Cloth pressing device for weaving machine with adjustable tensioning degree

A cloth pressing device and an adjustable technology, which can be used in textiles and papermaking, textile material inspection, fabric surface trimming, etc., can solve the problems of not being able to ensure that the cloth has no wrinkles, no cloth wrinkle detection, and cloth affecting the processing quality. Probability of wrinkles, avoiding inconvenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

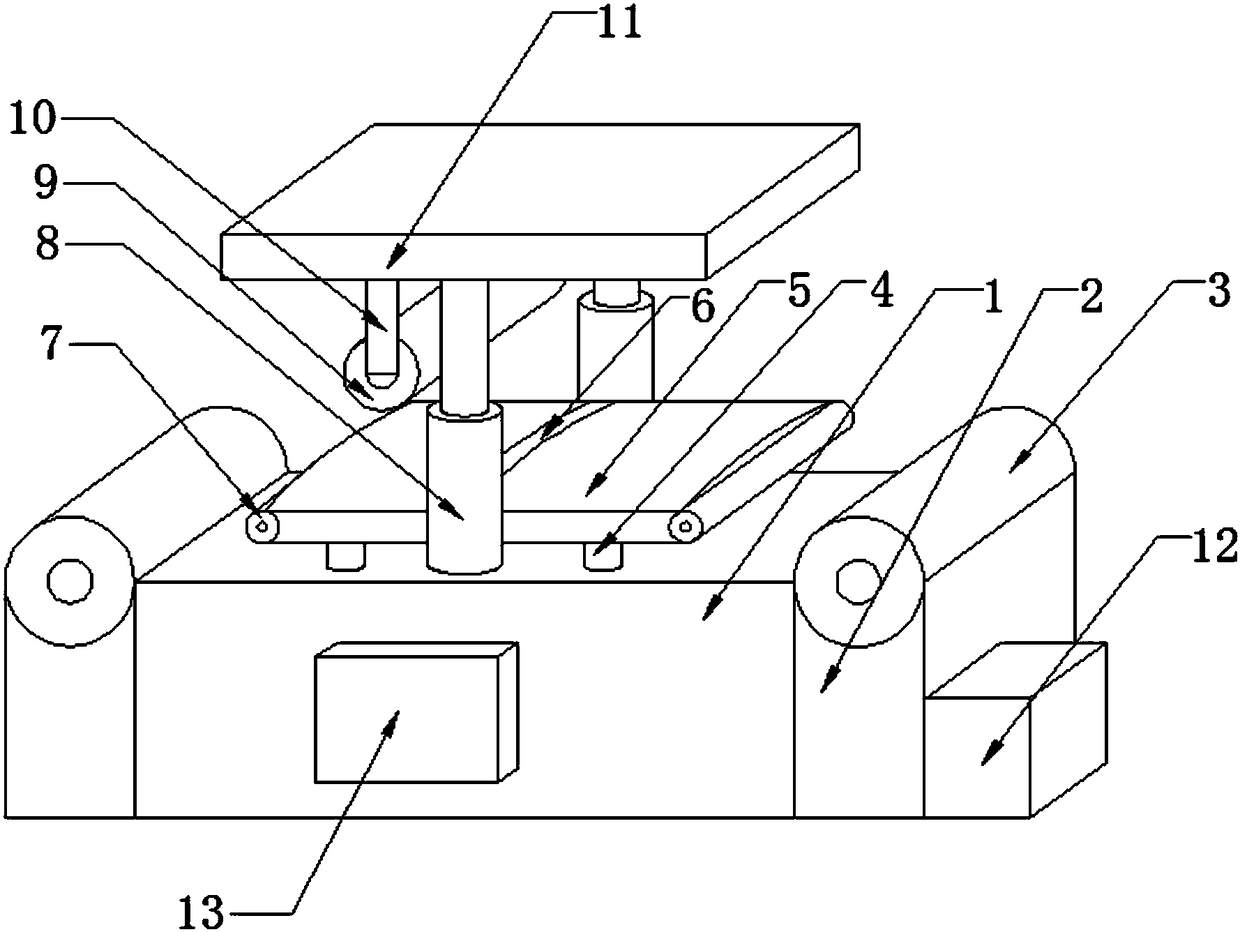

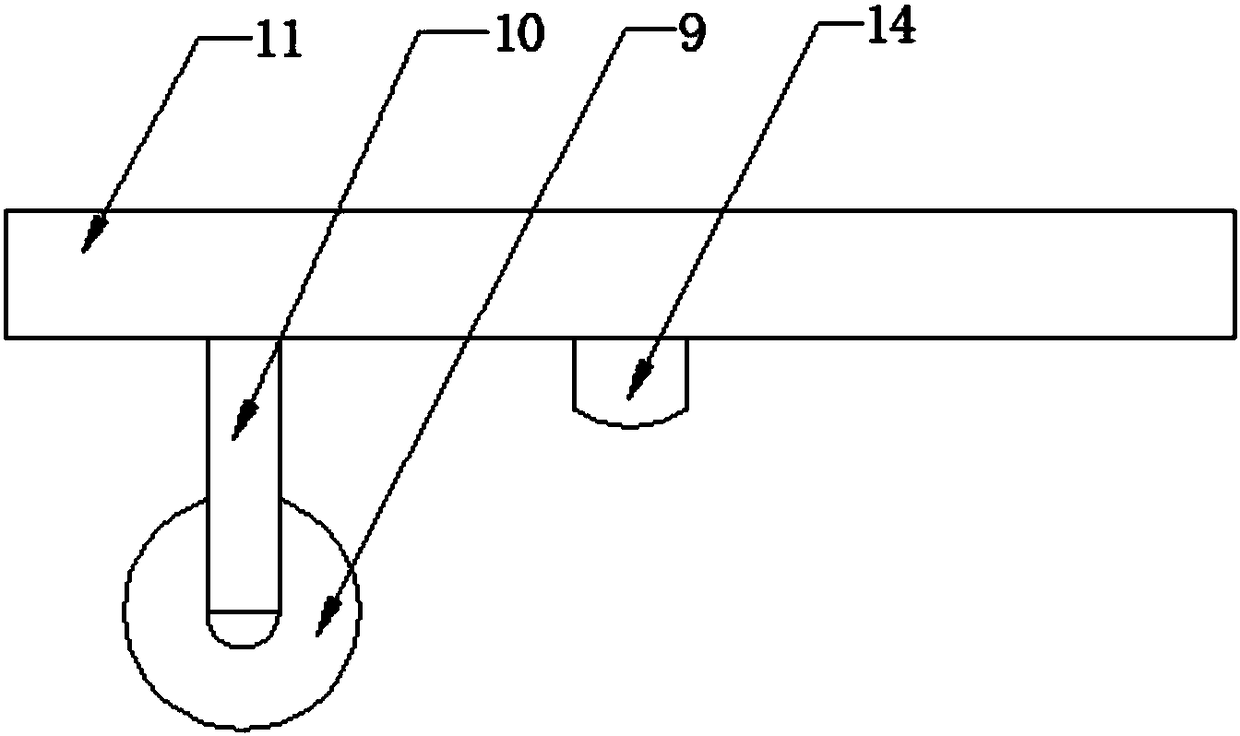

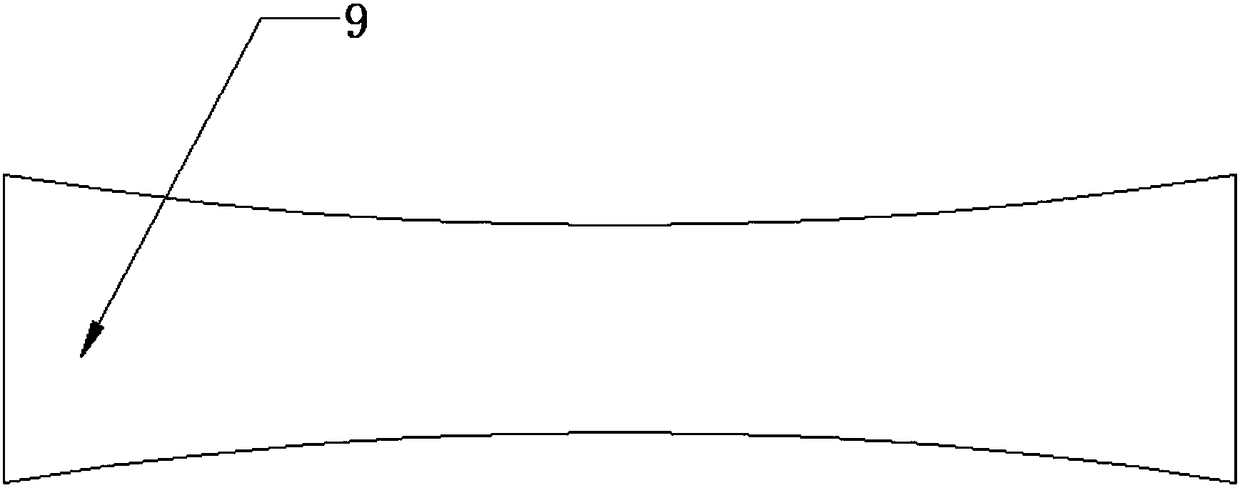

[0024] Such as Figure 1-4 As shown, a cloth pressing device for a textile machine with adjustable tension of the present invention includes: a base 1, both ends of the base 1 are fixed with support bases 2, and the top ends of the two support bases 2 are connected by a rotating shaft and a transmission The roller 3 is rotationally connected, and the top of the base 1 is fixedly connected to the four corners of the bottom of the bottom plate 5 through four first electric telescopic rods 4. A cloth pressing mechanism is provided, and a control panel 13 is fixedly provided on one side of the base 1. The control panel 13 is provided with a first electric telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com