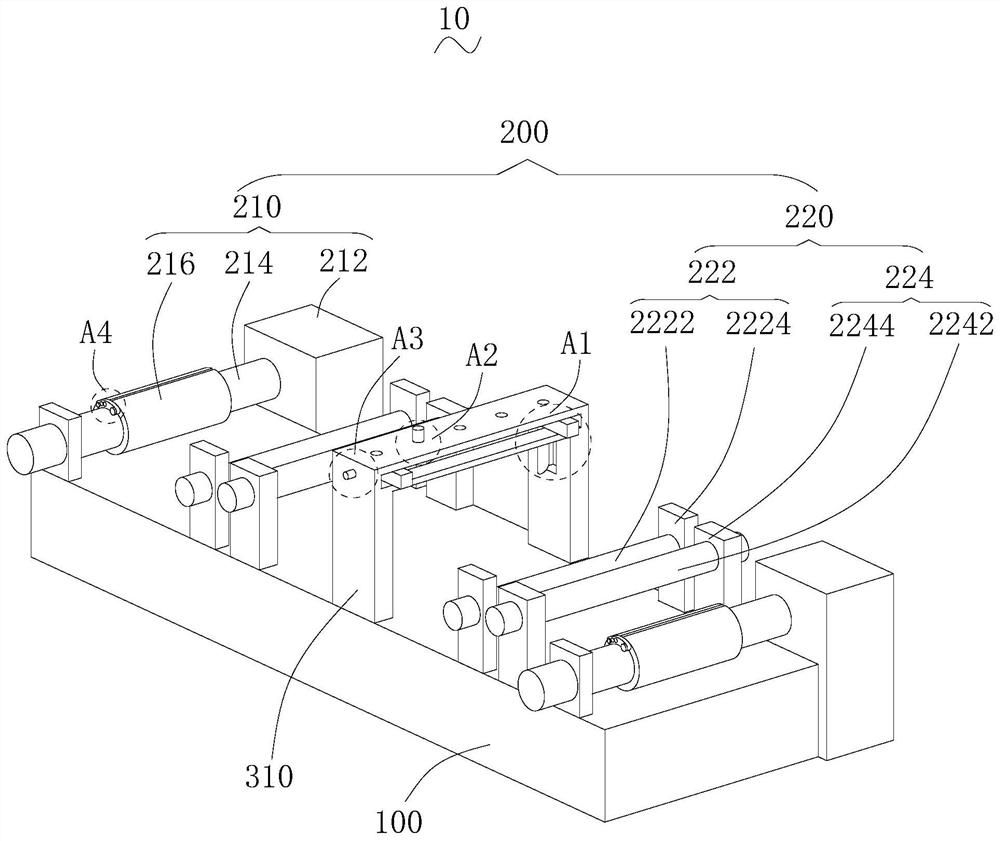

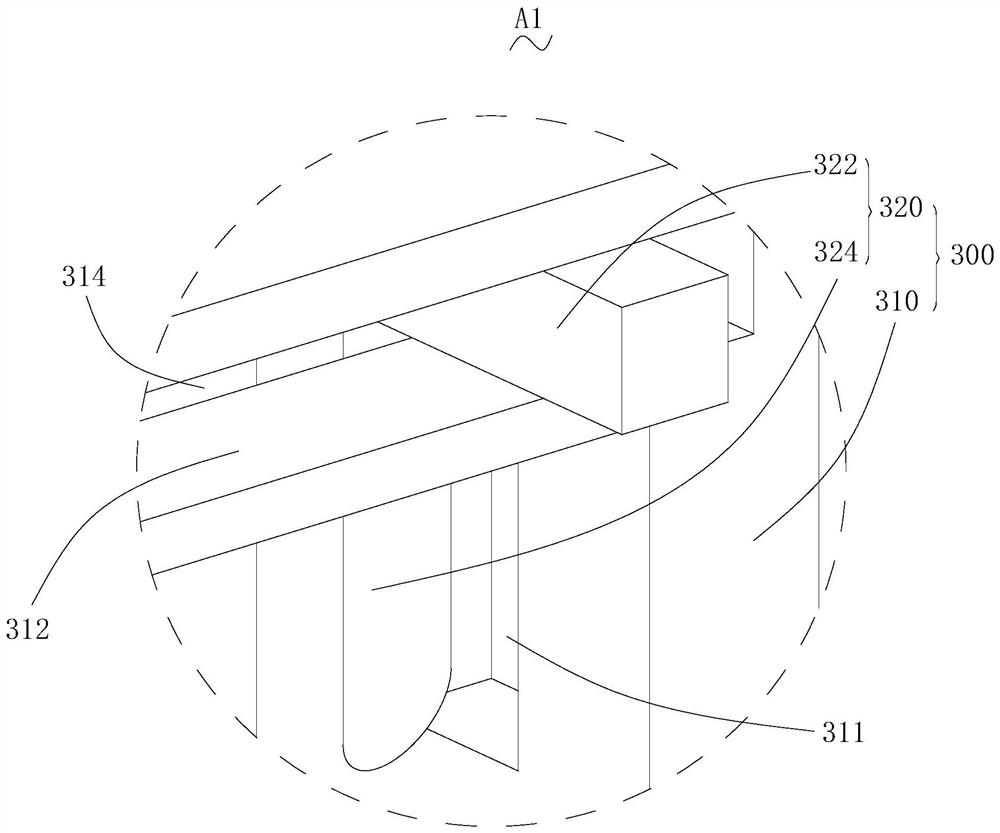

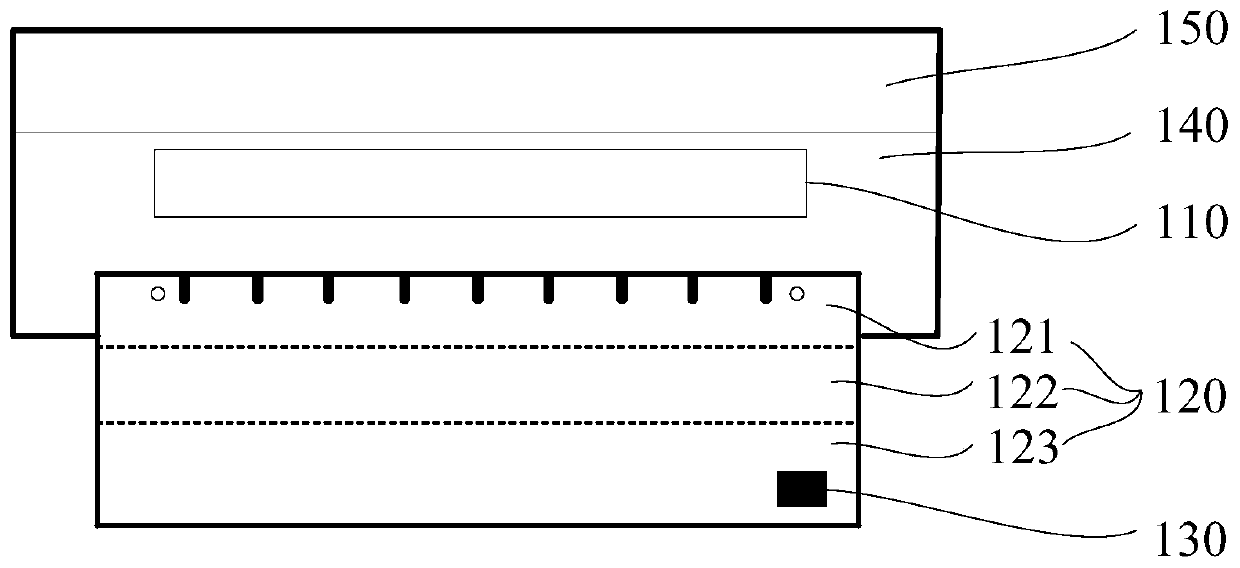

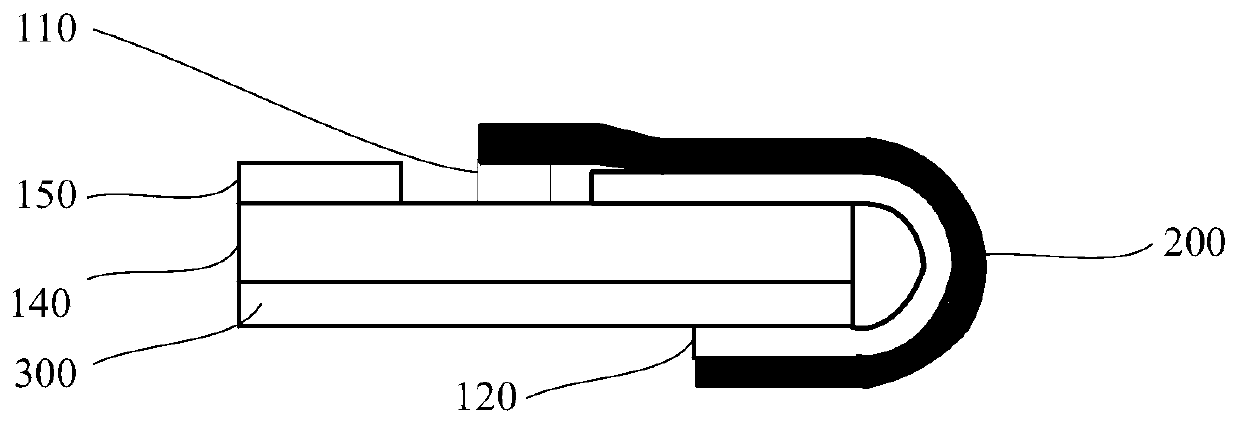

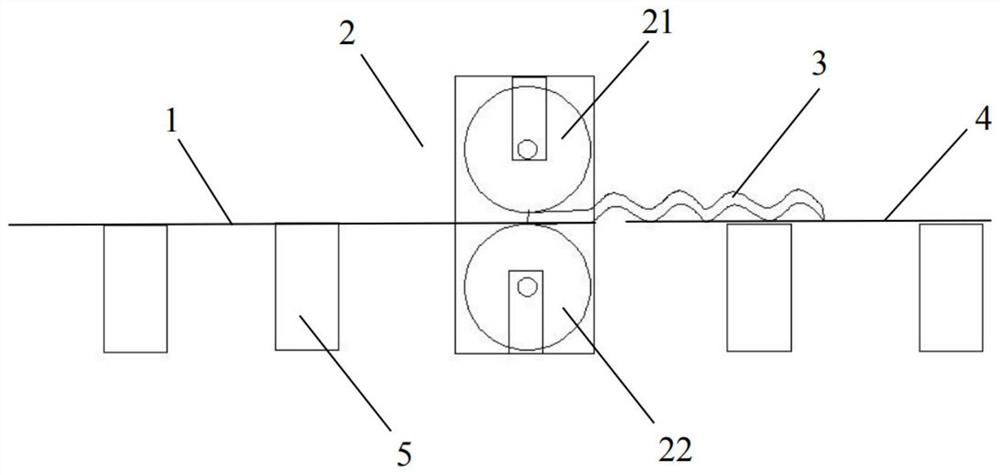

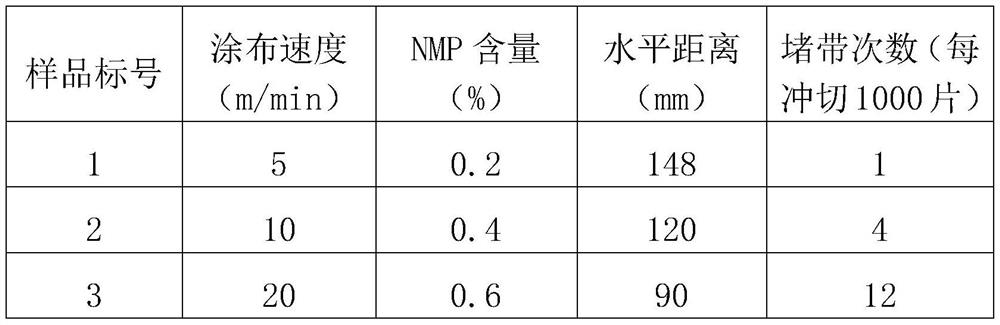

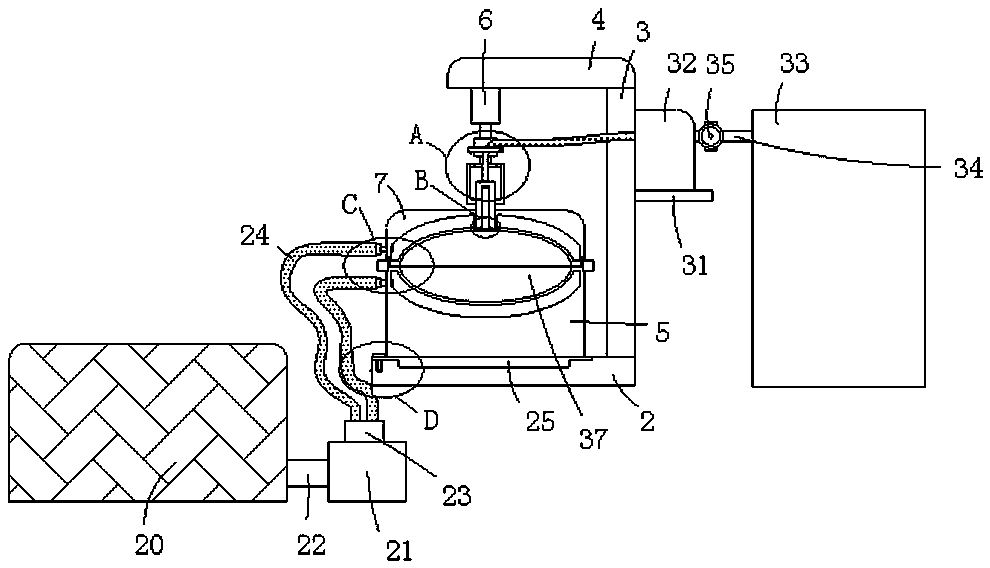

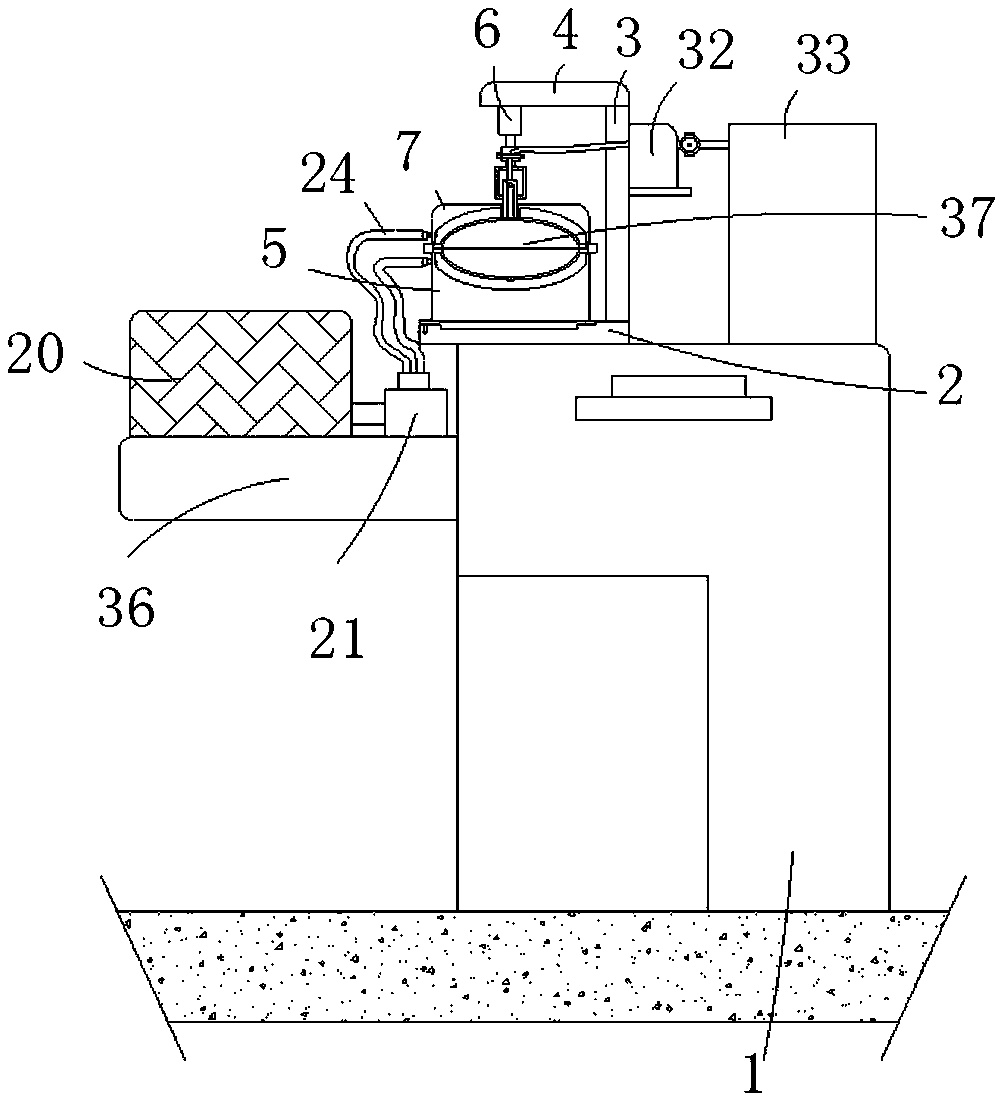

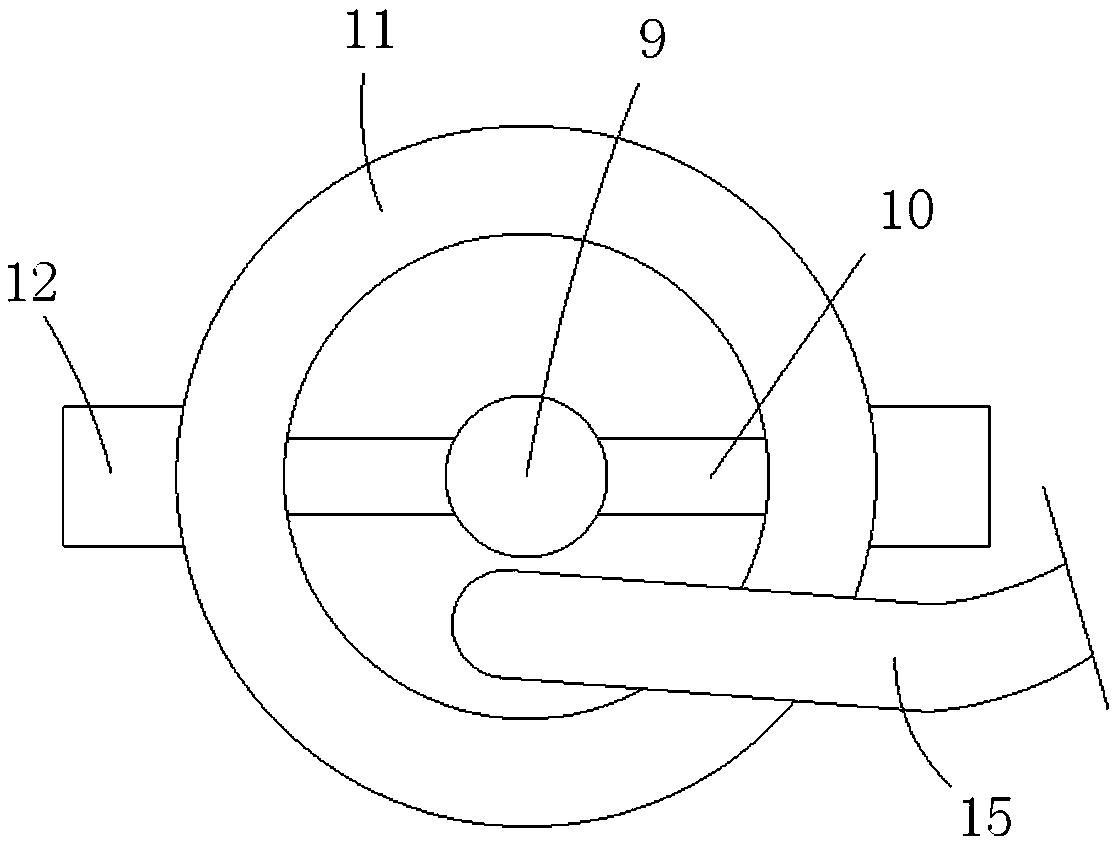

Tool and method for detecting flexibility of pole sheet after surface coating

PendingCN111721644AReduced chance of wrinklingReduce experimental investmentElectrode rolling/calenderingPreparing sample for investigationProduction lineStructural engineering

The invention provides a tool for detecting the flexibility of a pole sheet after surface coating. The tool comprises a feeding platform for placing a pole sheet, a measuring platform for measuring the flexibility of the pole sheet, and a pressing roller assembly, wherein the feeding platform and the measuring platform are sequentially and horizontally arranged, the pressing roller assembly comprises an upper pressing roller and a lower supporting roller which are arranged in an up-down spaced mode, the upper pressing roller and the lower supporting roller are located above and below the feeding platform respectively, and the rotating direction of the upper pressing roller is opposite to that of the lower supporting roller. The invention further provides a method for detecting the flexibility of a pole sheet by using the detection tool, wherein the flexibility of the pole sheet after surface coating can be judged and detected, the probability of belt blockage and wrinkling of the polesheet is reduced, the experimental investment is reduced, the method is suitable for batch detection of a mass production line, and whether drying parameters of surface coating cloth are reasonable can be reversely deduced.

Owner:TIANJIN ENERGIES

High-performance water-based lubricating oil for copper-zinc alloy cold stamping

ActiveCN107384567AIncrease temperatureReduce thermal frictionLubricant compositionCarbon monofluorideWater based

