Mask plate assembly and evaporation equipment

A mask and component technology, applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of edge color mixing, top damage to fine metal masks, etc., to reduce the probability of wrinkles, Avoid edge color mixing and improve the effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

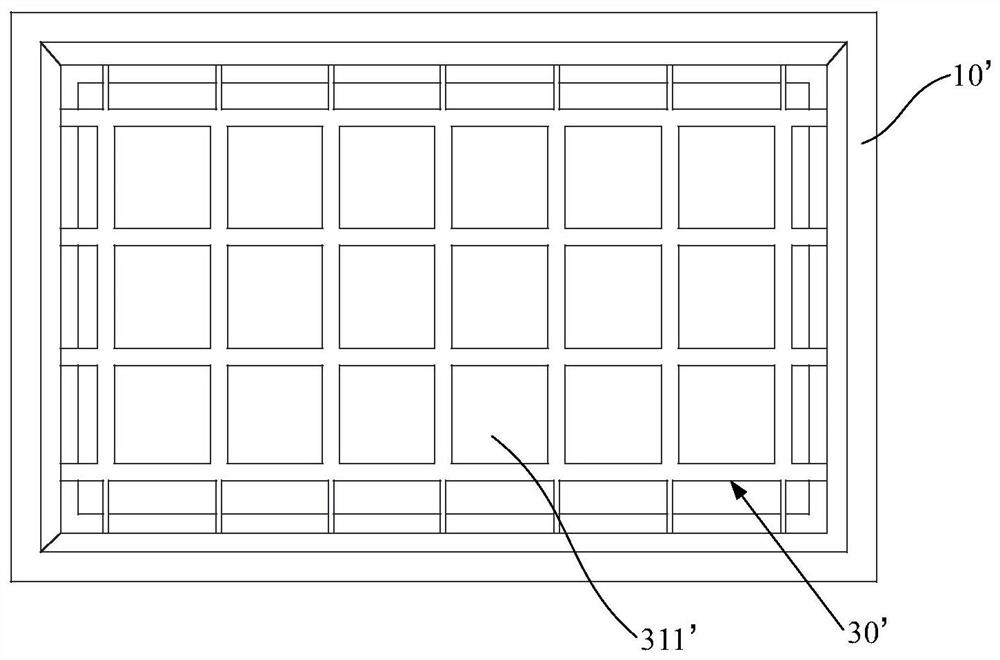

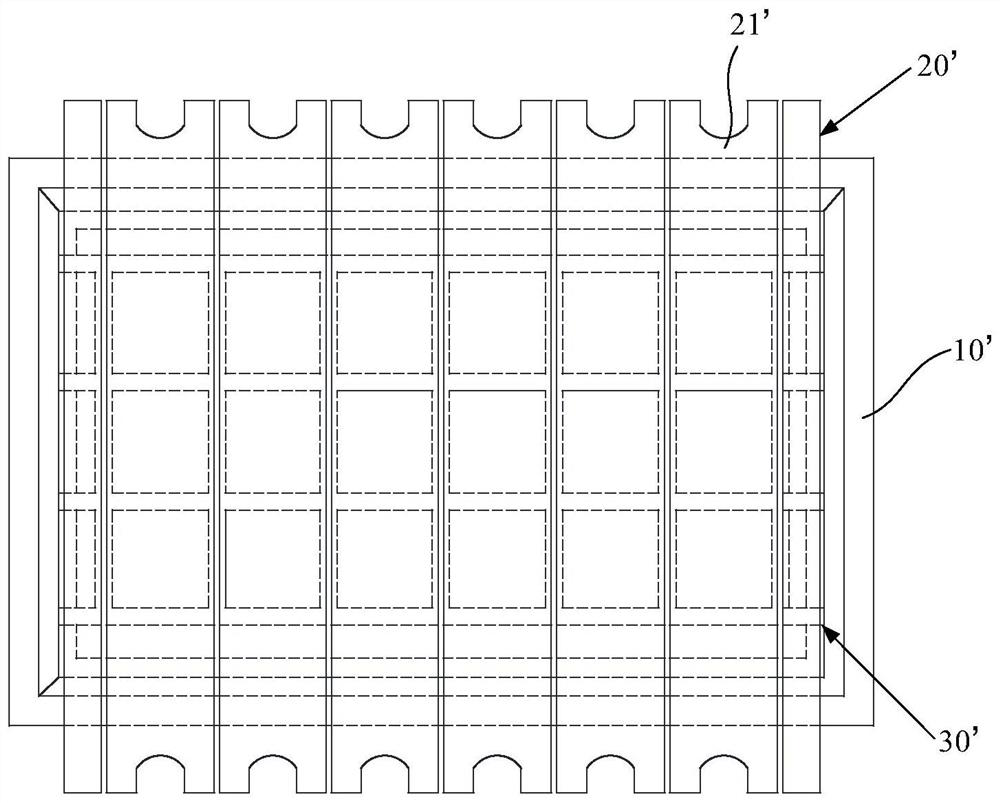

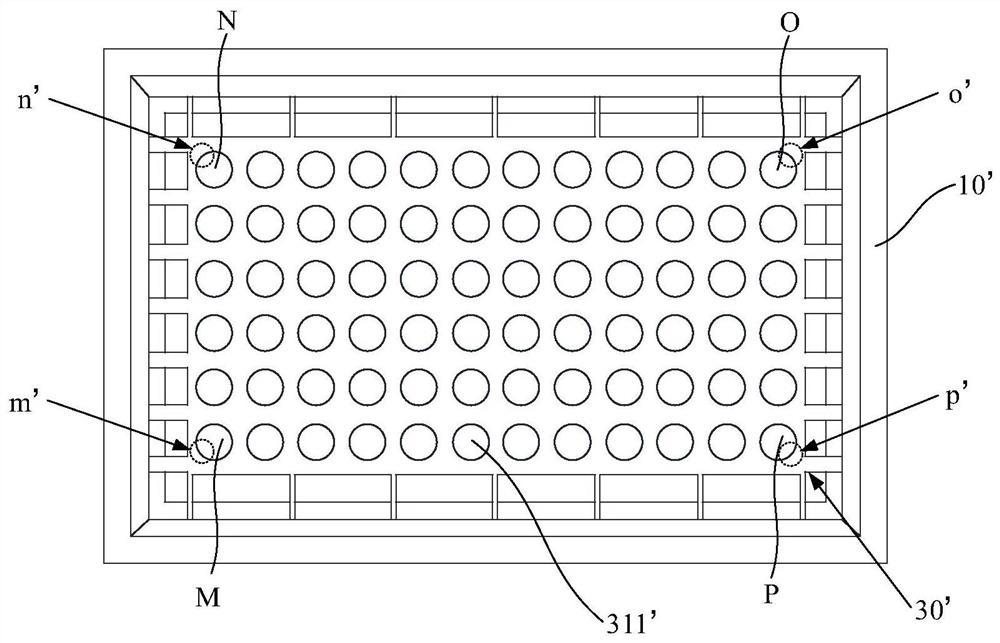

[0051] Please combine Figure 7 to Figure 13 It should be understood that this embodiment provides a mask assembly 1 . It includes: a frame 10, a first mask plate 20 and a second mask plate 30 stacked on the frame 10, the first mask plate 20 is located away from the frame from the second mask plate 30 10 on one side.

[0052] The first mask plate 20 includes a plurality of mask strips 21 arranged along the first direction, a gap 22 is provided between two adjacent mask strips 21, and each mask strip 21 is provided with a There are a plurality of pixel openings 311 arranged in an array. That is, the first mask 20 is a fine metal mask.

[0053] The second mask plate 30 includes a main body 31 and a support bar arranged along the outer periphery of the main body 31, the first end of the support bar is connected to the main body 31, and the first end of the support bar is the The portion of the support bar that does not coincide with the orthographic projection of the frame 10...

Embodiment 2

[0071] Such as Figure 14 to Figure 19 As shown, the overall structure of the mask assembly of this embodiment is basically the same as the structure in Embodiment 1. The structure of the mask assembly of this embodiment is based on the structure of Embodiment 1, and the rest of the first