Tool and method for detecting flexibility of pole sheet after surface coating

A technology for testing tooling and flexibility, which is used in the application of stable bending force to test the strength of materials, electrode manufacturing, battery electrodes, etc. It can solve problems such as high regular maintenance costs, scrapped pole pieces, and impact on cell performance. , to achieve the effect of reducing the bad rate of blocked belts, reducing the probability of wrinkling, and reducing experimental investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

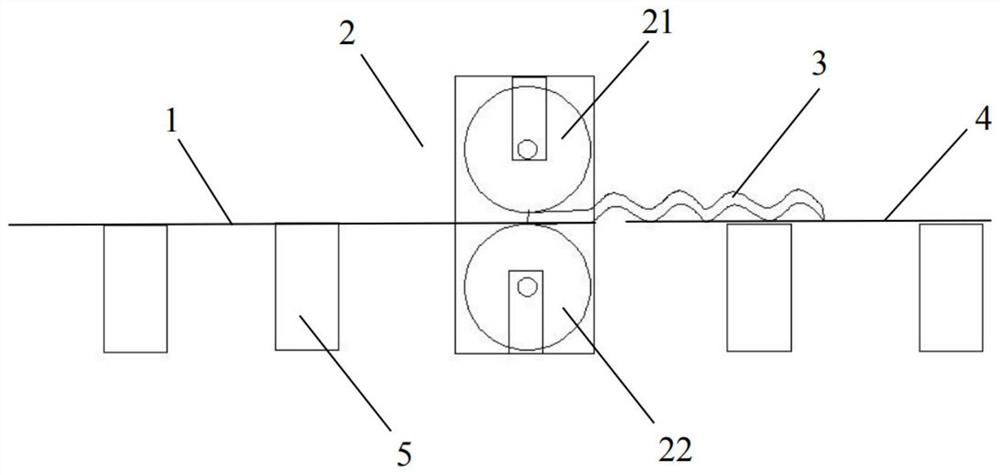

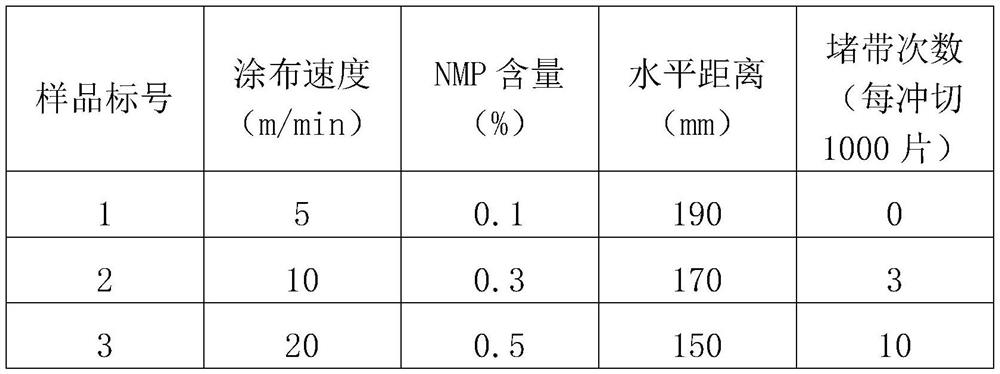

[0044] Take the surface-coated pole piece 3 of the graphite negative electrode, with a width of 267 mm and a length of 200 mm. Three samples of the same batch of pole piece 3 are taken, and the line speed of the lower support roller is set to 11 m / min. Put the pole piece 3 into the upper pressure roller 21 and the lower support roller. On the feeding platform 1 between the rollers, the pole pieces 3 are sent to the measuring platform 4 driven by the upper pressing roller 21 until all the pole pieces 3 leave the feeding platform 1 . Record the position A of the feeding end of the pole piece 3 on the measuring platform 4, measure the horizontal distance between the position A and the symmetrical center of the upper pressing roller 21, and judge the flexibility of the pole piece 3 according to this horizontal distance.

[0045]Pole pieces 3 with different NMP contents obtained by using different surface coating speeds have different flexibility, so the degree of bending of pole pi...

Embodiment 2

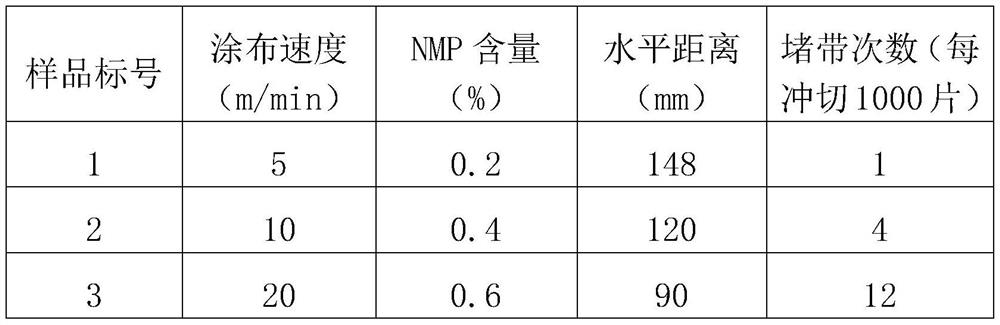

[0051] Take the surface-coated pole piece 3 of the silicon-carbon negative electrode, with a width of 267 mm and a length of 150 mm. Three samples of the same batch of pole piece 3 are taken, and the linear speed of the lower support roller is set to 11 m / min. The pieces 3 are sent to the measuring platform 4 until all the pole pieces 3 leave the feeding platform 1. Record the position A of the feeding end of the pole piece 3 on the measuring platform 4, measure the horizontal distance between the position A and the symmetrical center of the upper pressing roller 21, and judge the flexibility of the pole piece 3 according to this horizontal distance.

[0052] Pole pieces 3 with different NMP contents obtained by using different surface coating speeds have different flexibility, so the degree of bending of pole pieces 3 with different flexibility on the measurement platform 4 is different, and the measurement position A is symmetrical to the upper pressing roller 21. The horizo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com