Patents

Literature

35results about How to "Uniform film distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of nano titanium dioxide thin film materials loaded on surface of ceramic body

InactiveCN101817696AImprove photocatalytic activityUniform film distributionIonTemperature resistance

The invention provides a preparation method of nano titanium dioxide thin film materials loaded on the surface of a ceramic body. The preparation method comprises the following steps of: adding the organic titanium salt to the de-ionized water and stirring the de-ionized water and adding alkali liquor to adjust the pH value to be 6 to 8; centrifuging for separating the mixed solution, and adding the separated slurry to the mixed solution of absolute ethyl alcohol and acetylacetone; adding the dispersing agent to the mixed solution, sufficiently and uniformly stirring the mixed solution till the stable titanium dioxide sol is formed; soaking the high-temperature resistance and corrosion resistance ceramic body into the titanium dioxide sol, drying and forging the ceramic body for 2 to 4 hours to form one layer of nano titanium dioxide thin film material on the surface of the ceramic body. The thin film is distributed uniformly, and the thickness of the thin film is controllable. When being applied to treating the industrial waste water, the ceramic body loaded with nano titanium dioxide thin film can be utilized repeatedly and has low cost and no secondary pollution.

Owner:广州瑞塔光电科技有限公司

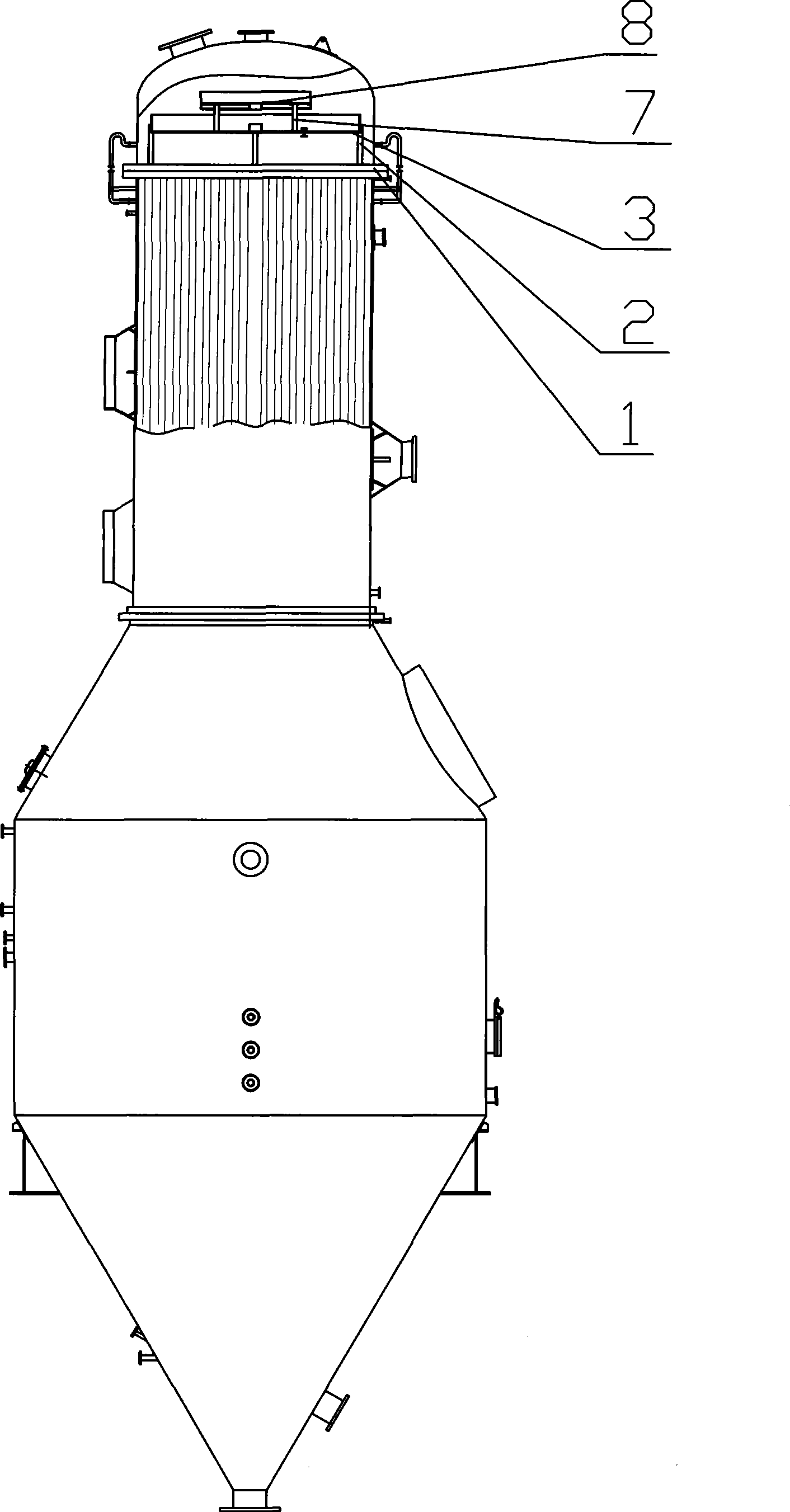

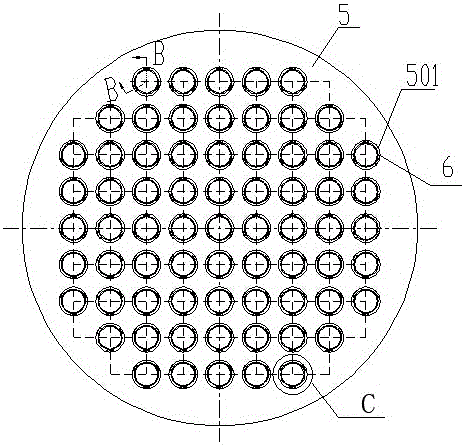

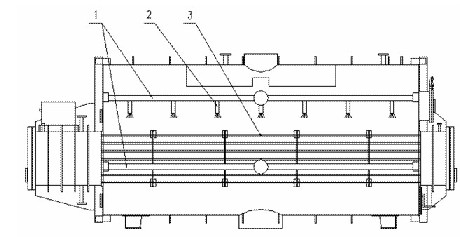

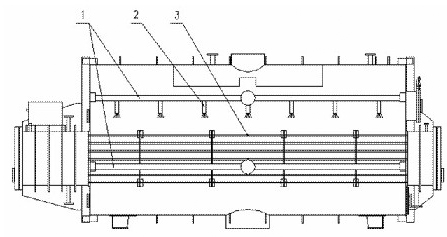

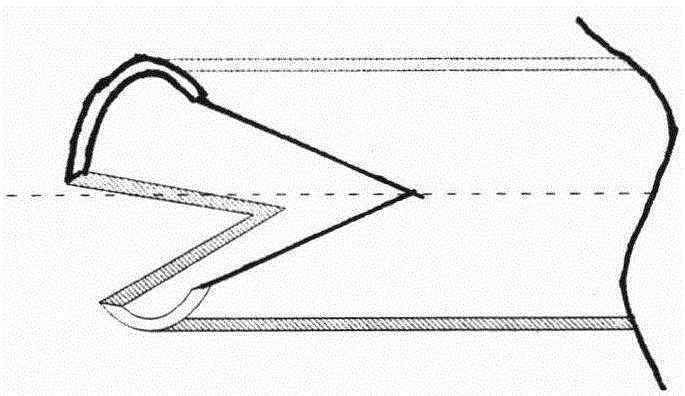

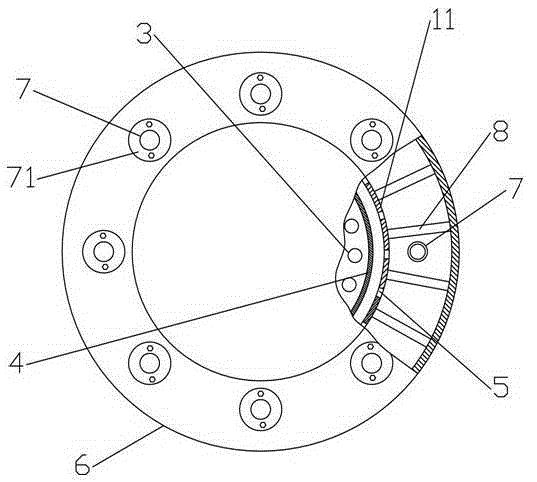

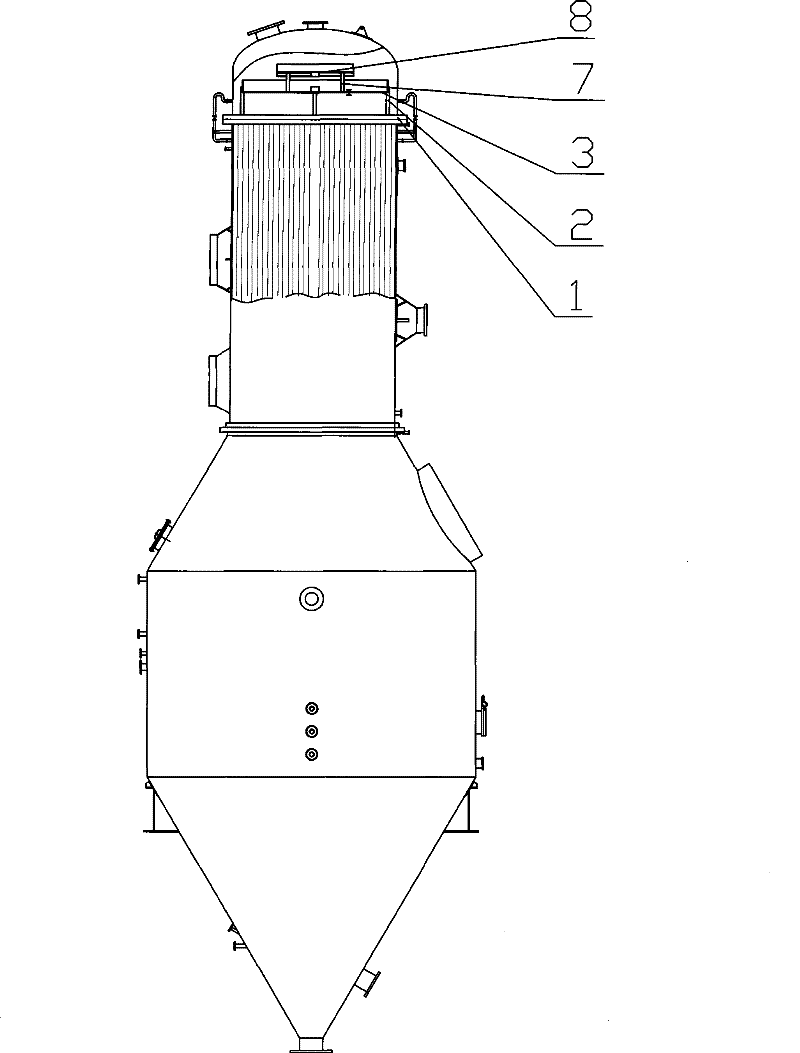

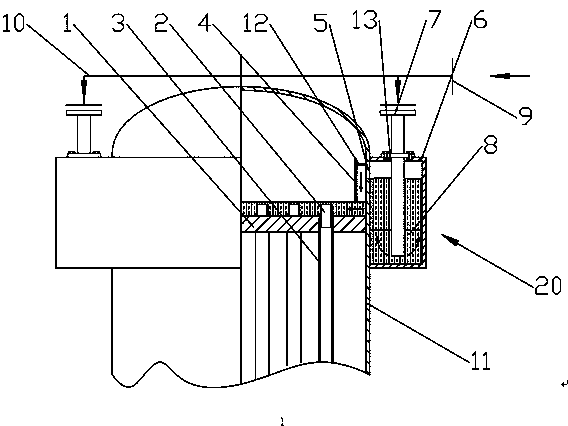

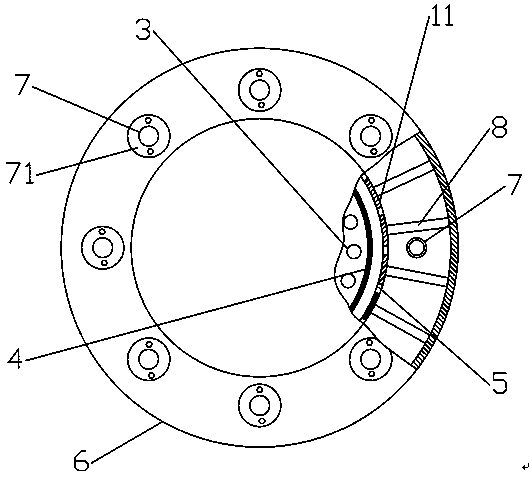

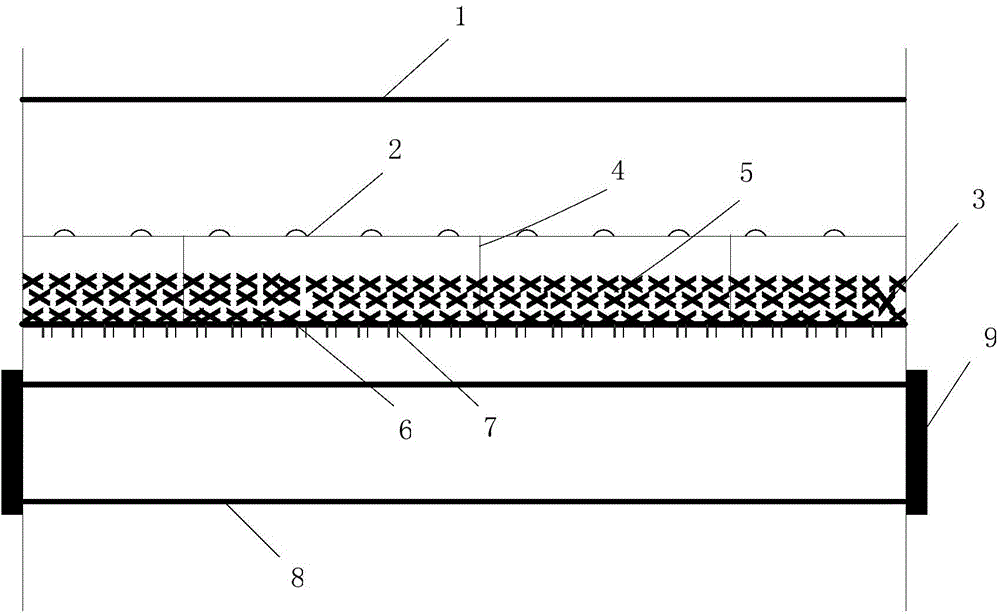

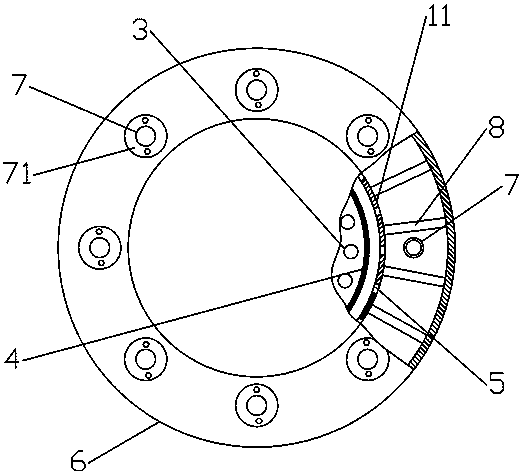

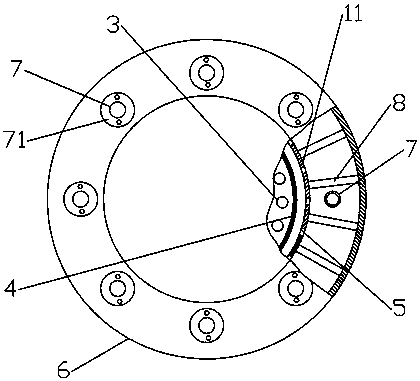

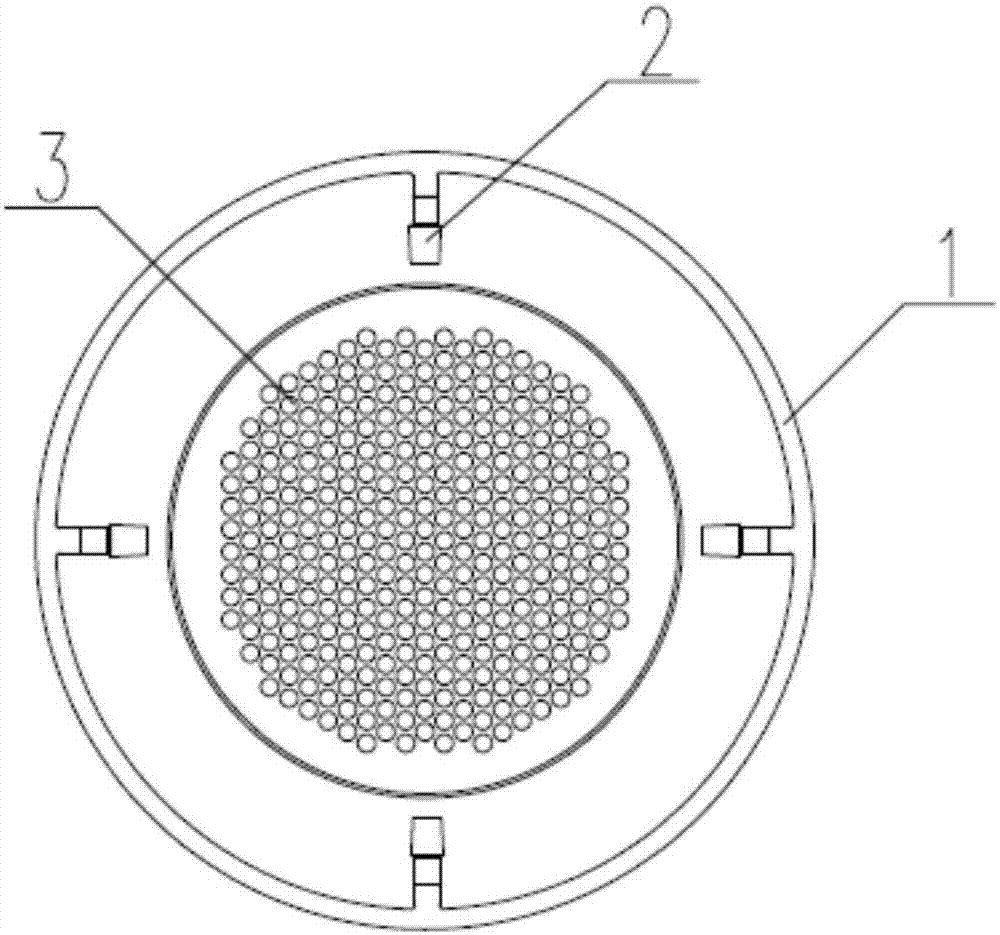

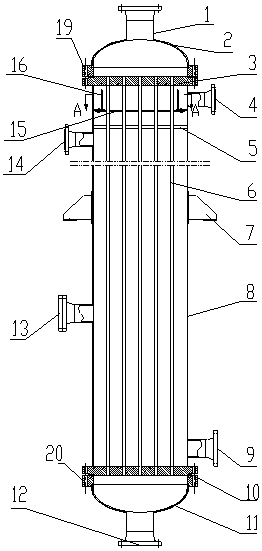

Film-distributing device of tube-type down-flow evaporator

InactiveCN101376066AExtended service lifeSimple structureEvaporators with vertical tubesEngineeringTubes types