The invention mainly relates to the technical field of stamping lubricants and discloses a high-performance water-based lubricating oil for copper-zinc alloy cold stamping. The high-performance water-based lubricating oil for copper-zinc alloy cold stamping is prepared from the following raw materials: tungsten disulfide, carbon monofluoride, fullerene, nickel sulfide, polyether modified silicon and water. Water is volatilized during cold stamping, so that the cold stamping temperature is reduced by 40-50 DEG C; the heat frictional force generated by copper-zinc alloy cold stamping is obviously reduced, and the copper-zinc alloy continuously flows during cold stamping, so that the breakage rate is reduced by 17.3%, and the wrinkling rate is reduced by 12.6%; tungsten disulfide and nickel sulfate are mixed at a high temperature, so that the resistance to oxidation of tungsten disulfide and the wear resistance of the nickel sulfate are increased; a golden yellow color and luster of a copper-zinc alloy cold stamping part can be maintained, the service life is prolonged, and the cold stamping temperature is relatively high, so that the size of nickel sulfate is reduced, the gaps between the copper-zinc alloy and a mold are reduced, and therefore, cold stamping is more accurate; the size of the nickel sulfate is gradually increased after temperature reduction, the gaps are increased, and demolding is facilitated, so that the surface of the copper-zinc alloy cold stamping part is smooth and the defective rate is reduced.

Owner:广州杜朗介质科技有限公司

Optical lens mold casting system

The invention discloses an optical lens mold casting system. The system comprises a bottom plate I fixed at the top end of a base, and a supporting plate is fixedly connected to the top end of the bottom plate I. According to the system, through the arrangement of an infusion pump II, stretching-out and drawing-back of a hydraulic rod is combined, a liquid outlet on a round rod is utilized, a liquid raw material at a temperature is poured into a molding cavity between an upper mold and a lower mold, the hydraulic rod is used to generate downward pressure on the upper