Steam box used for scouring and bleaching equipment, scouring and bleaching equipment and steaming method

A technology of steaming box, refining and bleaching, applied in the fields of refining and bleaching equipment and steaming and steaming box, can solve the problems of high requirements on technology and processing equipment, few processing steps, and the degree of fabric stretching is large, so as to reduce wrinkles. The effect of reducing the probability of processing, reducing processing costs, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

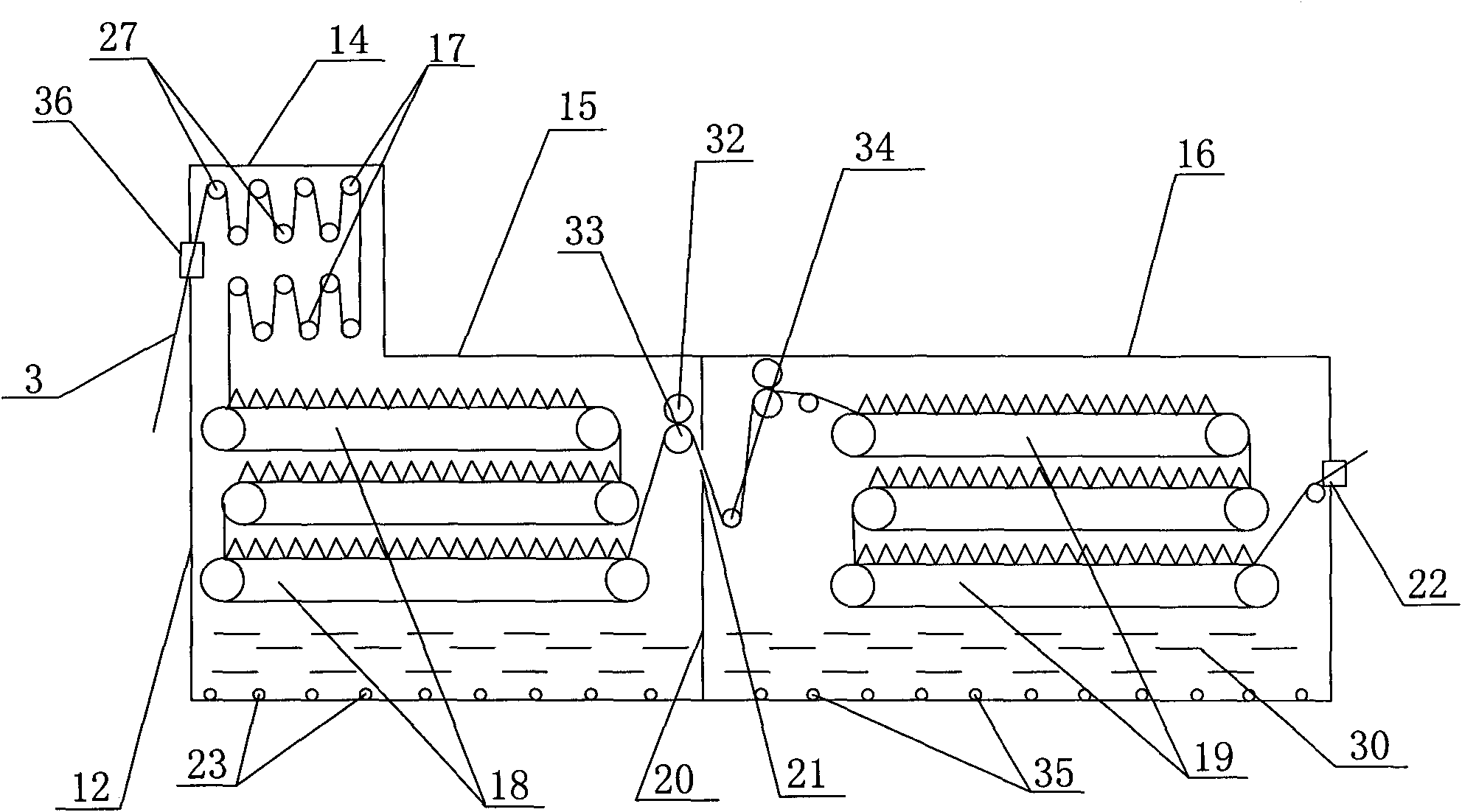

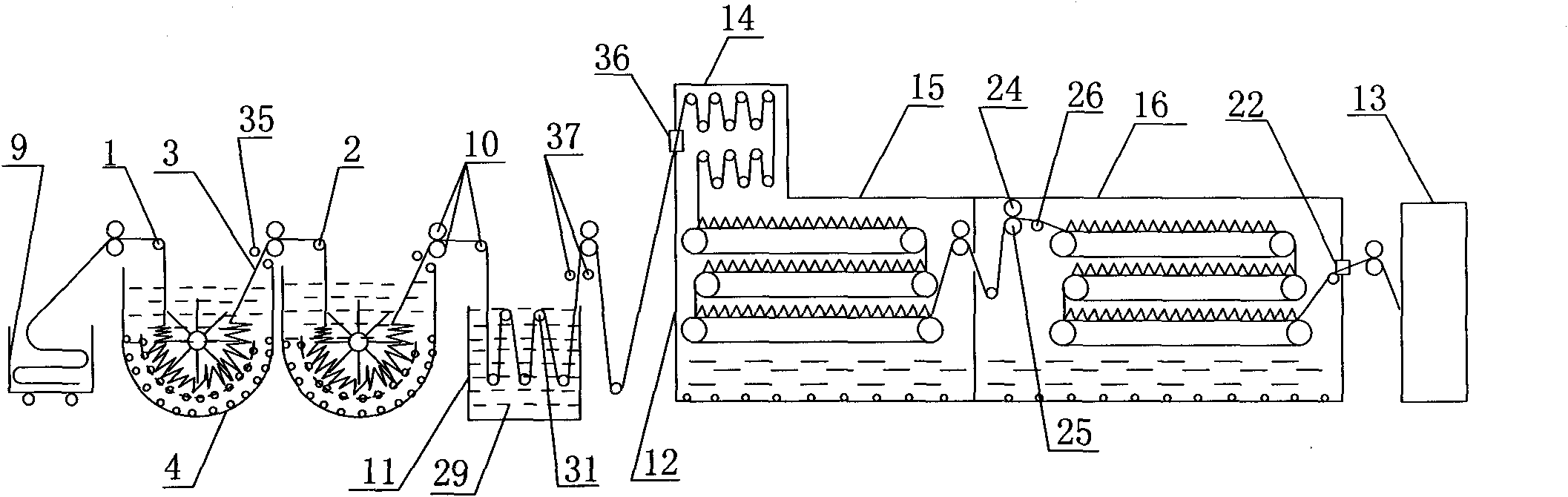

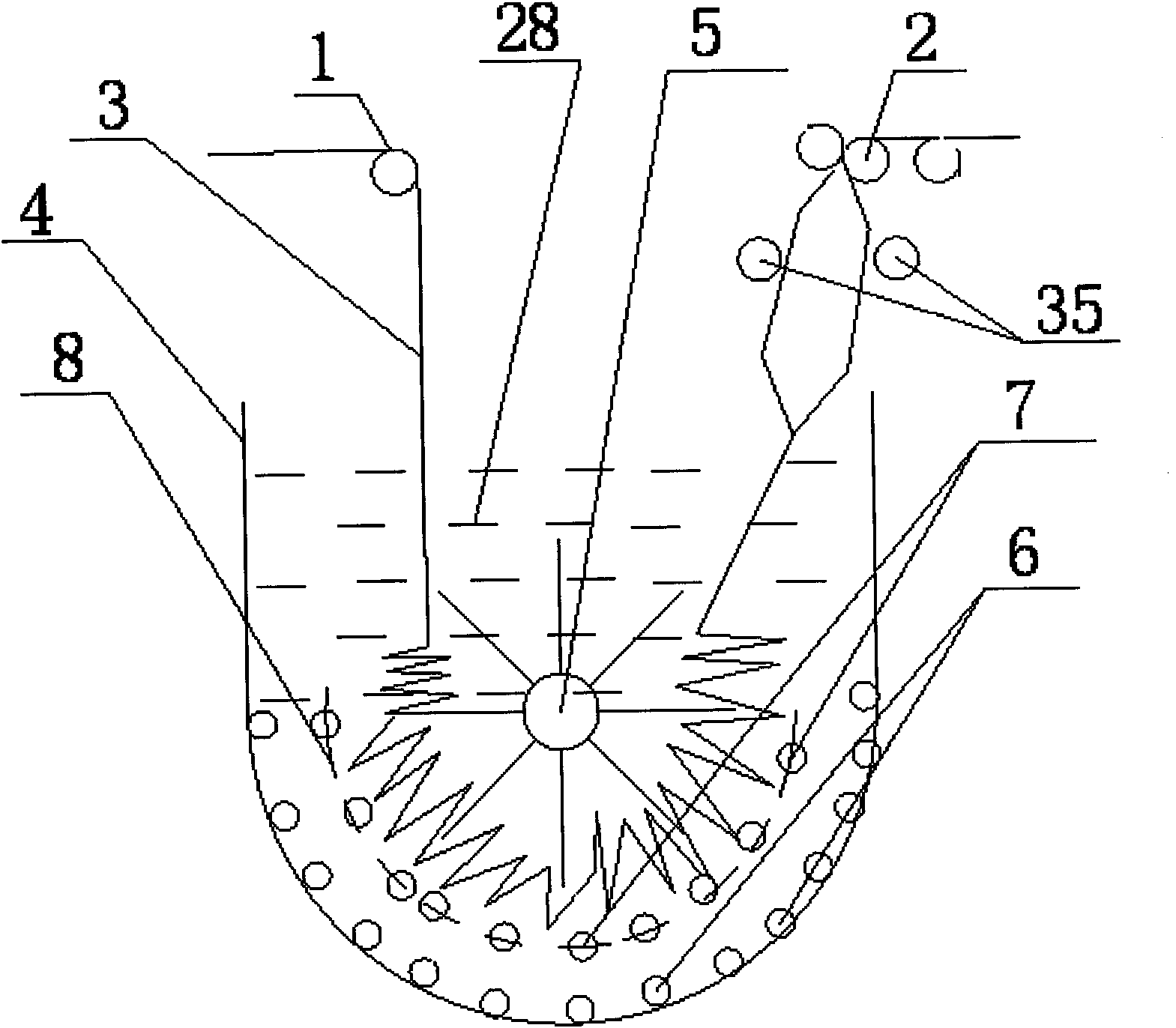

[0036] The present invention provides a steam box for scouring and bleaching equipment, scouring and bleaching equipment and a steaming method. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the following will describe the present invention in conjunction with the accompanying drawings and embodiments Further details.

[0037] The invention provides a steamer used for scouring and bleaching equipment. The first steaming is carried out at a lower temperature (80°C or 90°C). In order to ensure the normal operation of the steaming, the fabric that has been steamed for the first time is steamed for the second time at a higher temperature, that is, 100°C, so that the fabric is smoother and the fabric is reduced after two steamings. The degree of fiber damage is reduced, the utilization rate of hydrogen peroxide is improved, and the manufacturing cost is reduced. The basic structure of the steamer is as follows: figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com