True blind hole circuit board making process

A manufacturing process and circuit board technology, applied in multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems that affect the efficiency of operators' production enthusiasm, affect the appearance and exposure of product yield, and the impact of equipment and materials, etc., to achieve It is beneficial to widely promote the application, shorten the production cycle and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

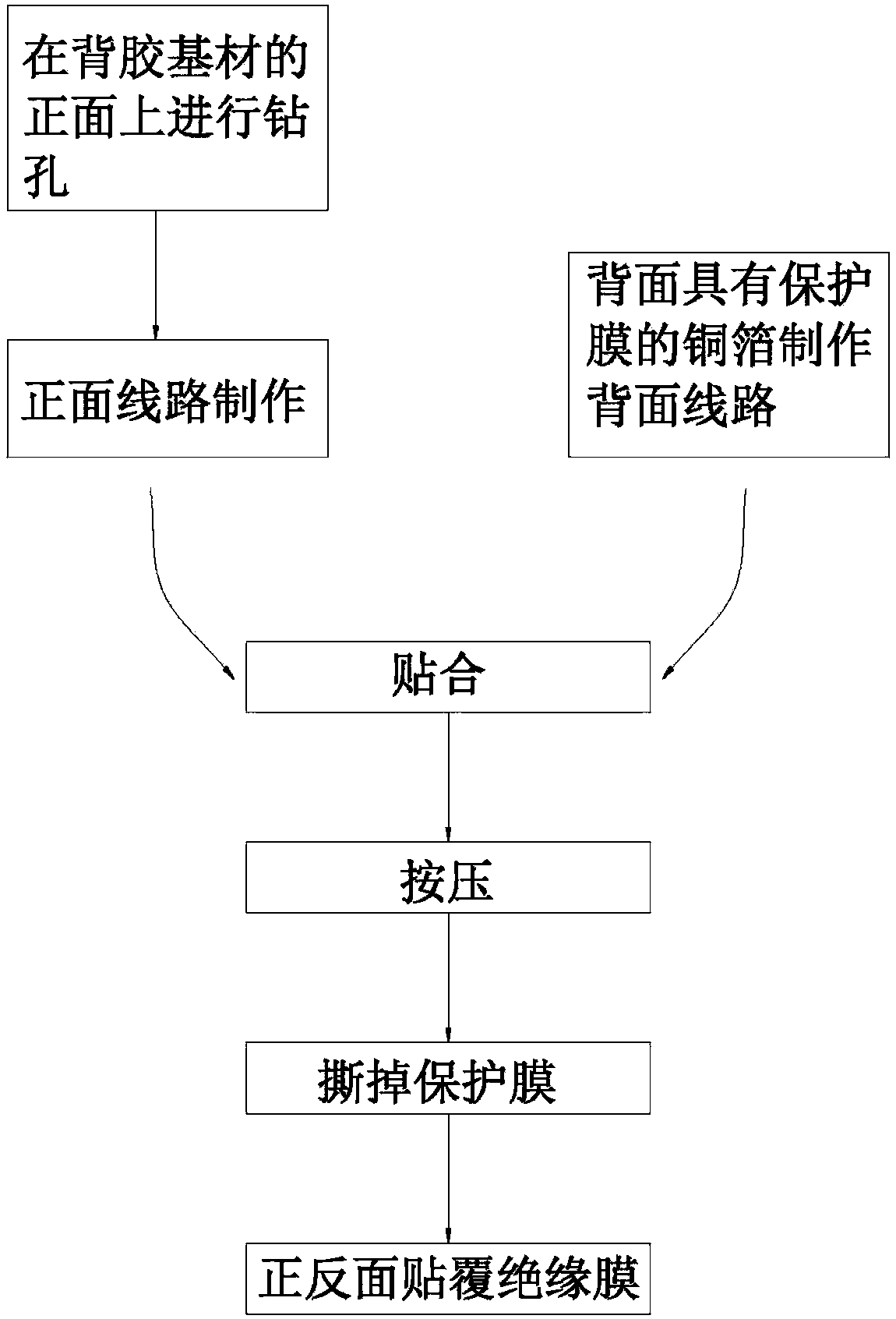

[0021] Example: see figure 1 , a kind of true blind hole circuit board manufacturing process provided by the present embodiment, it comprises the following steps:

[0022] (1) Drill holes on the front side of the adhesive-backed substrate, and then make the front-side circuit; the adhesive-backed substrate is adhesive-backed copper with a thickness of 80-120 microns. Adopt 120 mesh screen printing circuit in the described step (1), the SG of circuit etching cylinder: 1.28-1.32, HCL: 2.0-3.0mol / L, Cu2+: 120~180g / L, temperature 50 ± 2 ℃; Tank concentration 3-5%, temperature 50±2℃;

[0023] (2) The copper foil having a protective film on the back is etched on the back to realize the production of the back circuit; the copper foil is preferably a pure copper foil with a thickness of 18 to 25 microns, and the thickness of the protective film is preferably 55 to 65 microns;

[0024] SG: 1.28-1.32 of the line etching cylinder in the step (2), HCL: 2.0-3.0mol / L, Cu2+: 120~180g / L, te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com