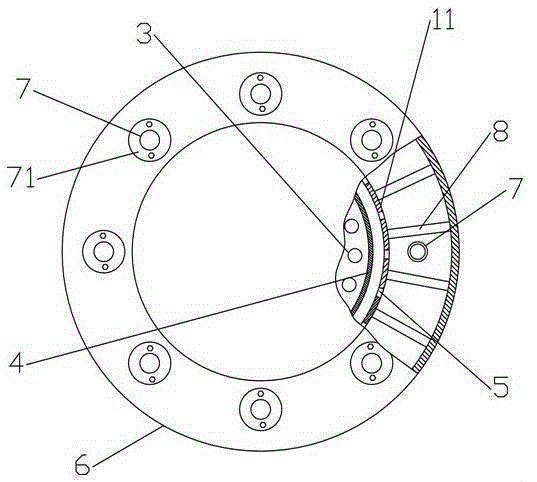

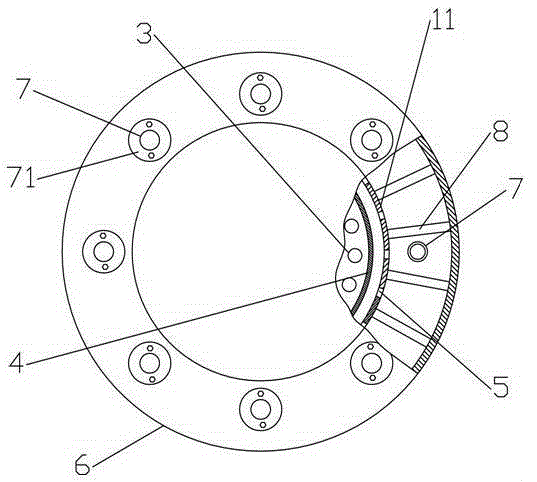

The invention discloses a cloth membrane device of a long-tube falling film evaporator, which comprises an upper tube sheet arranged in the housing of the evaporator, a plurality of lower support rods arranged on the upper tube sheet, and a distribution tray arranged at the upper end part of the lower support rod, wherein a plurality of distribution holes which are evenly distributed and communicated from top to bottom are formed on the distribution tray, and cloth membrane apparatus is arranged in the distribution holes; a lap of check rings are arranged on the distribution tray, and a plurality of support rods are formed on the distribution tray; an overfall tray is arranged on the support rods and a connecting pipe is arranged at the middle of the overfall tray; and a lap of overflow dam is arranged at the periphery of the overfall tray, and a corresponding overflow pipe is arranged at the middle part of the distribution tray which corresponds to the connecting pipe. The cloth membrane device has the advantages of simple structure and evenly distributed cloth membrane; besides, no dry film and split film are generated in a heating pipe, so that the service life of the long-tube falling film evaporator can be prolonged.

