Intelligent cable receiving device

It is a technology of a leader and a cable, which is applied in the field of a smart cable leader, which can solve the problems of manual operation and waste of time by the staff, and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

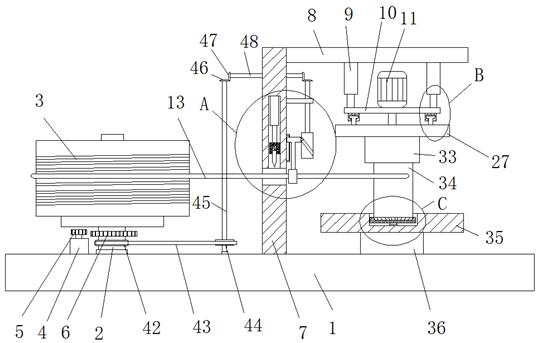

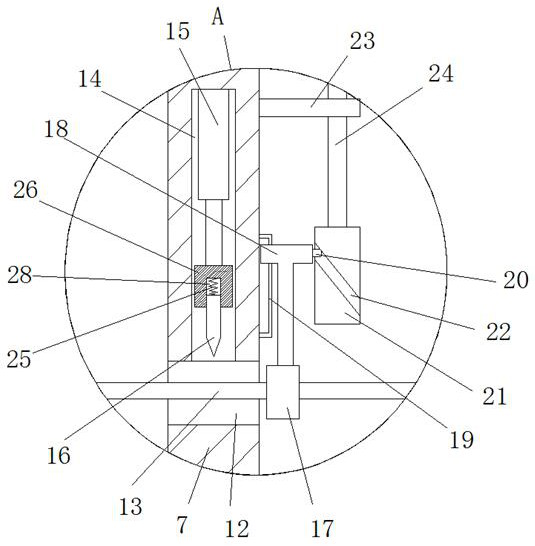

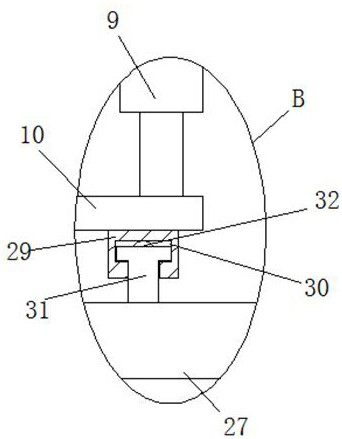

[0027] refer to Figure 1-5 , the intelligent cable receiving device, including a base plate 1, a cable reel placement mechanism is arranged on the top of the base plate 1, a cable reel 3 is placed on the top of the cable reel placement mechanism, and a cable 13 is wound on the cable reel 3, and the base plate 1 is equipped with a vertical plate 7 and a weighing device 36, the vertical plate 7 is provided with a wire hole 12, the top inner wall of the wire hole 12 is provided with a receiving groove 14, and a cutting mechanism is arranged in the receiving groove 14, and the cable 13 and the wire Holes 12 are movably connected, and the cutting mechanism is adapted to the cable 13. A horizontal plate 8 is installed on the top of the vertical plate 7, and a lifting mechanism is installed on the bottom of the horizontal plate 8. A circular plate 10 is installed on the lifting mechanism, and the top of the circular plate 10 Rotating motor 11 is installed, and rotating disc 27 is in...

Embodiment 2

[0035] refer to Figure 1-5 , the intelligent cable receiving device, including a base plate 1, a cable reel placement mechanism is arranged on the top of the base plate 1, a cable reel 3 is placed on the top of the cable reel placement mechanism, and a cable 13 is wound on the cable reel 3, and the base plate 1 is equipped with a vertical plate 7 and a weighing device 36, the vertical plate 7 is provided with a wire hole 12, the top inner wall of the wire hole 12 is provided with a receiving groove 14, and a cutting mechanism is arranged in the receiving groove 14, and the cable 13 and the wire Holes 12 are movably connected, and the cutting mechanism is adapted to the cable 13. A horizontal plate 8 is installed on the top of the vertical plate 7, and a lifting mechanism is installed on the bottom of the horizontal plate 8. A circular plate 10 is installed on the lifting mechanism, and the top of the circular plate 10 Rotating motor 11 is installed, and rotating disc 27 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com