mold, the tightness and the fitting degree between the upper mold and the lower mold are improved, so that the upper mold and the lower mold are not prone to deflection, after the raw material is poured, the hydraulic rod cancontract so that the side wall of the bottom end of the round rod and the side wall of the top end of the upper mold can form a whole, the wrinkling rate of the surface of an optical lens is reduced,a cooling device is adopted to cool the optical lens, so that the optical lens can be easily separated from the mold, a worker can conveniently take out the optical lens, the whole structure is simple, the mechanization degree is high, and the operation is very convenient.

Owner:江苏优立光学眼镜有限公司

A compound equipment for food packaging bag printing

ActiveCN107599603BScientific and reasonable designImprove efficiencyLaminationLamination apparatusEngineeringHot melt

The invention discloses a lamination device used for food package bag printing. The lamination device includes: a lamination device body, a leveling roller set, a smooth lamination bench, a reeling apparatus, a lamination film, two lamination rollers, a plurality of electric heater tubes, two anti-adhesion temperature-resistant resin layers, two hot melt adhesive rollers, an adhesive conveying permeation cotton, a hot adhesive storage chamber, a straightener, an unreeling apparatus, two primary pressing rollers, a connection case, an air pump, a through hole, a smooth position limiting layer,and a position-limiting and leveling device. The unreeling apparatus is arranged on the right end of the lamination device body. Compared with the prior art, the lamination device has scientific and reasonable design and allows double-surface simultaneous lamination, so that when double-surface lamination for a food package bag is required, the device greatly increases efficiency; secondly, the to-be-laminated food package bag is subjected to leveling treatment for several time, so that wrinkling rate before lamination is reduced and lamination effect is increased. The lamination device is widely applied to different work status.