Owner:苏州市中衡压力容器制造有限公司

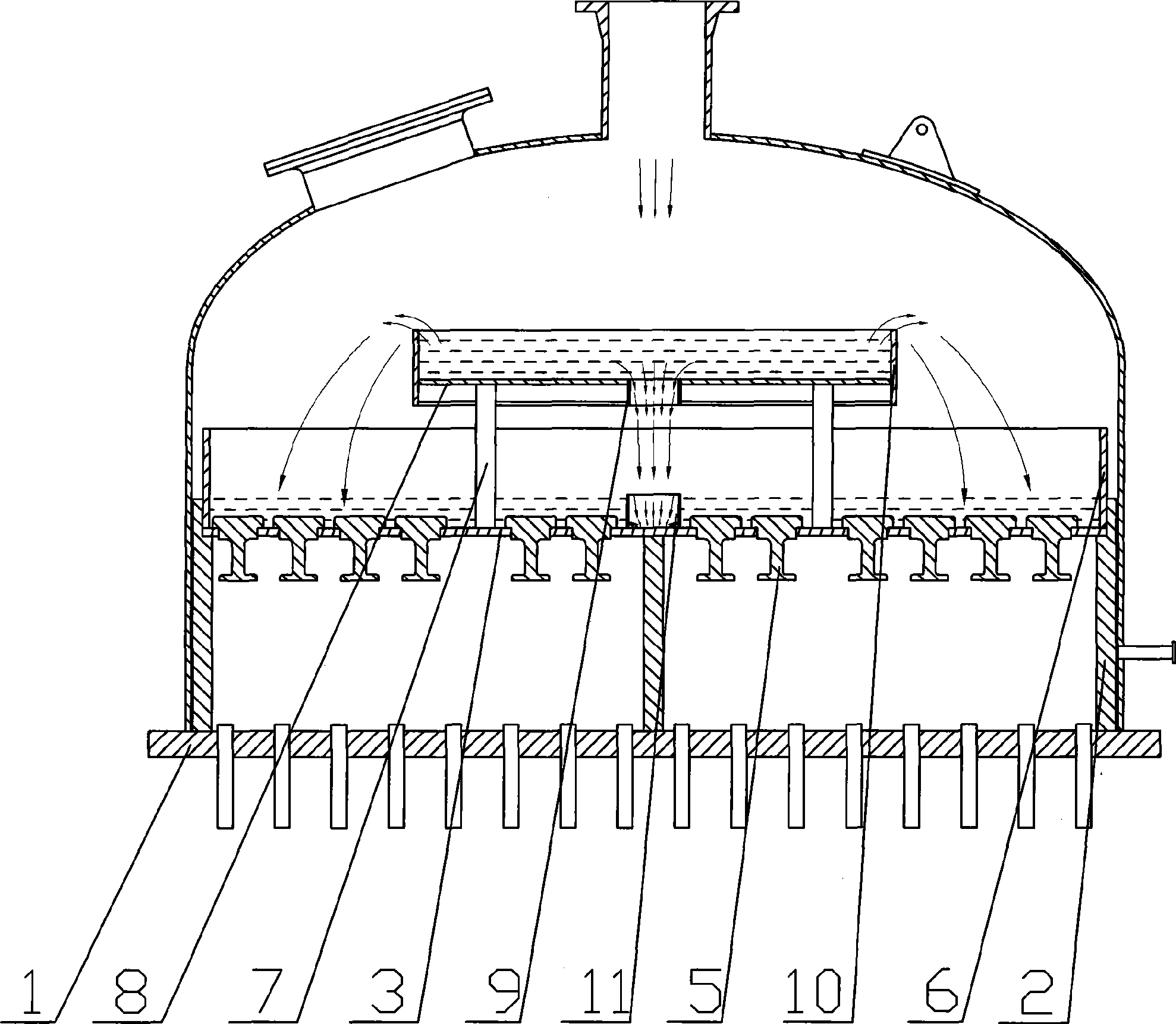

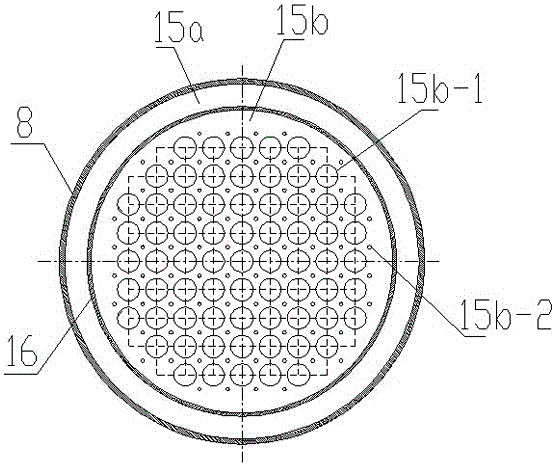

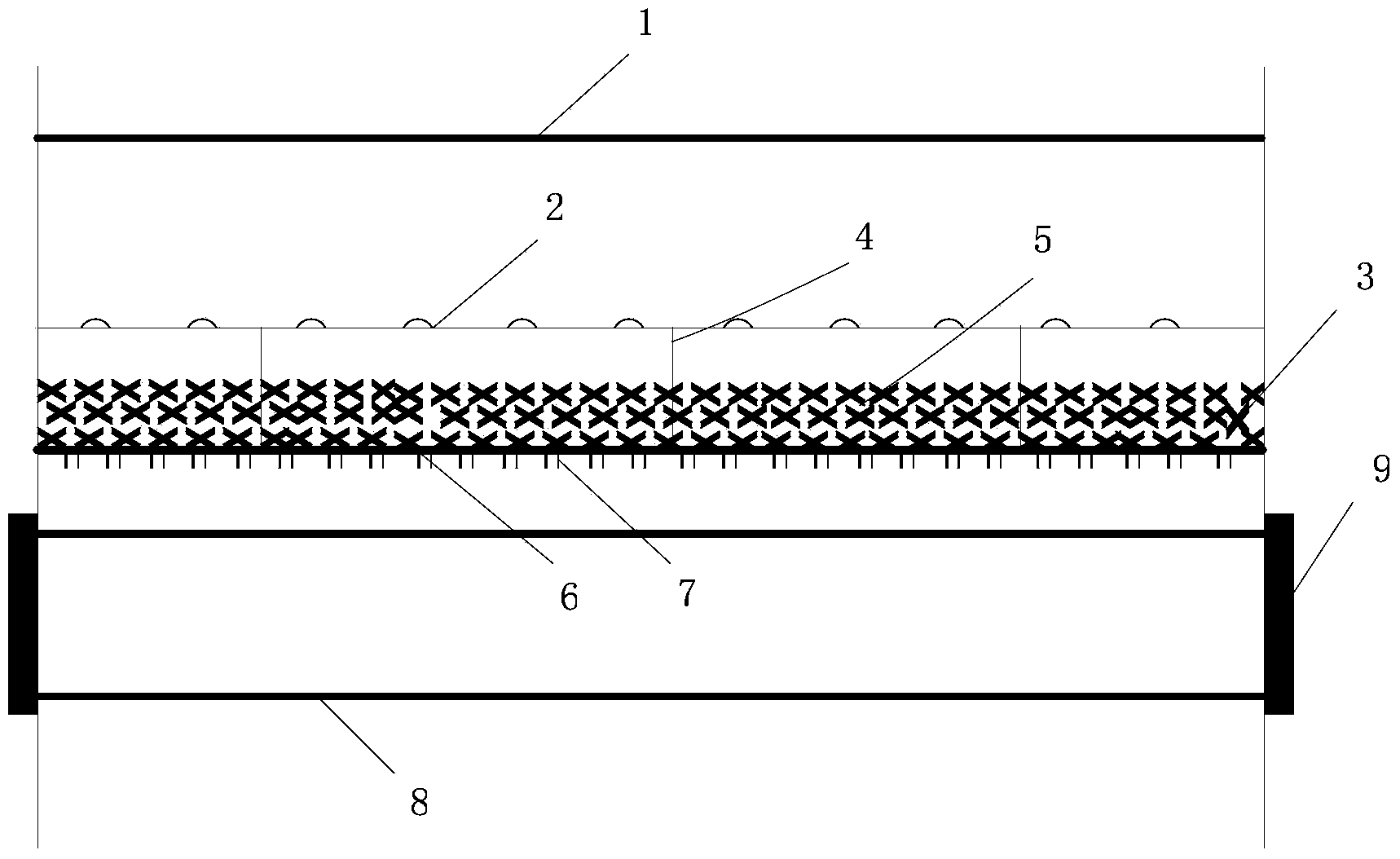

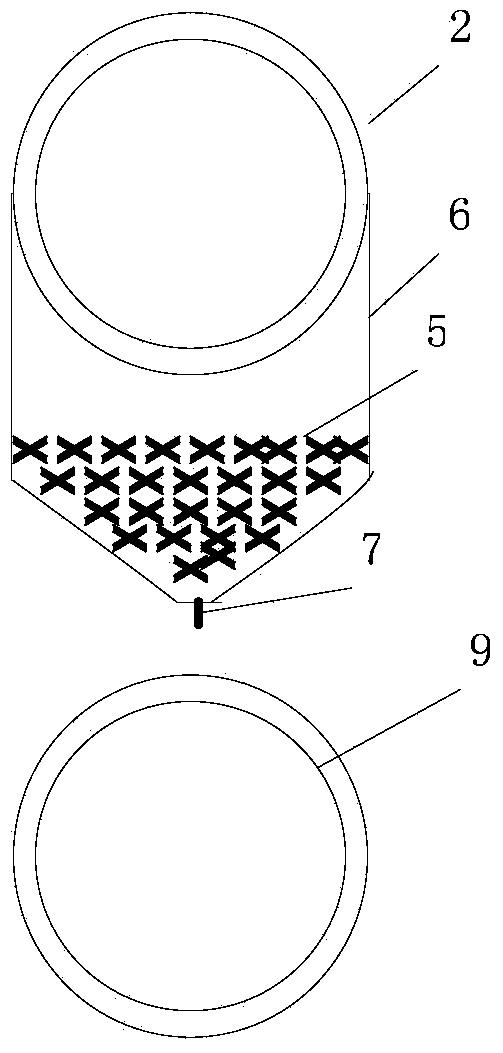

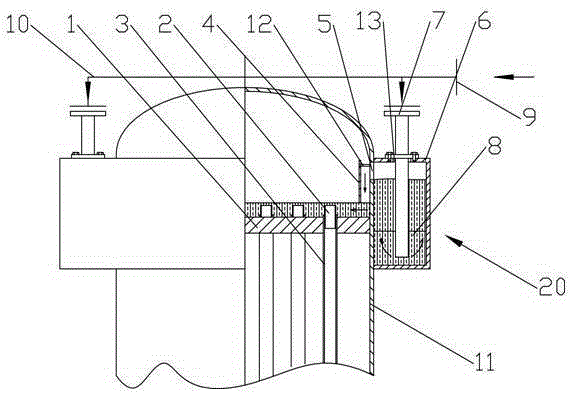

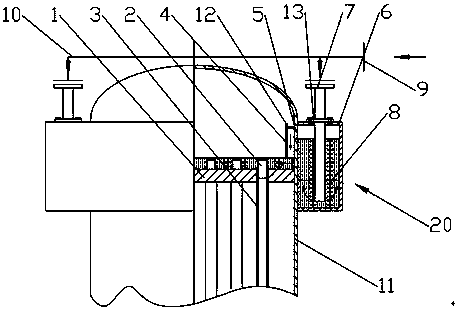

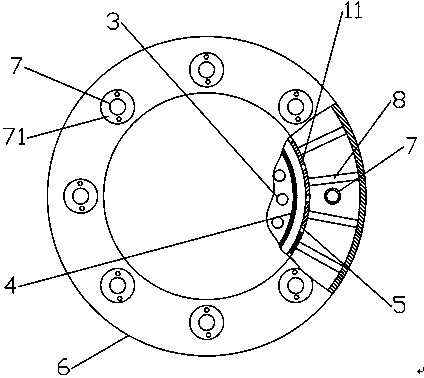

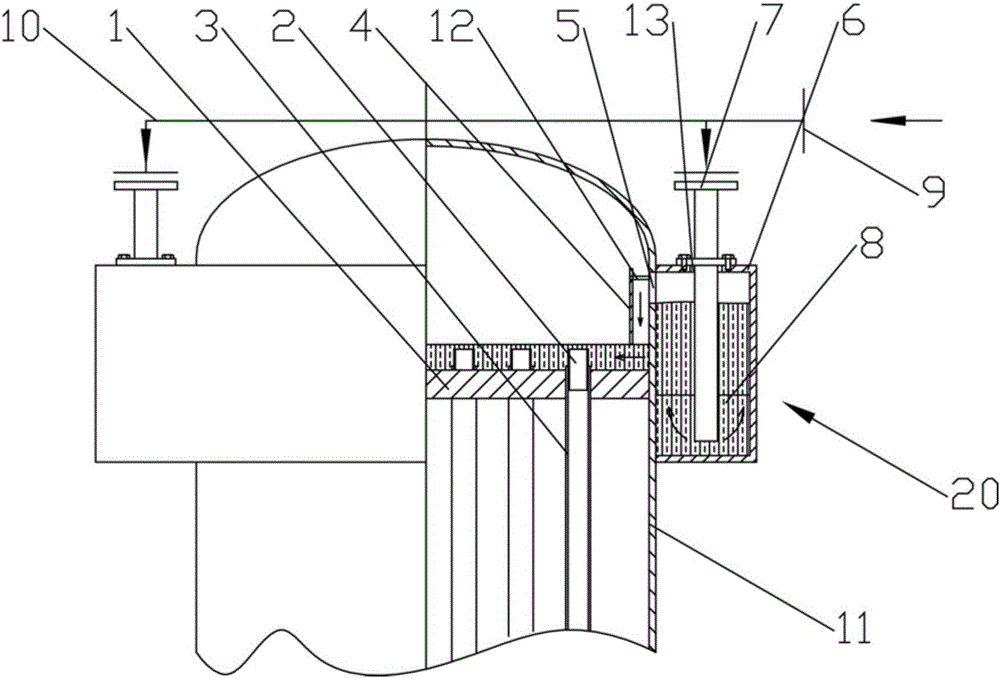

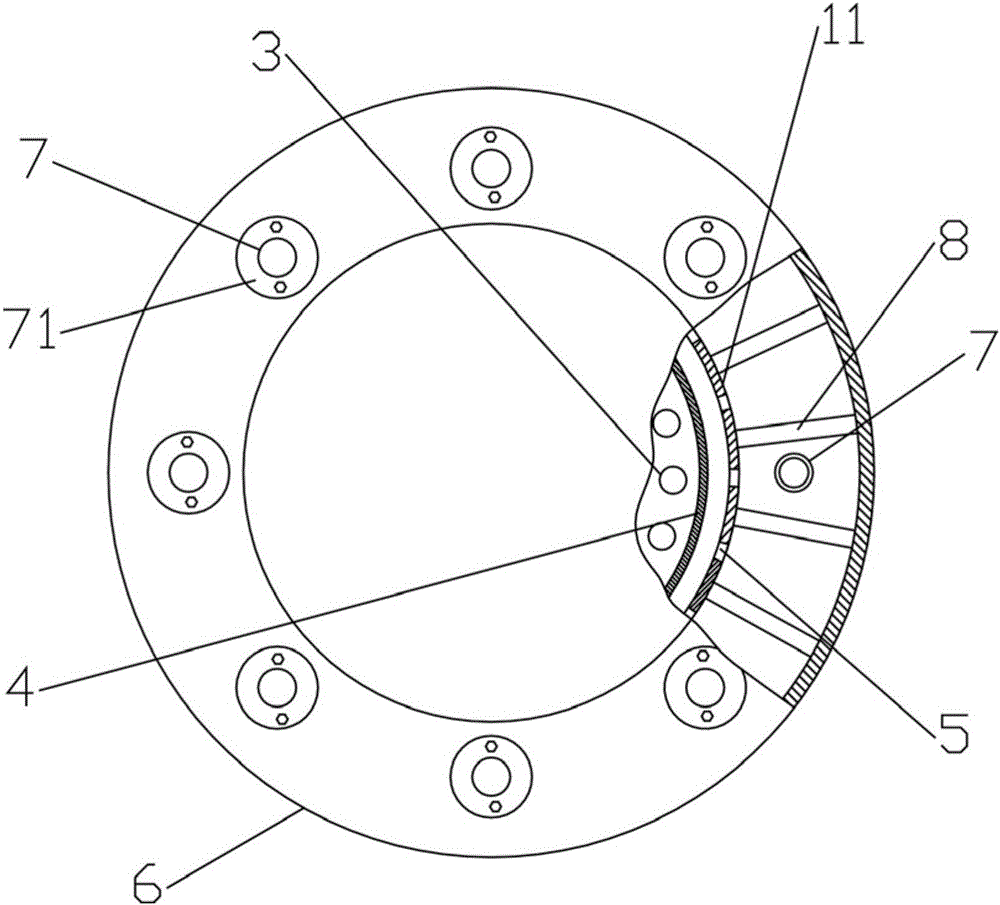

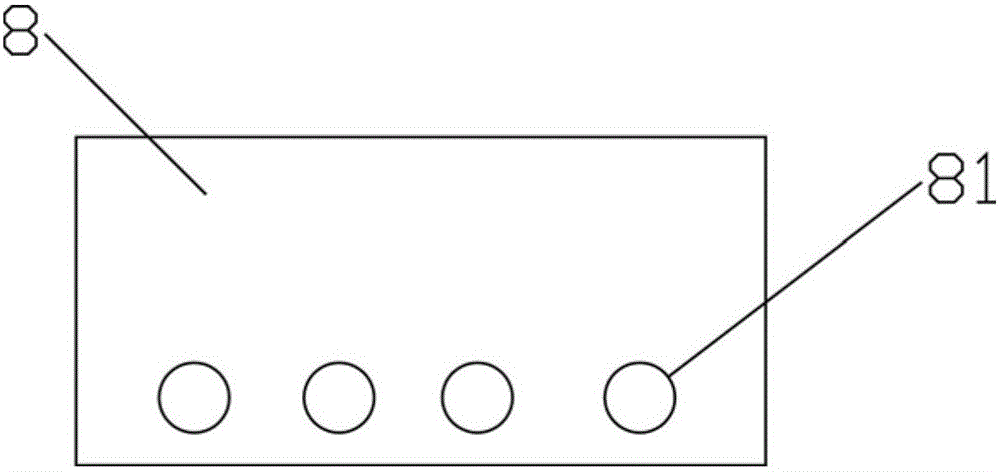

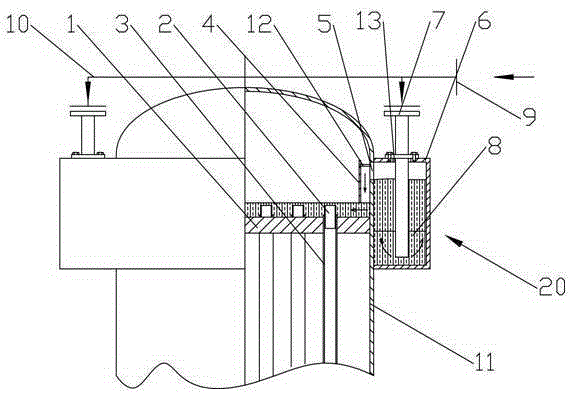

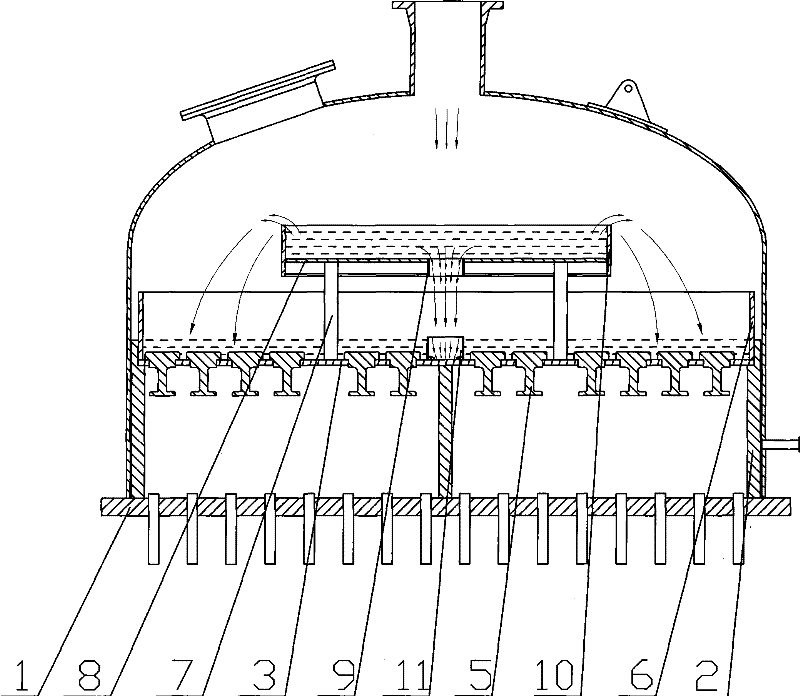

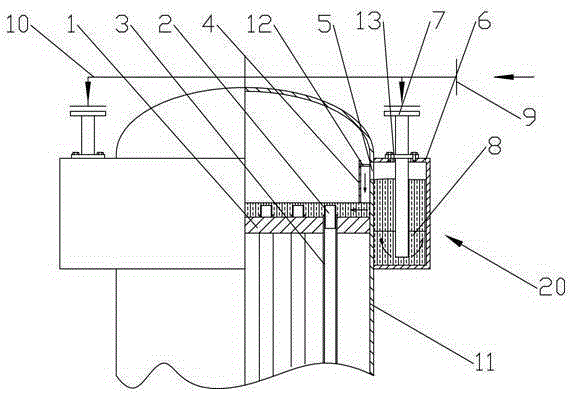

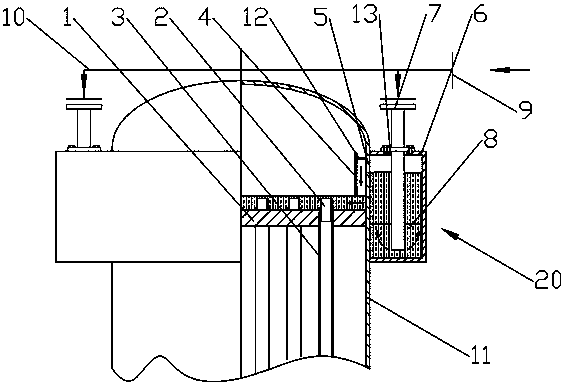

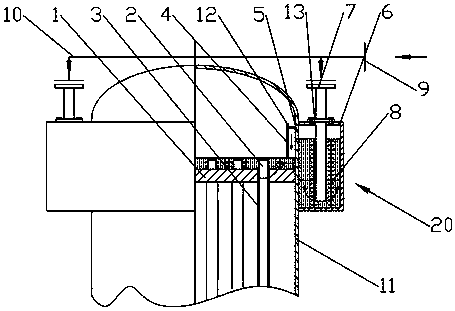

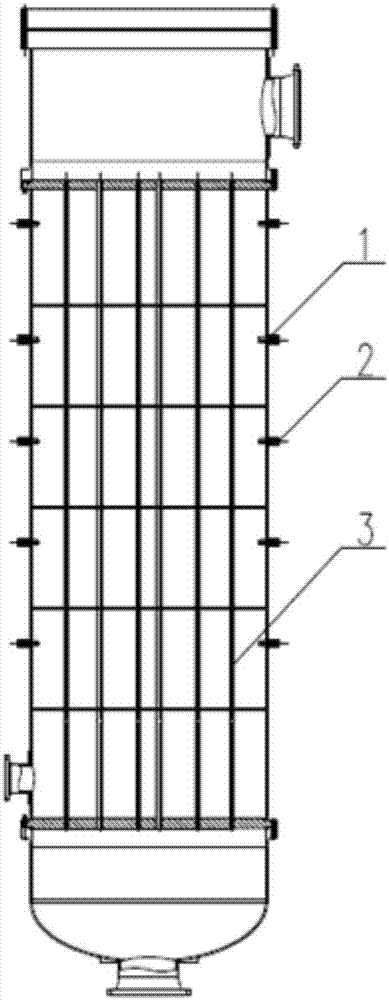

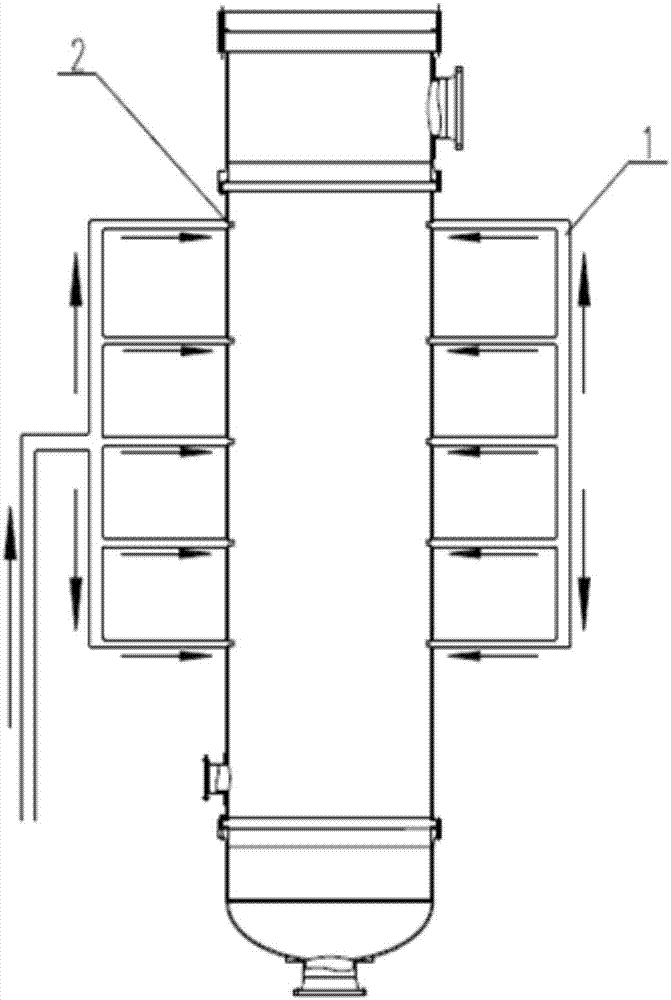

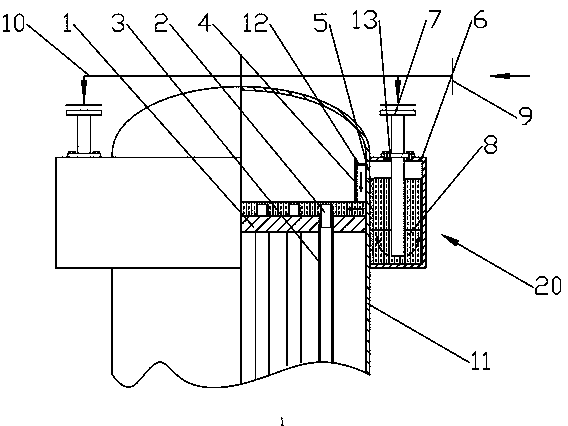

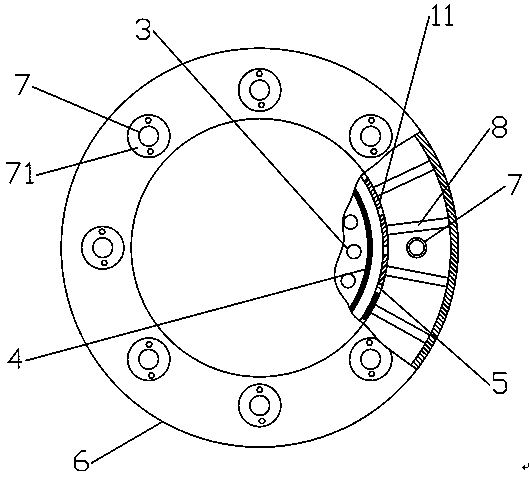

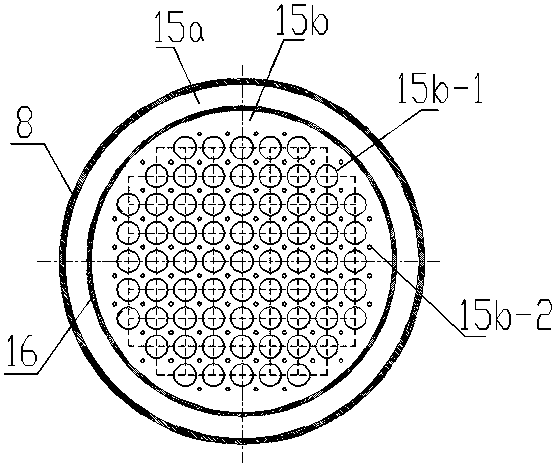

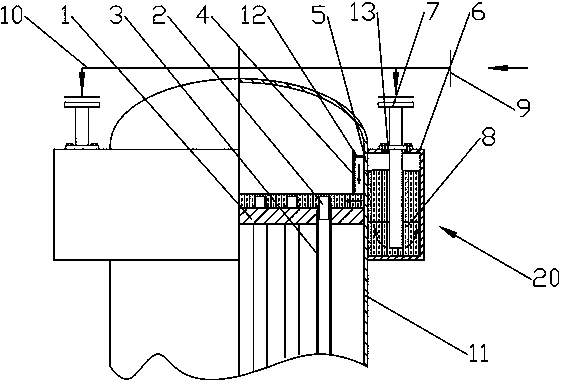

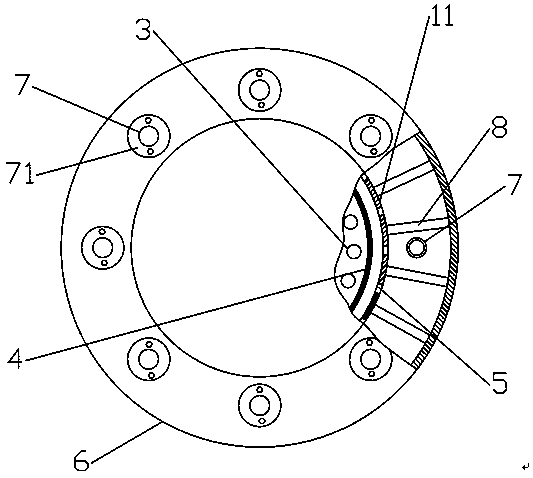

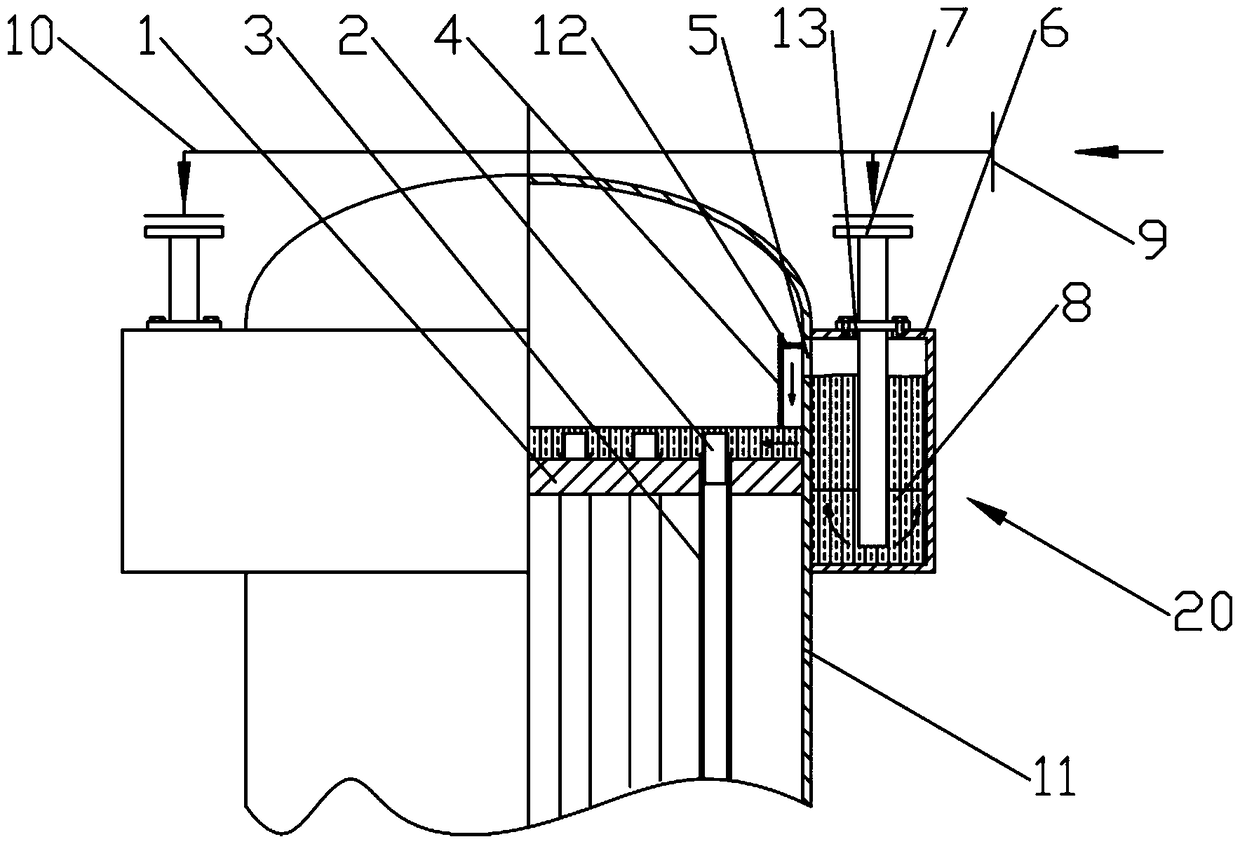

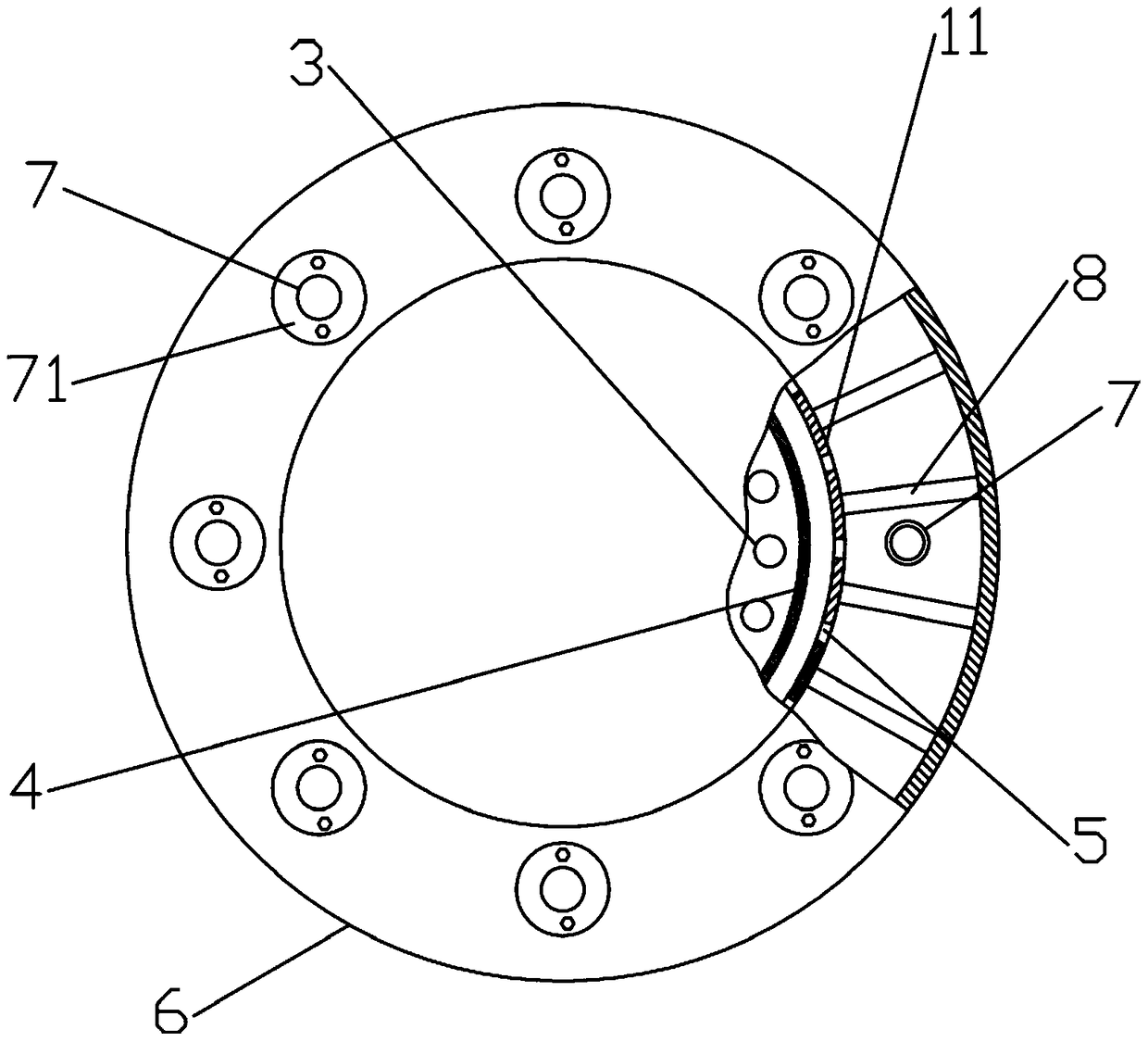

Vertical-tube falling film absorption reactor

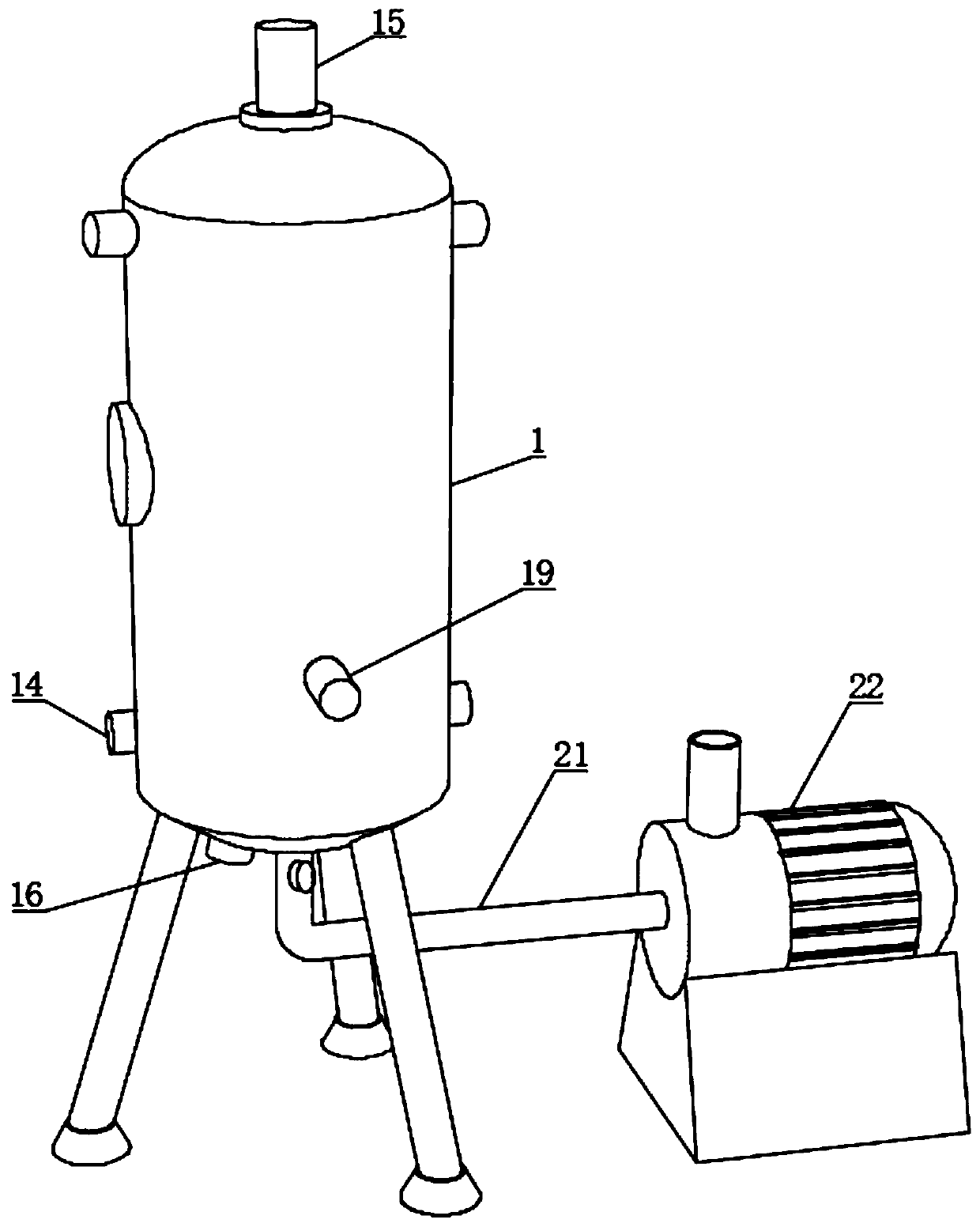

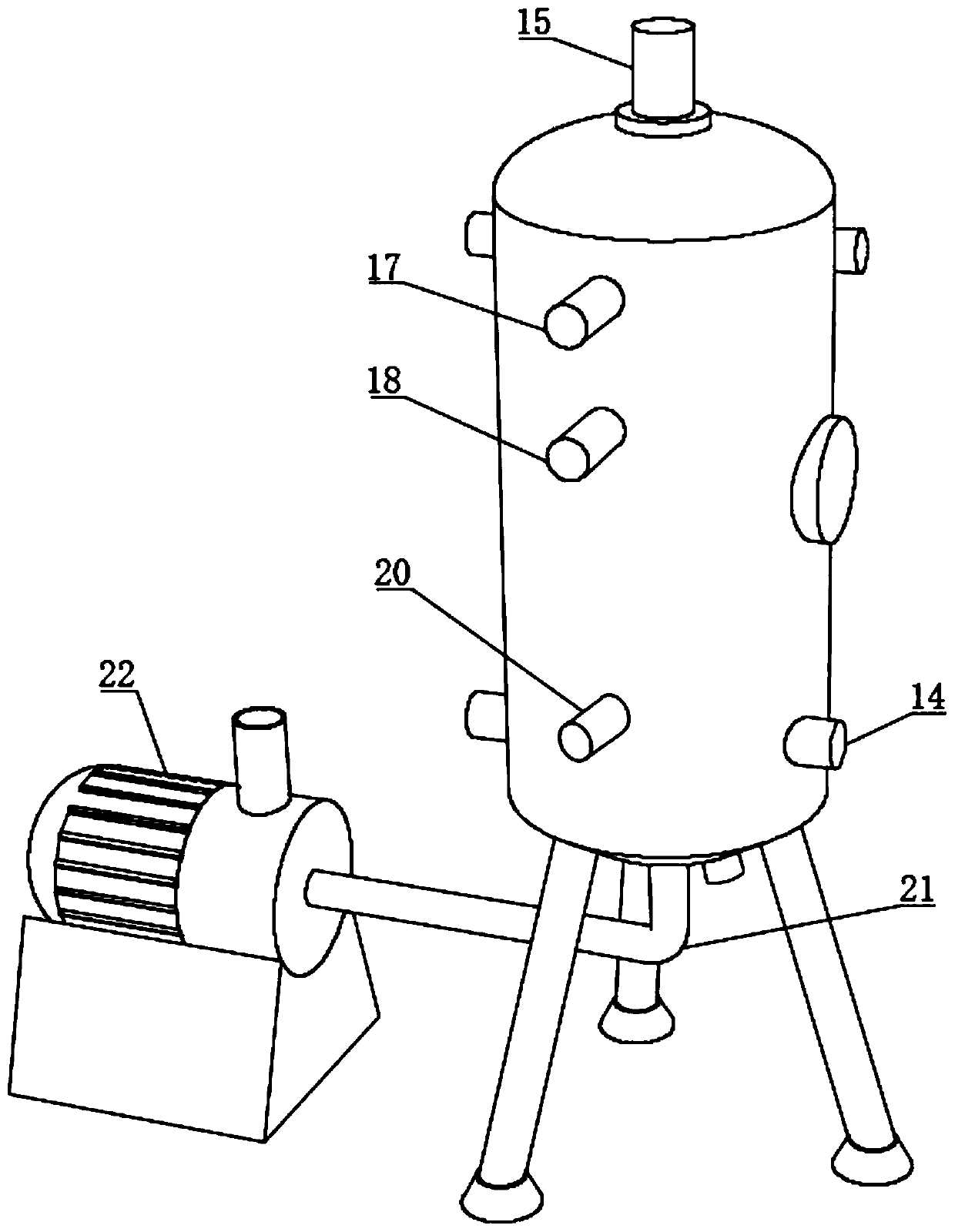

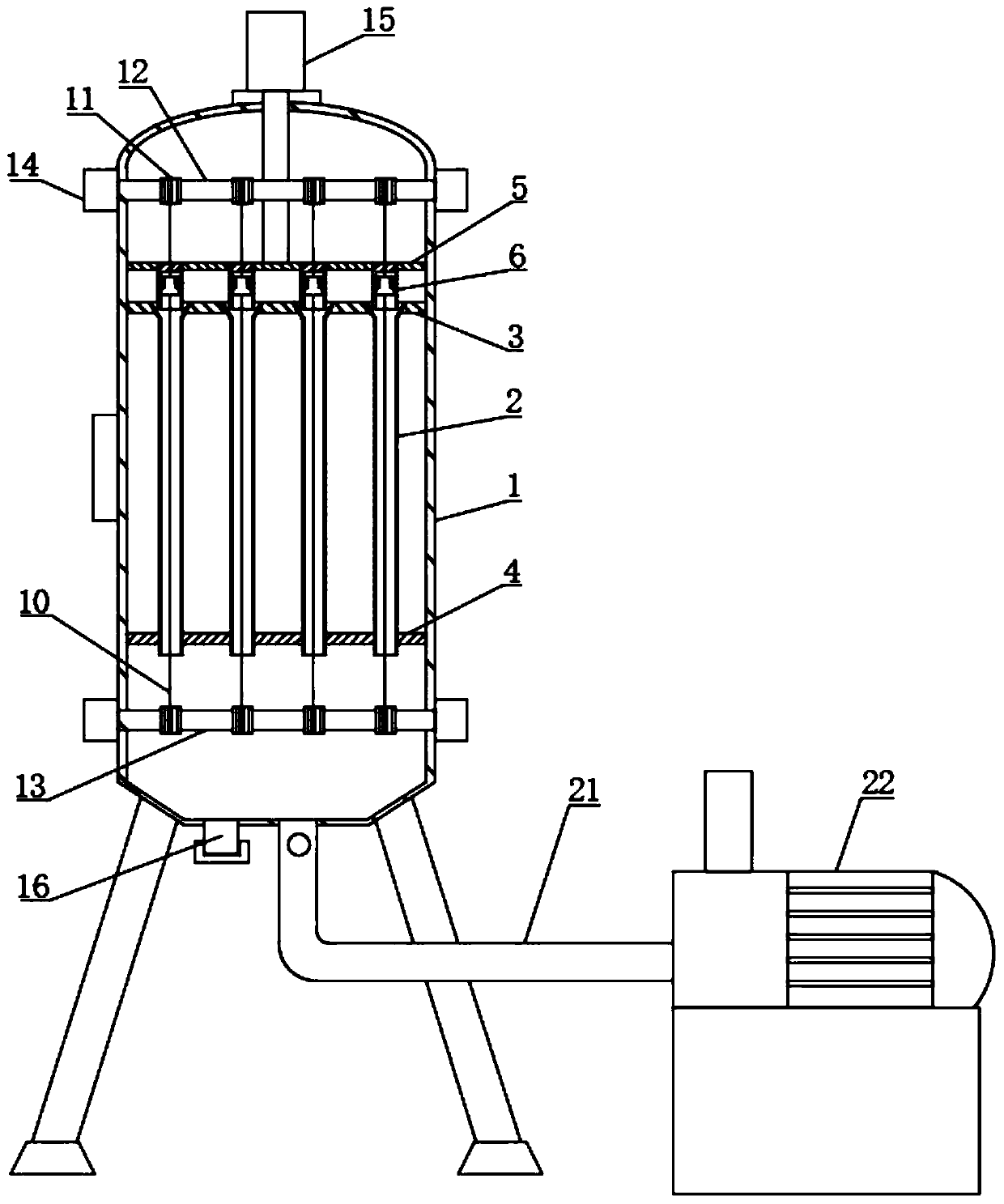

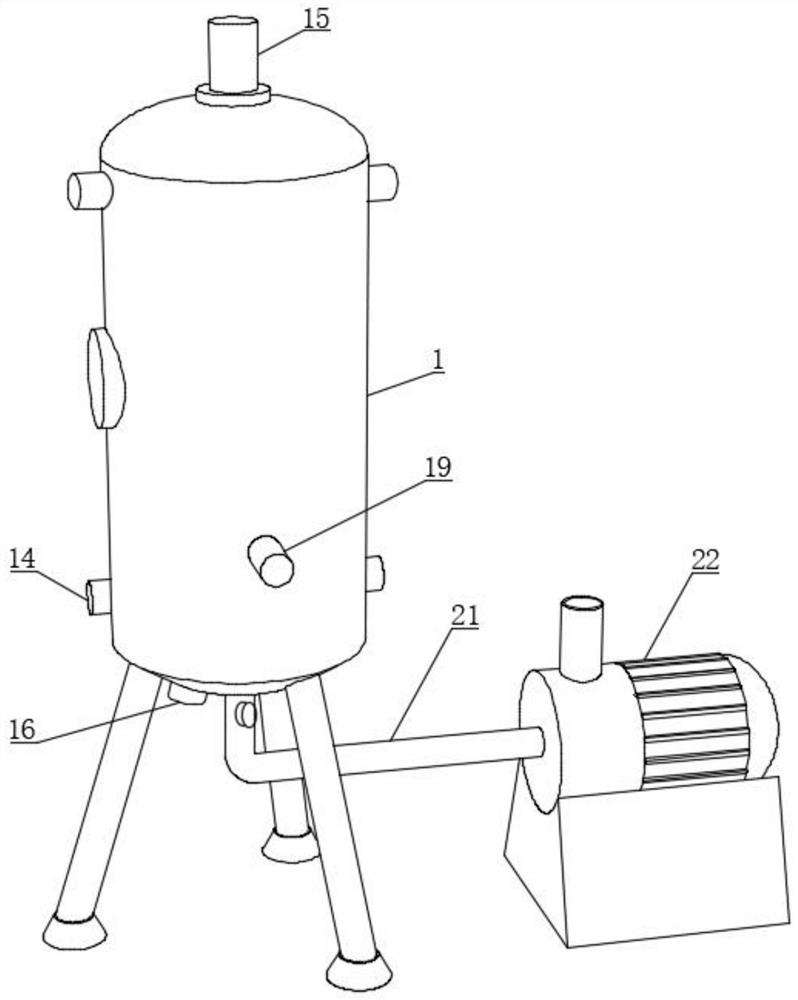

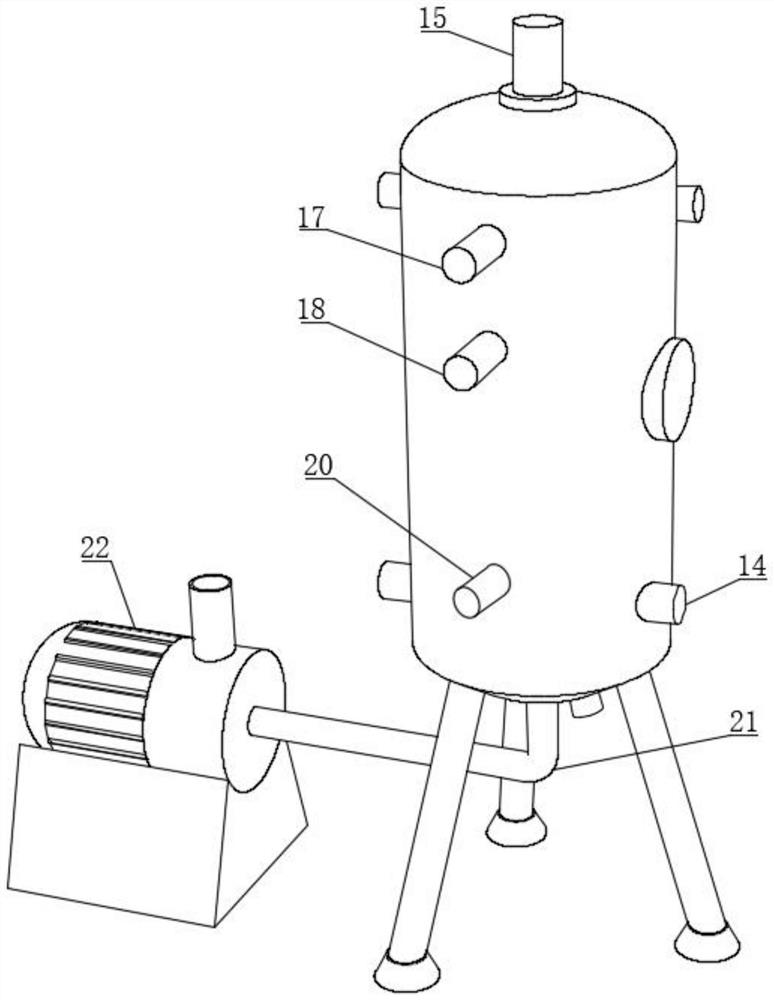

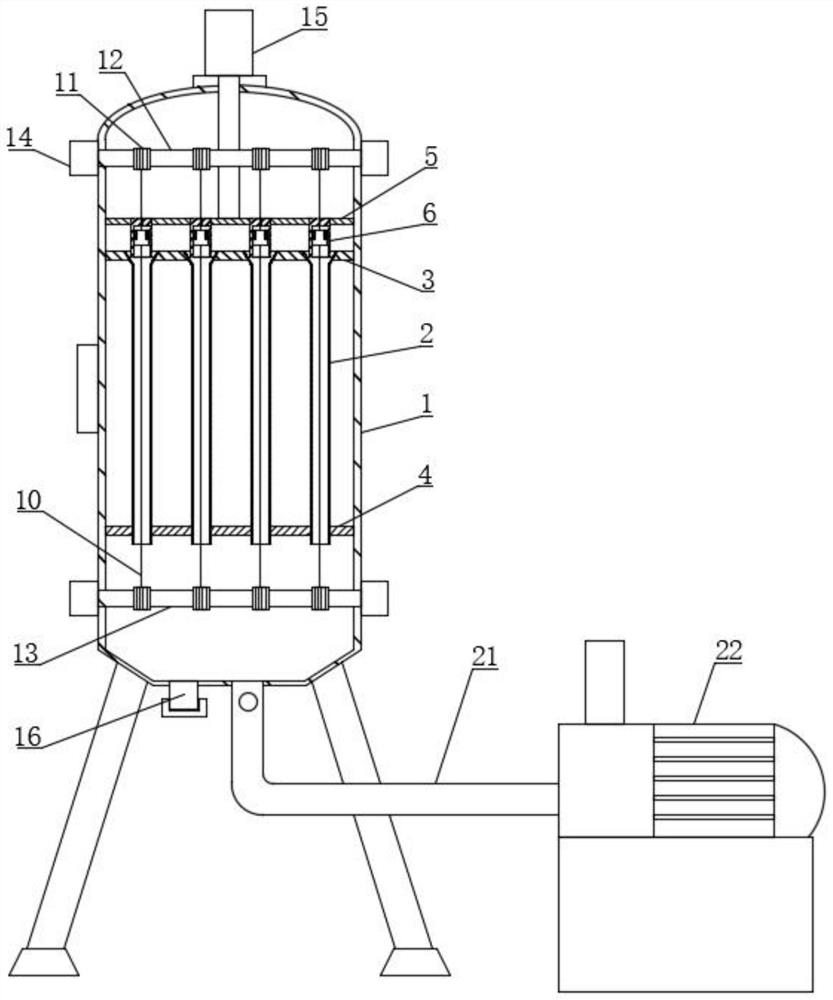

ActiveCN106268595AUniform film distributionUniform supplyLiquid-gas reaction of thin-film typeChemical/physical/physico-chemical stationary reactorsVertical tubeBarrel Shaped

