Patents

Literature

51results about How to "Simplify production cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of low-salt oil-free fermented bean curd

InactiveCN102696777APreserve the unique flavorGuarantee quality and safetyCheese manufactureFood scienceAlcoholHot peppers

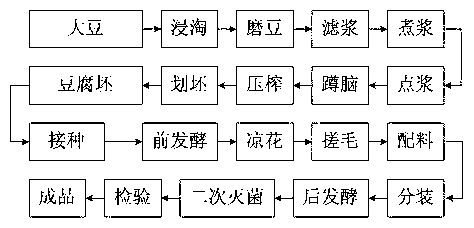

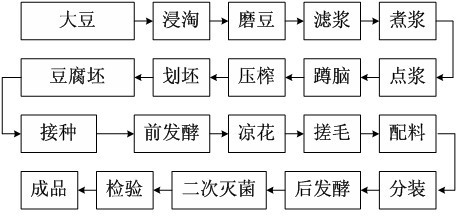

The invention discloses a production process of low-salt oil-free fermented bean curd. The production process comprises the following steps: after performing the steps of immersing and washing soybean, grinding the soybean, filtering pulp, boiling the pulp, mixing pulp, concentrating, squeezing, dividing, inoculating, performing primary fermentation, cooling and mildewing, adding 8 to 10 percent of salt and 6 to 8 percent of alcohol; adding a proper amount of spice such as hot pepper powder, ginger powder, garlic powder and the like according to the traditional process; subpackaging into small bottles in one step; integrating fermenting, storing and finished product packaging materials; vacuumizing, so that the vacuum degree of the small bottle is 0.8 to 1.0; performing secondary fermentation for 1 to 2 months under the natural condition; performing secondary sterilization on the mature fermented bean curd, wherein the sterilization central temperature is 80 to 85 DEG C and the sterilization time is 25 to 35 minutes; and obtaining the finished products after passing inspection. The production process has the advantages that the unique flavor of the local traditional fermented bean curd is maintained; the characteristics of the times are achieved; the production process is fashionable and novel; the edible range is widened; the low-salt oil-free fermented bean curd has high nutritional value and preference, can realize industrial production and is safe and healthy; and quality safety of the oil-free fermented bean curd is effectively guaranteed.

Owner:WANYUAN LICHUAN FOOD COMPREHENSIVE DEV

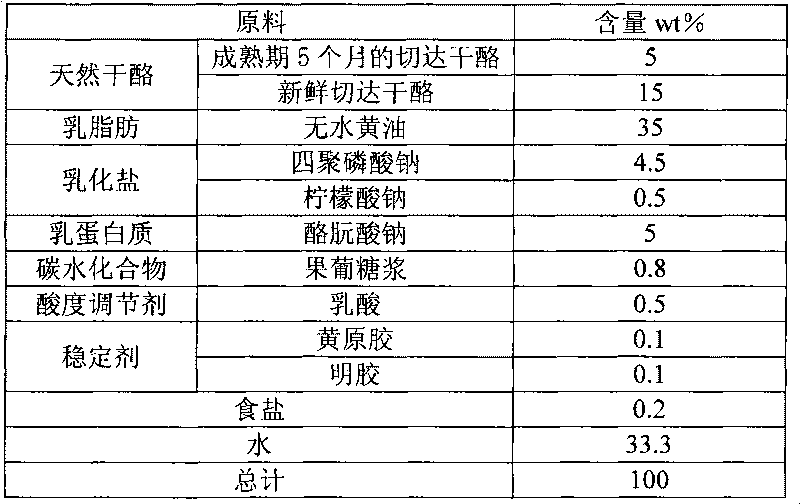

Method for preparing regenerated cream cheese and obtained cheese

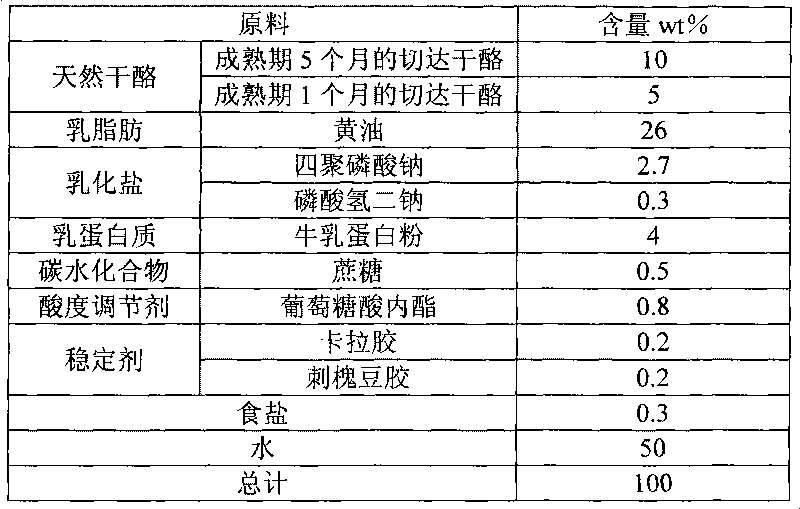

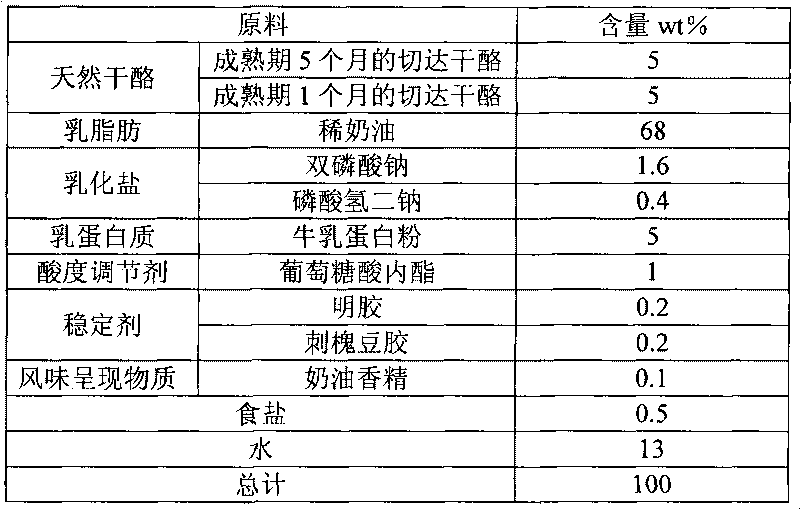

The invention discloses a method for preparing regenerated cream cheese, which comprises the following steps: (1) melting and mixing raw materials comprising natural cheese, milk fat, milk protein, emulsifying salt, carbohydrates, edible salt, stabilizer and water in addition to fermentation acid-producing yak milk type cheese; (2) low-temperature acid-adding process; (3) pasteurization; (4) homogenization process; and (5) fast cooling. The invention can overcome the defects of all aspects of the natural cream cheese process, the existing regenerated cream cheese process, the conventional regenerated cheese process and the like and provides the method for preparing the regenerated cream cheese; compared with the traditional natural cheese production process, the method is greatly simplified and has the advantages of simple production process, small equipment input and short production cycle, thereby having great advantages on the cost, leading a product to have high additional value, leading the better raw materials of the product to have relative advantages on the cost and being more realistic and convenient when in real production. Compared with the natural cheese, the senses of the prepared regenerated cream cheese are better.

Owner:BRIGHT DAIRY & FOOD

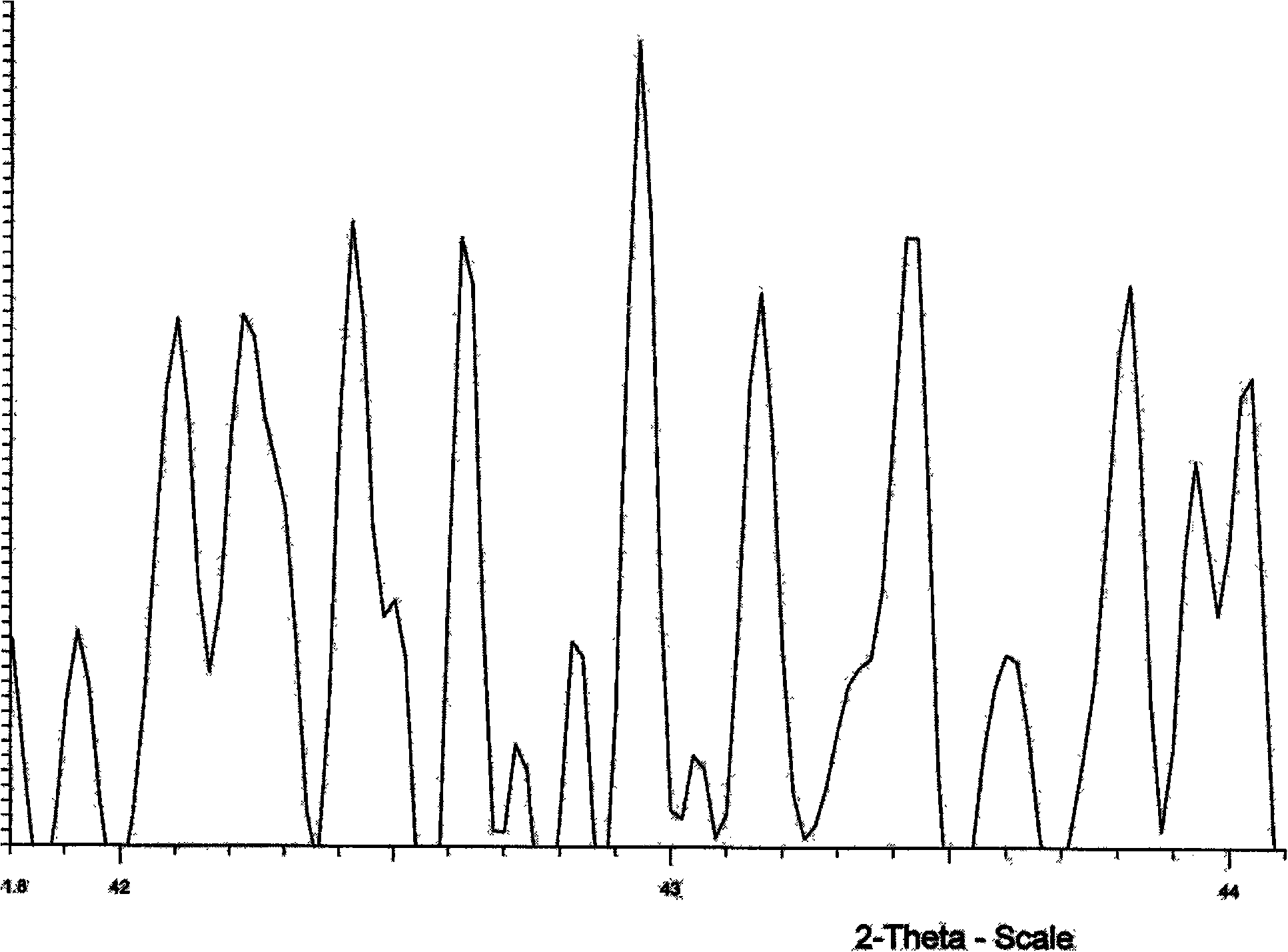

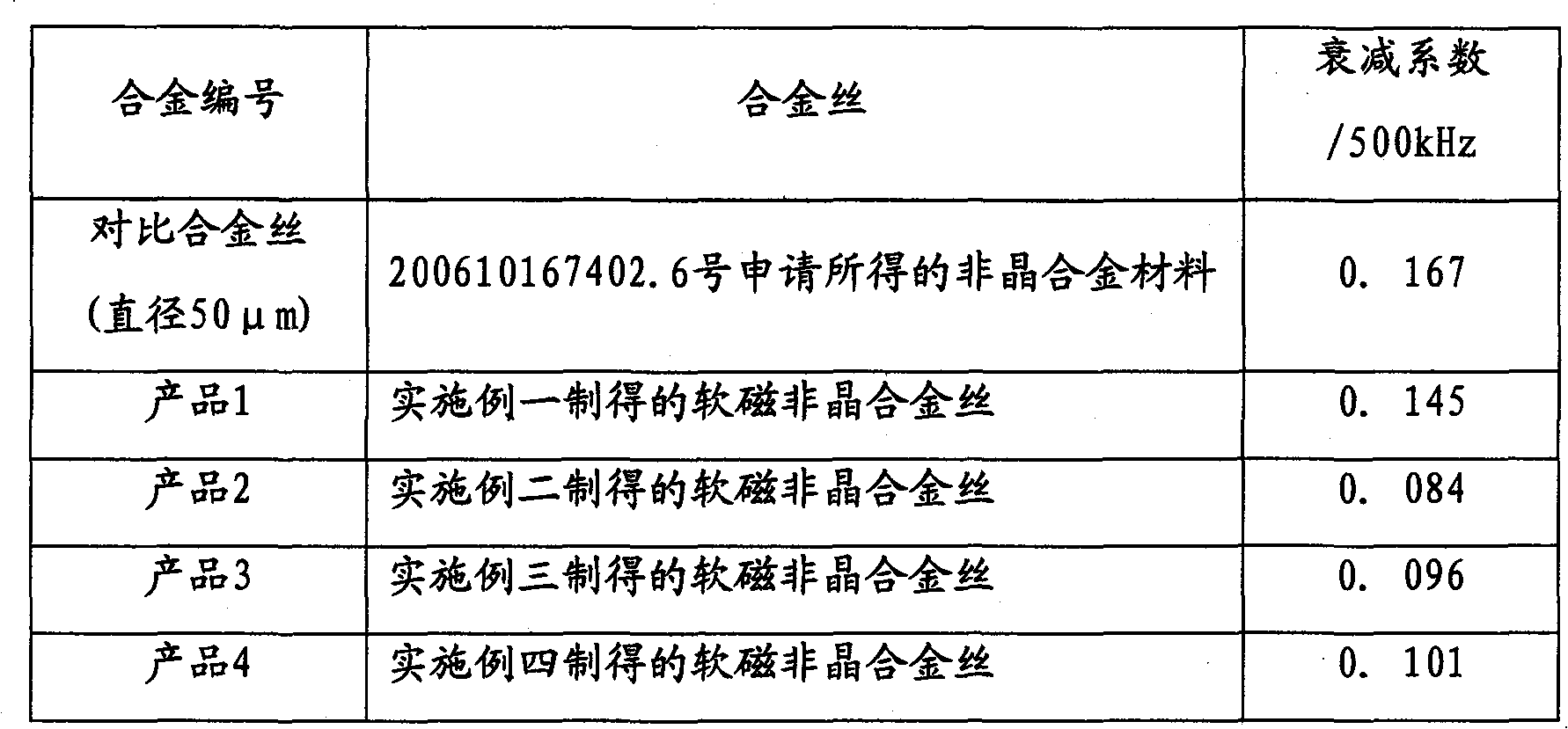

Soft magnetic amorphous alloy wire and preparation method thereof

The invention provides an Fe-based soft magnetic amorphous alloy wire with good magnetic property and low cost. The amorphous alloy wire is made of common raw materials, and alloy has low cost. The invention also provides a method for preparing the soft magnetic amorphous alloy wire. The method has simple processing equipment and convenient operation. The soft magnetic amorphous alloy wire comprises the following components in percentage by weight: 2 to 6 percent of Zr, 2 to 4 percent of Cu, 0.05 to 0.1 percent of Pr, 0.01 to 0.05 percent of Ce, 4 to 8 percent of B, 1 to 3 percent of Si, 3 to 6 percent of Al, 2 to 5 percent of P and the balance of Fe. The diameter of the alloy wire is between 5 and 100 mu m.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