Owner:广德美好包装科技股份有限公司

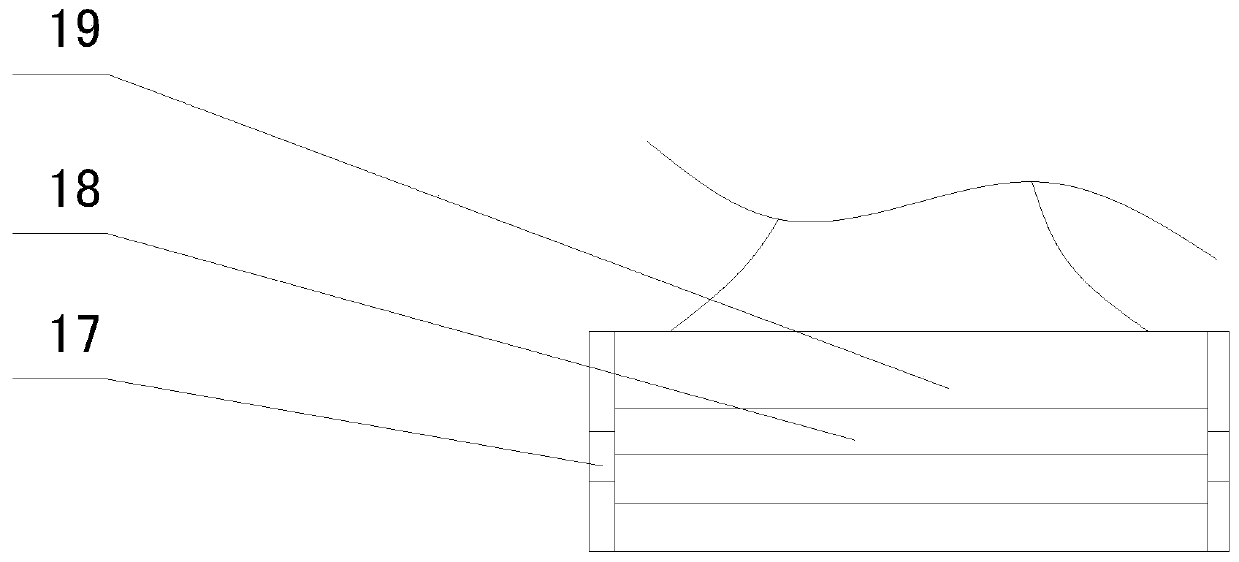

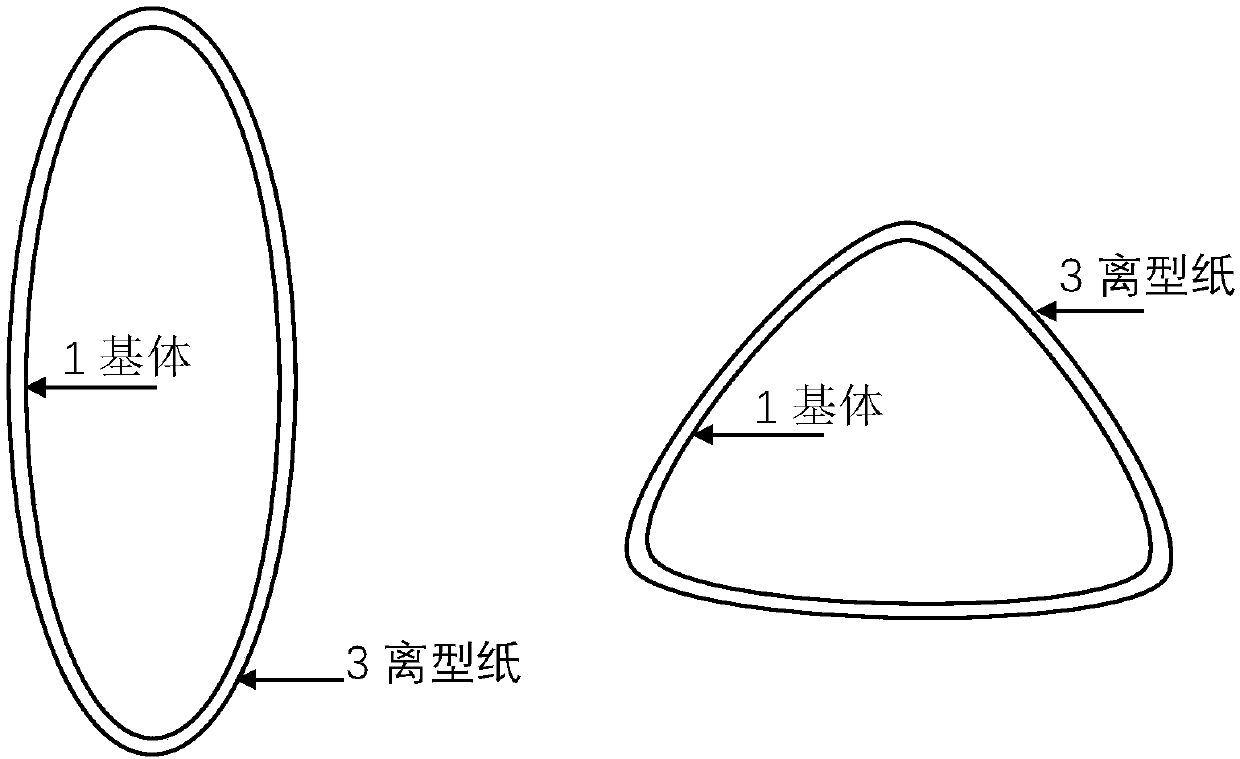

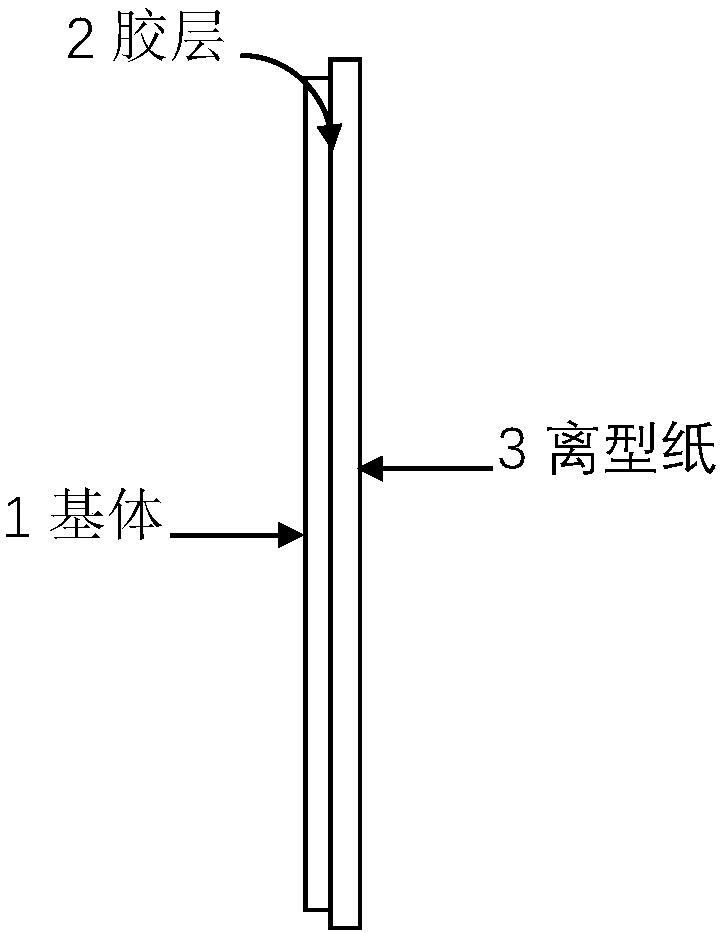

Kinesiology tape having nonlinear gradient biological mechanical characteristics

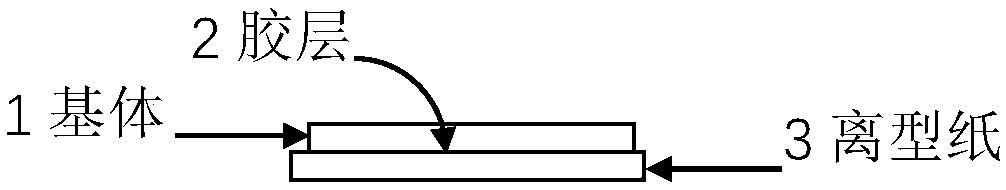

A kinesiology tape having nonlinear gradient biological mechanical characteristics is disclosed. The kinesiology tape includes a substrate having nonlinear gradient material performance, a two-dimensional wave-shaped glue layer and common release paper. The kinesiology tape is spindle-shaped or triangle as shown in attached drawings 1-3. By utilizing a fact that the nonlinear gradient material performance can reduce the wrinkle rate and enhance biological breathable effects during movement processes, a series of mechanical protection can be achieved, such as increase in muscle eccentric contraction force generation, exercise fatigue time prolonging, and movement impact damage reducing. In addition, a muscle-like shape design effectively improves the traction efficiency for muscles, and thetwo-dimensional wave-shaped glue layer can relieve tissue edema to a certain degree.