A vertical-tube falling film absorption reactor comprises an upper tube box, a lower tube box and a shell, wherein the shell is arranged between the upper tube box and the lower tube box and is connected with the upper tube box and the lower tube box in a sealed manner respectively; a tube plate is arranged at each of the upper end and the lower end of the shell; a vertical tube bundle is arranged between the two tube plates; a film distributing device is arranged inside the shell; the film distributing device comprises an upper liquid distributing plate, a lower liquid distributing plate, and a barrel-shaped overflowing plate arranged on the upper liquid distributing plate; film distributing annular spaces are formed between lower liquid distributing plate tube holes in the lower liquid distributing plate and heat exchange tubes running through the lower liquid distributing plate tube holes; centering bulges for centering the heat exchange tubes are arranged inside the lower liquid distributing plate tube holes; spiral grooves are formed in the outer walls of the heat exchange tubes. The vertical-tube falling film absorption reactor uses the more reasonable film distributing device, so that purposes of uniformly distributing a liquid film and stably forming the film can be achieved, a dry wall phenomenon can be avoided, and the heat transfer efficiency and the mass transfer efficiency are greatly improved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

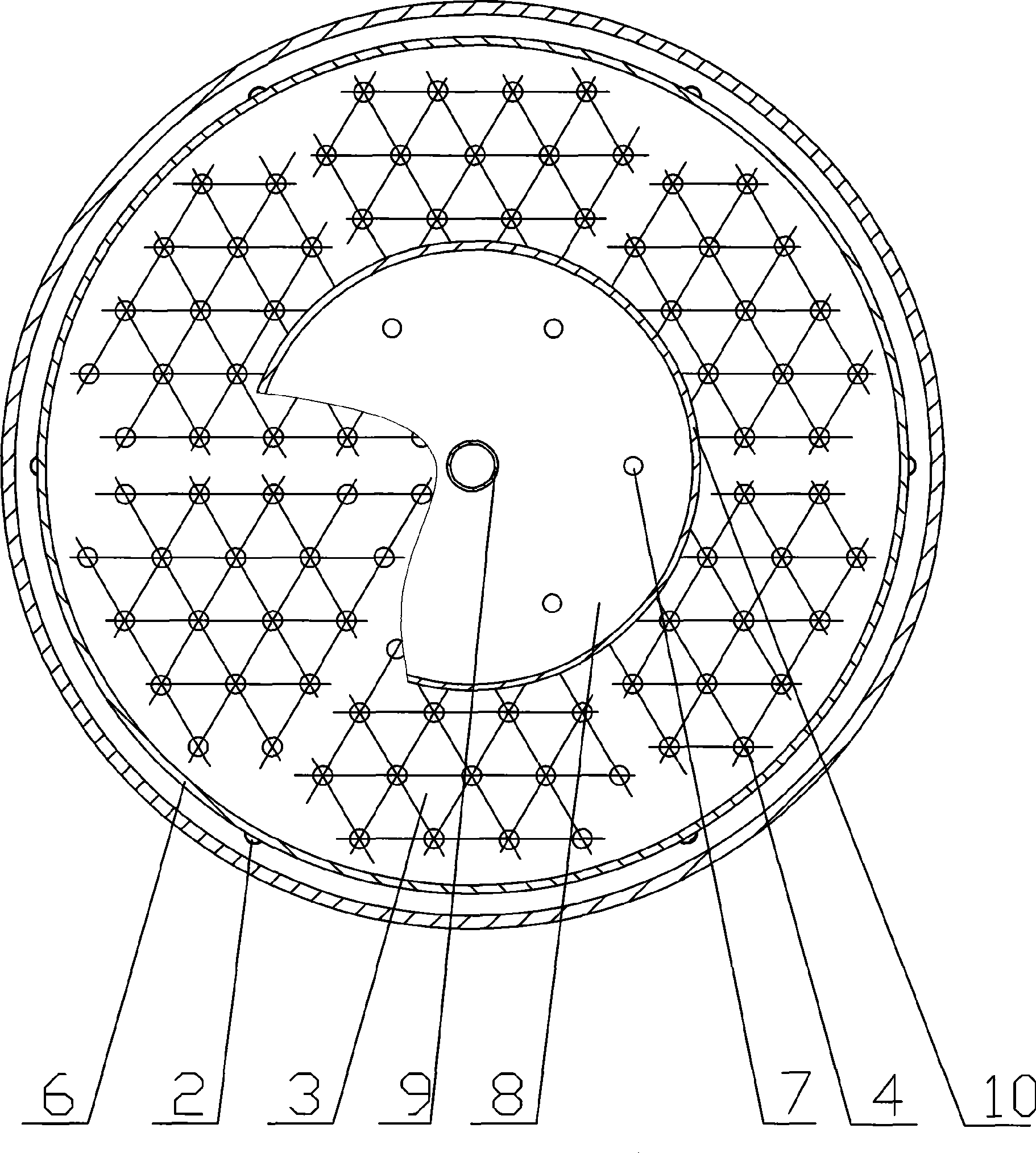

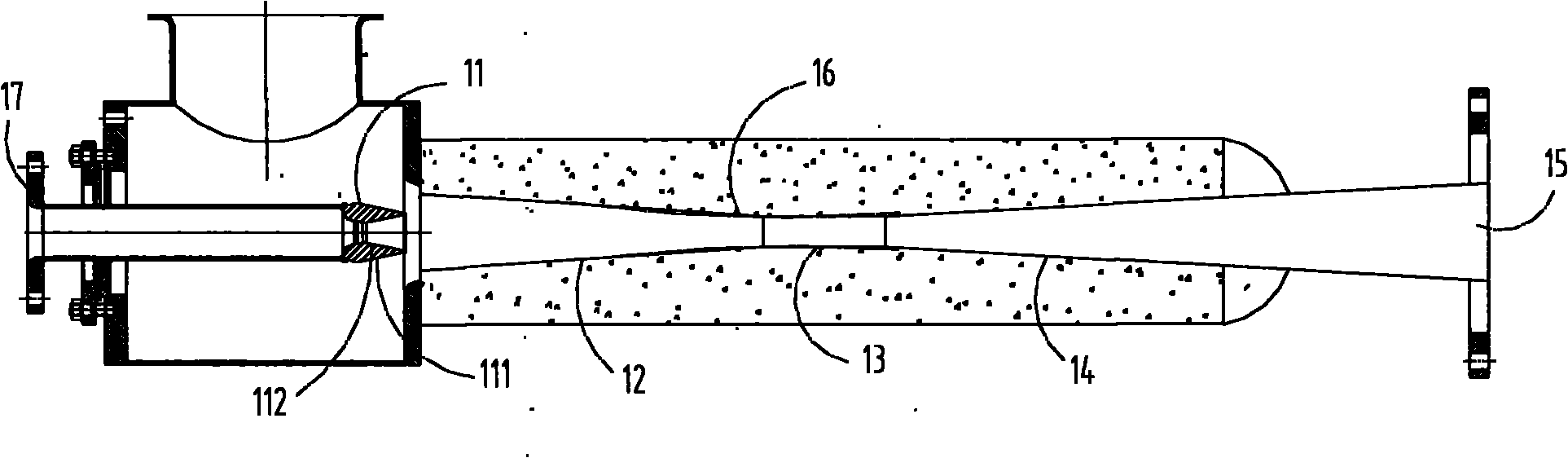

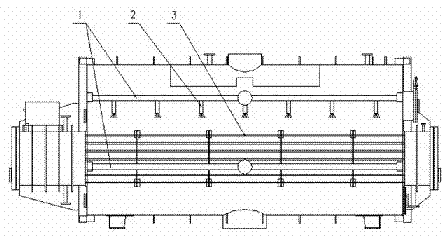

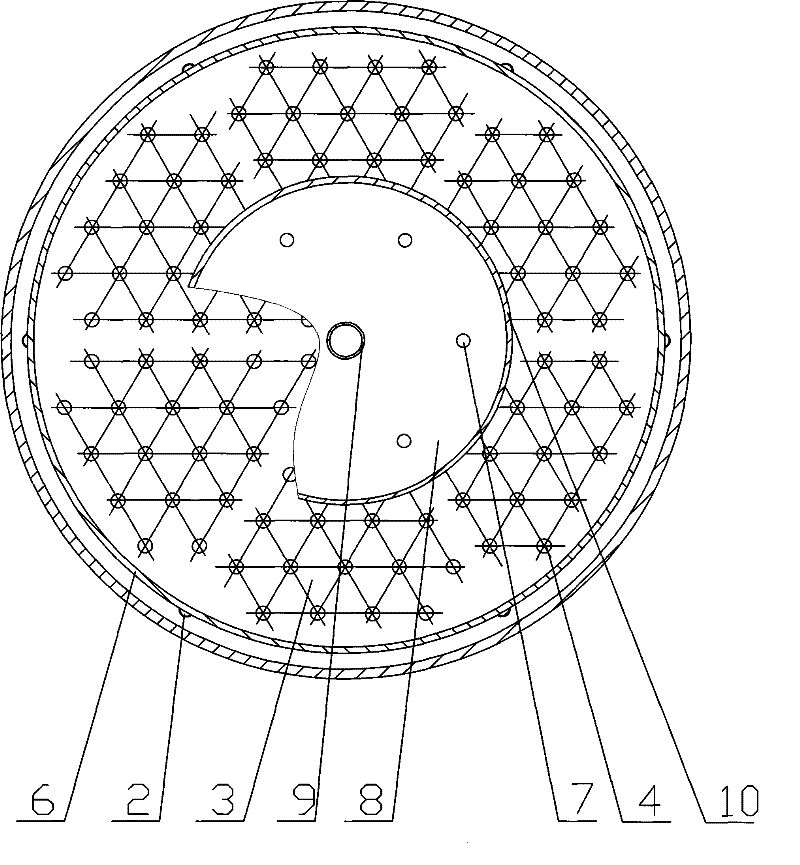

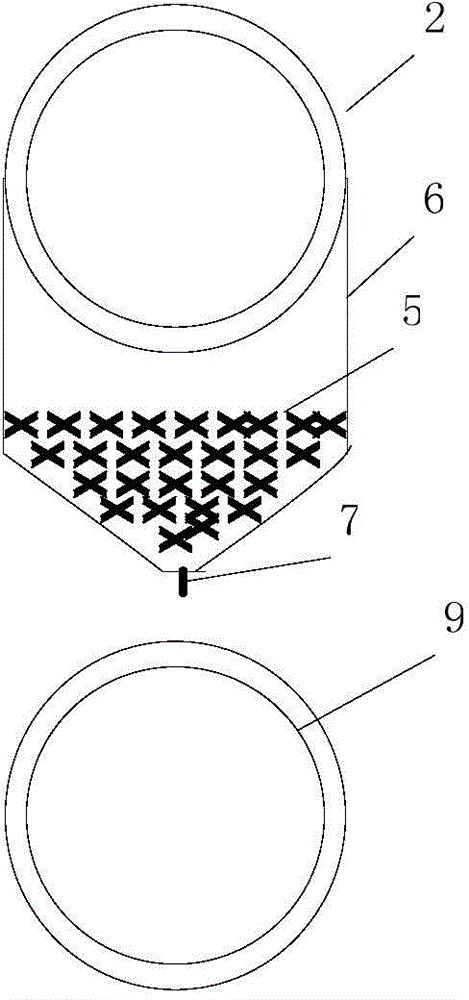

Distributer of horizontal falling film evaporator

InactiveCN103657123AImprove efficiencyEvenly distributedEvaporator accessoriesAgricultural engineeringFalling film evaporator

The present invention discloses a distributer of a horizontal falling film evaporator. The distributer comprises distribution pipe, a distribution tank and a falling film evaporation pipe, wherein the bottom of the distribution pipe is provided with primary distribution holes, various pipe holes are uniformly distributed, the distribution tank is arranged below the distribution pipe, presents a tapered shape, and is connected with the distribution pipe through a welding manner, the lower half portion of the distribution tank is filled with a porous material, a separation plate is longitudinally arranged to separate the distribution tank into mutually-noncommunicated areas, the bottom of the distribution tank is provided with uniformly-distributed secondary distribution holes, both sides of the secondary distribution holes are embedded with draining projections for providing a draining effect, the falling film evaporation pipe is positioned just below the distributer, the positions of the secondary distribution holes and the draining projections are just toward the axis center of the falling film evaporation pipe, both ends of the falling film evaporation pipe are sealed by using flanges and washers, and the distribution pipe and the distribution tank are respectively connected with the horizontal falling film evaporation cylinder body through welding. The distributer has characteristics of simple structure, easy installation processing, uniform film distribution, increased evaporator efficiency, and energy source saving.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