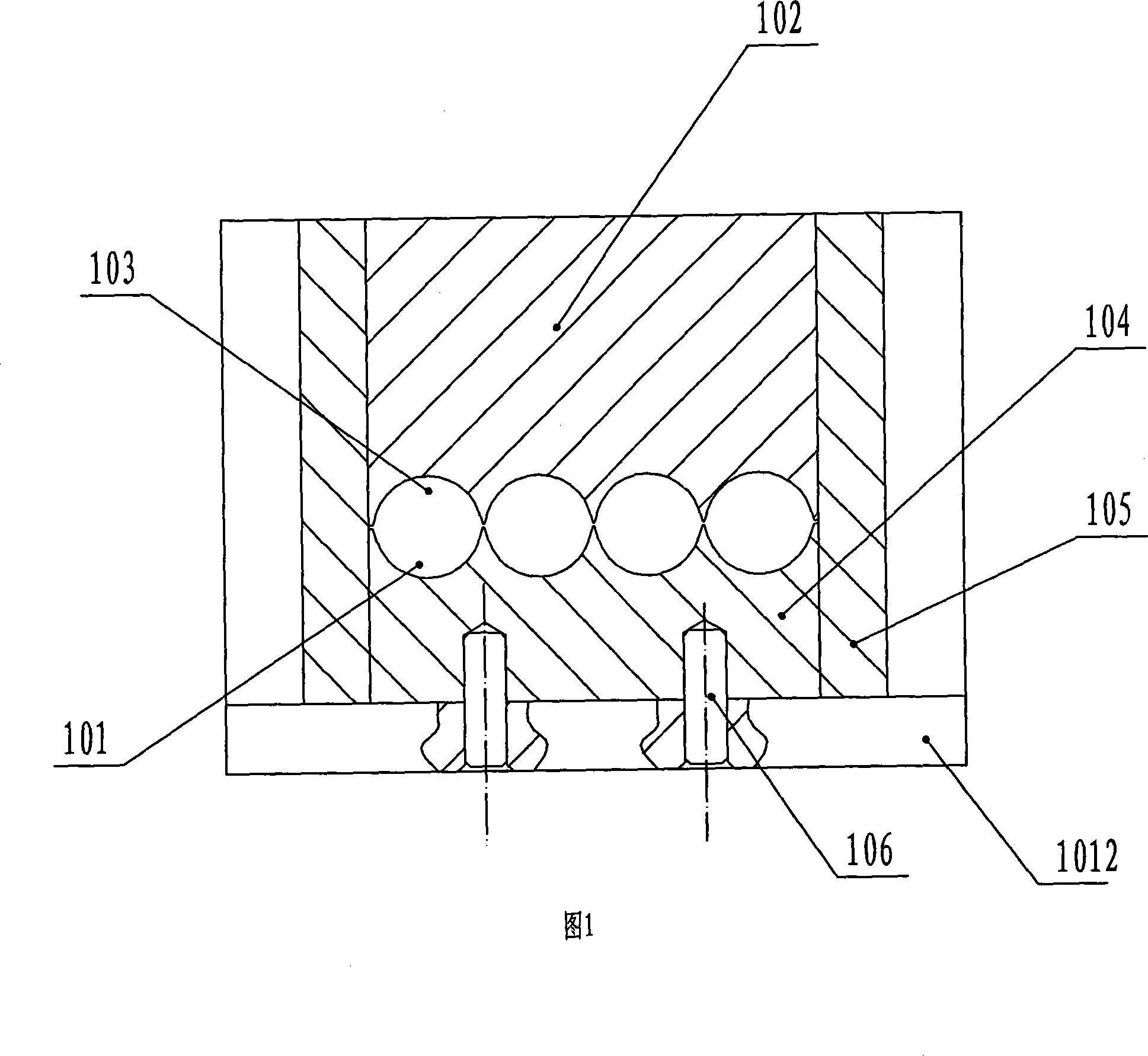

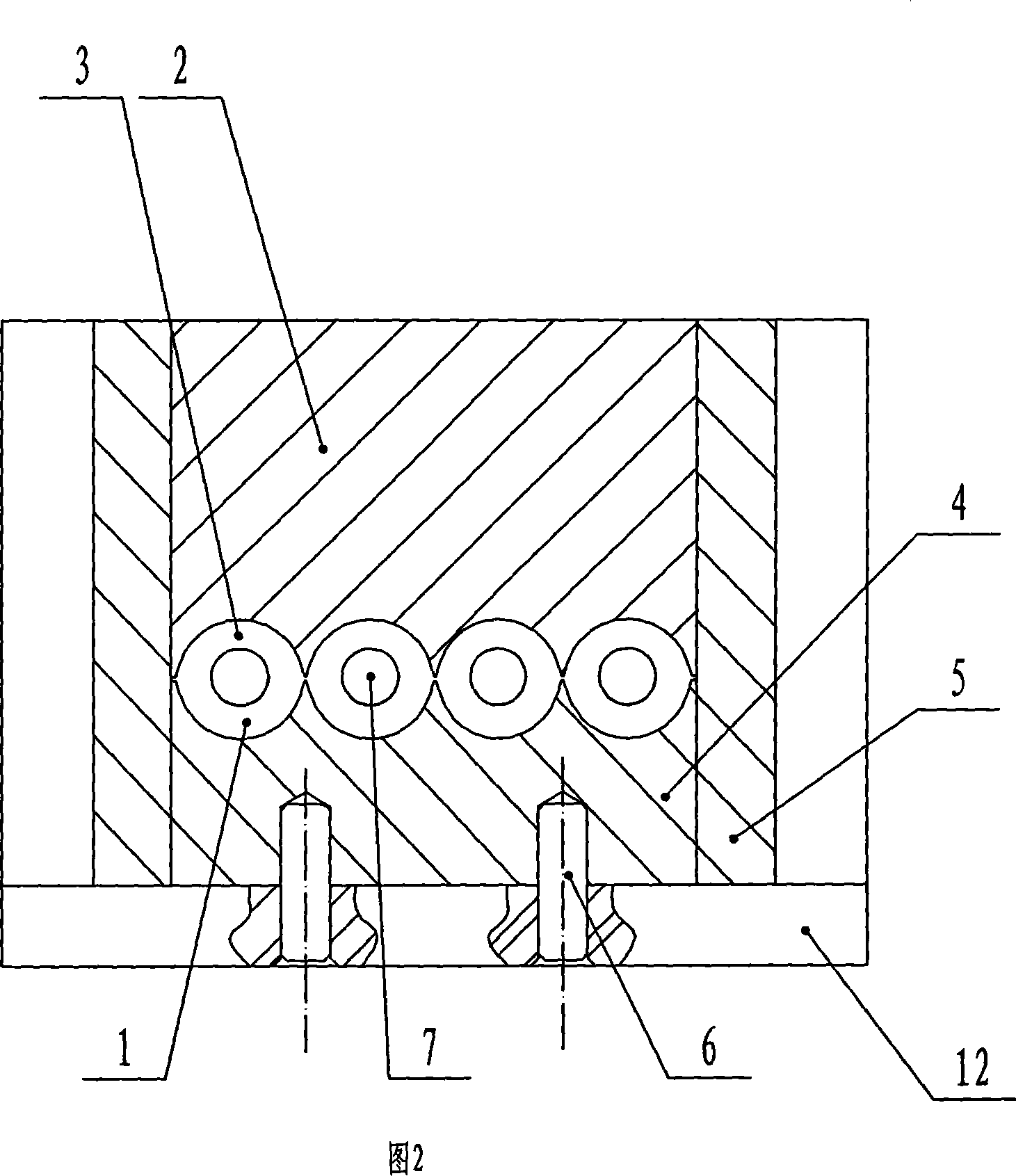

Neodymium-iron-boron cylindrical form permanent magnetic material with longitudinal through-hole molding method and special moulds

The invention discloses a forming method of Nd-Fe-B cylindrical permanent magnetic material which is equipped with a vertical through hole; a metal internal lower mold (4) is combined with a metal external mold and half of the quantitative starch is poured into the combination; and then a first metal internal upper mold is inserted and a magnetic field forming press is used for obtaining the lower cylindrical permanent material; stripping; the first metal upper mold is taken out and a metal round rod (7) is put in the semi-circle hole of lower semi-cylindrical permanent magnetic material and the other half of the starch is poured in and then a second metal internal upper mold (2) is inserted to be formed on the magnetic field forming press; the metal round rod (7) is taken out after stripping and the Nd-Fe-B cylindrical permanent magnetic material (11); the special mold is characterized in that one metal internal lower mold (4) is matched with two metal internal upper mold. The invention reduces the waste of material and promotes the product yield; at the same time, the production efficiency is increased and the production cost is reduced.

Owner:NINGBO JUYOU MAGNETIC IND

Technological process for producing brass pipe through upwards continuous casting, continuous rolling and drawing

InactiveCN102009078AReduce lossSimple processMetal rolling arrangementsZinc alloysContinuous rolling

The invention provides a technological process for producing brass pipes. The flow of the technological process comprises the following steps of: melting electrolytic copper or red impure copper and metallic zinc ingots or copper-zinc alloy brass complex materials through a melting furnace; fusing to generate copper-zinc alloy melts; enabling the copper-zinc alloy melts to enter a heat preserving furnace through a channel for heat preservation; then crystallizing through a crystallizer and cooling; carrying out upwards continuous casting to produce brass pipe blanks through a hauling machine; and subsequently rolling and drawing the brass pipe blanks into finished pipes. Compared with the traditional technological process, the technological process adopted in the invnetion simplifies a plurality of complex processes, i.e. melting, round copper billet casting, scaling, punching, heating, extruding and drawing, into the processes of upwards continuous casting, continuous rolling and the drawing, thereby greatly simplifying the process flow; and in addition, the technological process has the advantages of simple process, high finished product ratio, low energy consumption, little metal loss, almost no pollution and low labor intensity of workers and production cost and is the simplest and most efficient processing technology of technological processes for producing the brass pipes at present.

