Roller drive mechanism of quilting and embroidering machine allowing multiple pieces of cloth to be connected

A transmission mechanism and roller technology, which is applied to the mechanism of embroidery machines, embroidery machines, textiles and paper making, etc., can solve the problems of fabric waste and embroidery quality, unbalanced conveying speed, fabric wrinkle, etc., and reduce the chance of fabric wrinkling. , The effect of balanced conveying speed and balanced clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

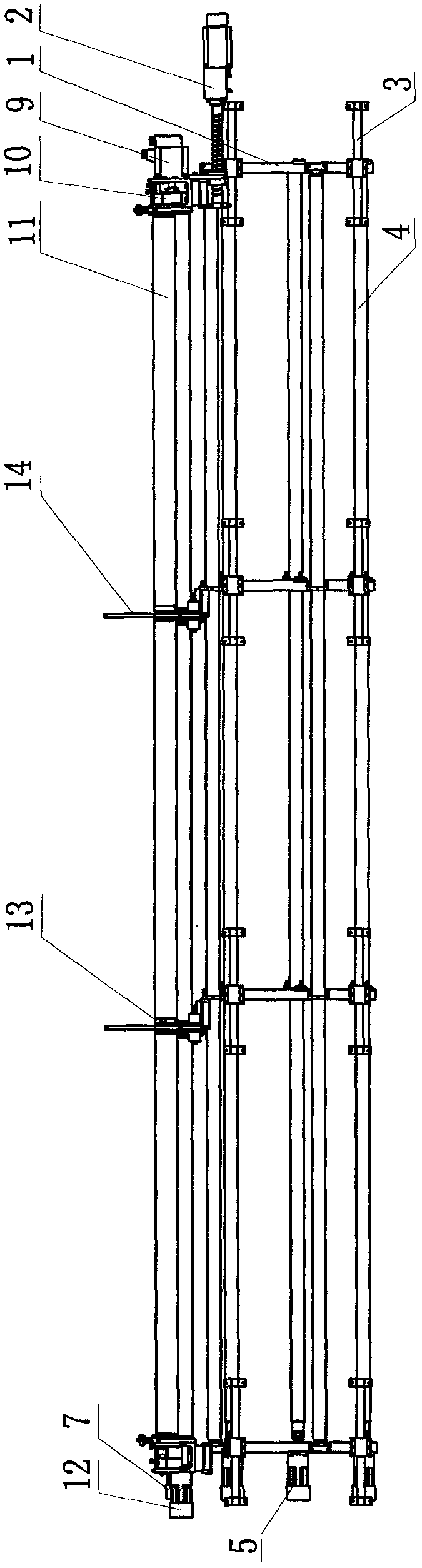

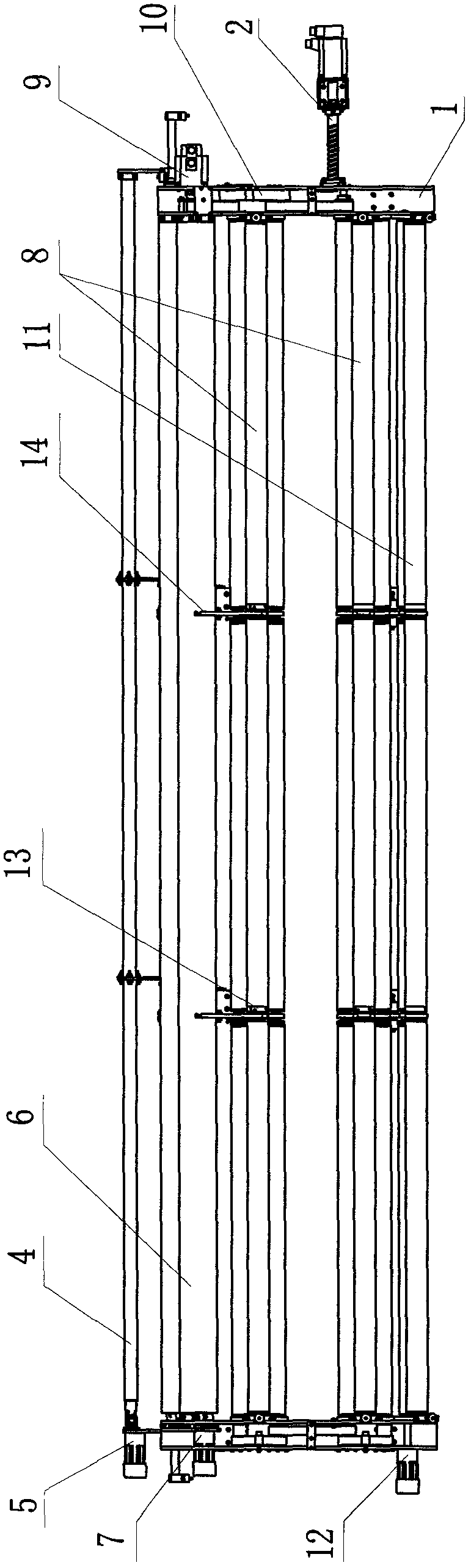

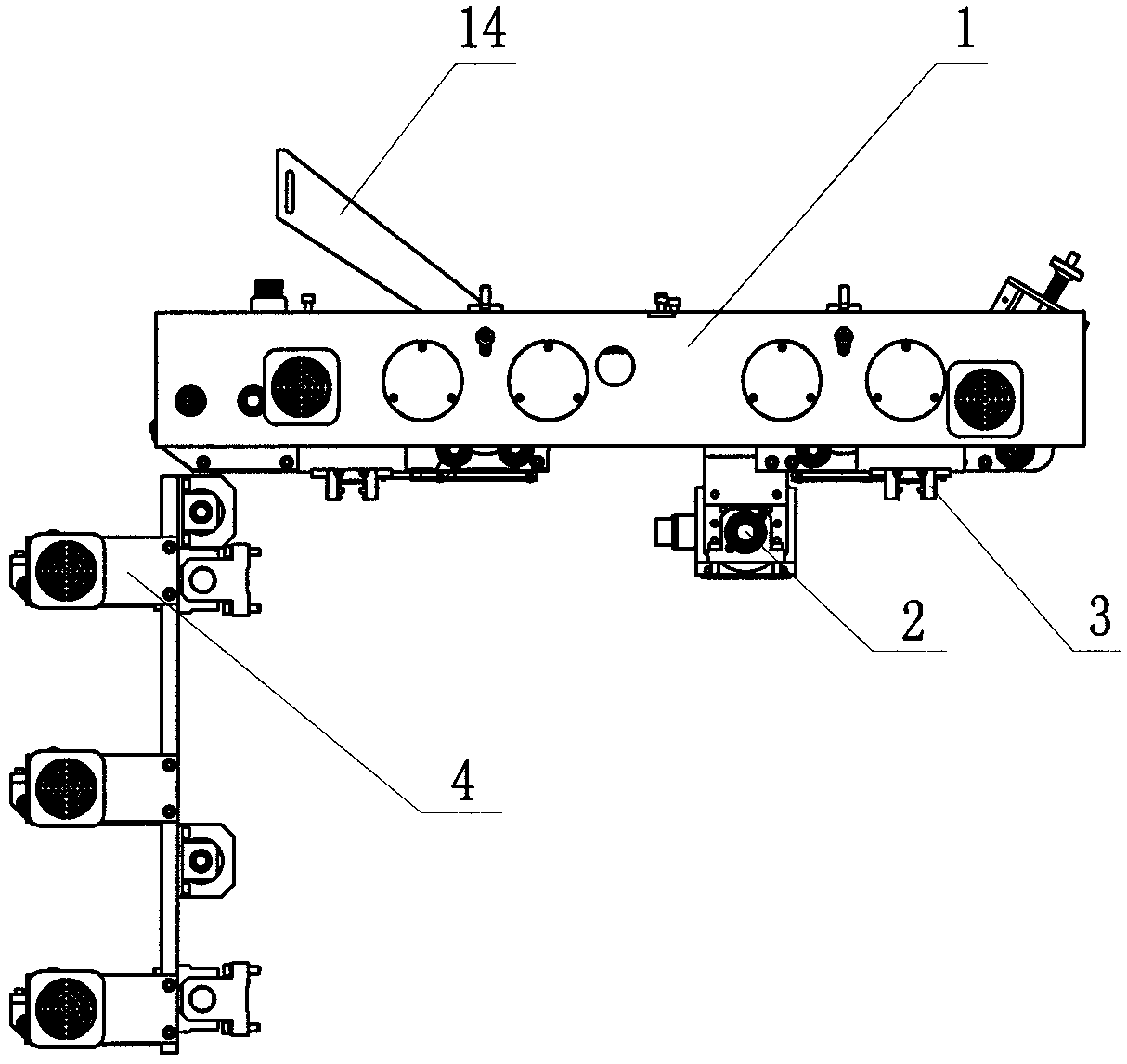

[0047] Depend on Figure 1-31As shown, the embodiment of the multi-piece connection quilting embroidery machine roller transmission mechanism of the present invention is: including the saddle frame 1 that is installed on the quilting embroidery machine frame to support the entire roller transmission mechanism and the X axial movement that moves it axially. The device 2 and the X-axis guide rail device 3 include the cloth coil feed roller group 4 installed on the saddle frame 1 and the coil feed drive motor 5 that drives it, and the feed roller group 6 and the feed drive device 7 that drives it , there is also a tensioning roller group 8 and the tensioning drive motor 9 and the transmission device 10 driven by it, as well as the discharging roller group 11 and the discharging driving motor 12 driven by it, and the described cloth roll delivery roller group 4 , the feeding roller group 6, the tensioning roller group 8 and the discharging roller group 11 can all pass through at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com