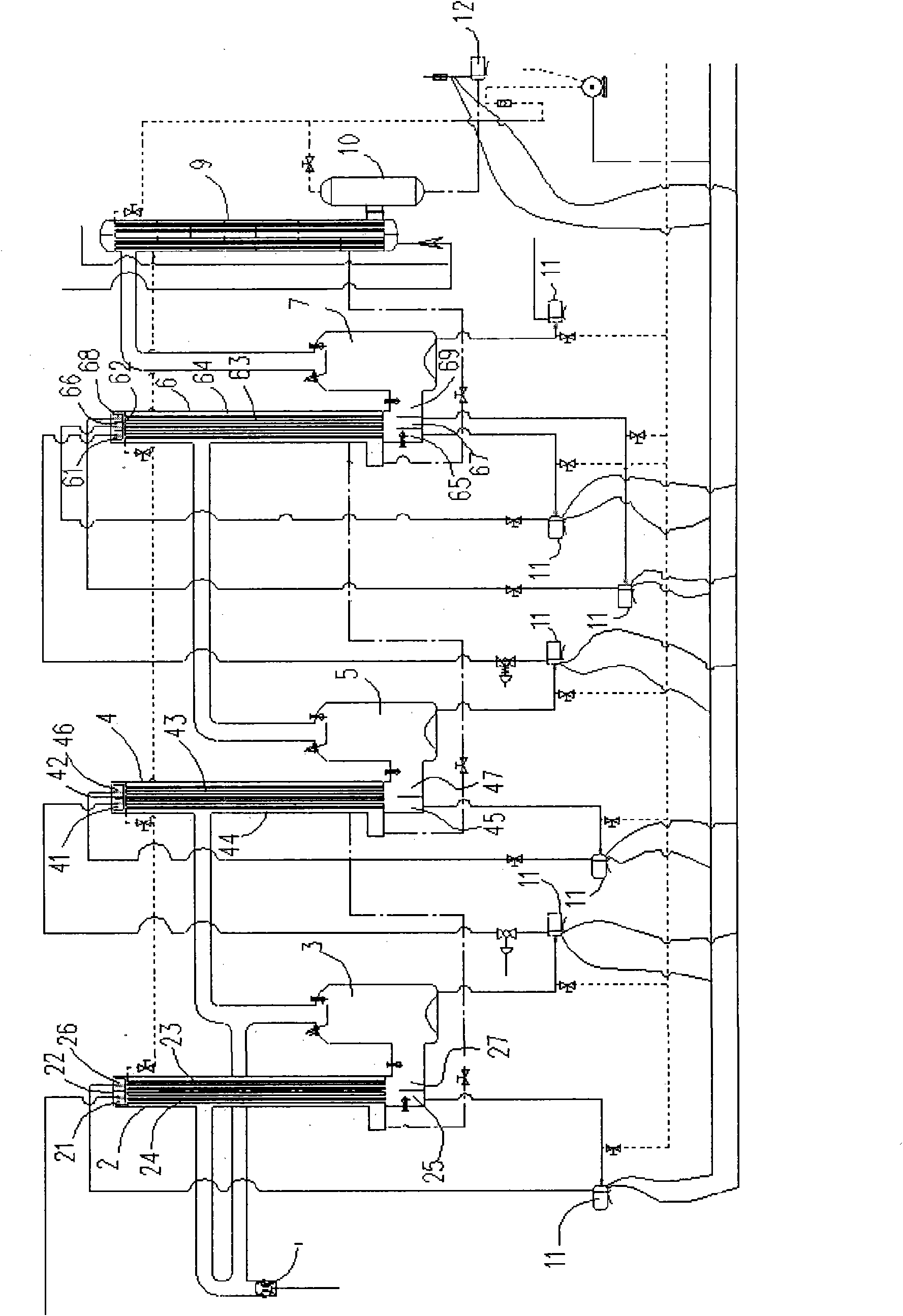

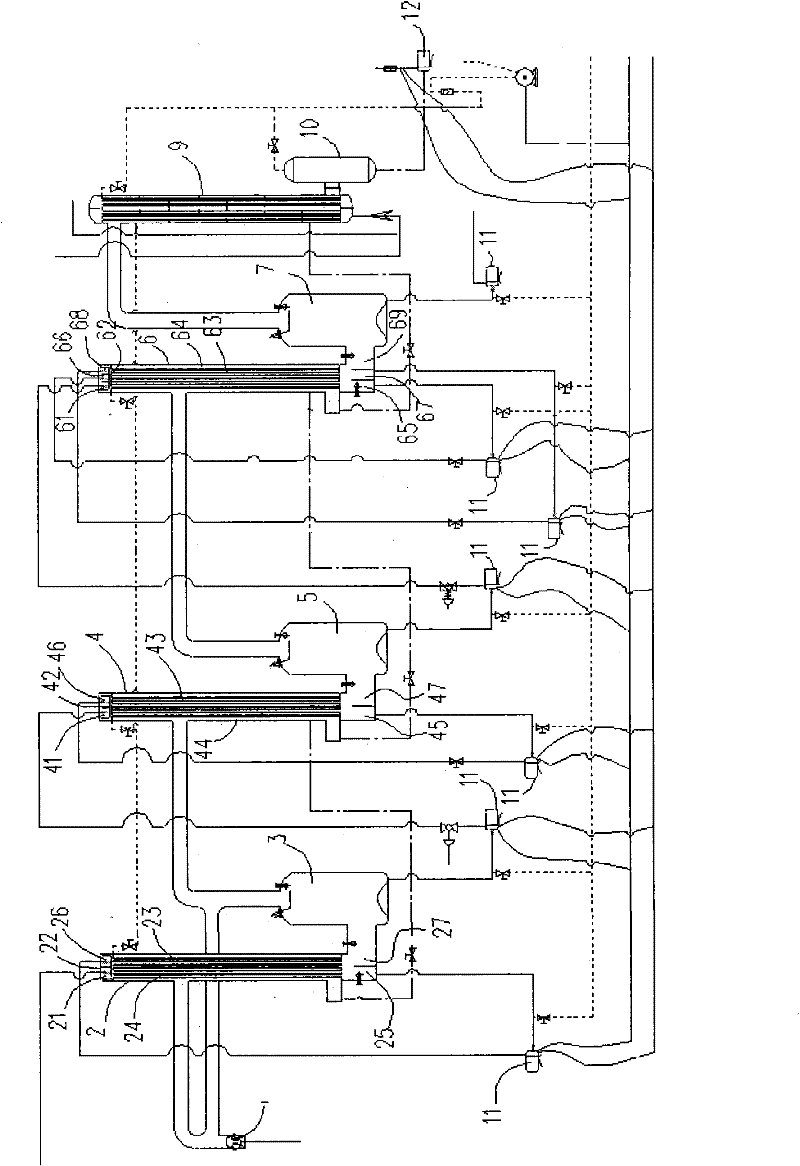

Triple effect seven-stroke falling film evaporator

InactiveCN101804262AReduce consumptionReduce power consumptionMultiple-effect evaporationEngineeringDistributor

The invention discloses a triple effect seven-stroke falling film evaporator, wherein each feed cavity and each discharge cavity are respectively divided into a plurality of feed cavities and a plurality of discharge cavities by a riser; a previous discharge cavity of each effect is connected with a latter feed cavity of the effect. The invention improves the evaporation effect effectively by increasing the stroke, and reaches the goal of disposable material feeding and product finishing; solves the problems of seriously affecting the quality of the products, such as insufficient supply of the back stroke falling film tube feed liquid, degraded irrigation rate of periphery of the falling film tube, poor film-forming property, phenomenon of tube burning and wall drying, by the mixed design of distributor; and has the advantages of wide application range, energy-saving and environmental protection.

Owner:温州市天龙轻工设备有限公司

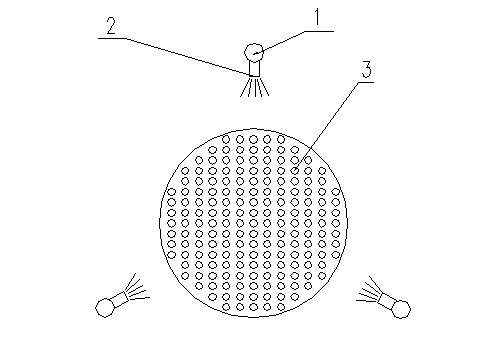

Film distributing device for horizontal tube type spraying falling-film evaporator

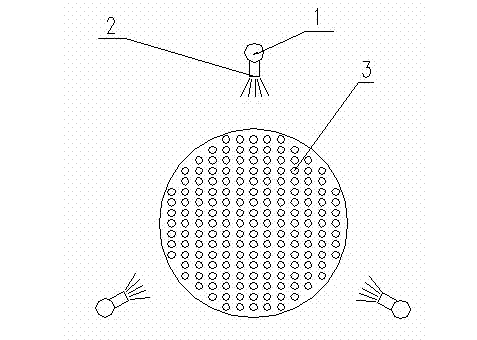

InactiveCN101991965AImprove efficiencyUniform film distributionEvaporator accessoriesEvaporators with horizontal tubesSpray nozzleTubes types

The invention discloses a film distributing device for a horizontal tube type spraying falling-film evaporator, which comprises a spray pipe and a plurality of nozzles on the spray pipe. In the device, a plurality of spray pipes are arranged on the periphery of a heat pipe bundle of the horizontal tube type spraying falling-film evaporator, when the number of the spray pipes is 3, the spray pipes enclosing the heat pipe bundle of the horizontal tube type spraying falling-film evaporator are distributed in an included angle of 120 degrees, wherein one spray pipe is positioned right above the heat pipe bundle of the horizontal tube type spraying falling-film evaporator; the nozzles are fog-shaped nozzles. The spray pipes and nozzles are arranged around the heat pipe bundle of the horizontal tube type spraying falling-film evaporator in a multidirectional manner, so the film on the surface of the heat pipe under the evaporator can be distributed uniformly, film drying and film cracking can be avoided, and the efficiency of the evaporator can be improved.

Owner:苏州市中衡压力容器制造有限公司

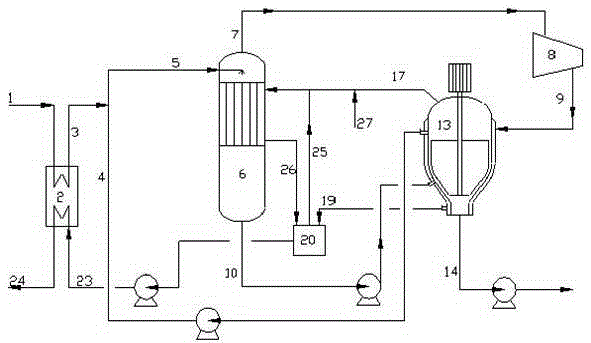

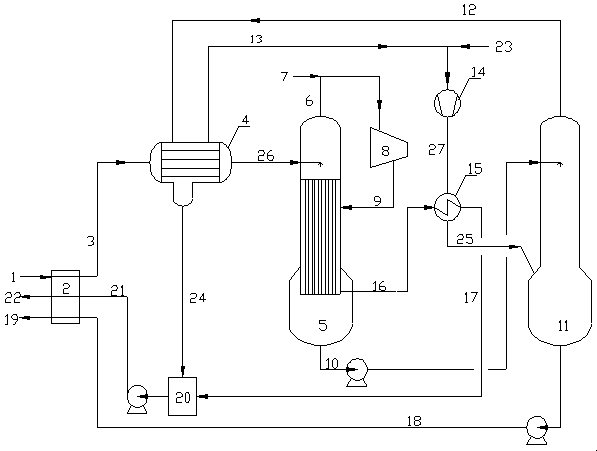

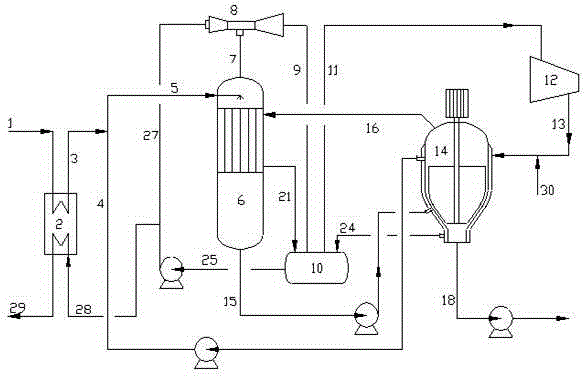

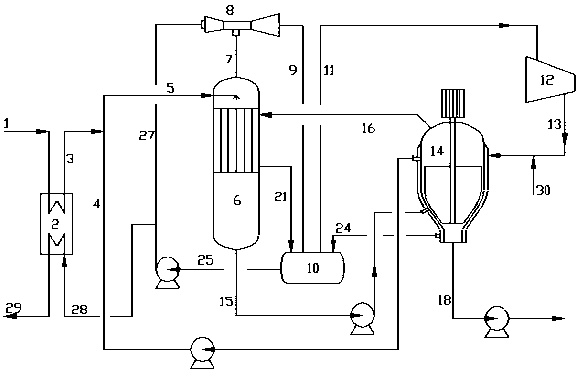

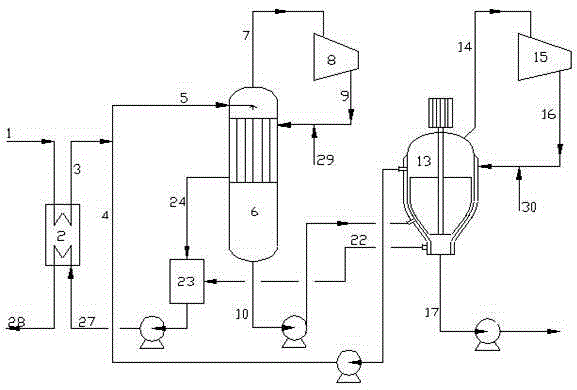

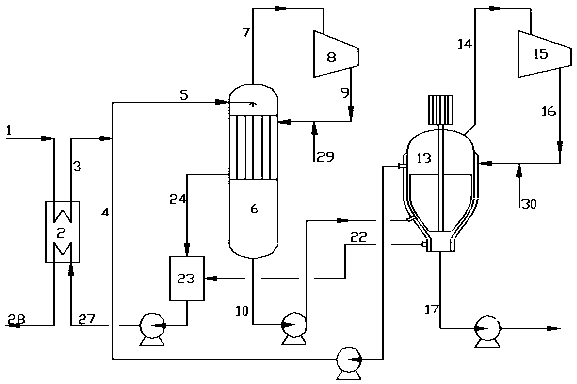

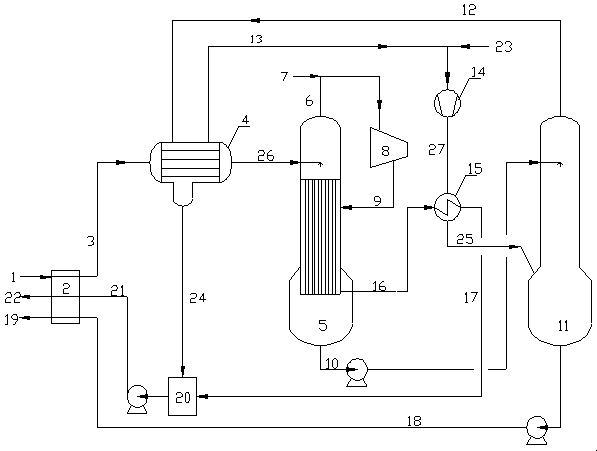

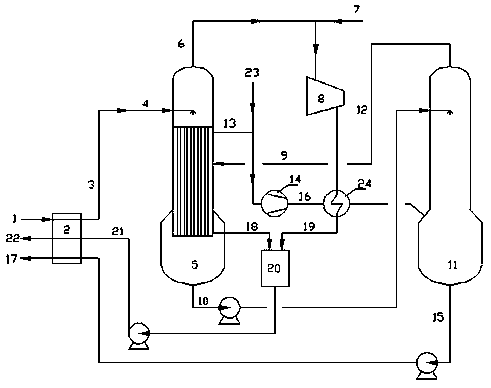

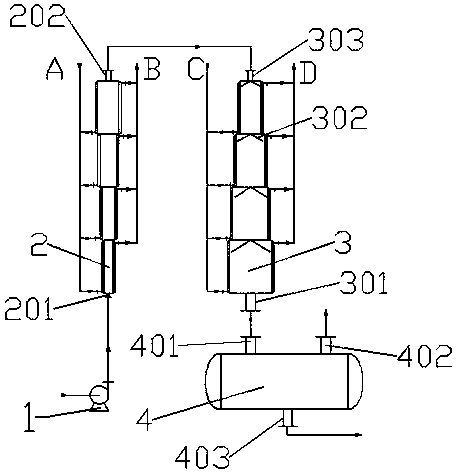

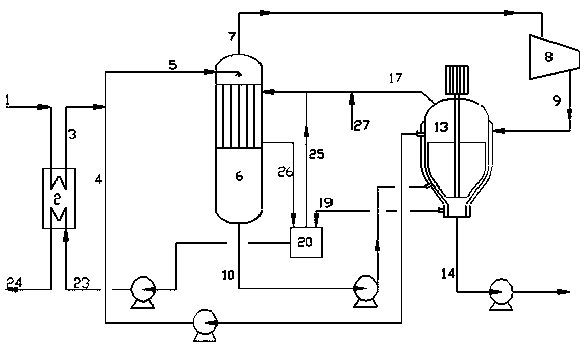

Method and device for treating wastewater containing organic matters

ActiveCN106630336AAchieve recyclingReach outWater contaminantsEvaporationOrganic matterWastewater disposal

The invention provides a method and device for treating wastewater containing organic matters. The device comprises a wastewater pre-heater, an evaporator, a scaling device, a steam compressor and a condensed water collector. The invention further provides the method for treating the wastewater containing the organic matters by adopting the device. The method and device for treating the wastewater, provided by the invention, have the advantages of safety and reliability, simple equipment, low operation cost, obvious energy-saving effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Double-effect combined inverted-cone-shaped graphite falling film evaporator

ActiveCN111467822AUniform film distributionEfficient cleaningEvaporator accessoriesGraphiteMechanical engineering

The invention discloses a double-effect combined inverted-cone-shaped graphite falling film evaporator, and belongs to the field of falling film evaporators. The double-effect combined inverted-cone-shaped graphite falling film evaporator comprises a shell; an upper disc and a lower disc are fixedly connected in the interior of the shell; the upper disc is positioned on the upper side of the lowerdisc; a plurality of uniformly distributed heat exchange tubes are arranged in the shell; and the upper ends and the lower ends of the heat exchange tubes penetrate the upper disc and the lower disccorrespondingly and are fixedly connected with the interiors of the upper disc and the lower disc. The cloth film thickness can be reasonably set according to the characteristics of viscosity, flowingproperty and the like of the feed liquid; the feed liquid can smoothly flow along the inner walls of the heat exchange tubes in a film shape; uniform film distribution of the feed liquid in the heatexchange tubes is ensured; compared with a conventional falling film evaporator, the provided falling film evaporator has better adaptability; the problem that feed liquid scales in the heat exchangetubes are difficult to clean is solved by arranging line connection type cleaning columns in a liquid separation groove, multiple heat exchange tubes can be efficiently and synchronously cleaned, andthe falling film evaporator can be well used for multiple times in cycle.