Owner:高玉树

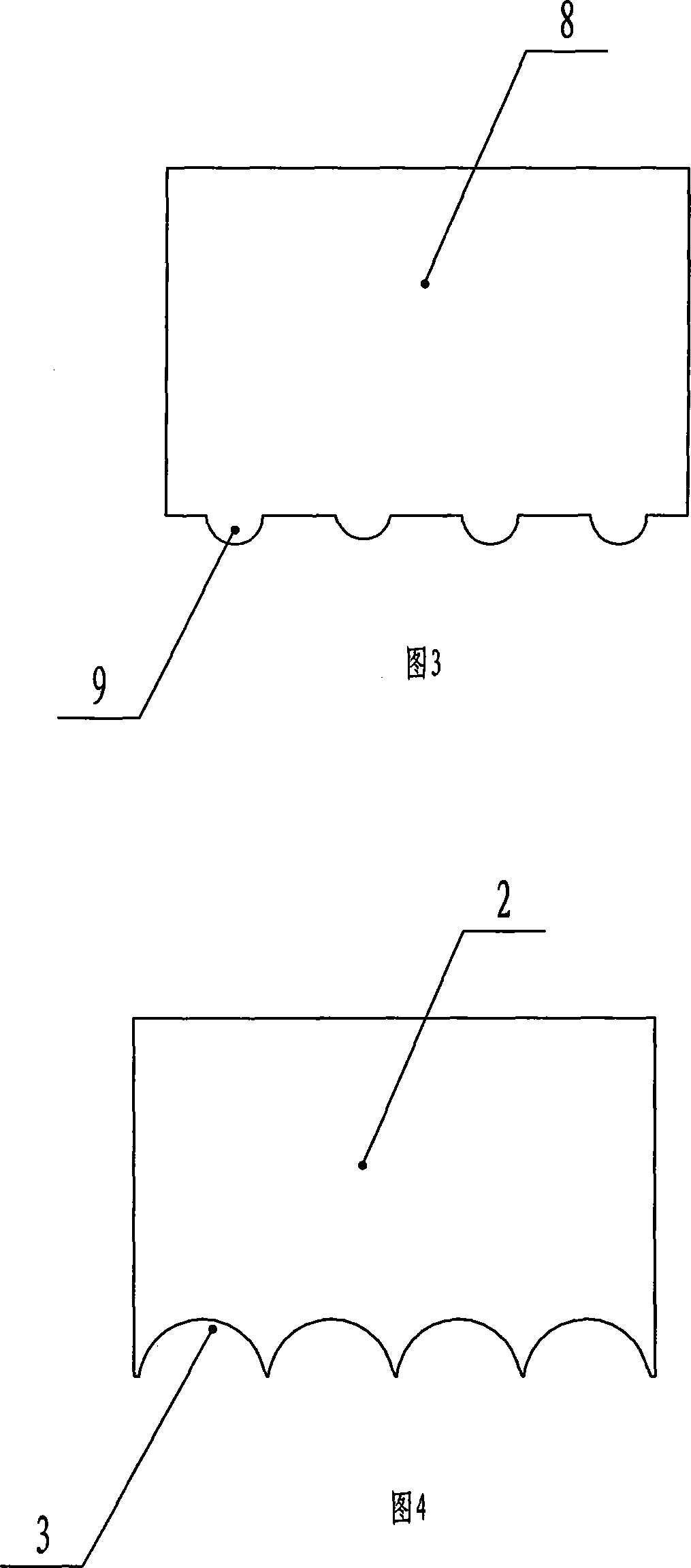

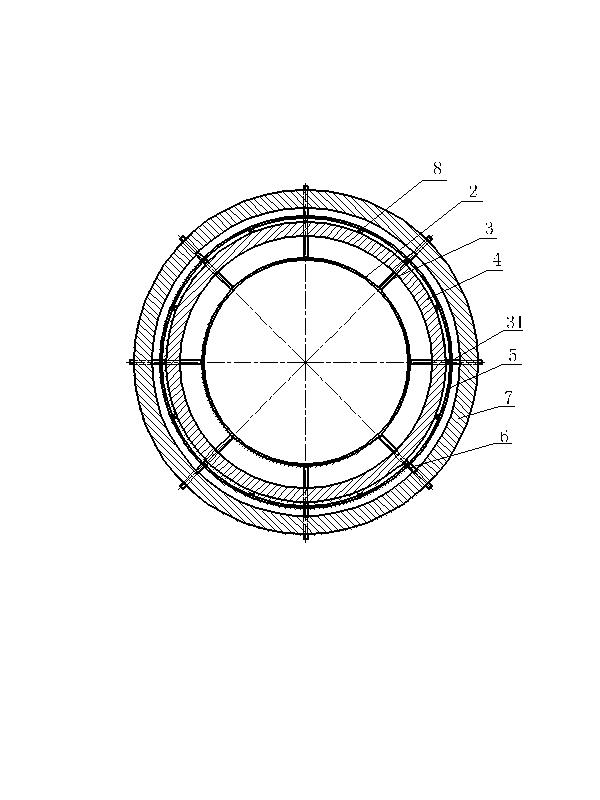

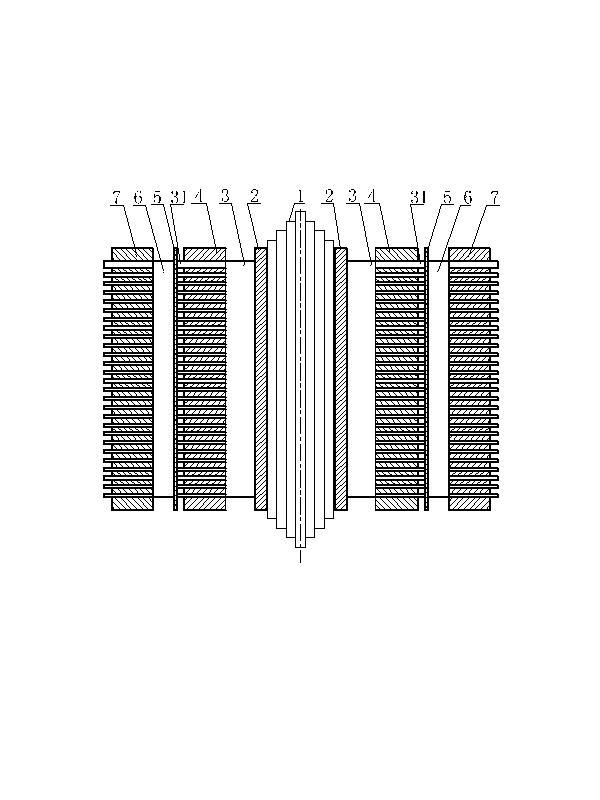

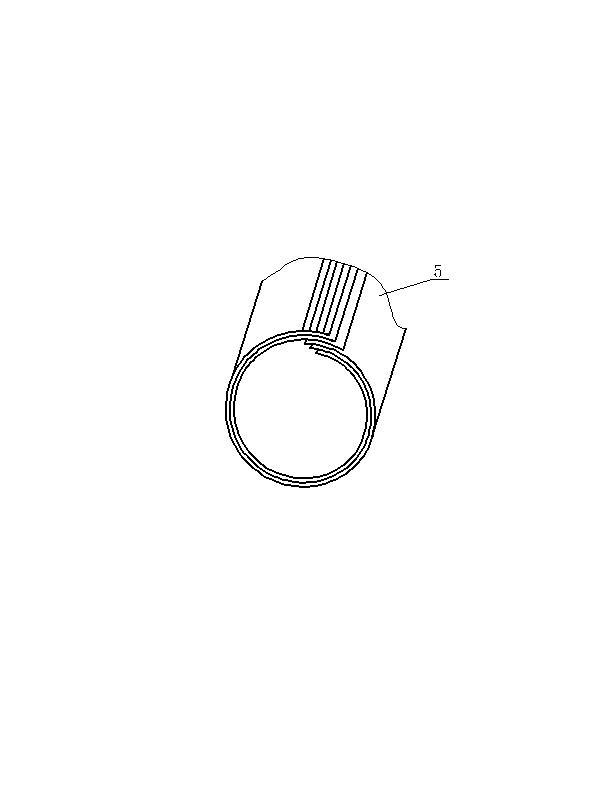

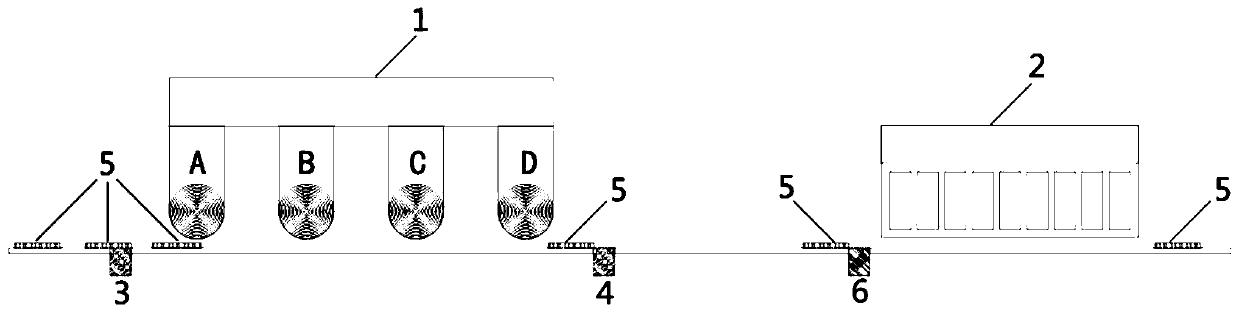

Co-wound high-voltage and low-voltage coil of transformer and winding method of co-wound high-voltage and low-voltage coil

ActiveCN102568772AReduce process stepsSimple winding processTransformers/inductances coils/windings/connectionsCoils manufactureEngineeringHigh pressure

The invention discloses a co-wound high-voltage and low-voltage coil. The co-wound high-voltage and low-voltage coil comprises an iron core and a high-voltage insulating barrel, wherein the high-voltage insulating barrel is arranged at the outer part of the iron core, a high-voltage coil supporting bar is arranged on an outer surface of the high-voltage insulating barrel, and a high-voltage coil is wound at the outer part of the high-voltage coil supporting bar. The co-wound high-voltage and low-voltage coil is characterized in that the high-voltage coil supporting bar is provided with a protruding end relative to the high-voltage coil, a low-voltage soft paper barrel is arranged at the outer part of the protruding end of the high-voltage coil supporting bar, a low-voltage coil supporting bar is arranged at the outer circumference of the low-voltage soft paper barrel, and a low-voltage coil is wound at the outer part of the low-voltage coil supporting bar. According to the invention, the problems of complex winding process and much tooling equipment of the high-voltage and low-voltage coil in the prior art are solved. The co-wound high-voltage and low-voltage coil has the advantages of simple structure, simple winding process, high production efficiency and low cost.

Owner:NEWONDER SPECIAL ELECTRIC

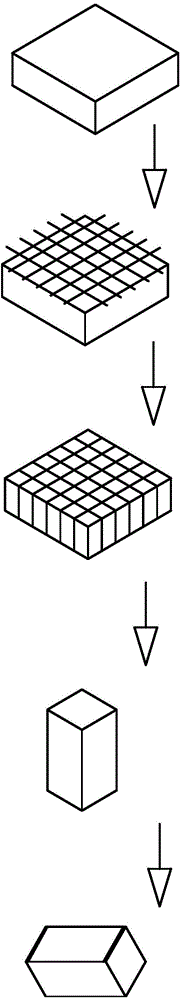

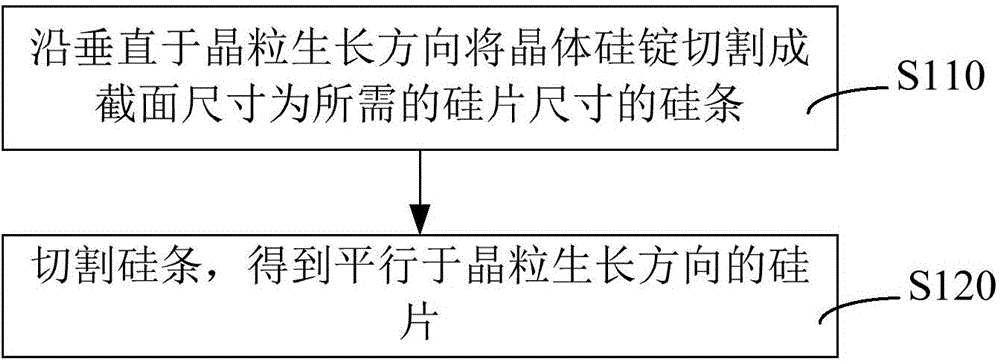

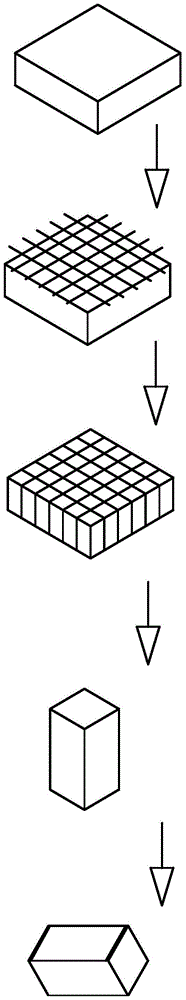

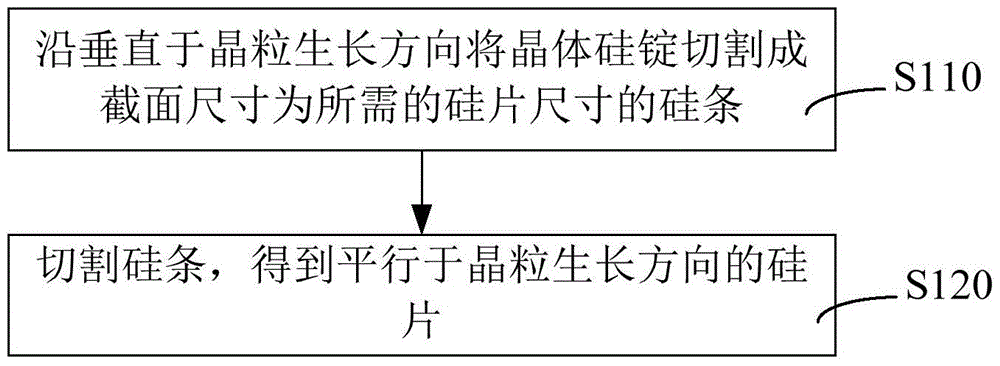

Cutting method of crystalline silicon ingot

ActiveCN104441276AQuality improvementOmit the truncation processFine working devicesIngotCrystalline silicon

The invention relates to a cutting method of a crystalline silicon ingot. The cutting method comprises the steps that the crystalline silicon ingot is cut in the direction perpendicular to the grain growth direction into silicon bars with the section size equal to the size of needed silicon wafers; the silicon bars are cut to obtain the silicon wafers with the grain direction parallel with the grain growth direction. According to the cutting method, the crystalline silicon wafers with the grain direction parallel with the grain growth direction are directly obtained through one-time radication and one-time wafer cutting, the cutting-off process is omitted, the production cycle is shortened, production efficiency is improved, the large-grain polycrystalline silicon wafers with the grain direction parallel with the grain growth direction can be obtained, grain boundaries are reduced, and the quality of the silicon wafers is improved.

