Method and equipment for treating side wrinkles of pole piece

A processing method and pole piece technology, which is applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve the problems of reduced pole piece qualification rate, pole piece wrinkling, and pole piece side flatness reduction, etc., to achieve wrinkles The effect of reducing the difficulty of processing, reducing the probability of wrinkles, and improving the flatness

Active Publication Date: 2020-11-10

MEIZHOU LIANGNENG NEW ENERGY SCI & TECHCO

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the low strength of aluminum foil and good elongation performance, the elongation rate of the coating area and the light foil area are different when passing the roller, and the stress of the slitting pole piece is not released in time, and the edge of the pole piece is wrinkled, which makes the tension and tightness of the two sides of the pole piece different. Inconsistency, resulting in uneven winding and dislocation of the battery cells behind, causing fire, explosion and other hidden dangers

[0004] In the traditional pole piece production process, the coated pole piece is rolled and then overwhelmed to the target thickness specification. The pole piece is not pretreated before rolling, which leads to the slitting process. The flatness of the side of the pole piece drops sharply, that is, there are serious wrinkles on the side of the pole piece, which leads to a decrease in the pass rate of the pole piece

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

[0049] Traditional examples 1 to 3 are the pole piece winding cores produced by the traditional pole piece production method. The pole piece strips that are about to be coated are rolled, and then the pole piece strips are slit and slitting to form multiple pole pieces. Finally, Wind each pole piece into a core;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

