Liquid phase substrate deposition metal film separation device

A metal deposition and thin film separation technology, applied in the field of magnetron sputtering, can solve problems affecting the use of metal thin films, wrinkles, metal thin film oxidation, etc., and achieve the effect of shortening the operation time and reducing the probability of thin film wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Put the deposited titanium nitride thin film sample into the acetone solution in the vacuum chamber;

[0020] 2) The substrate, simethicone oil, titanium nitride film and acetone solution are kept at a constant temperature;

[0021] 3) After the dimethyl silicone oil is dissolved, the titanium nitride film falls off in the constant temperature acetone solution;

[0022] 4) Turn off the vacuum system quickly, take out the titanium nitride film and the constant temperature acetone solution, and dry the titanium nitride film for storage.

[0023] The stripping of the titanium nitride film is carried out in a short time, preferably less than 2 hours, to prevent wrinkles.

Embodiment 2

[0027] 1) Select a silicon wafer or glass of suitable size as the deposition substrate, clean the surface of the substrate with an organic solvent, and after cleaning, dry it with cold air for later use;

[0028] 2) The target material is a titanium target, the surface of the target is polished and polished with sandpaper, and it is installed at the magnetron sputtering target position;

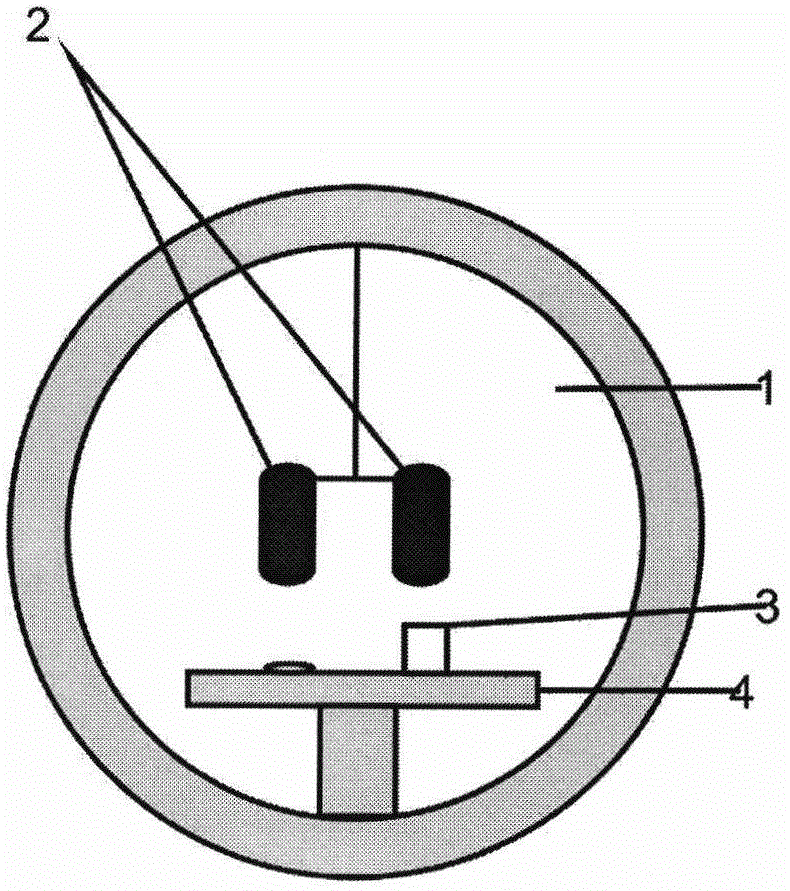

[0029] 3) Dimethyl silicone oil is evenly coated on the surface of the substrate, and the coated sample is placed in the sputtering position, and the height of the magnetron sputtering target position is adjusted.

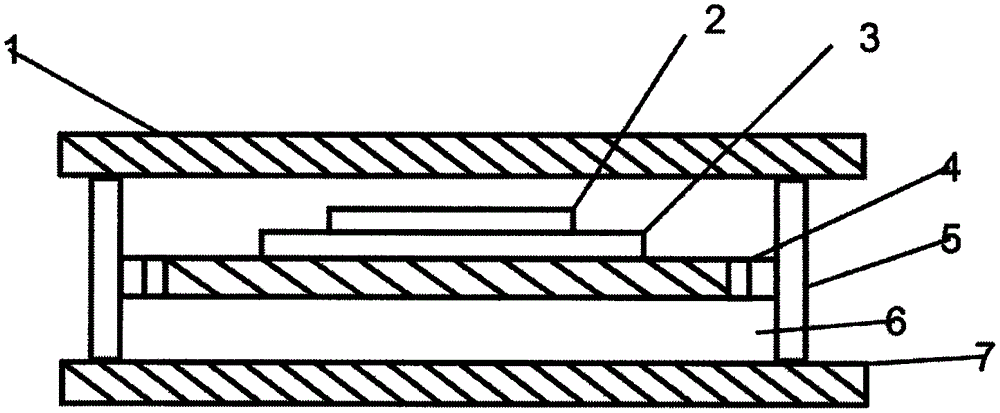

[0030] 4) The vacuum chamber is evacuated, and the magnetron sputtering process uses a background vacuum of 1.0-5.0×10 -4 Pa, filled with nitrogen as the reaction gas, nitrogen flow control at 30-105sccm, working vacuum 1.0-8.0×10 -1 Pa, pre-sputtering for 5 minutes, magnetron sputtering source power adjustment range 100-120W, negative bias 0V, sputtering for 10-15 minutes;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com