Owner:JIANGSU XIEXIN SILICON MATERIAL TECH DEV

Vitis heyneana wine preparation method

InactiveCN105316148AMaintain aroma propertiesGuaranteed health benefitsWine preparationBiotechnologySucrose

The invention discloses a vitis heyneana wine preparation method. Vitis heyneana wine is prepared from, by weight, 80-100 parts of vitis heyneana, 20-30 parts of saccharose and 3-5 parts of saccharomyces cerevisiae. The vitis heyneana wine preparation method includes the steps of stemming and crushing fresh mature vitis heyneana to prepare vitis heyneana juice, adding the saccharose and sulfur dioxide into the vitis heyneana juice, inoculating the saccharomyces cerevisiae, and performing alcoholic fermentation at the fermentation temperature of 22-25 DEG C for 3-5 days hermetically so as to obtain primary fermentation broth; fermenting the primary fermentation broth in a hermetic vessel at the fermentation temperature of 25-28 DEG C for 20-30 days so as to obtain secondary fermentation broth; fermenting the secondary fermentation broth in the hermetic vessel for fermentation for 6-8 months until wine sediments sink naturally so as to obtain raw vitis heyneana wine; freezing, clarifying, filtering and sterilizing the raw vitis heyneana wine so as to obtain a finished product. The vitis heyneana wine preparation method has the advantages that final alcoholicity of the vitis heyneana wine product is increased, so that the vitis heyneana wine is mellower and fuller in taste, and the original healthcare effect of a vitis heyneana fruit wine product is kept.

Owner:LUOCHENG MULAO AUTONOMOUS COUNTY YONGFU ECOLOGICAL PLANTING & BREEDING FARMERS SPECIALIZED COOP

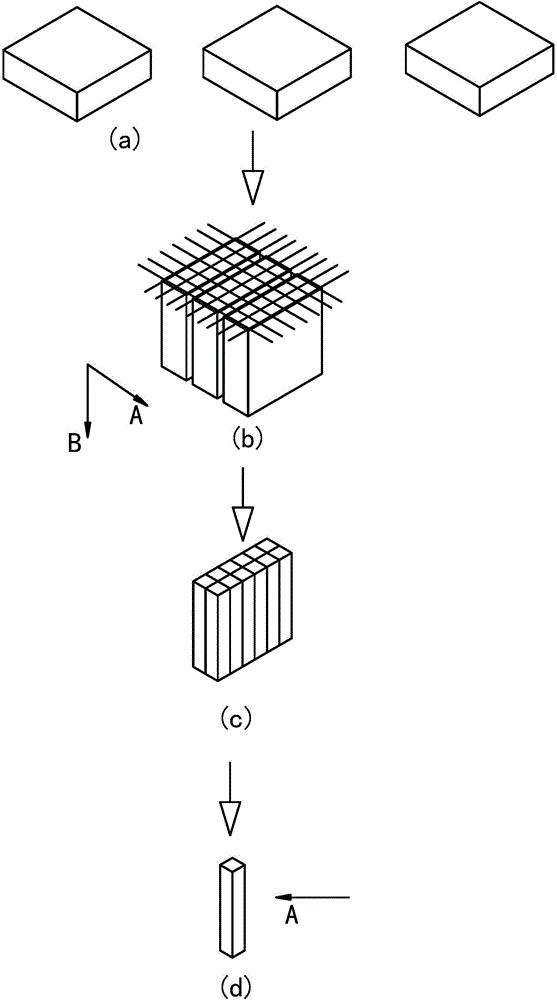

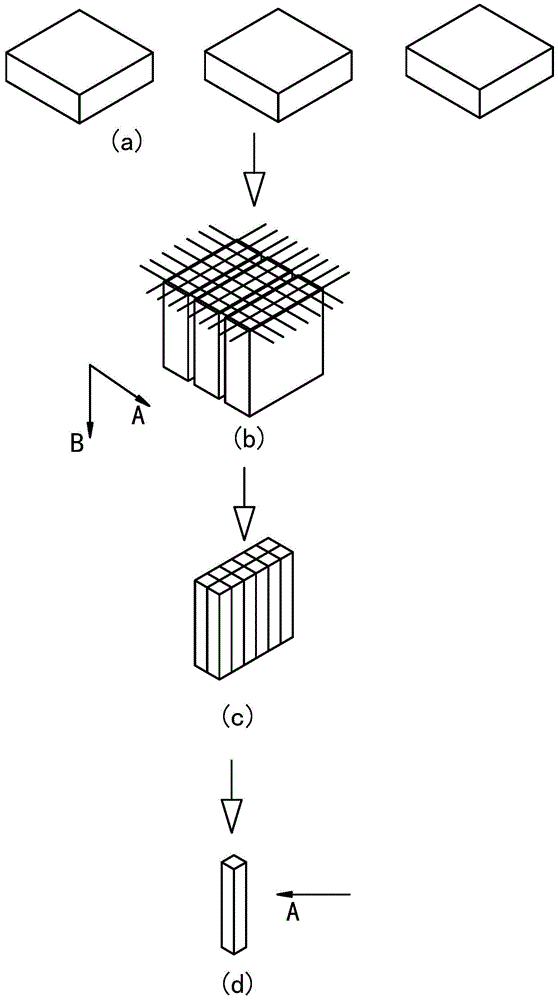

Manufacturing method of low-foaming arctic-ocean red grape sparkling wine

The invention relates to a manufacturing method of low-foaming arctic-ocean red grape sparkling wine. The arctic-ocean red grape sparkling wine manufactured by the method has the advantages that the fragrance characteristic of grape fruits are maintained, the defect of rough taste caused by low-sugar peracid is overcome and the brewing process is simplified. The manufacturing method comprises the following operation steps of: (1) material sorting: firstly adopting arctic-ocean red grape as a material of low-sparkling wine; (2) low-temperature pressing; (3) clarification and deacidification; (4) alcohol fermentation; (5) fermentation of a sealing tank; (6) fermentation stopping; (7) cold storage and aging; and (8) constant-pressure filtration and filling.

Owner:NORTHWEST A & F UNIV

Processing method for refrigerator bottom plate stamping part

InactiveCN106862379AFlat surfaceLight and thin materialMetal rolling arrangementsSheet steelRoom temperature

The invention discloses a processing method for a refrigerator bottom plate stamping part. The processing method comprises the following steps: after heating a steel billet, rolling the steel billet to form a steel plate, carrying out heat treatment on the steel plate, and finally, cooling the steel plate to the room temperature; carrying out deep stamping formation on the steel plate by using a stamping die to preliminarily prepare the geometrical shape and size of the required refrigerator bottom plate stamping part; carrying out edge cutting, edge folding, punching and bending on the steel plate, pressing the treated steel plate into a die to stamp, then, taking out the steel plate, and bending and indenting the steel plate; and finally, carrying out surface finishing, checking the quality after completing the treatment, and leaving the product from a factory if the quality is qualified. The processing method for the refrigerator bottom plate stamping part, disclosed by the invention has the advantages of simple processing procedures, simplicity in operation, high production and processing efficiencies, high finished product rate and low processing cost so as to be suitable for industrial production. The refrigerator bottom plate stamping part prepared by using the processing method has the characteristics of light and thin material, high strength, good rigidity, smooth surface and high size precision so as to be worthy of popularization.

Owner:CHUZHOU XINKANGDA METAL PROD

Production method and production line for ceramic tiles in which fixed patterns dynamically printed through rubber-covered rollers correspond to ink-jet patterns dynamically printed through ink jetting

ActiveCN110039922ARealize printingMeet the needs of personalized decorationDuplicating/marking methodsCeramic shaping apparatusProduction lineBrick

The invention relates to the technical field of ceramic decoration, in particular to a production method and a production line for ceramic tiles in which fixed patterns dynamically printed through rubber-covered rollers correspond to ink-jet patterns dynamically printed through ink jetting. The method includes the steps that a, the printing programs and sequences of a rubber-covered roller printing machine and a digital ink-jet printing machine are preset; b, one corresponding fixed pattern is printed in the fixed region of a ceramic tile blank by each rubber-covered roller; and c, one corresponding ink-jet pattern is printed in the fixed region of the ceramic tile blank, wherein the sequences of the step b and the step c can be interchanged, the step d further exists between the step b and the step c, and the fixed patterns dynamically printed through the rubber-covered rollers correspond to the ink-jet patterns dynamically printed through ink jetting. The fixed patterns dynamically printed through the rubber-covered rollers correspond to the ink-jet patterns dynamically printed through ink jetting one to one, pattern textures can be correspondingly overlapped, and therefore multiple ceramic decorative tiles with fixed pattern textures, special process effects and textures can be produced at a time.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +3

Method for extracting and preparing high-content dihydromyricetin from ampelopsis grossedentata

PendingCN112028865ASimple processShort production cycleOrganic chemistryAlcoholic beverage preparationEnvironmental chemistryAlcohol ethyl

The invention discloses a method for extracting and preparing high-content dihydromyricetin from ampelopsis grossedentata, which is used for preparing the high-content dihydromyricetin through the steps of extraction, separation, ethanol recrystallization and the like. Only solvent water and ethyl alcohol are used, and the method has the advantages of being free of pollution, simple in process, convenient to operate, high in benefit and the like and is suitable for production of dihydromyricetin.

Owner:劲牌持正堂药业有限公司

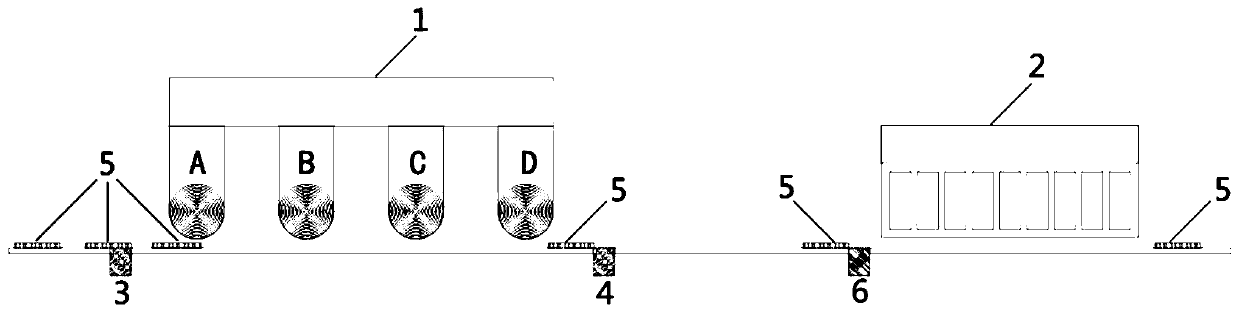

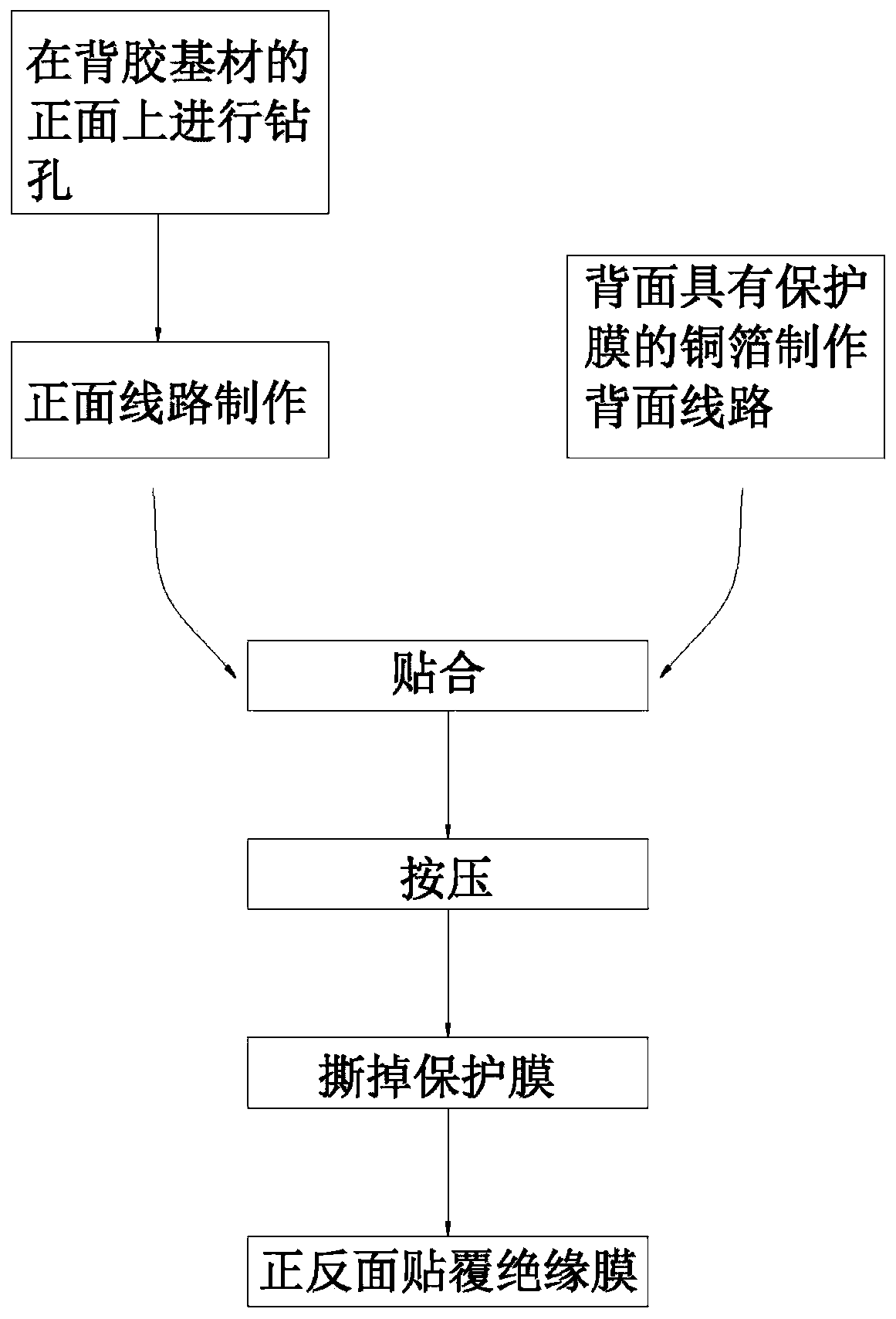

True blind hole circuit board making process

InactiveCN108184313AReduce the chance of wrinklingSimple processMultilayer circuit manufactureTectorial membraneEtching

The invention discloses a true blind hole circuit board making process. The process comprises steps that (1), drilling on a front side of a gum base material is carried out, and front side circuit making is carried out; (2), back etching of a copper foil having a protection film on the back side is carried out to make a back side circuit; (3), a back side of the gum base material and a front sideof the copper foil are bonded; (4), the gum base material and the copper foil which are bonded are pressed to synthesize a board body; (5), the protection film on the copper foil is torn; and (6), insulation films are pasted on front and back sides of the board body. The process is advantaged in that the process is simple, the circuits at the back and front sides are produced simultaneously, bonding is then carried out, the integral process steps are effectively and integrally simplified, the production period is greatly shortened, production efficiency is improved, manpower and material resources are effectively saved, production cost is reduced, the back side of the copper foil is supported through employing the protection film, the wrinkle rate of the copper foil is effectively reduced,the yield is improved, product quality is guaranteed, and wide popularization and application are facilitated.

