Cutting method of crystalline silicon ingot

A cutting method and technology of crystalline silicon, applied in fine working devices, manufacturing tools, stone processing equipment, etc., can solve problems such as long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

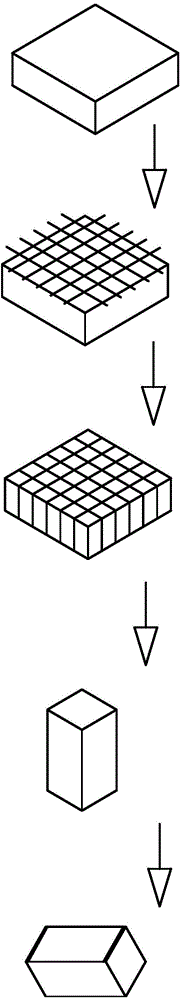

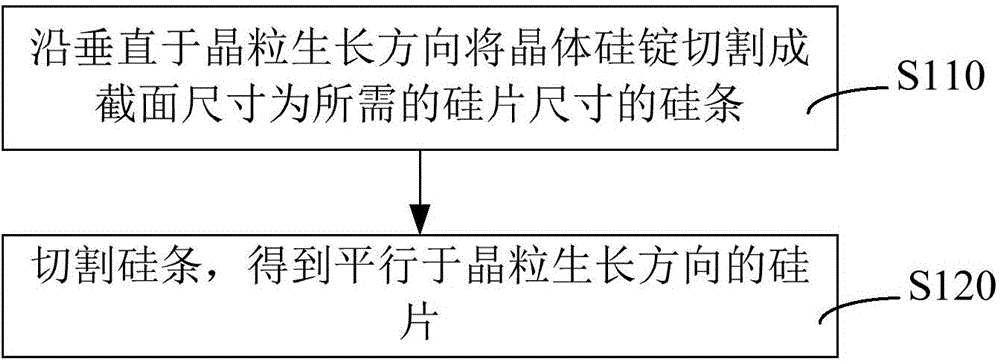

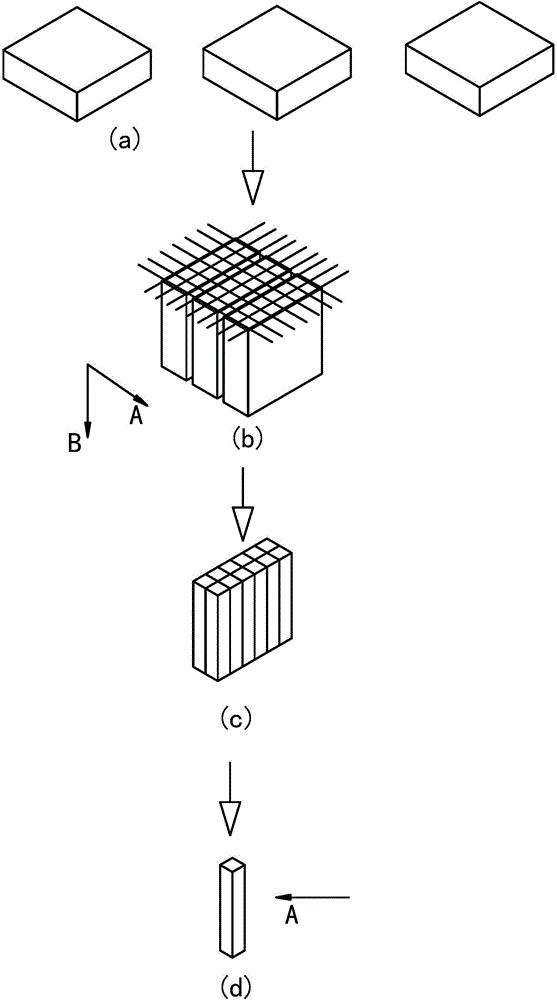

[0014] figure 2 A flow chart illustrating a method for cutting a crystalline silicon ingot according to the present invention. Combine below image 3 ,A detailed description figure 2 Implementation of the method shown.

[0015] The flow chart of the method for cutting a crystalline silicon ingot of the present invention includes the following steps.

[0016] Step S110 , cutting the crystalline silicon ingot into silicon strips with a cross-sectional size equal to the required silicon chip size along the direction perpendicular to the grain growth direction.

[0017] For details, please refer to image 3 , including the following steps:

[0018] (a) First erect the crystalline silicon ingot. After being erected, one side of the crystalline silicon ingot rests on the square tray, and the opposite side is used for wiring.

[0019] (b) Wiring is carried out on the side surface of the crystalline silicon ingot according to the required silicon wafer size. In the tradition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com