Air bubble film tensioning device

A tensioning device and bubble film technology, applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problems that the bubble film cannot be rolled flat and compact, does not have the adjustment function, and the bubble film is bent, etc. , to reduce the probability of bending and wrinkling, move smoothly and smoothly, and adjust the spacing quickly and accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

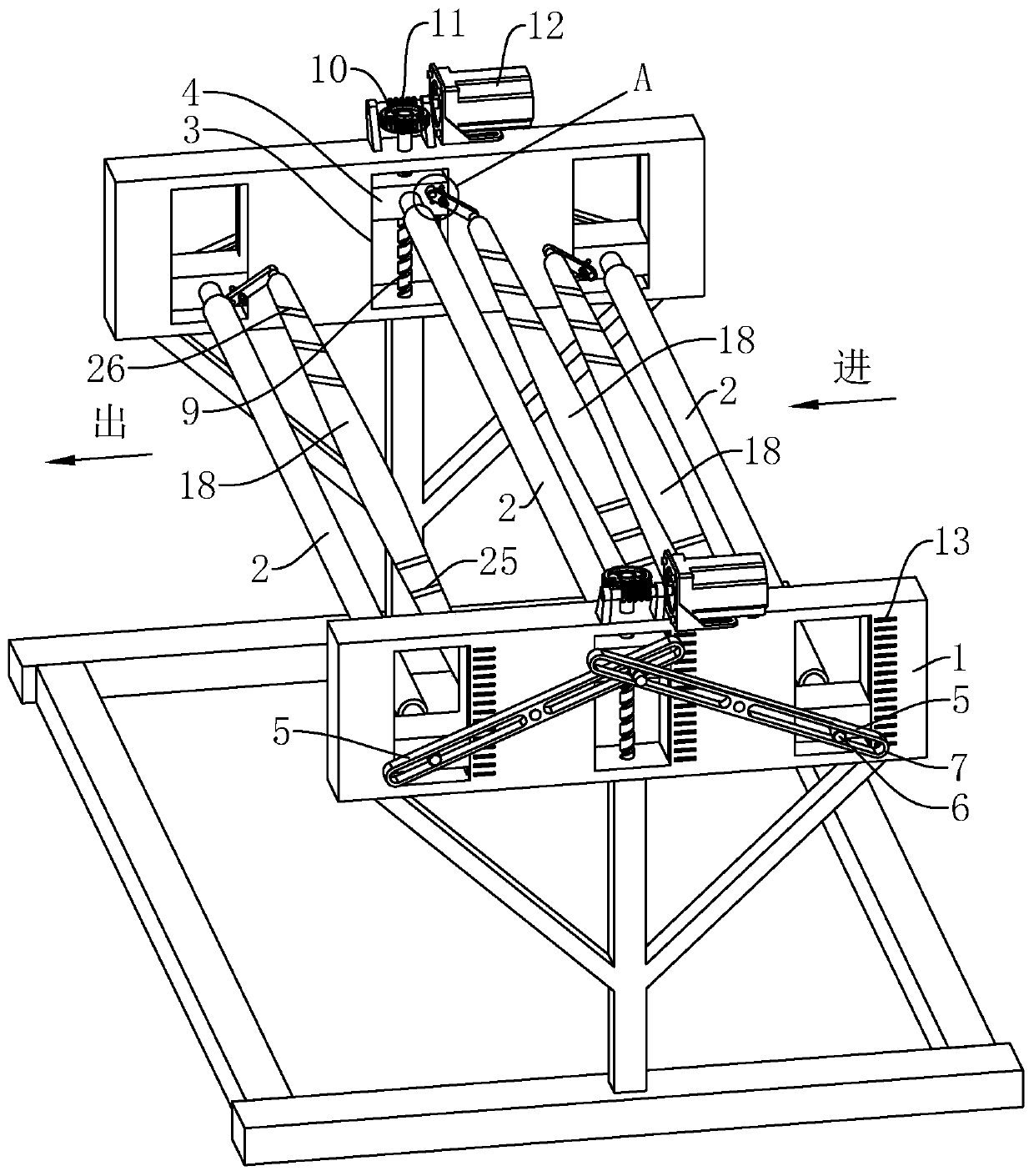

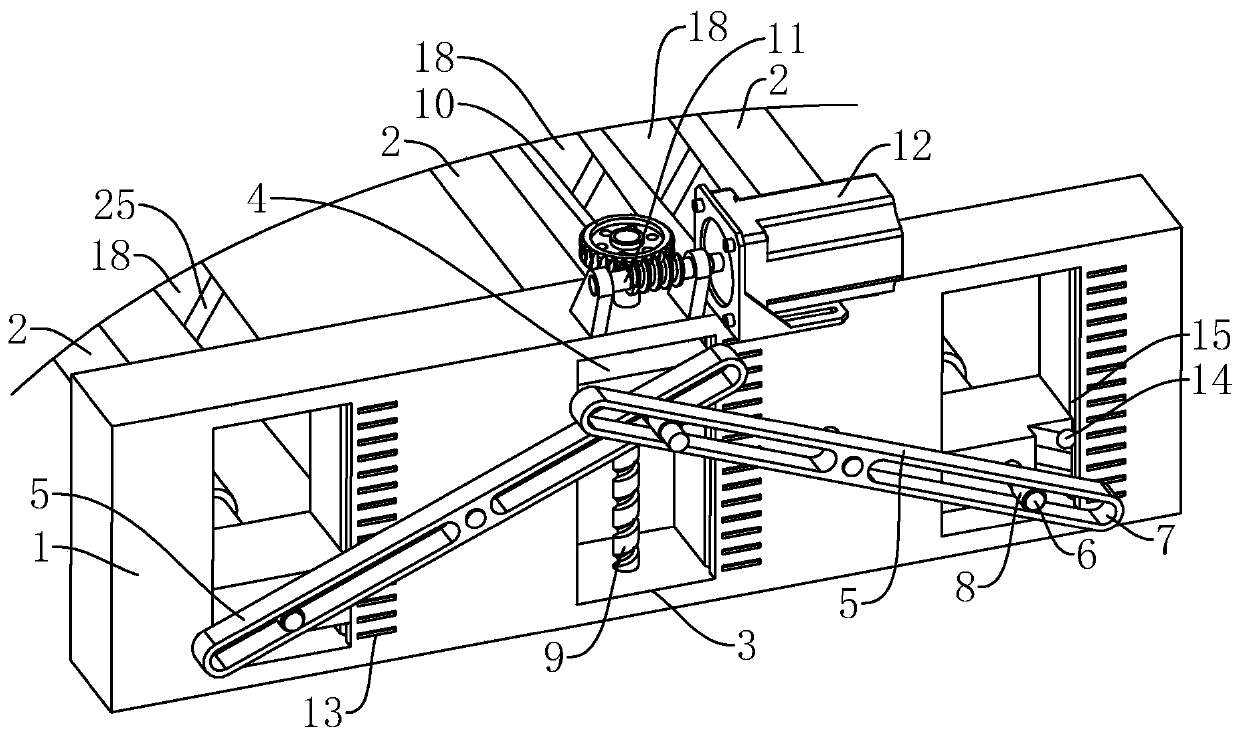

[0040] refer to figure 1 , an air bubble film tensioning device, comprising two installation plates 1 parallel to each other and spaced apart, and three first tension rollers 2 arranged between the two installation plates 1, the three first tension rollers 2 are arranged along the The installation boards 1 are evenly arranged in the length direction. The operator passes the air bubble film around the three first tensioning rollers 2 sequentially in a serpentine shape, and the three first tensioning rollers 2 will stretch and tighten the air bubble film to a certain extent in the length direction of the air bubble film to reduce air bubbles. The probability of bending and wrinkling of the film allows the air bubble film to be wound flat on the subsequent take-up roll.