Owner:东莞市天晖电子材料科技有限公司

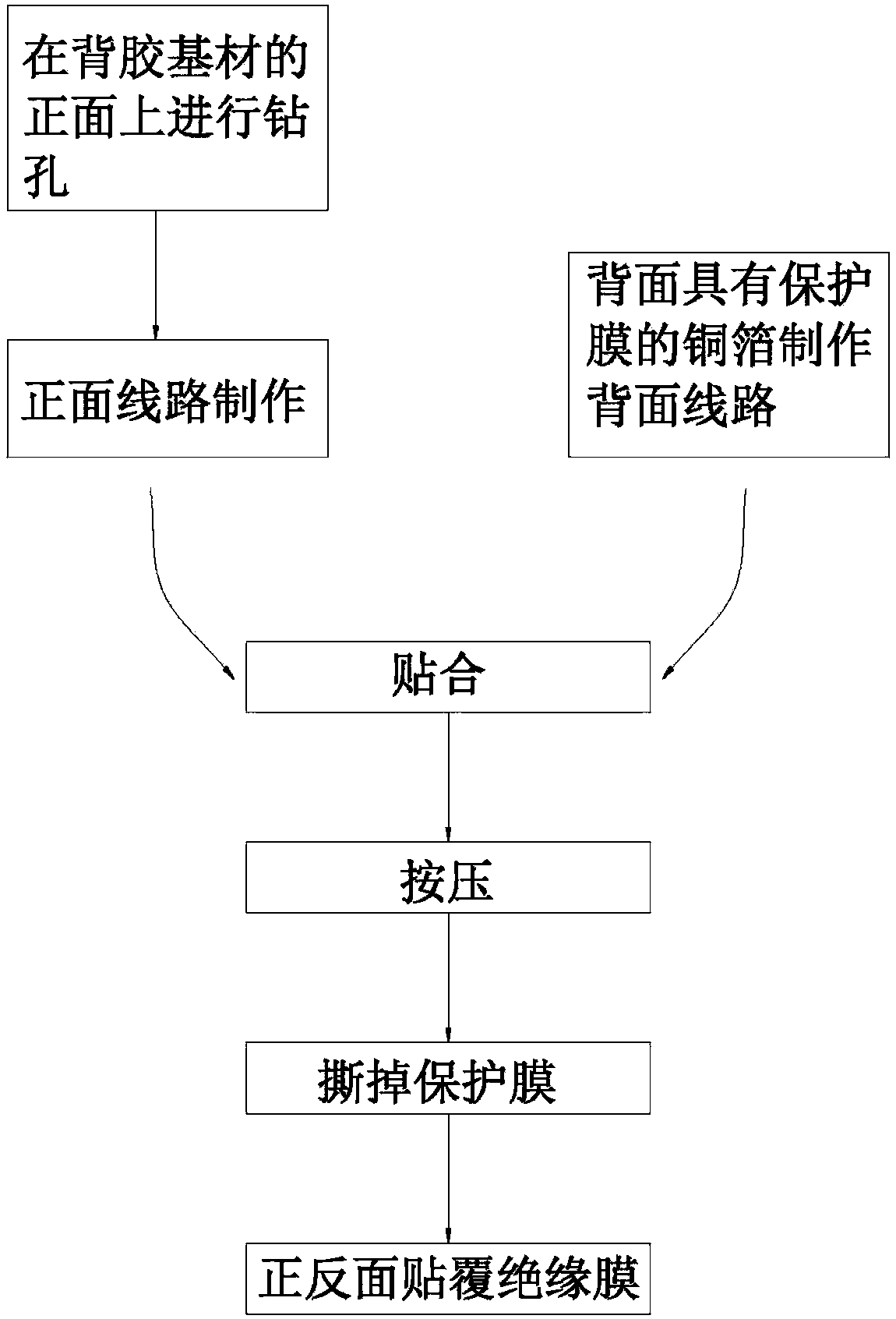

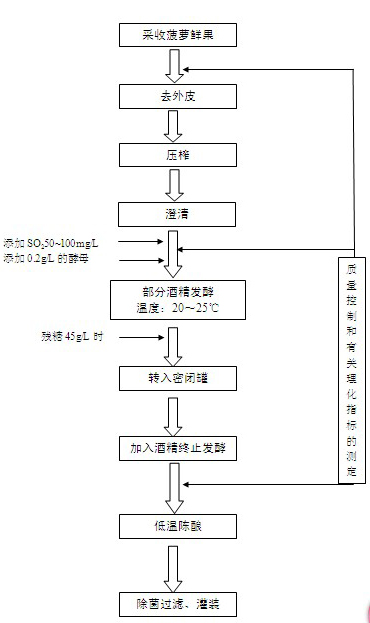

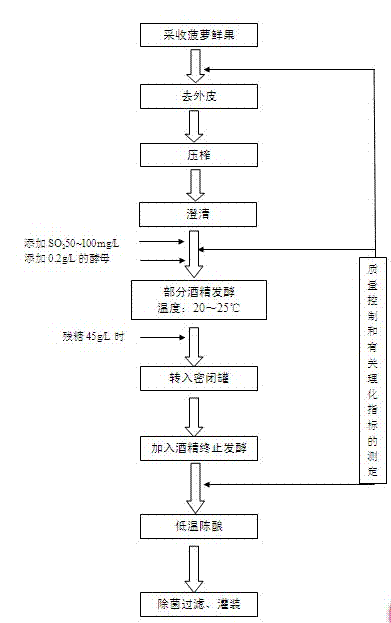

Method for making full pineapple juice sweet wine

ActiveCN102220212AQuality improvementPleasant wineMicroorganism based processesAlcoholic beverage preparationFruit wineAlcohol

The invention relates to a method for making full pineapple juice sweet wine, which can retain the original fragrance, natural value, natural alcohol volume and residual sugar of pineapple fruit, avoid damaging the mouthfeel of the fruit wine by adding sugar manually and simplifying the brewing process. The method comprises the following operation steps: (1) controlling the maturity of the raw material; (2) grinding, squeezing, and adding sulfur dioxide; (3) defoaming mechanically; (4) clarifying; (5) fermenting part of alcohol; (6) adding alcohol and terminating fermentation; (7) adding sulfur dioxide and separating; (8) refrigerating and aging; and (9) sterilizing, filtering and bottling.

Owner:NORTHWEST A & F UNIV

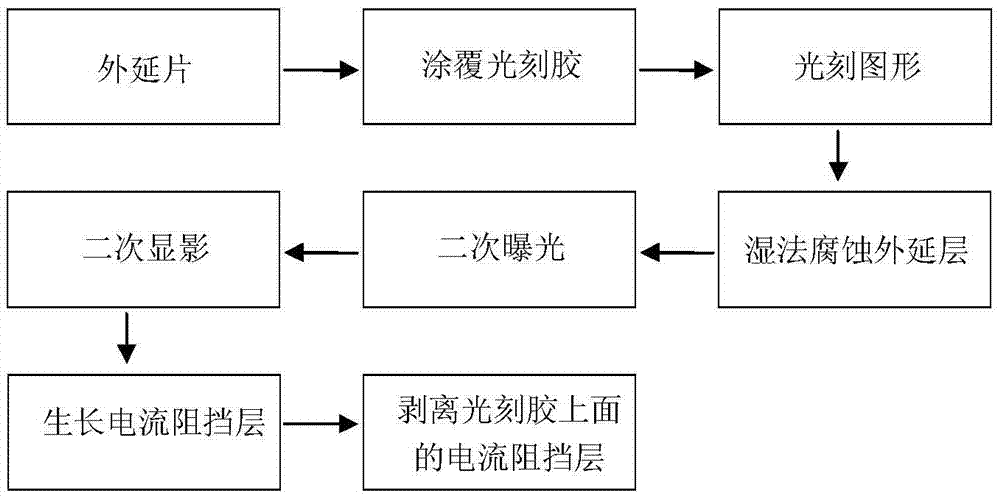

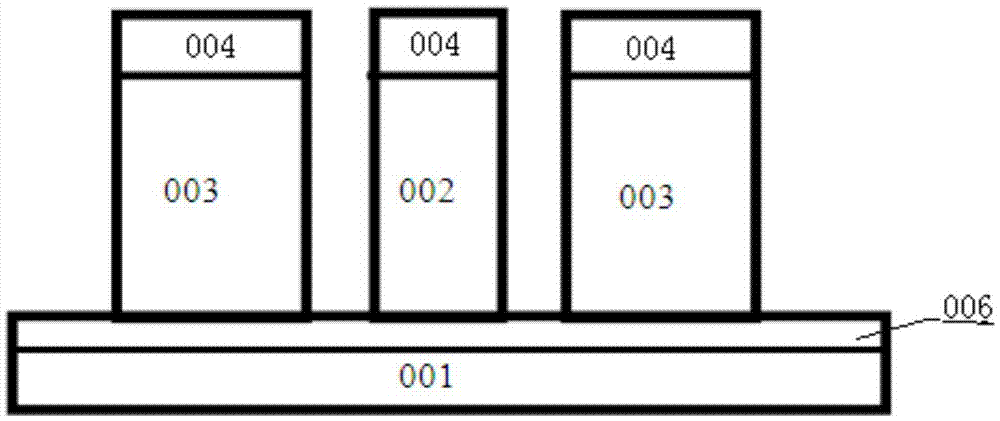

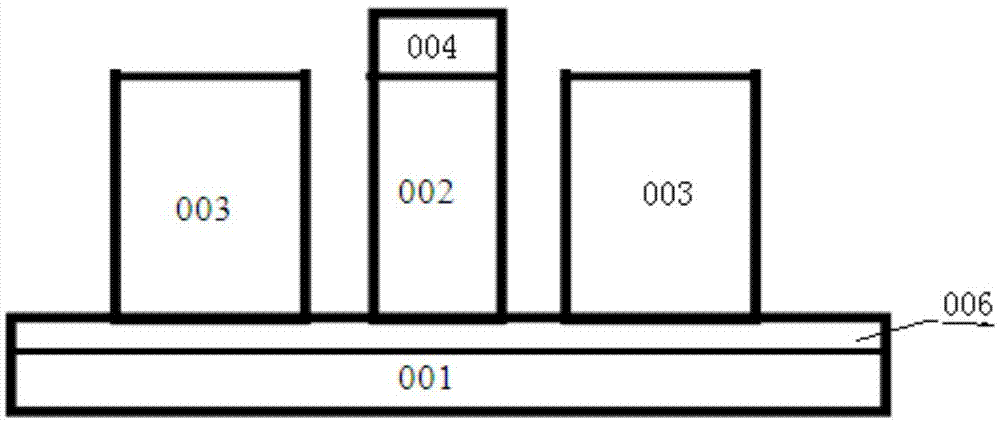

Double-shoulder-ridge GaAs-based laser preparation method and GaAs-based laser prepared therethrough

InactiveCN105449519AReduce consumptionWon't hurtOptical wave guidanceLaser detailsEvaporationOptoelectronics

The invention discloses a double-shoulder-ridge GaAs-based laser preparation method, and the method comprises the following steps: carrying out exposure, development and corrosion through employing a photoetching mask and preparing a needed pattern structure; carrying out secondary exposure; carrying out secondary development; growing a current blocking layer on an epitaxial wafer after the secondary development; peeling the current blocking layer of a photoresist place at the top of a ridge structure, forming a current injection window, carrying out the evaporation and thinning of a P-plane electrode, carrying out the evaporation, alloying and packaging of an N-plane electrode, and forming a GaAs-based laser. The method saves a part of steps in a conventional technology: removing photoresist after corrosion, growing the current blocking layer, and carrying out the pattern corrosion of the current blocking layer in a nesting mode. The method cannot damage to the epitaxial layer on a substrate, is convenient to operate, simplifies the technological steps, shortens the production cycle, and reduces the consumption of raw materials.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Production method of frozen konjac

InactiveCN108433053ARetain nutrientsGreat tasteFood freezingFood ingredient as gelling agentFood processingChemistry

The present invention relates to the field of food processing and particularly relates to a production method of frozen konjac. The method comprises the following steps: raw material preparing, stirring and puffing, static puffing, refining and stirring, gelation treating, extrusion molding, heat shaping, cutting, water permeating, quick-freezing, thawing and dehydrating. The production method overcomes the shortcomings of the prior art that the manufacture time and period of the frozen konjac are long, processes are complicated, device costs are high, manual operation is inconvenient, etc. Compared with the frozen konjac manufactured by the traditional method, the manufactured frozen konjac by the method is good in mouthfeel; the manufacture time is short; the method is simple and easy; the device cost is low; and the manual operation is convenient.