support The width of the first end 321 of the bar 32 also gradually increases from the direction away from the main body 31 to the direction close to the main body 31 . That is, not only the first support bar 32 located on the outermost side, but also the widths of the first ends 321 of the rest of the first support bars 32 gradually increase from the direction away from the main body 31 to the direction close to the main body 31, That is, the widths of the first ends 321 of all the first support bars 32 gradually increase from a direction away from the main body 31 to close to the main body 31 . In order to further improve the supporting strength of the first supporting bar 32 to the main b...

Embodiment 3

[0081] Such as Figure 20 and Figure 21 As shown, the overall structure of the mask assembly 1 of this embodiment is basically the same as that in Embodiment 2, the difference is that, on the basis of the structure of Embodiment 2, the rest of the second support bars 33 The width of the first end 331 also gradually increases from the direction away from the main body 31 to close to the main body 31 . That is, not only the outermost second support bar 33, but also the widths of the first ends 331 of the other second support bars 33 gradually increase from the direction away from the main body 31 to the direction close to the main body 31, That is, the widths of the first ends 331 of all the second supporting bars 33 gradually increase from a direction away from the main body 31 to close to the main body 31 . In order to further improve the supporting strength of the second supporting bar 33 to the main body 31 .

[0082] In this example, please refer to Figure 20 and Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com