Secondary spray roughing device, and production line and process for textured geomembrane

A technology of geomembrane and roughening, which is applied to spraying devices, spraying devices with movable outlets, and other household appliances, etc. It can solve the problems of overlapping swing ranges of hot air nozzles and uneven materials, and reduce the possibility of free sloshing , reduce the probability of wrinkles, reduce the effect of overlapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

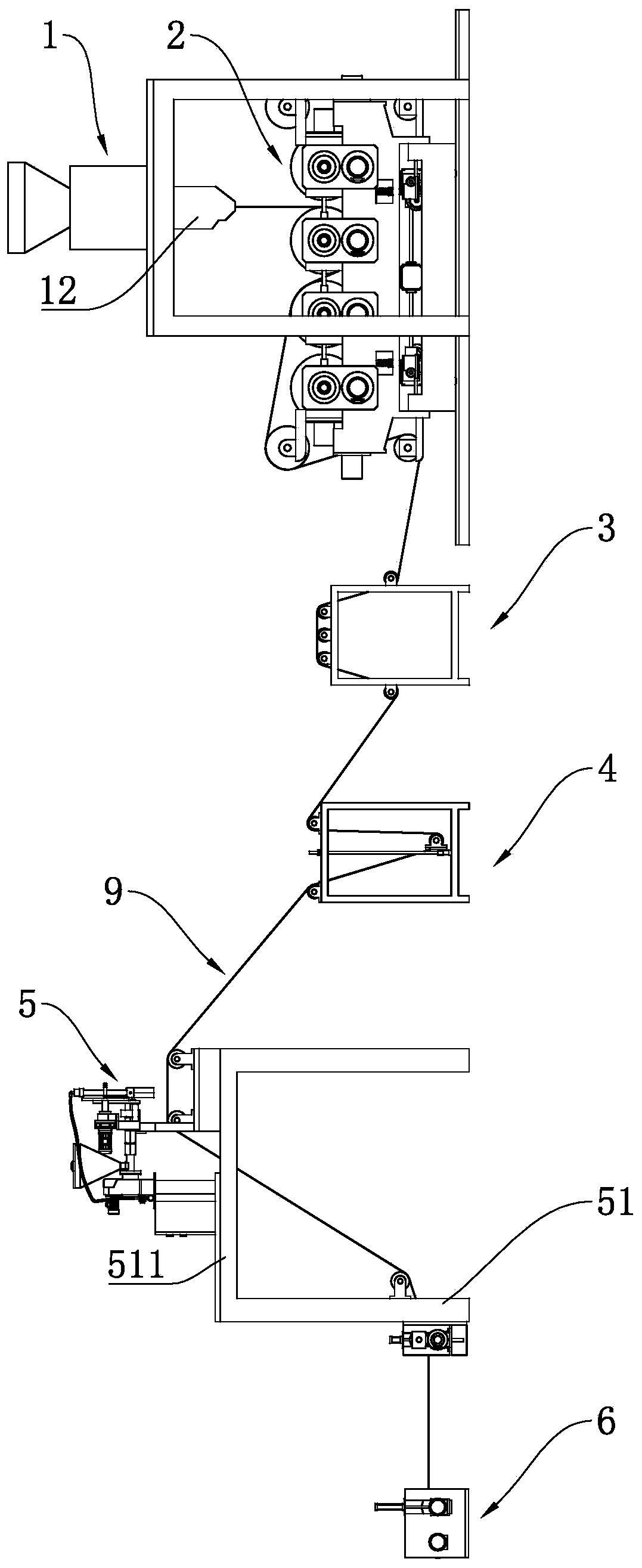

[0068] refer to figure 1 , which is a production line between a secondary roughening device and a rough geomembrane disclosed in this embodiment, a plate extruding device 1, a calendering device 2, a transmission device 3, a storage film Device 4, secondary roughening device 5 and winding device 6.