Owner:安徽旺德福食品有限公司

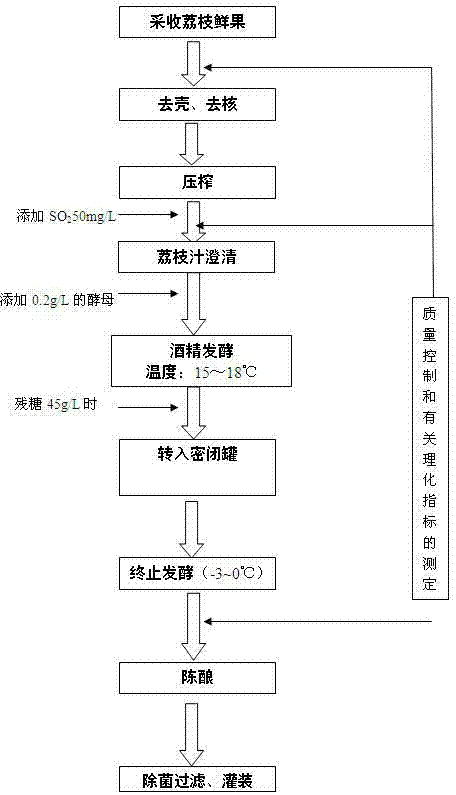

Preparation method of full-juice lichi sweet wine

ActiveCN102212444BQuality improvementMaintain aroma propertiesAlcoholic beverage preparationMicroorganism based processesFruit wineAlcohol content

The invention relates to a preparation method of wine, in particular to a preparation method of full-juice lichi sweet wine. In the preparation method, lichi fresh fruits serve as raw materials of the full-juice sweet wine, so the intrinsic fragrance of the lichi fruits is maintained, the natural value of the lichi fruits is preserved, the natural alcohol content and the residual sugar of the lichi fruit are retained, damage to mouthfeel of the fruit wine caused by artificially sugaring is avoided, and the brewing process is simplified. The preparation method comprises the following operating steps of: (1) harvesting the lichi fresh fruits serving as the raw materials; (2) removing shells and kernels; (3) juicing the lichi and adding sulfur dioxide into the juice; (4) clarifying; (5) performing alcoholic fermentation; (6) revolving a tank; (7) stopping fermentation; (8) refrigerating and ageing; and (9) degerming, filtering and encapsulating.

Owner:NORTHWEST A & F UNIV

Cutting method of crystalline silicon ingot

ActiveCN104441276BQuality improvementOmit the truncation processFine working devicesIngotCrystalline silicon

The invention relates to a method for cutting a crystalline silicon ingot, which comprises the following steps: cutting the crystalline silicon ingot into silicon strips whose cross-sectional size is the required silicon sheet size along the direction perpendicular to the crystal grain growth; cutting the silicon strips to obtain silicon wafer in the direction of grain growth. The above cutting method directly obtains a crystalline silicon wafer parallel to the growth orientation of the crystal grain through one square extraction and one slicing process. This method omits the truncation process, simplifies the production cycle, and improves the production efficiency. Growth-oriented polycrystalline silicon wafers with larger grains reduce grain boundaries and improve the quality of silicon wafers.

Owner:JIANGSU XIEXIN SILICON MATERIAL TECH DEV

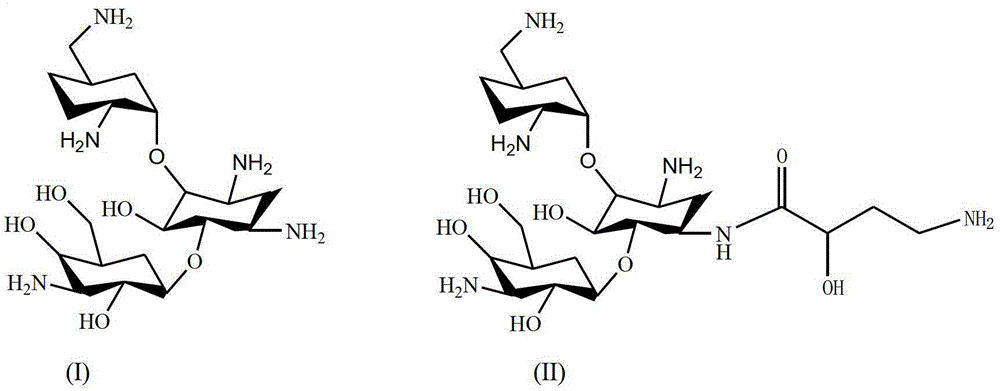

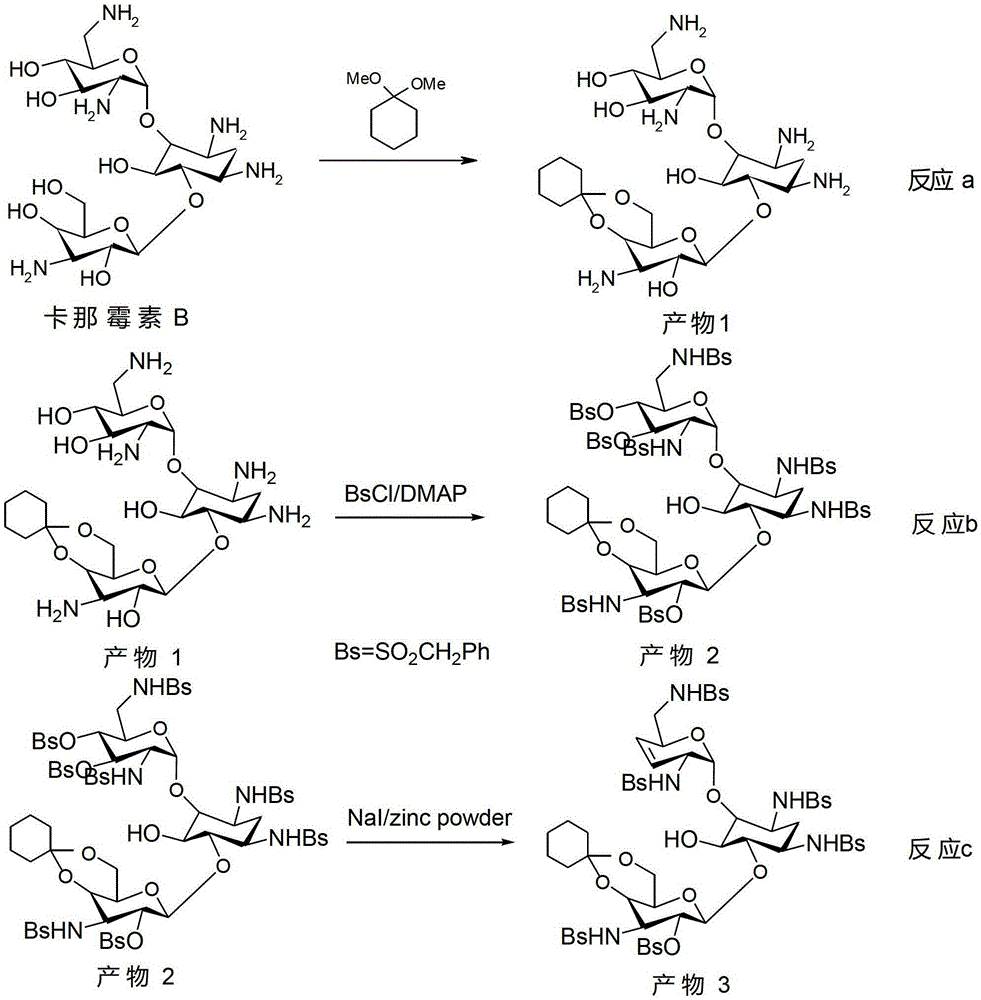

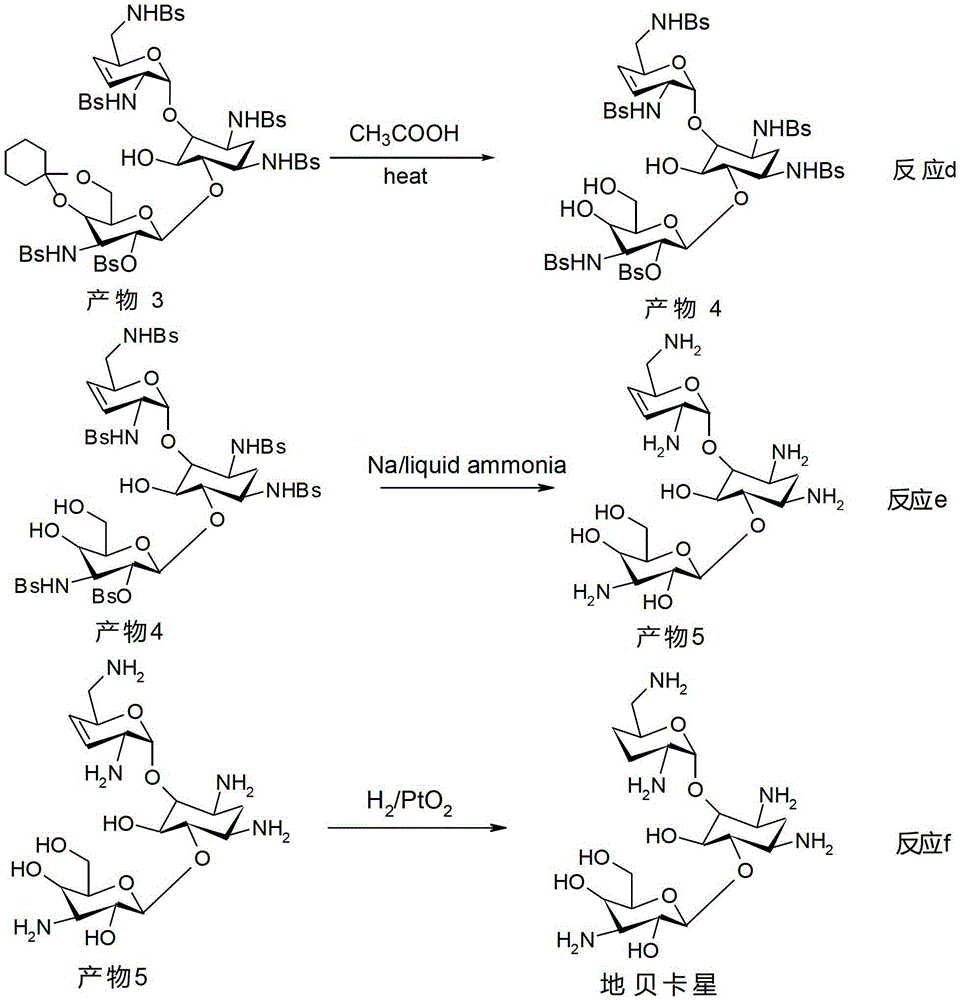

The synthetic method of dibekacin and arbekacin

ActiveCN103204887BEase of industrial productionReduce usageSugar derivativesSugar derivatives preparationTert-Butyloxycarbonyl protecting groupSynthesis methods

Owner:SHANDONG LIANGFU PHARM CO LTD

Preparation technology of fish dissolved pulp protein powder

InactiveCN107475333AIncrease added valueImprove liquidityPeptide preparation methodsFermentationTemperature controlEnzymatic hydrolysis

The invention discloses a preparation technology of fish dissolved pulp protein powder. The preparation method comprises the following steps: 1) degreasing; 2) distributed enzymolysis; 3) fishy smell removal; 4) ultrafiltration; 5) desalting; and 6) spray drying. The preparation technology has the following advantages: fish dissolved pulp is used as raw material, so the environment is protected, resources are reasonably used, and the added values of the fish dissolved pulp are increased; the prepared protein powder has the advantages of small molecular weight, no fishy smell, high purity and high activity in proteins, and excellent quality; a fishy smell removal solution can react with generated fishy substances in the proteins to achieve the fishy smell removal effect, and also can inhibit the oxidation of the proteins in order to make the protein powder product always keep a fishy smell-free state within the shelf life; and infrared temperature control is adopted during enzymatic hydrolysis, so the production period is greatly shortened, the time cost and the labor cost are reduced, and the preparation technology is simple, has high reappearance, and is suitable for large-scale production.