Owner:南通熠能精细石墨科技有限公司

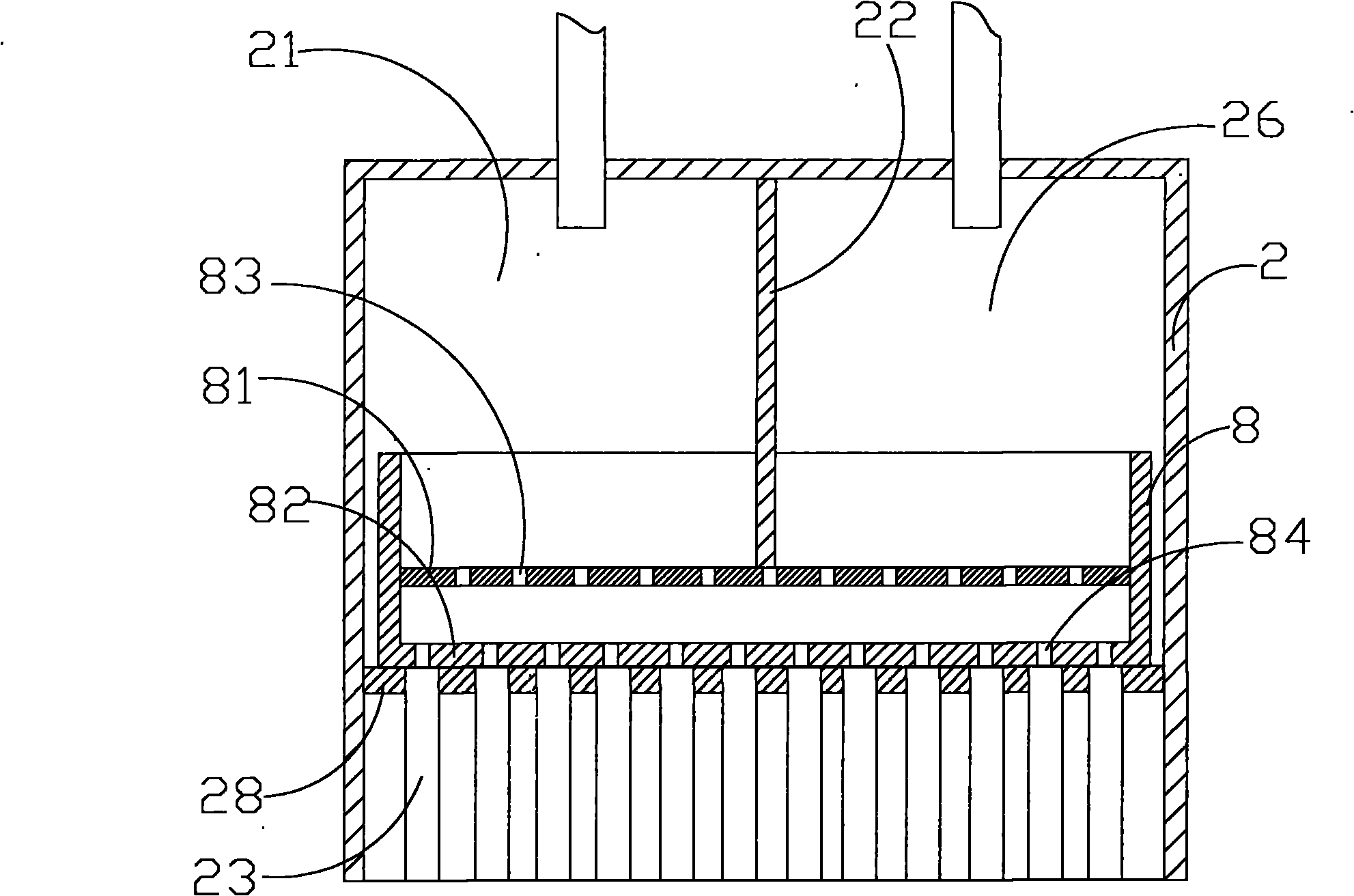

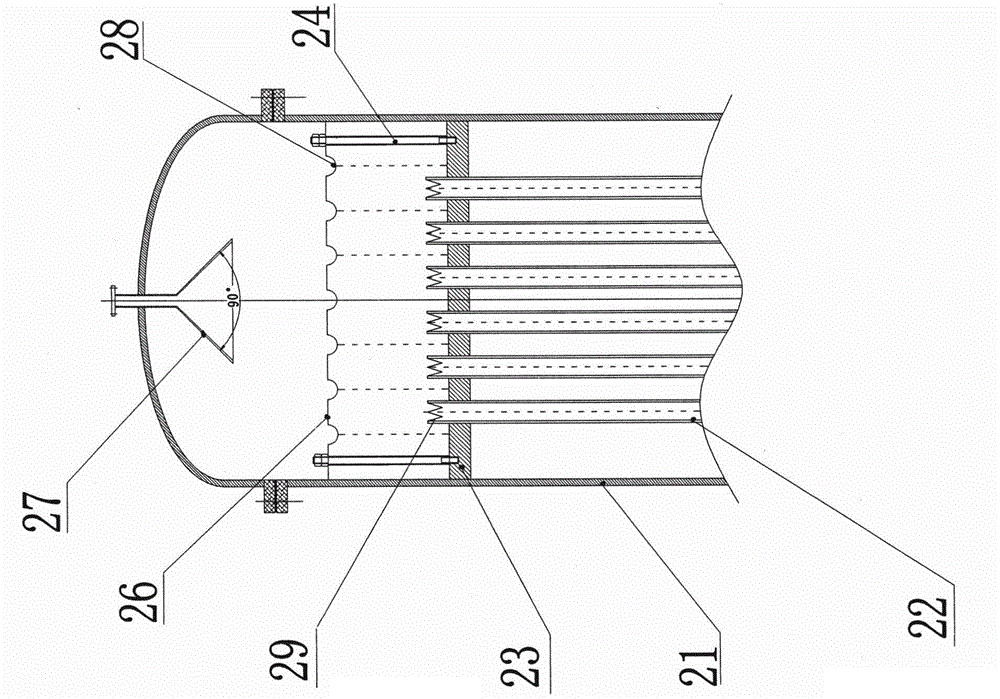

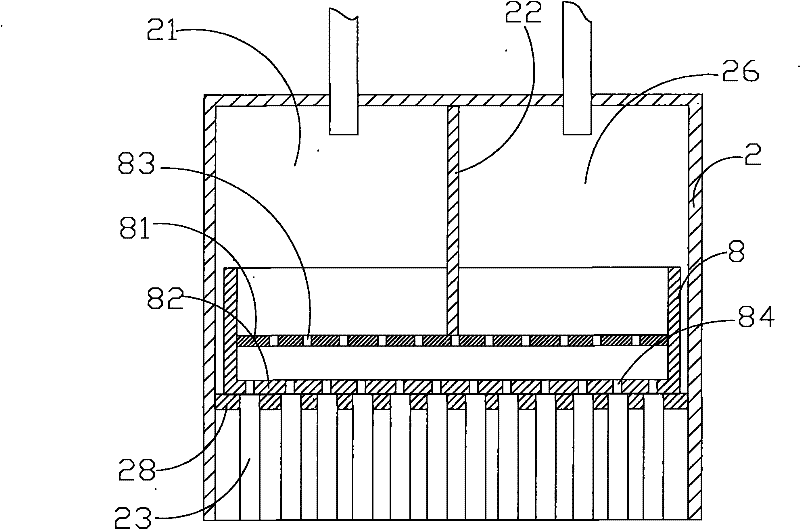

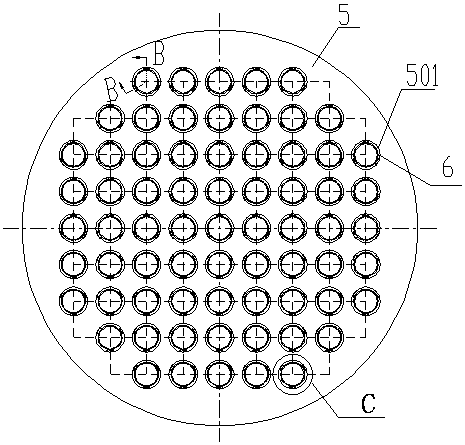

Three-grade-film-falling distribution heater

The invention discloses a three-grade-film-falling distribution heater. The three-grade-film-falling distribution heater comprises a heater cylinder (21), heating tubes (22) and a tube plate (23). A first-grade distribution spraying head (27) is installed in the top of the heater cylinder (21). A second-grade distribution disc (26) is installed at the portion, in the heater cylinder (21), between the first-grade distribution spraying head (27) and the tube plate (23). Tube openings of the heating tubes (22) extend to the portion above the tube plate (23) and are provided with sawtooth-shaped overflowing openings (29). According to the three-grade-film-falling distribution heater, due to a three-grade-film-falling distribution mode, material film-type distributing is even, film-type flowing evaporation of materials is formed in the heating tubes, the aim that coking and walling drying of the heating tubes are avoided is achieved, and the effect of improving the heating efficiency of the heater is achieved.

Owner:ZHEJIANG SUNNY MACHINERY TECH

Wastewater treatment method and system

ActiveCN108069479AHigh latent heatAvoid foulingWater/sewage treatment by heatingWater/sewage treatment by degassingGas compressorWater resources

The invention provides a wastewater treatment method and system. The system comprises a wastewater preheater, a wastewater heater, an evaporator, a stripping tower, a vapor compressor, a heat exchanger, a non-condensable gas compressor and a condensed water collector. The invention further provides the wastewater treatment method adopting the system. The wastewater treatment method and system havethe advantages that safety and reliability are achieved, equipment is simple, operating cost is low, energy-saving effect is remarkable and the like, and 50%-95% of water resource can be recycled.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

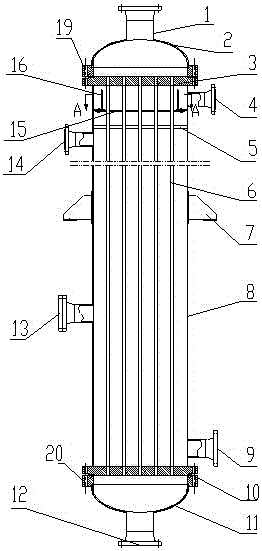

Lateral-feed falling-film evaporator

ActiveCN106267869ACompact structureIncrease the heat exchange areaEvaporationEngineeringFalling film evaporator

The invention relates to the field of chemical heating equipment, and discloses a lateral-feed falling-film evaporator including a shell body, a pipe plate, evaporation pipes and a liquid supply device, and the pipe plate is arranged on the upper part of the shell body; a plurality of evaporation pipes are vertically arranged in the shell body, and the upper ends of the evaporation pipes pass through the pipe plate; the upper ends of the evaporation pipes are provided with a flow guiding device; the liquid supply device comprises a liquid inlet groove and branched feed pipes, and the liquid inlet groove is vertically arranged at the upper part of the outer wall of the shell body and surrounds the whole shell body; the liquid inlet groove is uniformly provided with a plurality of branched feed inlets; the branched feed inlets are formed on the upper side wall of the liquid inlet groove, the lower ends of the branched feed pipes vertically pass through the branched feed inlets and extend into the liquid inlet groove, and the lower ends of the branched feed pipes are close to the bottom of the liquid inlet groove; the shell body is provided with a plurality of overflow channels communicating with the liquid inlet groove. The lateral-feed falling-film evaporator has the advantages of simple and compact structure, and effectively shrinks the height of the device; the lateral-feed falling-film evaporator has the advantages of large liquid flowing amount, and convenience in operation and maintenance; and with use of the device, the liquid distribution rate is high, the film distribution is uniform, and the device is not easy to block and is easy to clean.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method and treatment apparatus for organic wastewater

ActiveCN106630338AAchieve recyclingPrevent scalingWater contaminantsEvaporationGas compressorWater collection

The present invention provides a treatment method and a treatment apparatus for organic wastewater. The treatment apparatus comprises a wastewater preheater, an evaporator, an ejector, a fouling device, a steam compressor and a condensation water collection separator. The present invention further provides a method for treating organic wastewater by using the treatment apparatus. According to the present invention, the treatment method and the treatment apparatus have advantages of safety, reliability, simple equipment, low operation cost, energy saving, significant effect, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Film distributing device for horizontal tube type spraying falling-film evaporator

InactiveCN101991965BImprove efficiencyUniform film distributionEvaporator accessoriesEvaporators with horizontal tubesEngineeringTubes types

Owner:苏州市中衡压力容器制造有限公司

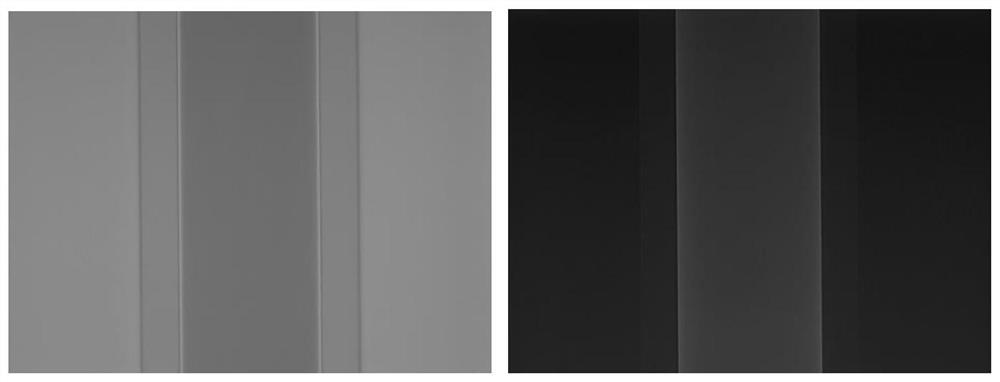

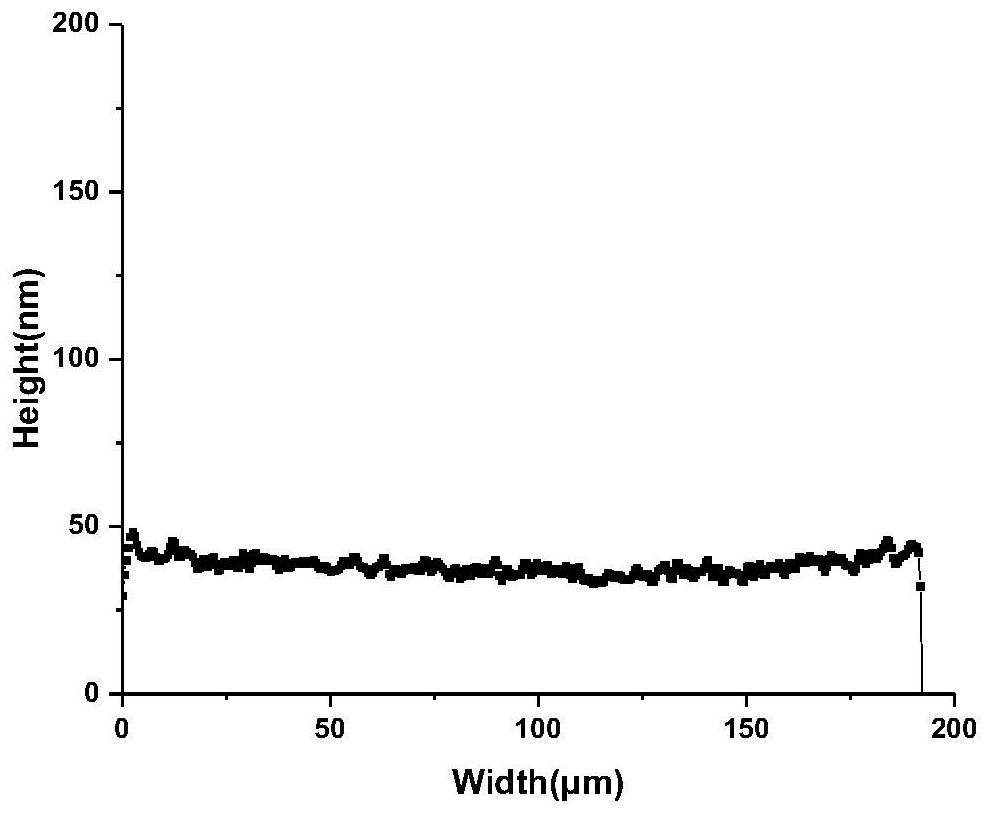

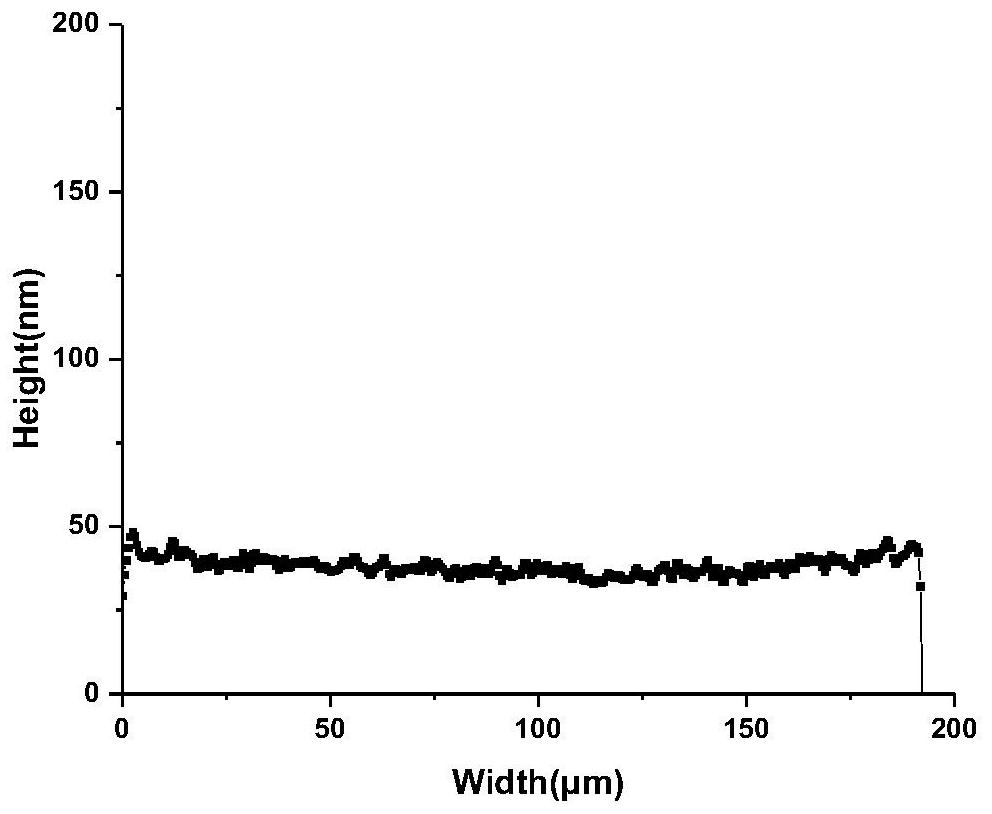

A kind of organic luminescent material ink and its preparation method and inkjet printing method

ActiveCN111876020BQuality improvementUniform film distributionDuplicating/marking methodsInksOrganic solventHigh surface

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Film-distributing device of tube-type down-flow evaporator

InactiveCN101376066BExtended service lifeSimple structureEvaporators with vertical tubesEngineeringTubes types

The invention discloses a cloth membrane device of a long-tube falling film evaporator, which comprises an upper tube sheet arranged in the housing of the evaporator, a plurality of lower support rods arranged on the upper tube sheet, and a distribution tray arranged at the upper end part of the lower support rod, wherein a plurality of distribution holes which are evenly distributed and communicated from top to bottom are formed on the distribution tray, and cloth membrane apparatus is arranged in the distribution holes; a lap of check rings are arranged on the distribution tray, and a plurality of support rods are formed on the distribution tray; an overfall tray is arranged on the support rods and a connecting pipe is arranged at the middle of the overfall tray; and a lap of overflow dam is arranged at the periphery of the overfall tray, and a corresponding overflow pipe is arranged at the middle part of the distribution tray which corresponds to the connecting pipe. The cloth membrane device has the advantages of simple structure and evenly distributed cloth membrane; besides, no dry film and split film are generated in a heating pipe, so that the service life of the long-tubefalling film evaporator can be prolonged.