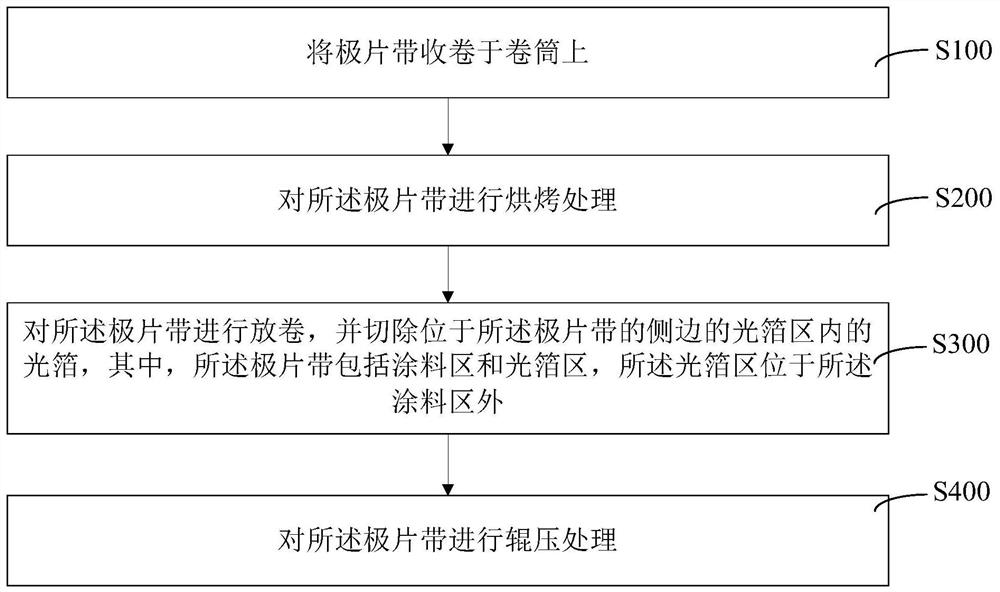

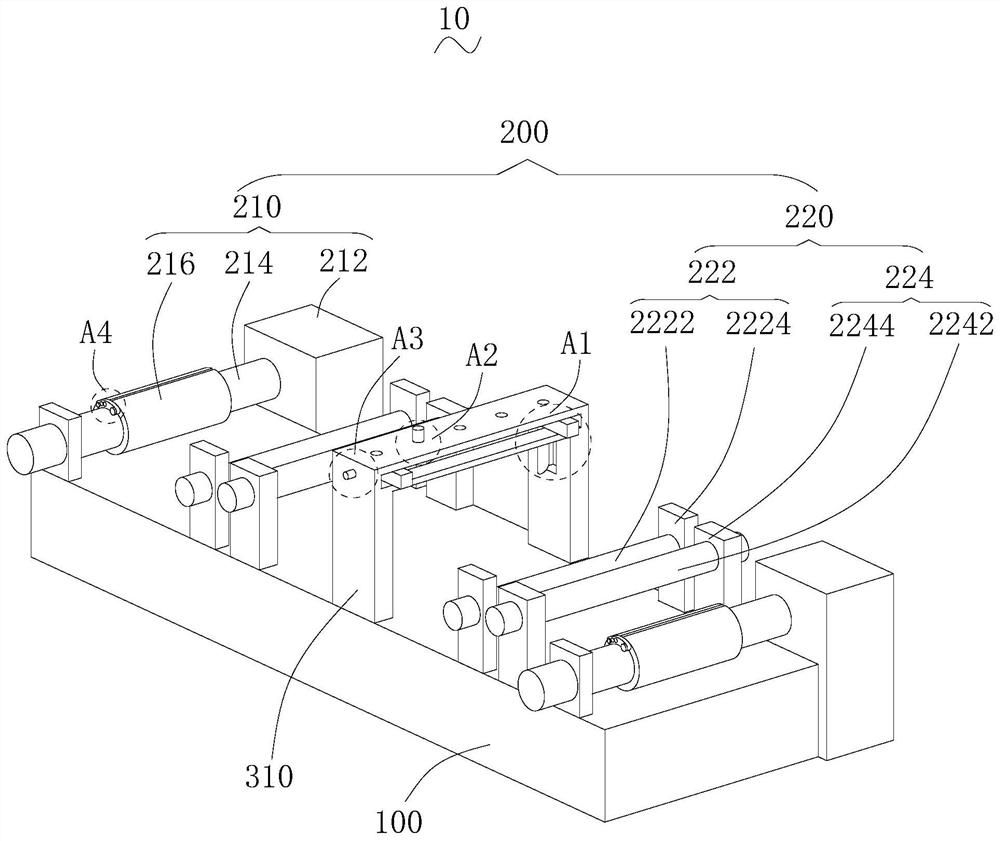

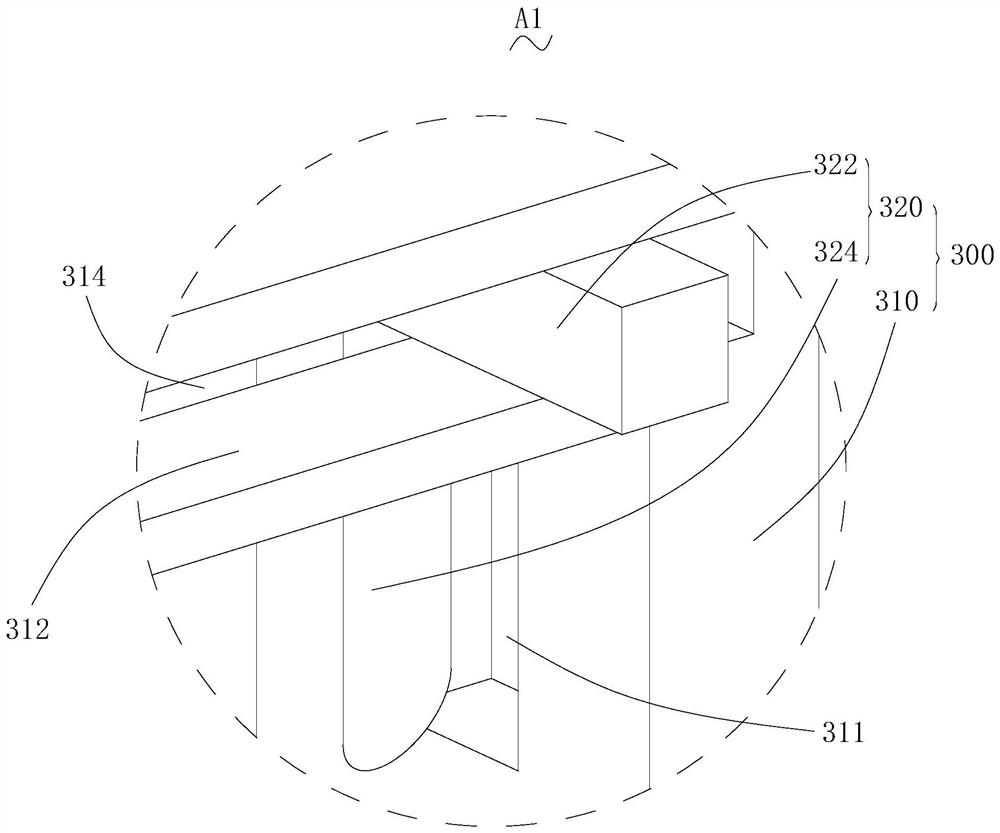

The invention provides a method and equipment for treating wrinkles on the side edge of a pole piece. The method comprises the following steps: winding a pole piece belt on a winding drum; carrying out baking treatment on the pole piece belt; unreeling the pole piece belt, and cutting light foil located in a light foil area on the side edge of the pole piece belt, wherein the pole piece belt comprises a coating area and a light foil area, and the light foil area is located outside the coating area; and carrying out rolling treatment on the pole piece belt. Before the pole piece belt is rolled,the pole piece belt is wound, the wound pole piece belt is baked, the stress release of the two sides of the pole piece belt is guaranteed, and then smooth foils on the side edges of the pole piece belt are cut off, so the thickness of the side edges of the pole piece belt is consistent, and therefore the ductility of the side edges of the pole piece belt is consistent; therefore, when the pole piece belt is stripped, the side edge of the pole piece belt is uniformly stressed, the flatness of the side edge of the pole piece belt is improved, and the probability of wrinkles of the pole piece belt is reduced.

Description

technical field [0001] The invention relates to the technical field of lithium ion pole pieces, in particular to a method and equipment for treating side wrinkling of pole piece strips. Background technique [0002] With the development of lithium-ion battery technology, the scope of use of lithium-ion is rapidly expanding. It has the characteristics of small size, light weight and long power supply time, and has been widely used in various portable electronic devices. Among them, the output efficiency of lithium-ion electric energy and the quality of pole pieces are an important link, and pole piece rolling is an essential process for lithium-ion batteries. [0003] As people's requirements for battery power and energy density are getting higher and higher, the compaction density of the pole piece after rolling is increasing, resulting in excessive extension of the edge of the pole piece after rolling. Due to the low strength of the aluminum foil and good elongation perfor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/139H01M4/04H01M10/0525

CPCH01M4/0435H01M4/139H01M10/0525Y02E60/10

Inventor 朱力强王守军刘新华

Owner MEIZHOU LIANGNENG NEW ENERGY SCI & TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com