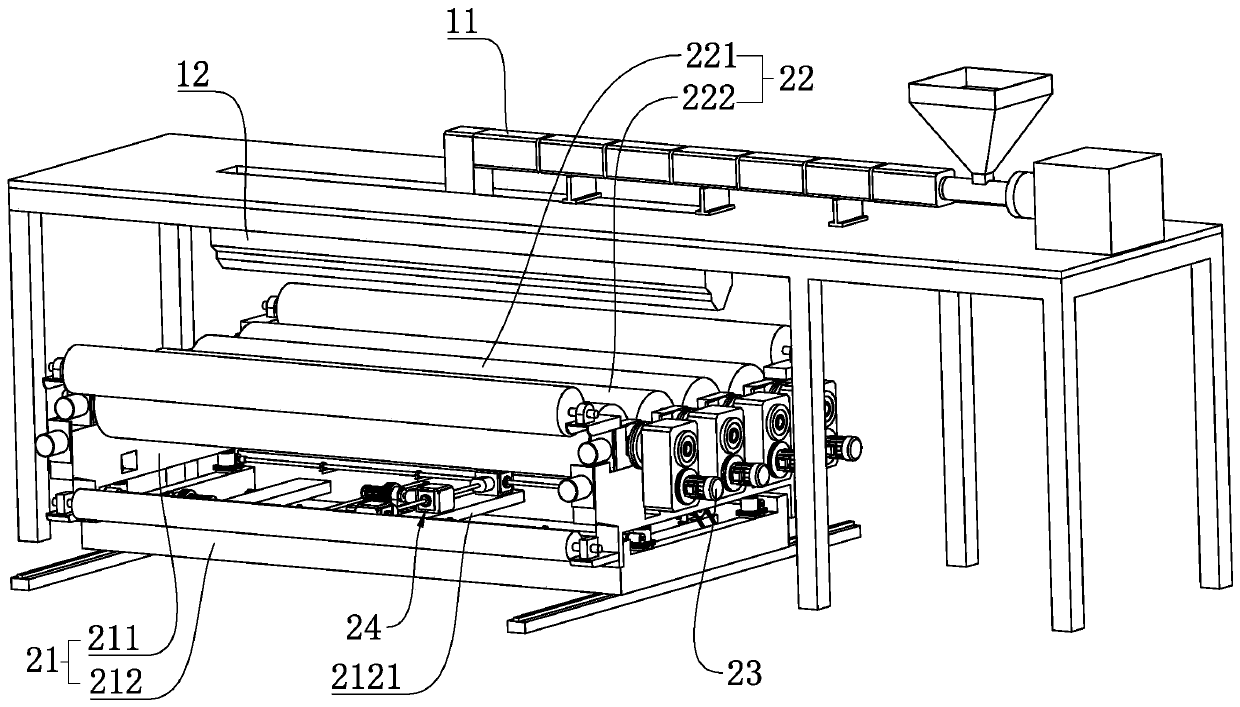

[0069] refer to figure 2 , The sheet extrusion device 1 in this embodiment includes a first screw extruder 11 and a sheet extrusion die 12 connected to the discharge port of the first screw extruder 11 .

