Powder packaging machine

A packaging machine and powder technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of easy scratches on packaging bags, jamming of packaging bags, puncture of packaging bags, etc., to reduce the probability of jamming, The effect of reducing the probability of damage and improving the quality of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

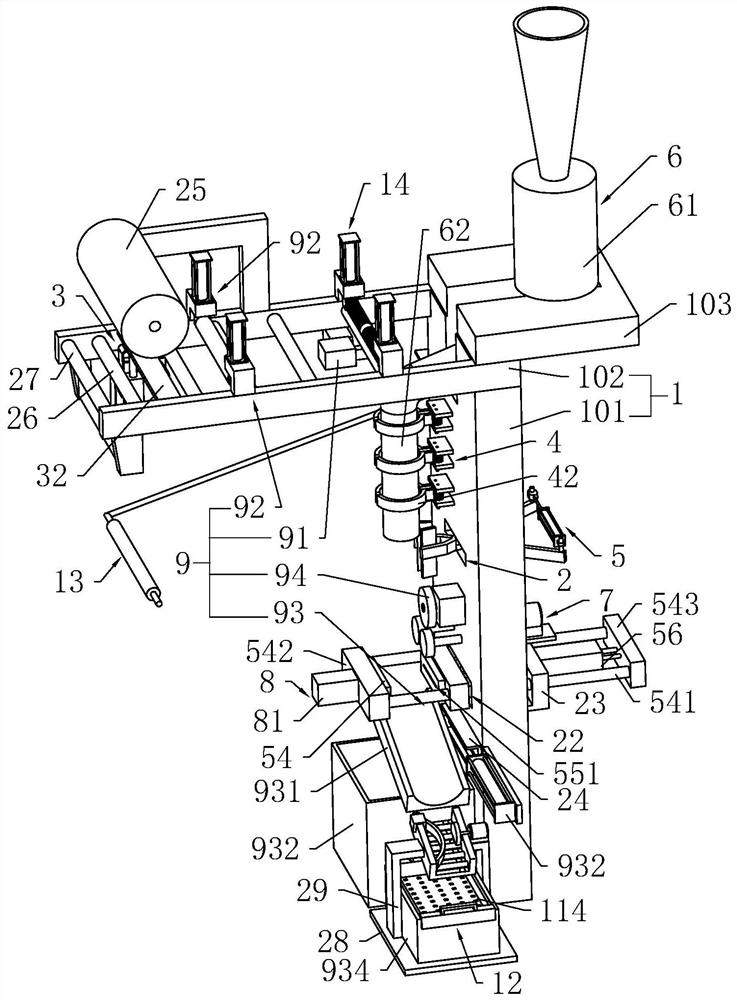

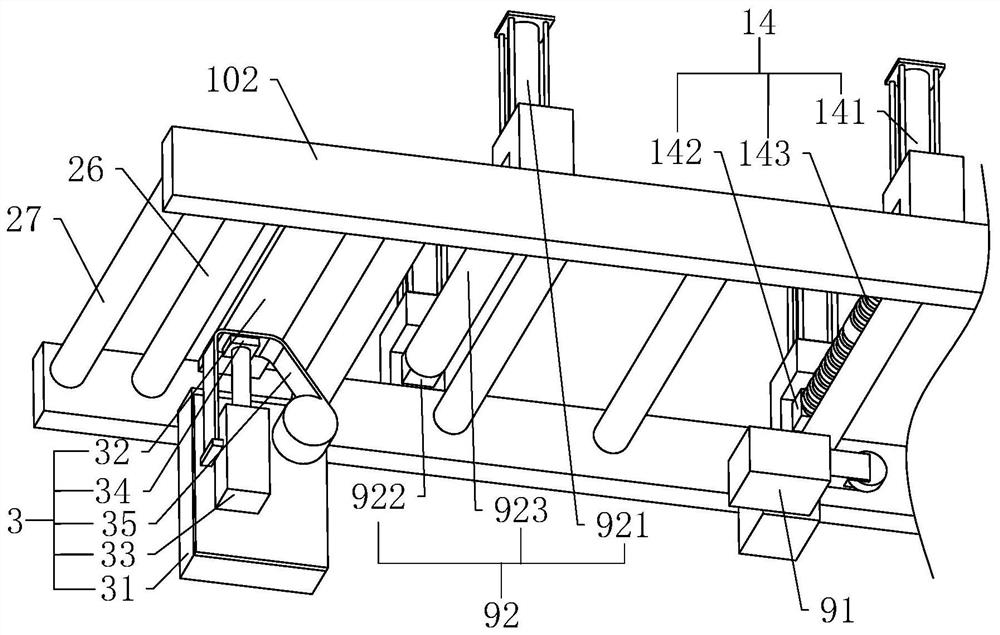

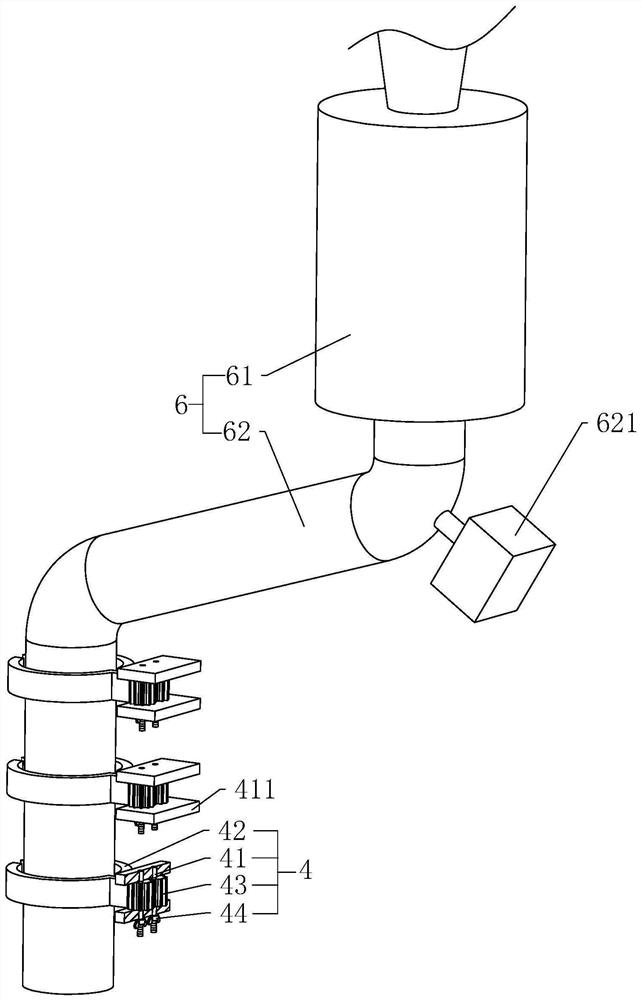

[0046] refer to figure 1 , is a kind of powder packing machine of invention, comprises frame 1, and frame 1 comprises vertical machine base 101 and the horizontal frame 102 that is fixedly installed on the top of machine base 101, and the top of horizontal frame 102 is rotatably installed with coiled The unwinding roller 25 of the packaging bag; the horizontal frame 102 is rotatably equipped with conveying rollers 26, and the conveying rollers 26 are provided with a plurality of arrays along the horizontal direction, while the horizontal frame 102 is positioned at the conveying roller 26 and rotates near the unwinding roller 25 side A guide roller 27 is installed, and a bag holding mechanism 4, an edge sealing mechanism 5, a feeding mechanism 6, a driving mechanism 7, and a cutting mechanism 8 are sequentially arranged on the machine base 101 along the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com