Intermediate-frequency pipe bending machine

A pipe bender and intermediate frequency technology, which is applied in the field of intermediate frequency pipe benders, can solve the problems of reducing the bending quality and bending accuracy of intermediate frequency pipe bends, correcting the wrinkle rate and ovality, and affecting the use of related equipment, so as to reduce the wrinkle rate and ellipse degree, control uniformity, enhance the effect of bending quality and bending accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

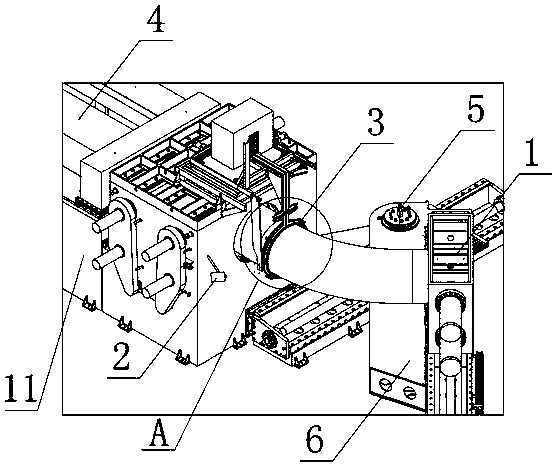

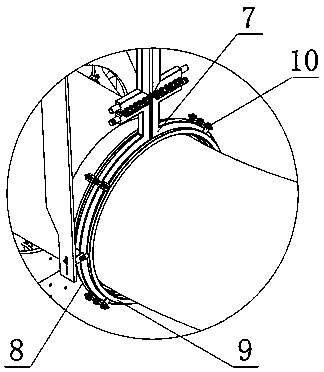

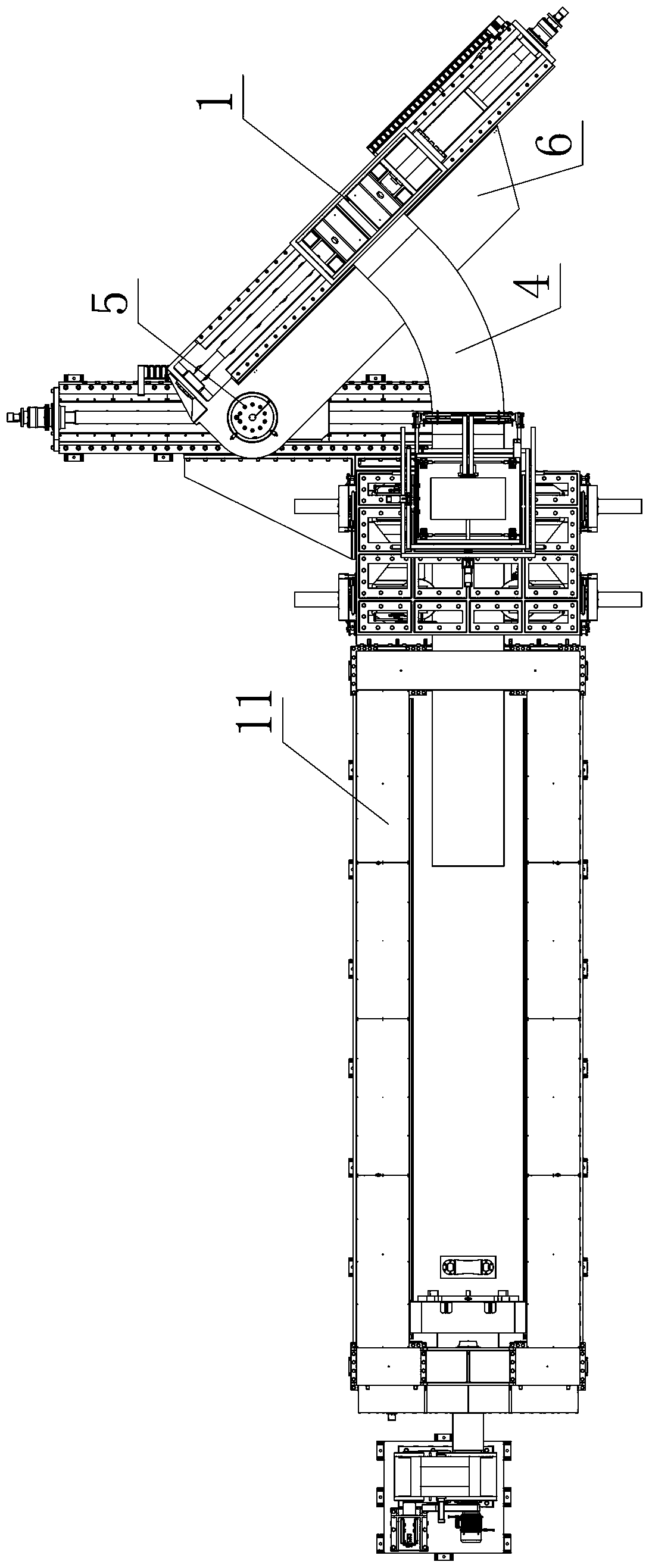

[0021] like Figure 1-Figure 3 As shown, an embodiment of the intermediate frequency pipe bending machine of the present invention includes a frame 11 for placing pre-bent steel pipes. The top of the frame 11 is provided with a steel pipe propulsion device for pushing the steel pipe 4 to move. The front end of the frame 11 A three-ring heating and cooling coil group 3 for being sleeved on the steel pipe 4 for heating and cooling and a bending assembly for bending the steel pipe 4 are provided. The three-ring heating and cooling coil group 3 includes a heating coil 7 and is separately arranged on The gas injection coil 8 and the cooling coil 9 on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com