Owner:ZHEJIANG FENGYU MARINE BIOLOGICAL PROD

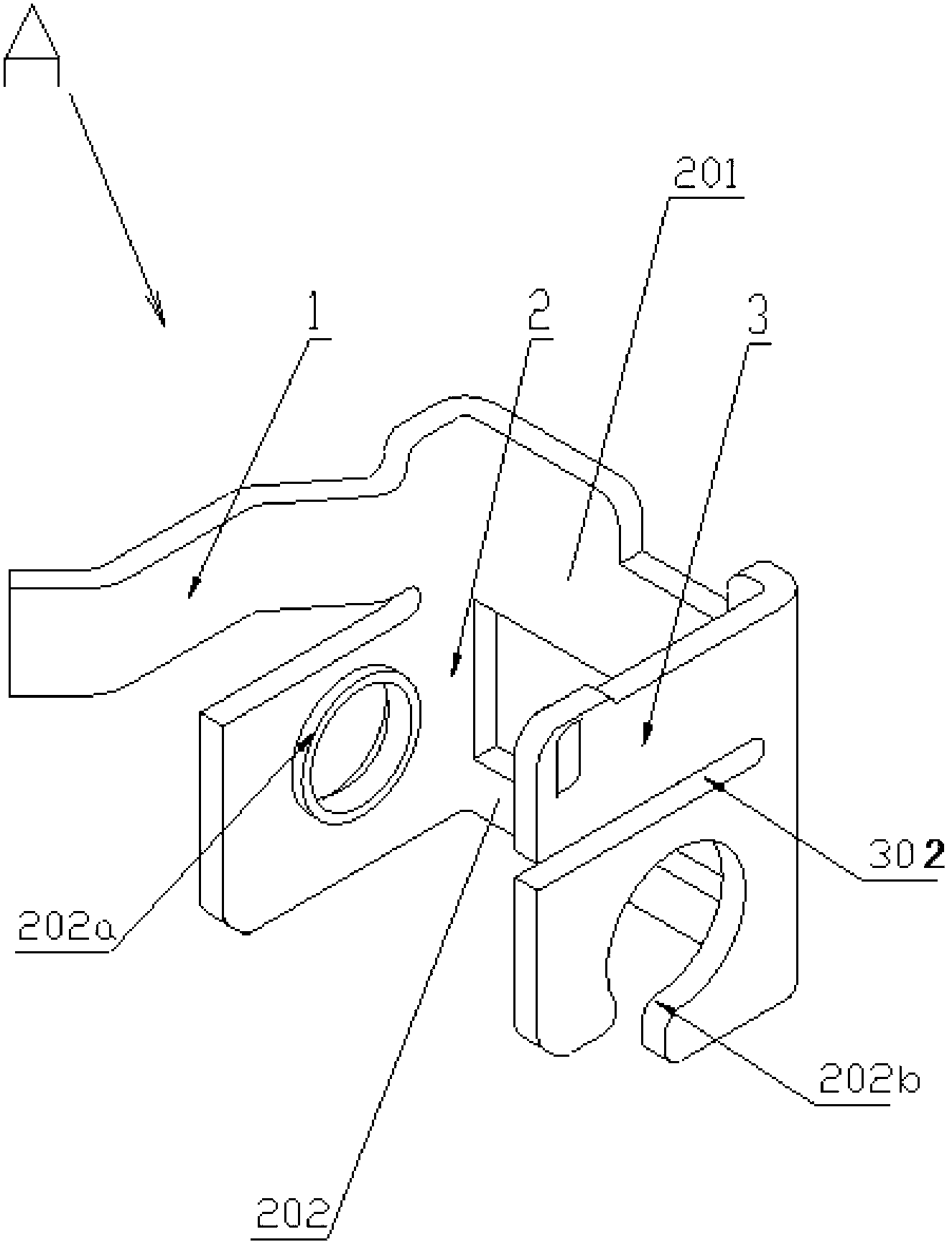

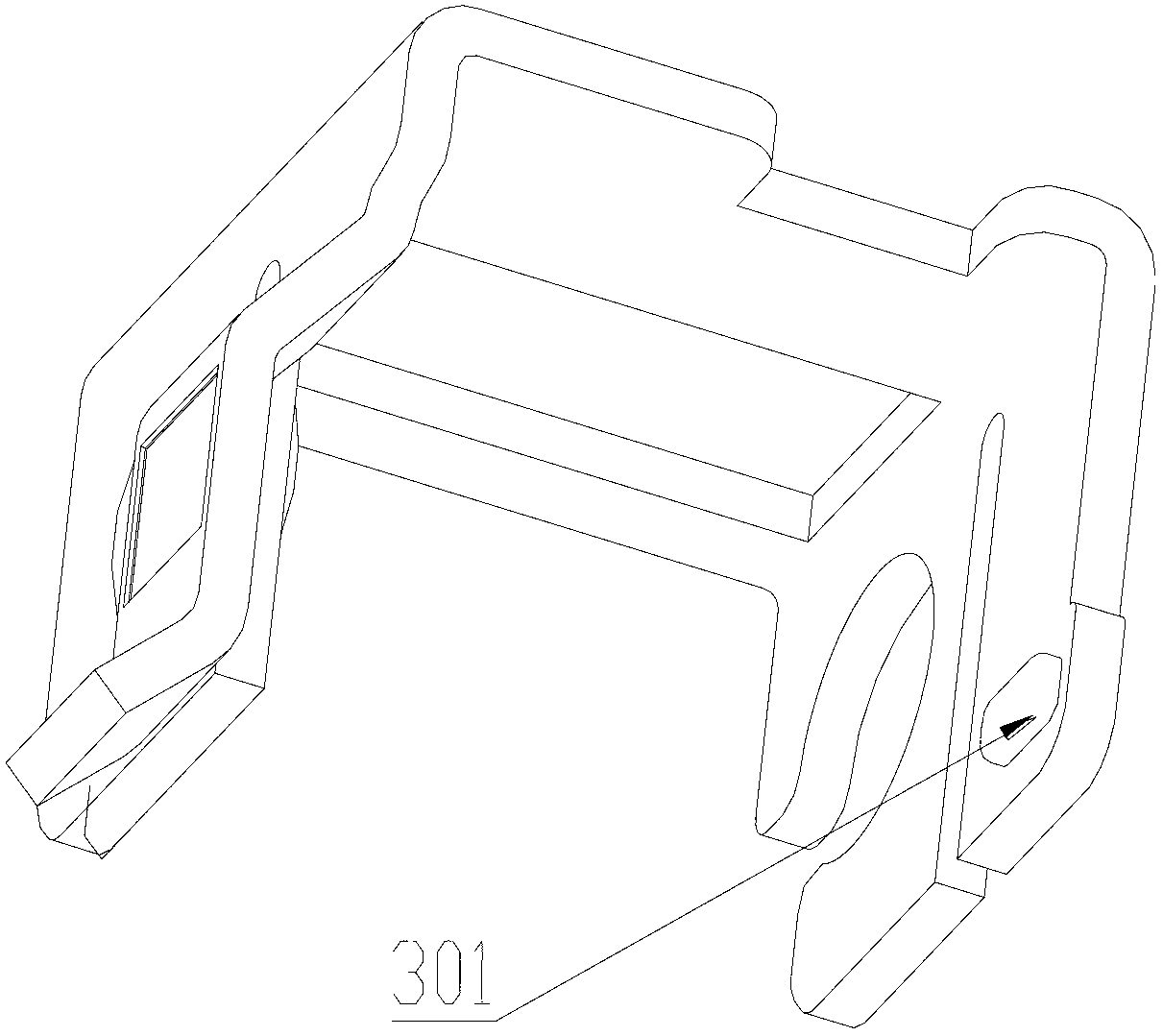

Integrated thermomagnetic system bracket of small circuit breaker and manufacturing method thereof

ActiveCN102709130ASimple structureLow costEmergency protective device manufactureProtective switch operating/release mechanismsDual actionConductive materials

The invention relates to an integrated thermomagnetic system bracket of a small circuit breaker, which comprises a static contact plate, a magnet yoke and a double-metal positioning piece. The magnet yoke is located between the static contact plate and the double-metal positioning piece. The static contact plate, the magnet yoke and the double-metal positioning piece are integrally structured. The magnet yoke comprises a conductive part and a magnetic inductive part. The conductive part is made of a metal conductive material and the magnetic inductive part is made of a ferro magnetic material. According to the thermomagnetic system bracket provided by the invention, the static contact plate, the magnet yoke and the double-metal positioning piece are integrally structured so that the number of parts is reduced, the stability of a magnet yoke magnetic field is enhanced, and the stability of a tripping mechanism of the circuit breaker is improved. At the same time, the cost of the magnet yoke is saved according to dual functions of the magnet yoke where current passes through and which generates the magnetic field, so that the thermomagnetic system bracket as a whole is simpler, and further, the defect that conventional bracket welding leads to deformation of the bracket can be avoided.

Owner:良信电器(海盐)有限公司 +1

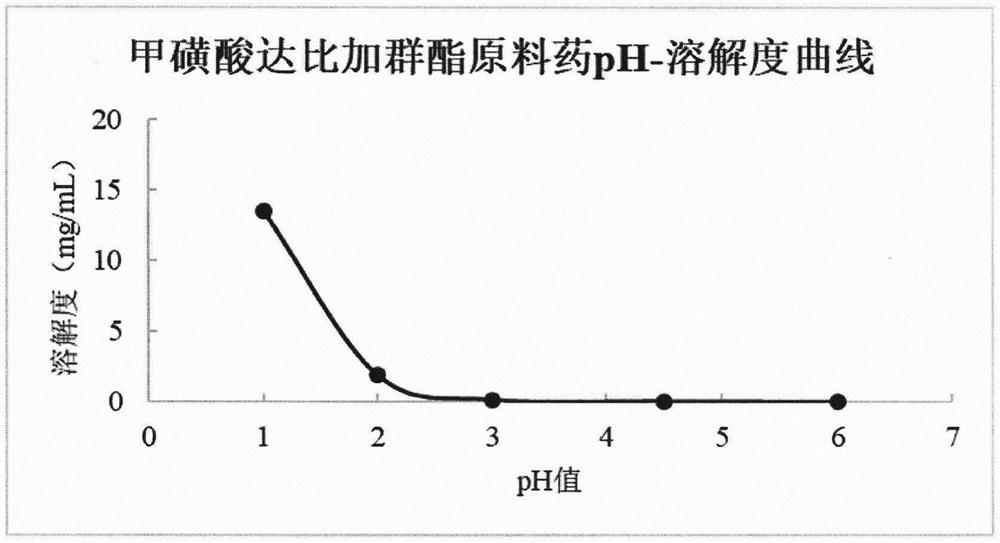

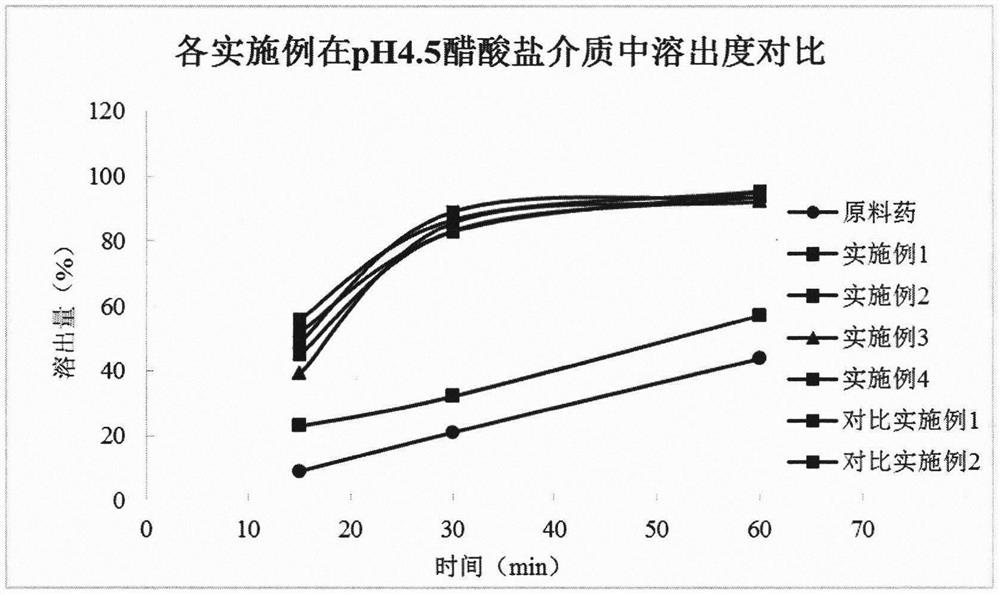

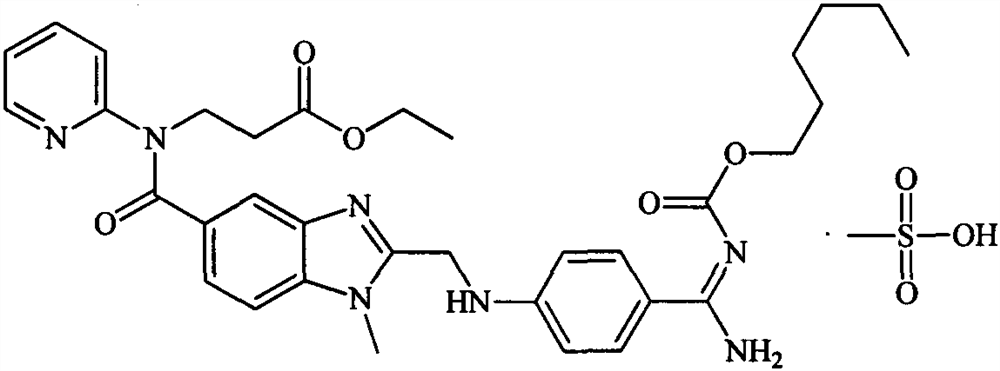

Pharmaceutical composition containing dabigatran etexilate mesylate and preparation method thereof

InactiveCN112933048AReduce stomach irritationImprove compliancePowder deliveryOrganic active ingredientsOrganic acidActive agent

The invention discloses a pharmaceutical composition containing dabigatran etexilate mesylate and a preparation method of the pharmaceutical composition. The dabigatran etexilate mesylate composition is prepared from an active substance dabigatran etexilate mesylate, a water dispersible surfactant, a hydrophilic polymer and other pharmaceutically acceptable auxiliary materials. Wherein the melting temperature of the water dispersible surfactant is 40-80 DEG C, and the content of the water dispersible surfactant is 15-25%; and the melting temperature of the hydrophilic polymer is 60-100 DEG C, and the content of the hydrophilic polymer is 25-35%. The pharmaceutical composition prepared by the invention avoids the use of organic acid, reduces the stimulation to the stomach of a patient with excessive gastric acid secretion, and improves the compliance of the patient. According to the invention, the dissolution rate of the pharmaceutical composition in an acetate medium with the pH value of 4.5 is improved by using the solubilization effect of the water dispersible surfactant, and the dissolution amount in 30 minutes can reach 80% or more, so that the solubility of dabigatran etexilate mesylate in the stomach of a patient with gastric acid deficiency in a relatively high pH value environment is effectively solved, the in-vivo bioavailability is improved, and the variability among individuals is reduced; and the low hygroscopicity of hydrophilic polymerization is utilized to improve the stability problem of the pharmaceutical composition in the production and storage processes. The pharmaceutical composition is prepared by adopting a hot-melting stirring granulation process, water is not contacted and an organic solvent is not used in the process, the degradation of active substances is effectively reduced, the stability of the pharmaceutical composition is improved, meanwhile, the production process is simple, the period is short, the cost is low, the pharmaceutical composition is green and environment-friendly, and industrial mass production is easy to realize.