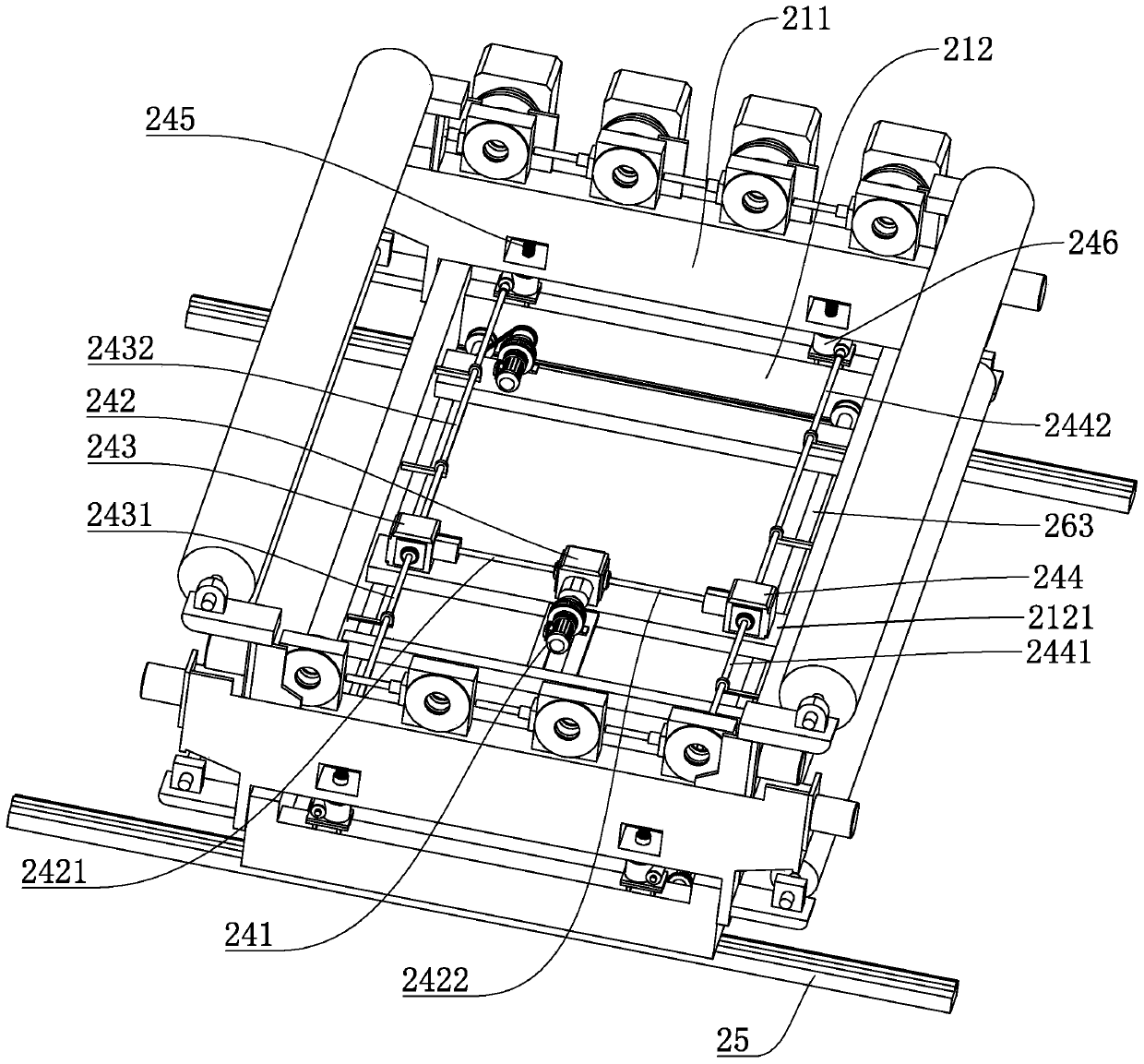

[0070] refer to figure 2 , the calendering device 2 includes a mounting frame 21 , and the mounting frame 21 includes a first layer frame 211 and a second layer frame 212 located below the first layer frame 211 . The upper end of the first layer frame 211 is provided with a pressure roller 22, the pressure roller 22 extends along the width direction of the geomembrane 9 and the length of the pressure roller 22 is greater than the width of the geomembrane. The pressure roll...

Embodiment 2

[0104] refer to Figure 11 , is a secondary roughening device disclosed in this embodiment and the production line of the rough surface geomembrane. The difference between this embodiment and Embodiment 1 is that the frame 51 is fixed below the upper shelf plate 511 The lower shelf 512, the upper shelf 511 and the lower shelf 512 are respectively provided with the roughening mechanism 53 in Embodiment 1, so that the roughening device in this embodiment forms two rows of roughening stations up and down, and the upper shelf 511 The roughening mechanism 53 on the top is close to the film storage device 4 , and the roughening mechanism 53 on the lower shelf 512 is close to the winding device 6 . A reversing roller 513 is provided on the side of the frame 51 close to the winding device 6 , and both ends of the reversing roller 513 in the length direction are connected to the frame 51 in rotation.

[0105] The implementation principle of this embodiment is: when the sheet-shaped ge...

Embodiment 3

[0108] refer to Figure 12 The difference between this embodiment and Embodiment 2 is that the roughening outer tubes 7 are movably socketed on the outer peripheral surfaces of all the roughening tubes 531 , and the roughening outer tubes 7 are located below the high-pressure hot air pipe 532 . On the frame 51, a stroke rail 8 is fixed on the side near the second screw extruder 52 of the roughened outer pipe 7, and the stroke rail 8 extends along the length direction of the frame 51, and the upper shelf plate 511 and the lower shelf plate 512 Corresponding positions are all provided with this travel rail 8.

[0109] refer to Figure 13 One end of the travel rail 8 facing the spray pipe 531 is provided with a sliding groove 81 , and the sliding groove 81 extends along the length direction of the travel rail 8 . The outer periphery of each rough spraying outer tube 7 is connected with a slide bar 71 to rotate toward the side of the sliding groove 81, and the end of the sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com