Owner:BEIHANG UNIV

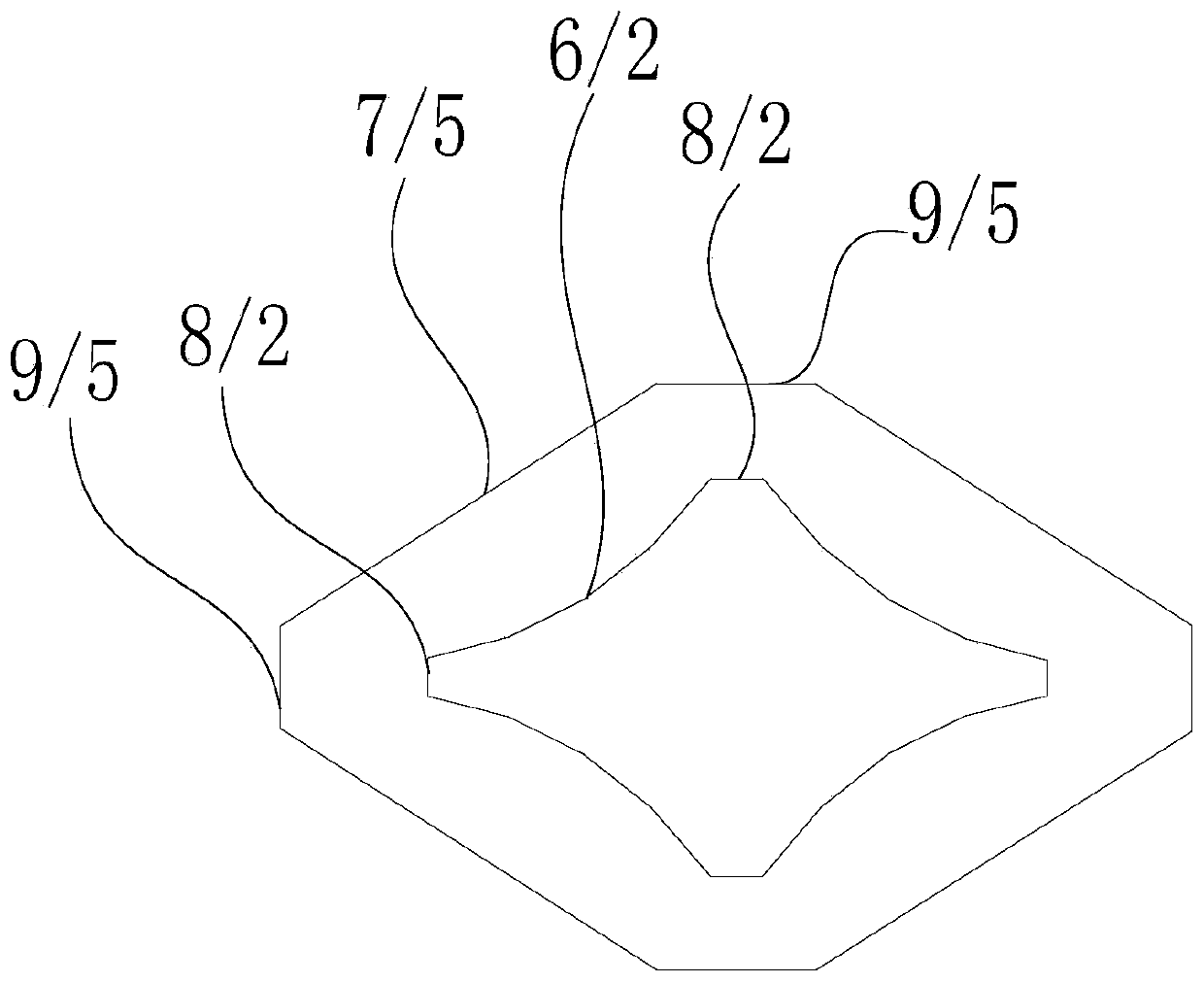

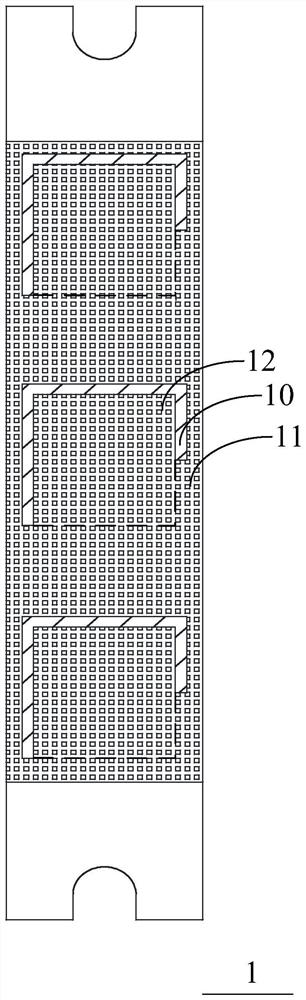

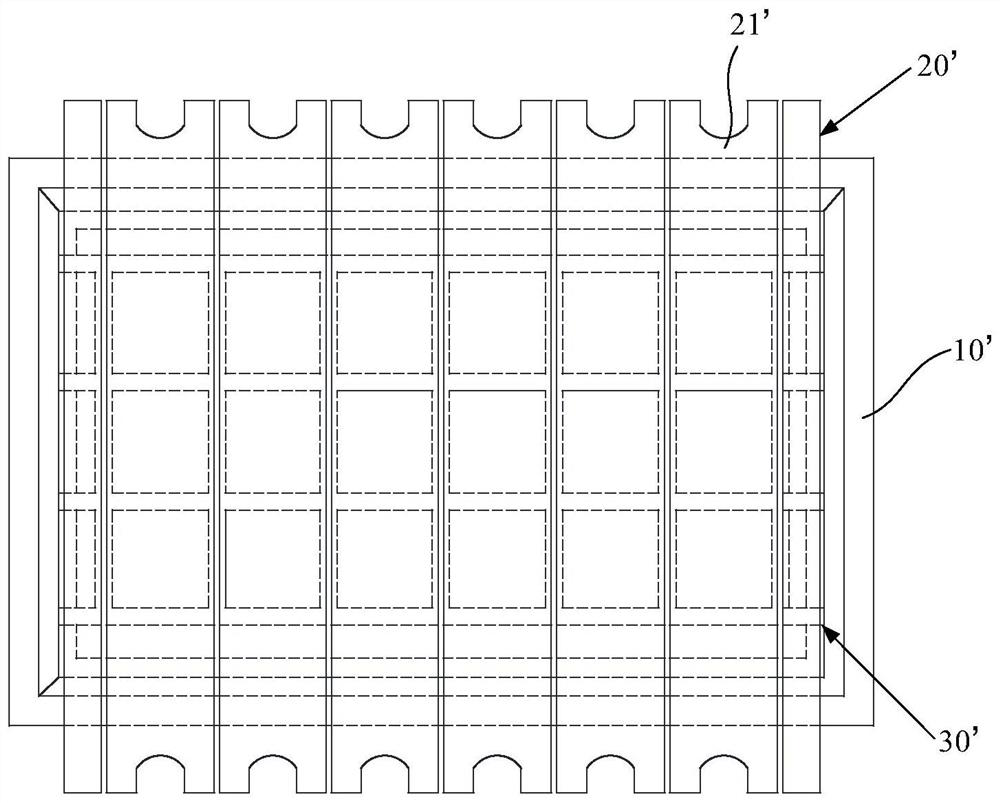

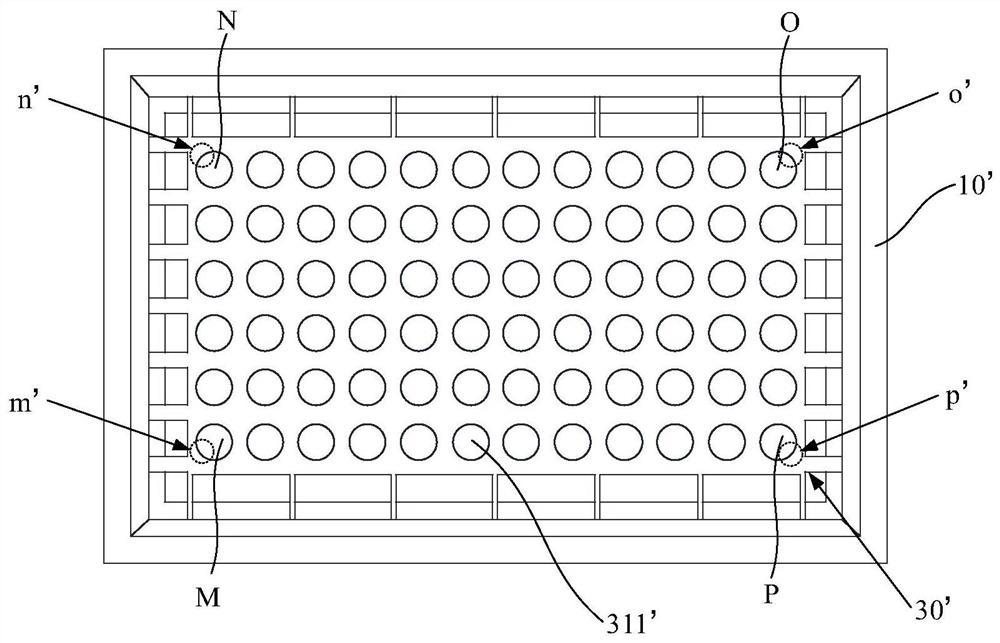

Mask plate assembly and evaporation equipment

ActiveCN113046686AReduced chance of wrinklingStable supportVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention provides a mask plate assembly and evaporation equipment. The mask plate assembly aims to reduce the probability that a first mask plate is wrinkled effectively, and avoid edge color mixing effectively. The mask plate assembly comprises a frame, a first mask plate and a second mask plate, wherein the first mask plate and the second mask plate are stacked on the frame; the first mask plate comprises a plurality of mask strips arranged in the first direction, and a gap is formed between every two adjacent mask strips; the second mask plate comprises a main body and a supporting strip, and the supporting strip comprises a plurality of first supporting strips arranged in the first direction and a plurality of second supporting strips arranged in the second direction; and the width of the first end of the first supporting strip located on the outermost side and the width of the first end of the second supporting strip located on the outermost side are gradually increased from the direction away from the main body to the direction close to the main body, and the first supporting strips are arranged corresponding to the gaps. The evaporation equipment comprises the mask plate assembly.