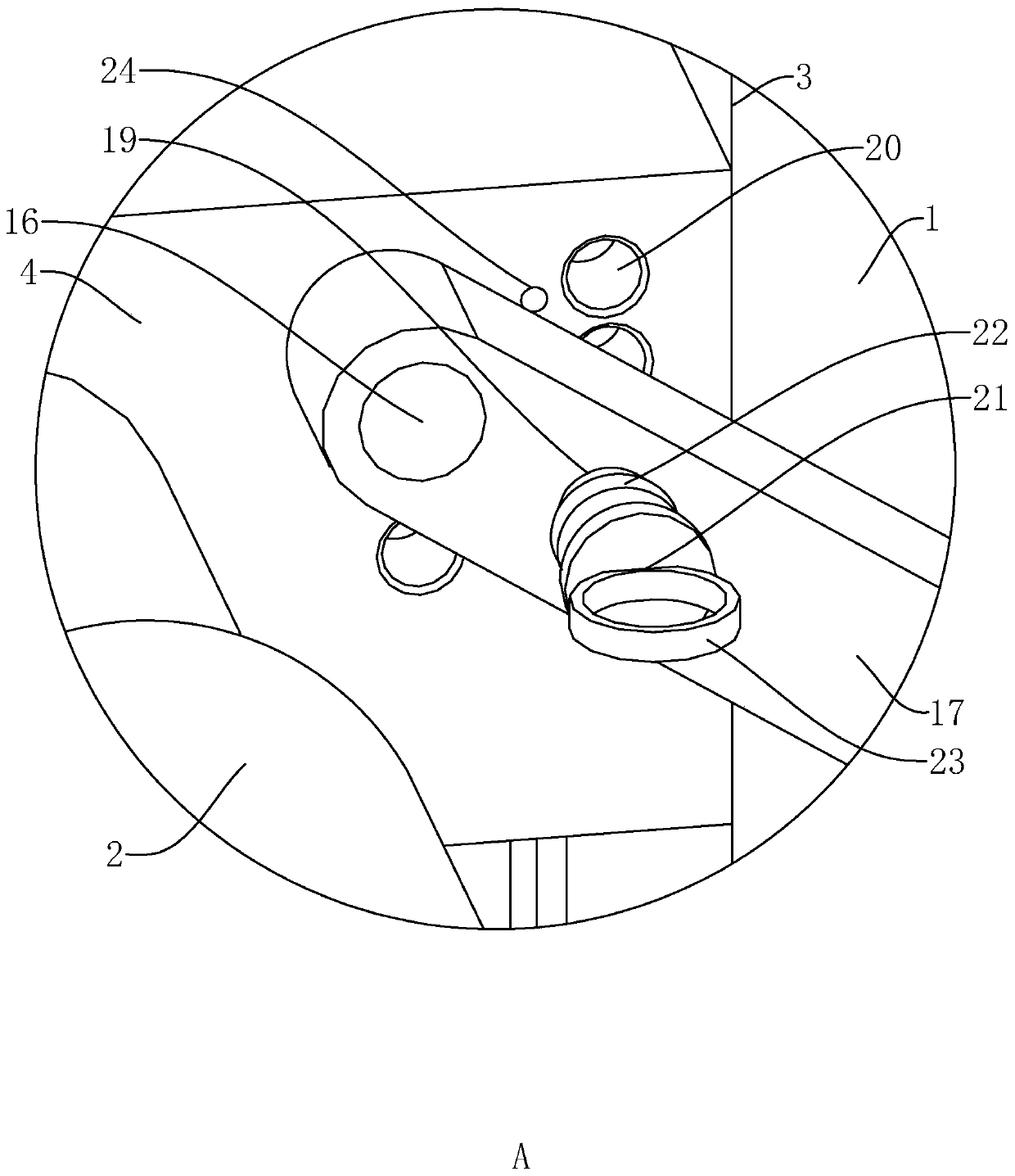

[0041] Three vertical first through grooves 3 are opened on the two mounting plates 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com