Owner:南京海辰药业股份有限公司

Environment-friendly nanocrystallizing compound deep modifying method for metal materials

InactiveCN104846327AMeet the surface propertiesHigh hardnessSolid state diffusion coatingHardnessCleansing Agents

The invention relates to an environment-friendly nanocrystallizing compound deep modifying method for metal materials, in particular to a brand new composite surface strengthening and modifying technology for the metal materials. The environment-friendly nanocrystallizing compound deep modifying method includes the steps of (1) nanocrystallizing; (2) detergent degreasing; (3) nitriding; (4) oxidizing; (5) desalting by cold water; (6) drying. The environment-friendly nanocrystallizing compound deep modifying method has a deep modifying effect, can form a high-quality nanocrystallized infiltrated layer with a certain depth and certain hardness on the surface of a workpiece and is capable of improving performance of the workpiece.

Owner:郭伟

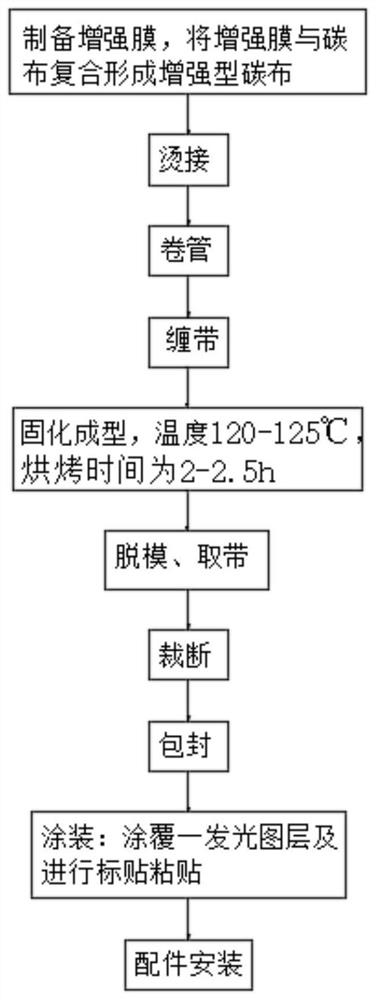

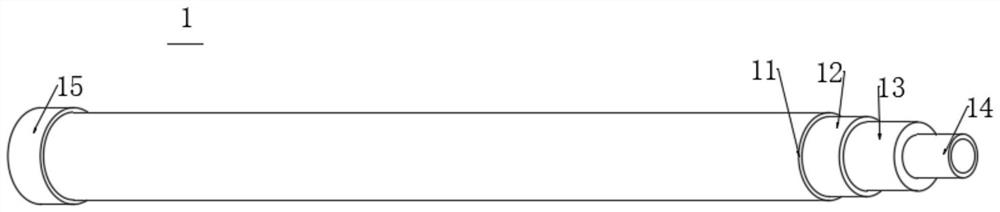

Enhanced fishing rod and manufacturing method thereof

The invention provides an enhanced fishing rod and a manufacturing method thereof. The manufacturing method comprises the steps of enhanced carbon cloth manufacturing, ironing connection, pipe rolling, tape winding, curing, demolding, cutting, encapsulating, coating and installing, wherein an enhanced film is prepared from 5%-15% of polyether sulfone, 85%-95% of bisphenol A epoxy resin and 1%-8% of toner. The manufactured enhanced fishing rod comprises a fishing rod pipe and auxiliary accessories arranged on the fishing rod pipe, the fishing rod pipe comprises a pipe body, and the surface of the pipe body is coated with the enhanced film. According to the manufacturing method of the enhanced fishing rod, the carbon cloth is compounded with the enhanced film before ironing connection, so that the strength, the toughness and the practicability of the manufactured enhanced fishing rod are greatly enhanced, the fishing rod is light in weight, smooth in surface, tough, good in external electrical insulating property and high in safety, and compared with an existing conventional fishing rod manufacturing method, the manufacturing method has the advantages that the process flow is simplified, the production period is greatly shortened, the production efficiency is improved, meanwhile, the fishing rod pipe is not damaged, the quality of the fishing rod is enhanced, the production qualification rate is increased, and the production cost is reduced.

Owner:威海亿美运动器械有限公司

Processing method of protein powder product from small trash fishes

InactiveCN107467342AIncrease added valueHigh purityProtein composition from fishPeptide preparation methodsTemperature controlUltrafiltration

The invention discloses a processing method of a protein powder product from small trash fishes, and the processing method comprises the operation steps: 1) pretreatment; 2) degreasing; 3) enzymolysis; 4) deodorization; 5) ultrafiltration; 6) desalting; and 7) spray drying. The processing method of the protein powder product from small trash fishes has the beneficial effects: the processing method takes the small trash fishes as the raw material, has low cost, increases a treatment route for the low-value small trash fishes, carries out reasonable application of resources and increases the added value of the small trash fishes; the prepared protein powder from the small trash fishes has small molecular weight, is easy to digest and absorb by a human body, and has no fishy smell, high purity and activity of protein, and excellent product quality; during enzymolysis, infrared temperature control is adopted, thereby greatly shortening the production cycle and reducing the time cost and manpower cost; and the processing method is simple, high in reproductivity and suitable for large-scale production.

Owner:ZHEJIANG FENGYU MARINE BIOLOGICAL PROD

Method for making full pineapple juice sweet wine

ActiveCN102220212BQuality improvementPleasant wineMicroorganism based processesAlcoholic beverage preparationFruit wineAlcohol

The invention relates to a method for making full pineapple juice sweet wine, which can retain the original fragrance, natural value, natural alcohol volume and residual sugar of pineapple fruit, avoid damaging the mouthfeel of the fruit wine by adding sugar manually and simplifying the brewing process. The method comprises the following operation steps: (1) controlling the maturity of the raw material; (2) grinding, squeezing, and adding sulfur dioxide; (3) defoaming mechanically; (4) clarifying; (5) fermenting part of alcohol; (6) adding alcohol and terminating fermentation; (7) adding sulfur dioxide and separating; (8) refrigerating and aging; and (9) sterilizing, filtering and bottling.

Owner:NORTHWEST A & F UNIV

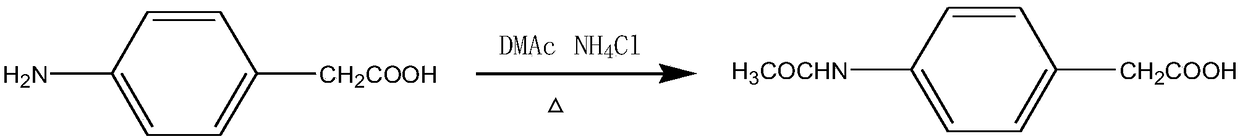

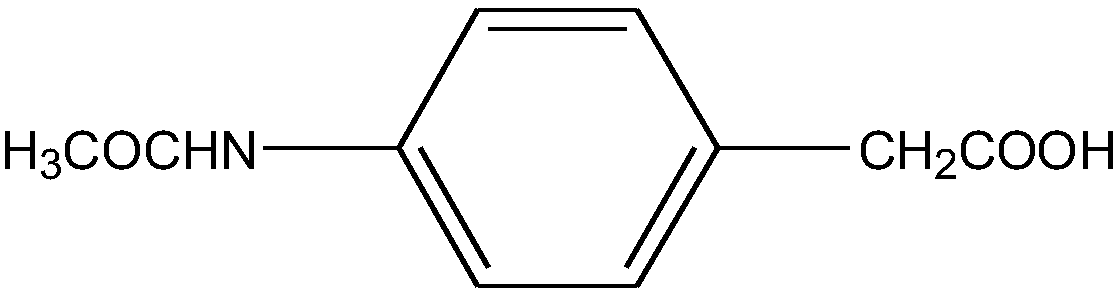

A kind of preparation method of acetaminophenacetic acid

ActiveCN106278925BHigh yieldHigh purityOrganic compound preparationCarboxylic acid amides preparationRefluxCrystallization

The invention discloses a method for preparing 4-acetylaminophenylacetic acid. The method includes the steps that p-nitrophenylacetic acid, N,N-dimethylacetamide and ammonium chloride are evenly mixed, heating reflux, cooling and crystallizing are conducted, and crystals are obtained to obtain 4-acetylaminophenylacetic acid. The production cost is low, the yield is high, product purity is good, operation is easy, the production period is short, and the method is suitable for industrial mass production.

Owner:HEFEI PINGGUANG PHARMA

Soft magnetic amorphous alloy wire and preparation method thereof

Owner:NANJING UNIV OF INFORMATION SCI & TECH

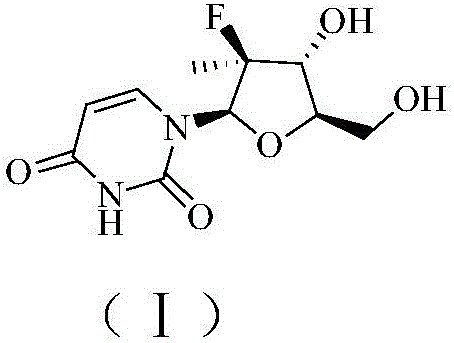

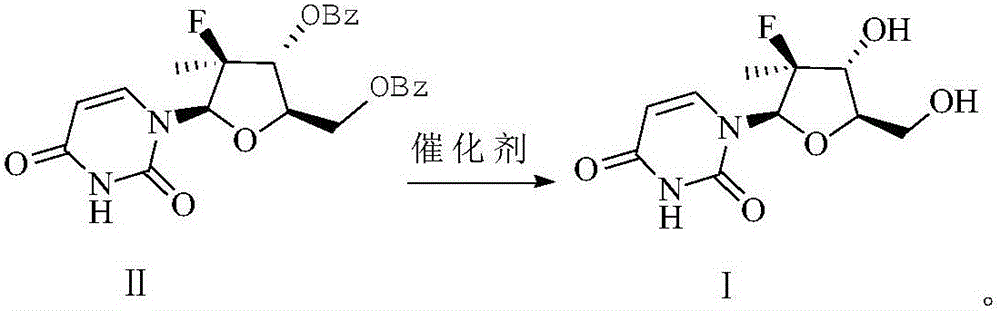

Preparation method of (2'R)-2'-deoxy-2'-fluoro-2'-methyluridine

InactiveCN105859811ALow priceShort reaction timeSugar derivativesSugar derivatives preparationInorganic saltsAlcohol

The invention relates to a preparation method of (2'R)-2'-deoxy-2'-fluoro-2'-methyluridine (I). The preparation method comprises the steps that (2'R)-2'-deoxy-2'-fluoro-2'-methyluridine 3', 5- dibenzoate (II) is adopted as the raw material, and catalysis for deprotection is conducted through a catalyst in anhydrous polar solvent, so that the (2'R)-2'-deoxy-2'-fluoro-2'-methyluridine (I) is obtained, wherein the catalyst is a mixture of inorganic base and inorganic salt or an alcoholic alkali metal compound. The preparation method has the advantages that an inorganic compound or the alcoholic alkali metal compound is adopted, reaction time is shorted and only needs 4-10 hours, a reaction is conducted completely, the post-treatment mode is simplified, the production cycle is shorted, and in addition, the inorganic compound is relatively low in price, so that production cost is lowered; meanwhile, the yield of a product prepared through the preparation method can reach 95% or above, and extremely great industrialized production prospect is achieved.

Owner:JINGHUA PHARMA GRP NANTONG

True blind hole circuit board manufacturing process

InactiveCN108184313BReduced chance of wrinklingSimple processMultilayer circuit manufactureEtchingEngineering

The invention discloses a true blind hole circuit board making process. The process comprises steps that (1), drilling on a front side of a gum base material is carried out, and front side circuit making is carried out; (2), back etching of a copper foil having a protection film on the back side is carried out to make a back side circuit; (3), a back side of the gum base material and a front sideof the copper foil are bonded; (4), the gum base material and the copper foil which are bonded are pressed to synthesize a board body; (5), the protection film on the copper foil is torn; and (6), insulation films are pasted on front and back sides of the board body. The process is advantaged in that the process is simple, the circuits at the back and front sides are produced simultaneously, bonding is then carried out, the integral process steps are effectively and integrally simplified, the production period is greatly shortened, production efficiency is improved, manpower and material resources are effectively saved, production cost is reduced, the back side of the copper foil is supported through employing the protection film, the wrinkle rate of the copper foil is effectively reduced,the yield is improved, product quality is guaranteed, and wide popularization and application are facilitated.

Owner:东莞市天晖电子材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com