Owner:BOE TECH GRP CO LTD +1

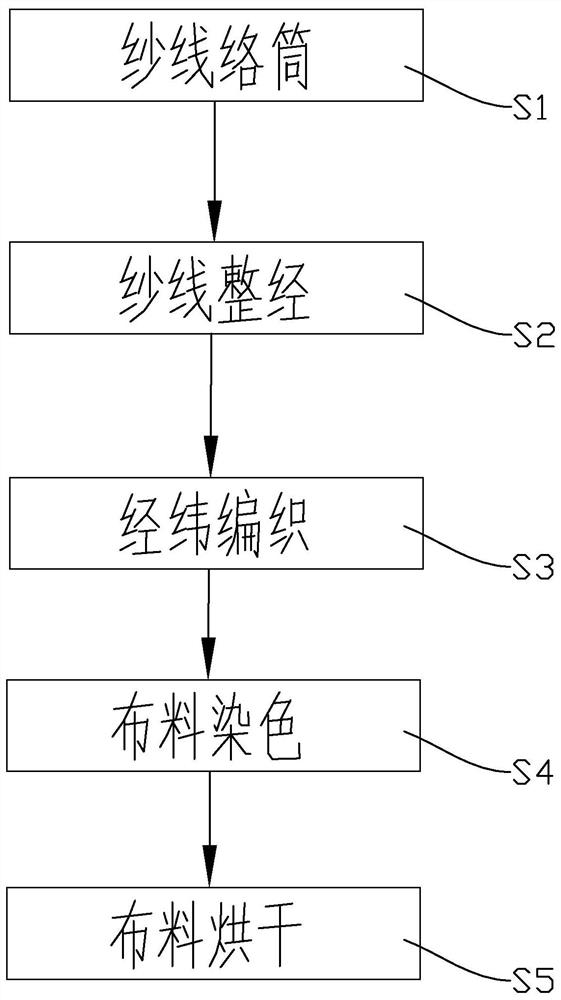

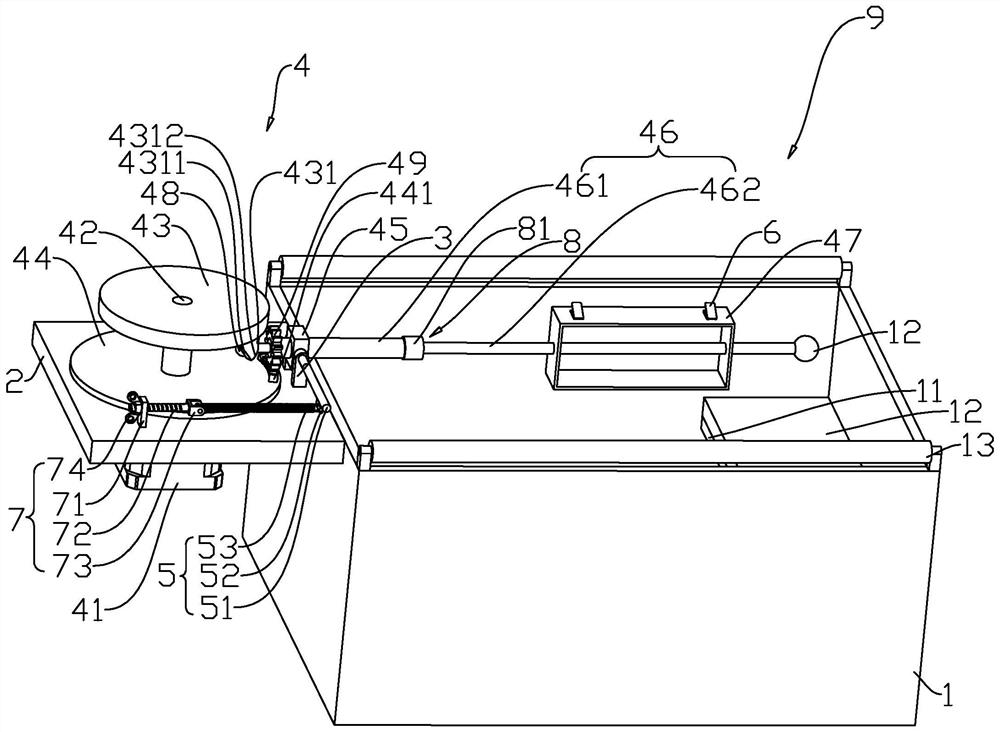

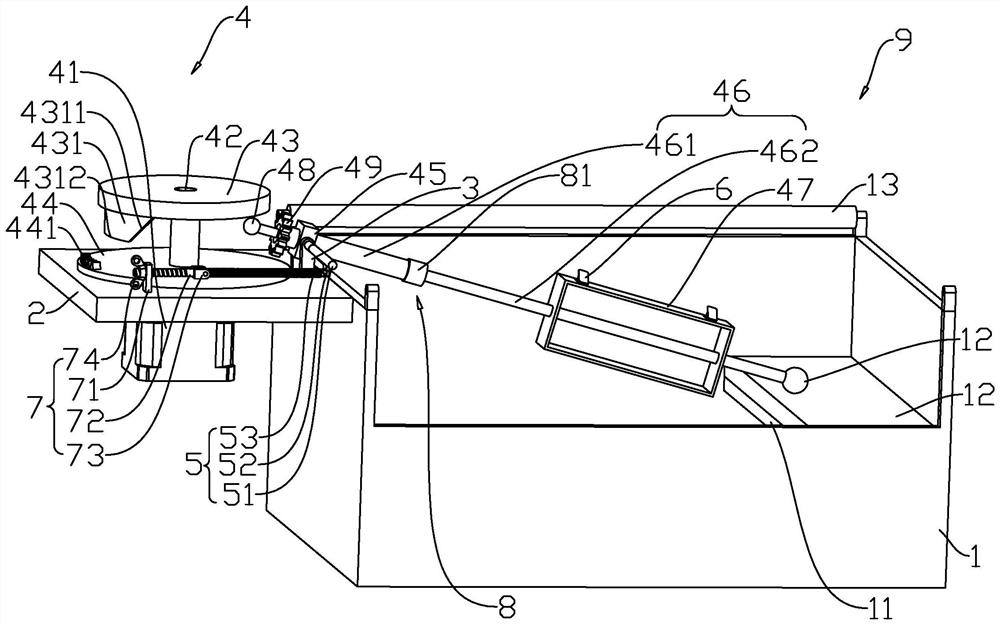

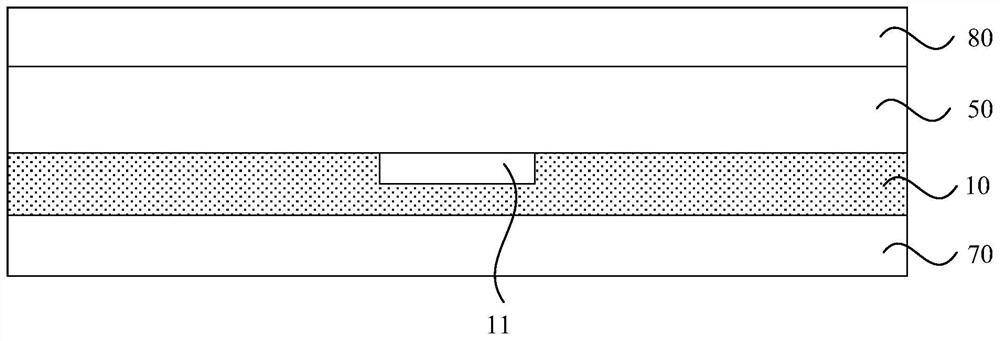

Cloth processing technology

ActiveCN112746412AEasy to dyeSave the kneading processLiquid/gas/vapor treatment machines driving mechanismsTextile treatment carriersYarnPolymer science

The invention relates to a cloth processing technology. The cloth processing technology comprises the following technological steps of S1, yarn spooling: rewinding a white bobbin yarn of a finished product by adopting a spooling machine to prepare a cheese; S2, yarn warping: winding the cheese on a warp beam in parallel by adopting a warping machine, and penetrating every two warps on the warp beam into a heald hole and a reed; S3, weaving warps and wefts: weaving the wefts and the warps in a criss-cross manner by adopting a large rapier machine, and weaving white grey cloth in a manner that every two warps and one weft are interwoven up and down at intervals; S4, cloth dyeing, wherein the woven gray fabric is put into a dyeing cylinder filled with a dyeing solution, a dyeing mechanism used for repeatedly immersing the gray fabric into the dyeing solution is arranged on the dyeing cylinder, and the dyeing mechanism comprises a winding disc used for winding the gray fabric; and S5, cloth drying: after standing the dyed grey cloth for 15-20 minutes, putting the grey cloth into a drying box for drying. The cloth processing technology has the advantage that the probability that wrinkles are generated when cloth is dyed can be reduced.

Owner:江苏锐晟纺织科技有限公司

Display panel, manufacturing method thereof and display device

ActiveCN113077721ACushion stretch effectBuffer stretch effectIdentification meansDisplay deviceEngineering

The invention discloses a display panel, a manufacturing method thereof and a display device. The display panel includes a foldable area, and a first stress buffer layer; and the first stress buffer layer comprises a first stress buffer structure, the first stress buffer structure is located in the foldable area, and the first stress buffer structure comprises a plurality of grooves formed in the first stress buffer layer, the inner surfaces of the grooves comprise a plurality of protruding parts. According to the display panel, manufacturing method thereof and display device of the embodiment of the invention, the stress of a film layer can be buffered when the display panel is folded, so that the phenomenon of unevenness of creases caused by folding of the display panel is reduced, the display effect is ensured, and the user experience is improved.

Owner:HEFEI VISIONOX TECH CO LTD

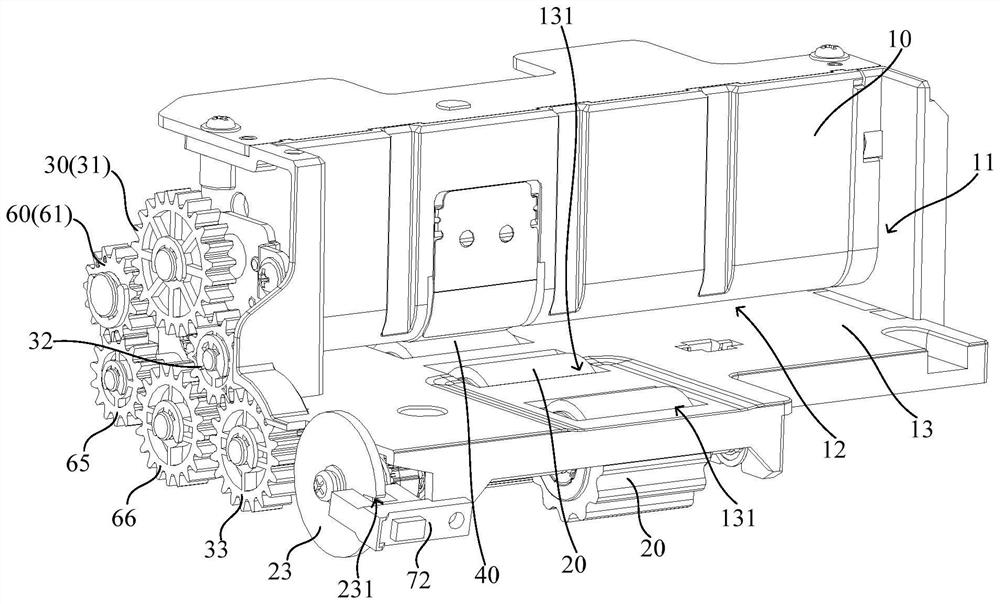

Bill issuing box and bill issuing device

PendingCN112884998ASimple materialReduced chance of wrinklingApparatus for meter-controlled dispensingStructural engineeringIndustrial engineering

The invention relates to a bill issuing box and a bill issuing device. The bill issuing box comprises a box body, a bill taking wheel, a first driving assembly, a bill distributing wheel, a reversing wheel, a second driving assembly, a first sensor and a controller. The box body is provided with a ticket storage chamber, and the side wall of the bottom of the ticket storage chamber is provided with a ticket outlet. The bill taking wheel is rotatably arranged on the bottom wall of the bill storage chamber, and the bill taking wheel is used for making contact with the bottommost bill in the bills stacked in the bill storage chamber and driving the bottommost ticket to move outwards through the bill outlet. The contact part of the wheel surface of the bill separating wheel and the wheel surface of the reversing wheel is opposite to the bill outlet; and the bill separating wheel is used for driving the bottommost bill to move outwards through the bill outlet. When the bill separating wheel drives the bottommost bill to move away from the bill taking wheel, the controller controls the first driving assembly to stop driving the bill taking wheel, the bill taking wheel stops rotating, and the bad phenomenon that the last but one bill is driven to move towards the bill outlet and makes contact with the reversing wheel to cause wrinkles is avoided. The probability of overlapping, connecting and bill wrinkling can be greatly reduced.

Owner:GRG BAKING EQUIP CO LTD

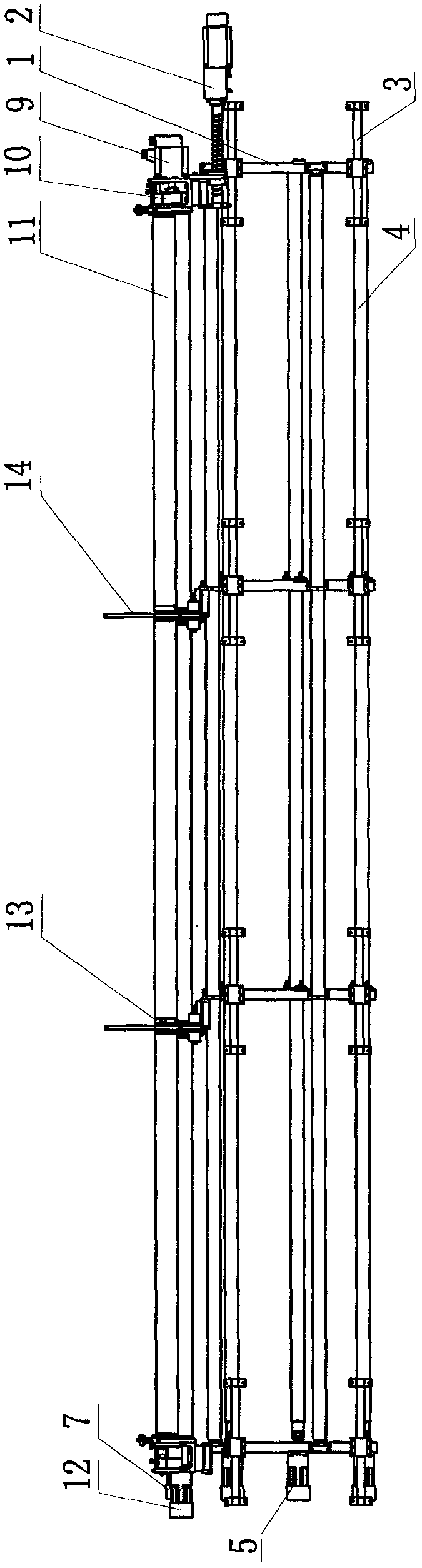

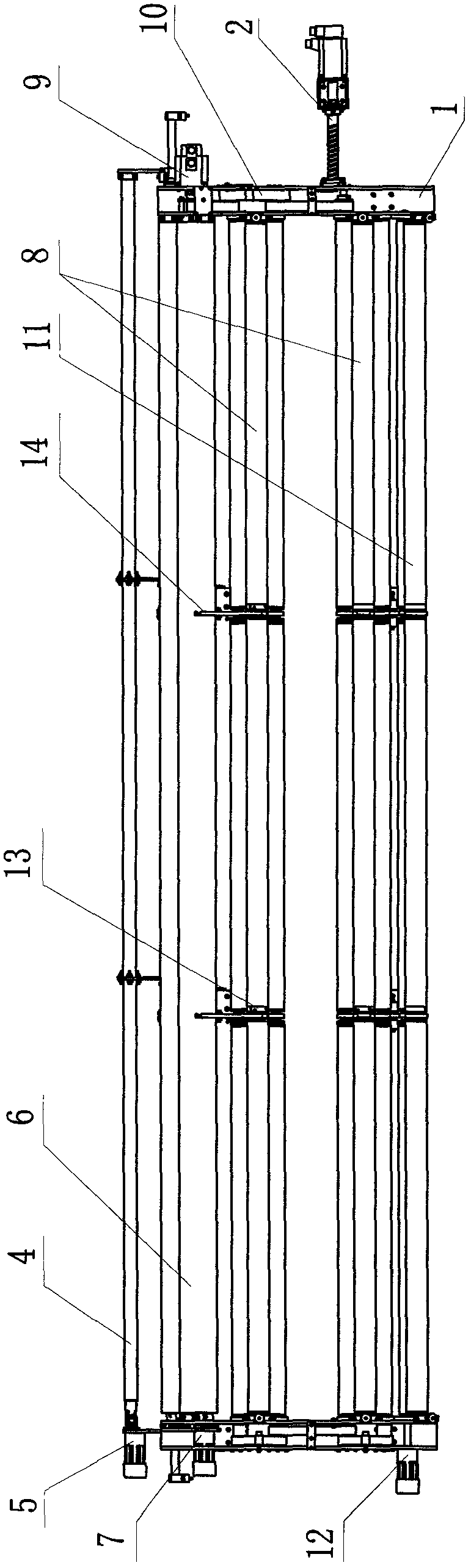

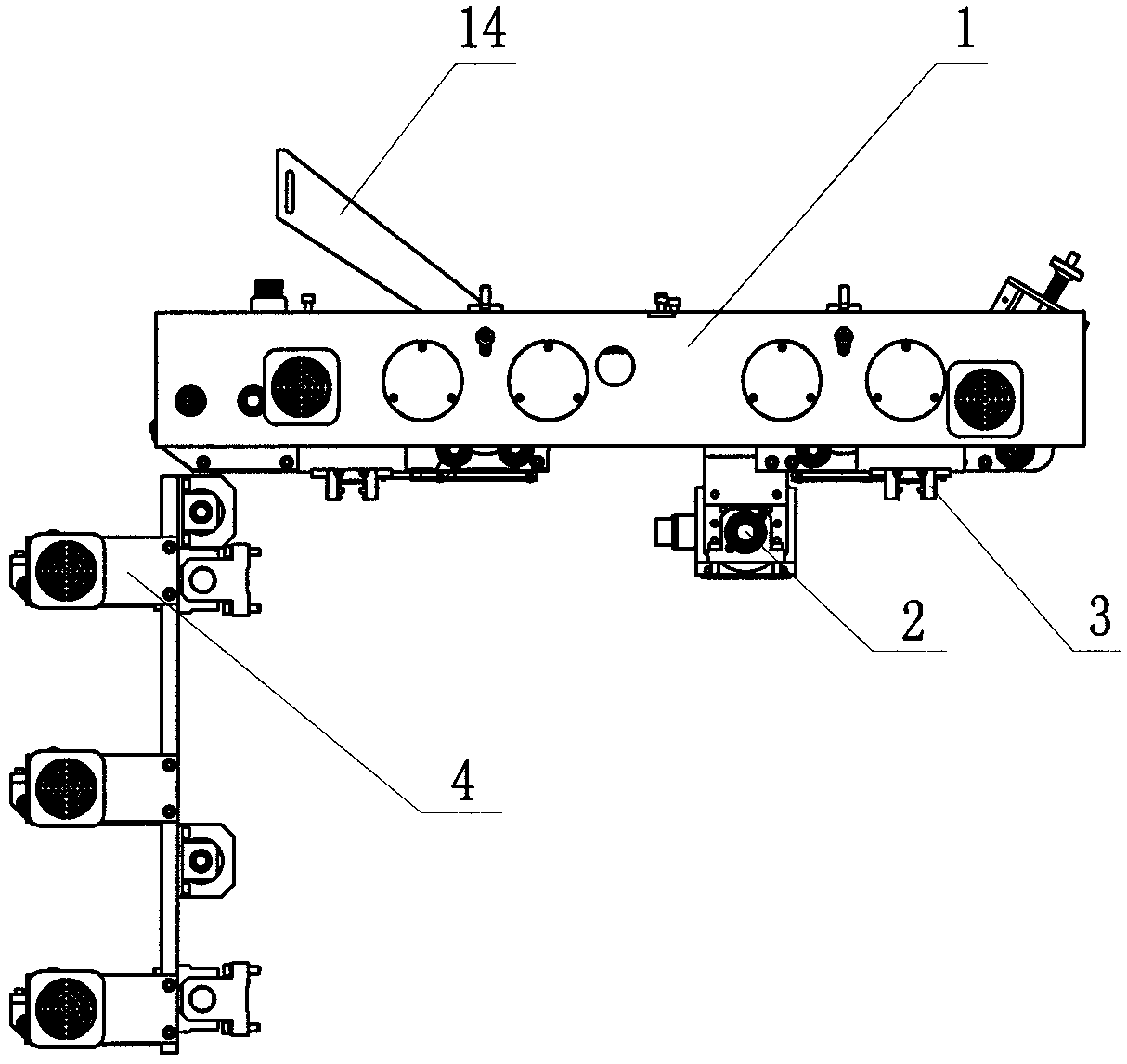

Roller drive mechanism of quilting and embroidering machine allowing multiple pieces of cloth to be connected

The invention discloses a roller drive mechanism of a quilting and embroidering machine allowing multiple pieces of cloth to be connected. The roller drive mechanism comprises a saddle frame, an X-axis axial mobile device, an X-axis axial guide rail device, a cloth rolling feeding roller set, a rolling feeding drive motor, a feeding roller set, a feeding drive device, a tension roller set, a tension drive motor, a transmission device, a discharging roller set and a discharging drive motor. All the roller sets can allow at least two pieces of cloth to pass through side by side; the rigid bearing points of all the roller sets are supported by bearing support devices; the cloth rolling feeding roller set is provided with three reel rollers, and the positions of the reel bearing support devices of the reel rollers in the vertical direction are mutually staggered so that the edges of the cloth on different rollers can be connected in a splicing or spliced mode; the feeding roller set is provided with a guiding roller, two feeding rollers and feeding bearing support devices; the tension roller set is provided with two three-roller roller sets and a tension bearing support device, and the lower surface of a bearing pedestal of the tension bearing support device is provided with a notch; the discharging roller set is provided with discharging rollers, clamping rollers and a discharging bearing support device, and the lower surface of a bearing pedestal of the discharging bearing support device is provided with a notch. The roller drive mechanism has the advantages that the multiple pieces of cloth can be connected together side by side and conveyed for synchronous embroidering, the embroidery area of the cloth is increased, the cloth is not prone to creasing, and efficiency and quality are improved.

Owner:陈展新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com