Owner:苏州市中衡压力容器制造有限公司

Method and device for treating organic wastewater

ActiveCN106630338BAchieve recyclingPrevent scalingWater contaminantsEvaporationProcess engineeringWater collection

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic matter-containing wastewater treatment method and device

ActiveCN106630339AAchieve recyclingReach outWater contaminantsEvaporationOrganic matterOperating cost

The invention provides an organic matter-containing wastewater treatment method and device. The treatment device comprises a wastewater pre-heater, an evaporator, a scaling device, a first-effect steam compressor, a second-effect steam compressor and a condensation water collector. The invention also provides the organic matter-containing wastewater treatment method adopting the device. The wastewater treatment method and device provided by the invention have the advantages of safety, reliability, simple equipment, low operating cost, obvious energy saving effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A double-effect combined inverted conical graphite falling film evaporator

ActiveCN111467822BUniform film distributionEfficient cleaningEvaporator accessoriesEngineeringGraphite

Owner:南通熠能精细石墨科技有限公司

A distributor of horizontal falling film evaporator

InactiveCN103657123BImprove efficiencyEvenly distributedEvaporator accessoriesAgricultural engineeringFalling film evaporator

The present invention discloses a distributer of a horizontal falling film evaporator. The distributer comprises distribution pipe, a distribution tank and a falling film evaporation pipe, wherein the bottom of the distribution pipe is provided with primary distribution holes, various pipe holes are uniformly distributed, the distribution tank is arranged below the distribution pipe, presents a tapered shape, and is connected with the distribution pipe through a welding manner, the lower half portion of the distribution tank is filled with a porous material, a separation plate is longitudinally arranged to separate the distribution tank into mutually-noncommunicated areas, the bottom of the distribution tank is provided with uniformly-distributed secondary distribution holes, both sides of the secondary distribution holes are embedded with draining projections for providing a draining effect, the falling film evaporation pipe is positioned just below the distributer, the positions of the secondary distribution holes and the draining projections are just toward the axis center of the falling film evaporation pipe, both ends of the falling film evaporation pipe are sealed by using flanges and washers, and the distribution pipe and the distribution tank are respectively connected with the horizontal falling film evaporation cylinder body through welding. The distributer has characteristics of simple structure, easy installation processing, uniform film distribution, increased evaporator efficiency, and energy source saving.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method and device for treating waste water containing organic matter

ActiveCN106630339BAchieve recyclingReach outWater contaminantsEvaporationProcess engineeringOrganic matter

The invention provides an organic matter-containing wastewater treatment method and device. The treatment device comprises a wastewater pre-heater, an evaporator, a scaling device, a first-effect steam compressor, a second-effect steam compressor and a condensation water collector. The invention also provides the organic matter-containing wastewater treatment method adopting the device. The wastewater treatment method and device provided by the invention have the advantages of safety, reliability, simple equipment, low operating cost, obvious energy saving effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of wastewater treatment method and system

ActiveCN108069479BPrevent scalingAchieve recyclingWater/sewage treatment by heatingWater/sewage treatment by degassingGas compressorWater resources

The invention provides a wastewater treatment method and system. The system comprises a wastewater preheater, a wastewater heater, an evaporator, a stripping tower, a vapor compressor, a heat exchanger, a non-condensable gas compressor and a condensed water collector. The invention further provides the wastewater treatment method adopting the system. The wastewater treatment method and system havethe advantages that safety and reliability are achieved, equipment is simple, operating cost is low, energy-saving effect is remarkable and the like, and 50%-95% of water resource can be recycled.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

Organic luminescent material ink, preparation method thereof and ink-jet printing method

ActiveCN111876020AQuality improvementUniform film distributionDuplicating/marking methodsInksOrganic solventLuminescent material

The invention provides an organic light-emitting material ink. The organic light-emitting material ink comprises 20-89.9 wt% of a first solvent; 5 wt%-39.9 wt% of a second solvent; 5 wt%-39.9 wt% of athird solvent; and 0.1 wt%-5wt% of a solute; wherein the sum of the contents of the components is 100%. The first solvent is a low-boiling-point high-surface-tension organic solvent; the second solvent is a high-boiling-point low-surface-tension organic solvent; the third solvent is a high-boiling-point and high-viscosity organic solvent; the solute is an organic light-emitting small molecular material which can be dissolved in the first solvent, the second solvent, the third solvent or a mixed solvent thereof. The uniformity of the film is cooperatively controlled through a three-solvent system, dewetting of the small molecular light-emitting film is inhibited, the high-quality large-area patterned organic small molecular light-emitting film can be obtained, uniform film distribution isachieved, and thereby high-quality printing preparation of a high-efficiency large-area organic photoelectric device can be achieved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Triple effect seven-stroke falling film evaporator

InactiveCN101804262BReduce consumptionReduce power consumptionMultiple-effect evaporationEnvironmental resistanceEngineering

The invention discloses a triple effect seven-stroke falling film evaporator, wherein each feed cavity and each discharge cavity are respectively divided into a plurality of feed cavities and a plurality of discharge cavities by a riser; a previous discharge cavity of each effect is connected with a latter feed cavity of the effect. The invention improves the evaporation effect effectively by increasing the stroke, and reaches the goal of disposable material feeding and product finishing; solves the problems of seriously affecting the quality of the products, such as insufficient supply of the back stroke falling film tube feed liquid, degraded irrigation rate of periphery of the falling film tube, poor film-forming property, phenomenon of tube burning and wall drying, by the mixed design of distributor; and has the advantages of wide application range, energy-saving and environmental protection.

Owner:温州市天龙轻工设备有限公司

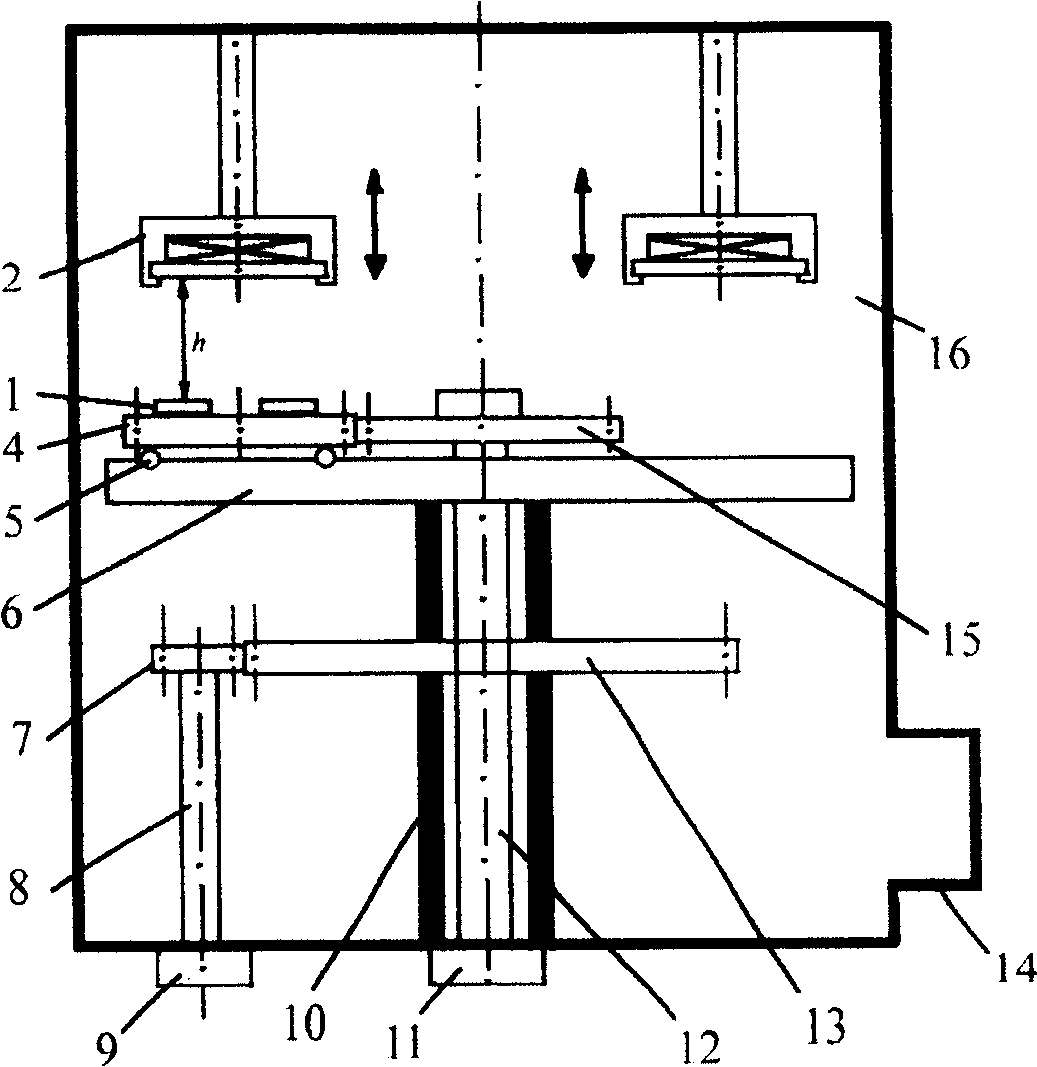

Film distribution device suitable for falling-film evaporator of ocean thermoelectric power generation system

InactiveCN106943762AIncrease heat exchange intensityUniform film distributionEvaporator accessoriesEngineeringTextile

The invention relates to a film distribution device suitable for a falling-film evaporator of an ocean thermoelectric power generation system. The film distribution device is characterized by comprising spraying pipes, nozzles and heating tube bundles, wherein a plurality of spraying pipes are arranged along the length direction of a barrel of the falling-film evaporator at intervals; each spraying pipe surrounds the wall of the barrel of the falling-film evaporator in a circle along the circumferential direction; the nozzles are respectively arranged at the inner sides, close to the wall of the barrel of the falling-film evaporator, of all the spraying pipes; the nozzles extend into the barrel of the falling-film evaporator; the plurality of heating tube bundles are arranged in the barrel of the falling-film evaporator. The film distribution device is convenient in structure installation and is beneficial to realization of skid mounting.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A wastewater treatment process and system

ActiveCN106629937BPrevent scalingAchieve recyclingWater/sewage treatment by heatingGas compressorWater resources

Owner:CHINA PETROLEUM & CHEM CORP +1

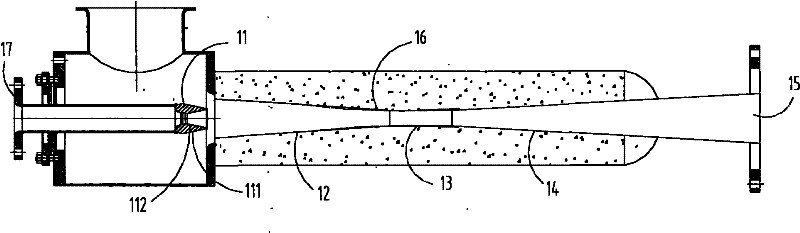

Evaporation device for heat-sensitive materials with high boiling point and high viscosity

ActiveCN106621425BAvoid sex changeAvoid decompositionEvaporator accessoriesChemical industryEnvironmental resistanceChemical industry

The invention relates to an evaporation device for a high-boiling-point high-viscosity heat-sensitive material. The evaporation device comprises a feed pump, wherein the feed pump is connected with an inlet at the lower end of a climbing film diameter-variable evaporator; an outlet at the upper end of the climbing film diameter-variable evaporator is connected with an inlet at the upper end of a falling film diameter-variable evaporator; a conical baffle plate is arranged in the falling film diameter-variable evaporator; an outlet at the lower end of the falling film diameter-variable evaporator is connected with an inlet of a steam-liquid separating tank; the upper end of the steam-liquid separating tank is further provided with a steam outlet; and the lower end of the steam-liquid separating tank is provided with an evaporation residue outlet. The evaporation device provided by the invention combines the advantages of the traditional climbing film and falling film evaporators, overcomes the defect of the traditional climbing film and falling film evaporators such as nonuniform in-pipe steam speed, has the advantages of short retention time, uniform material distribution on the evaporation pipe wall, high heat transfer efficiency, low energy consumption, low scaling possibility and the like, and is particularly suitable for evaporation of a high-boiling-point high-viscosity heat-sensitive material in the chemical industry, pharmacy, light industry, environmental protection and biological energy source industry.

Owner:ZHEJIANG UNIV OF TECH

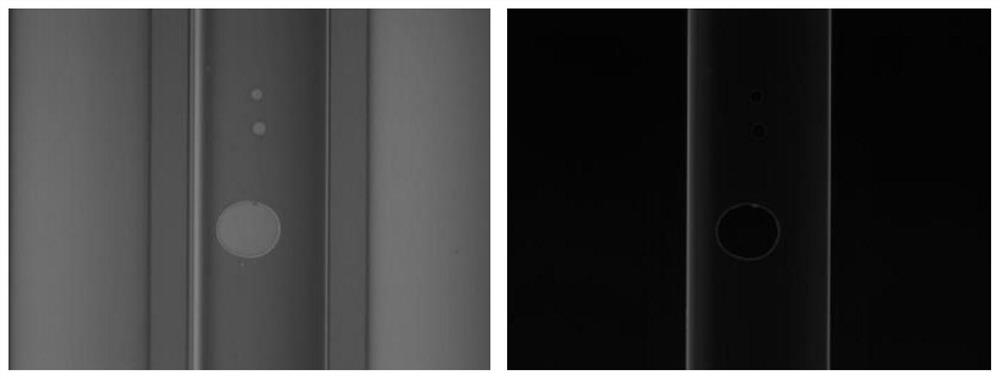

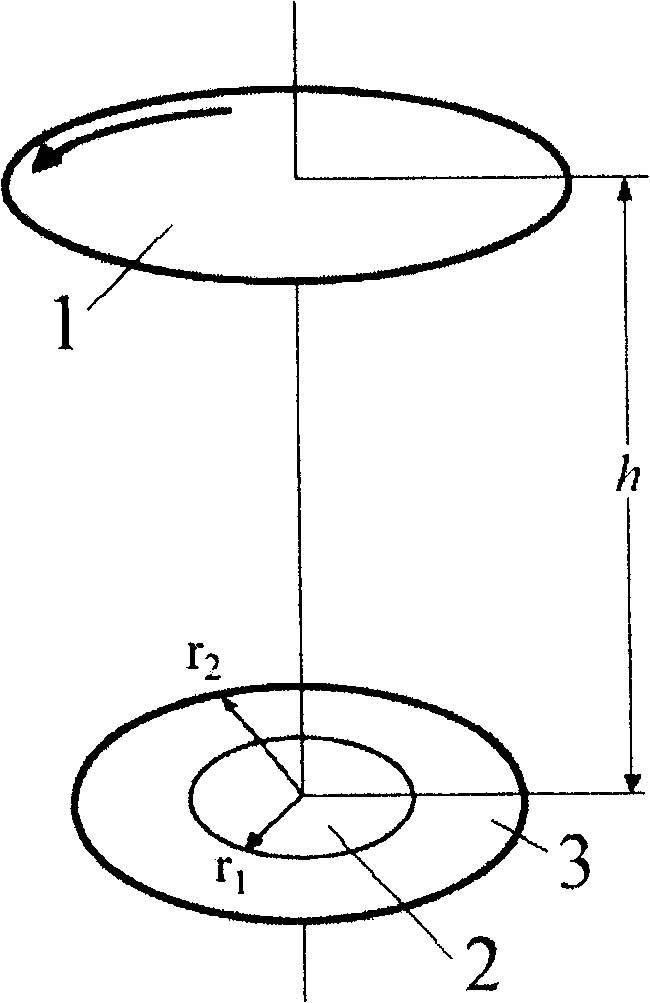

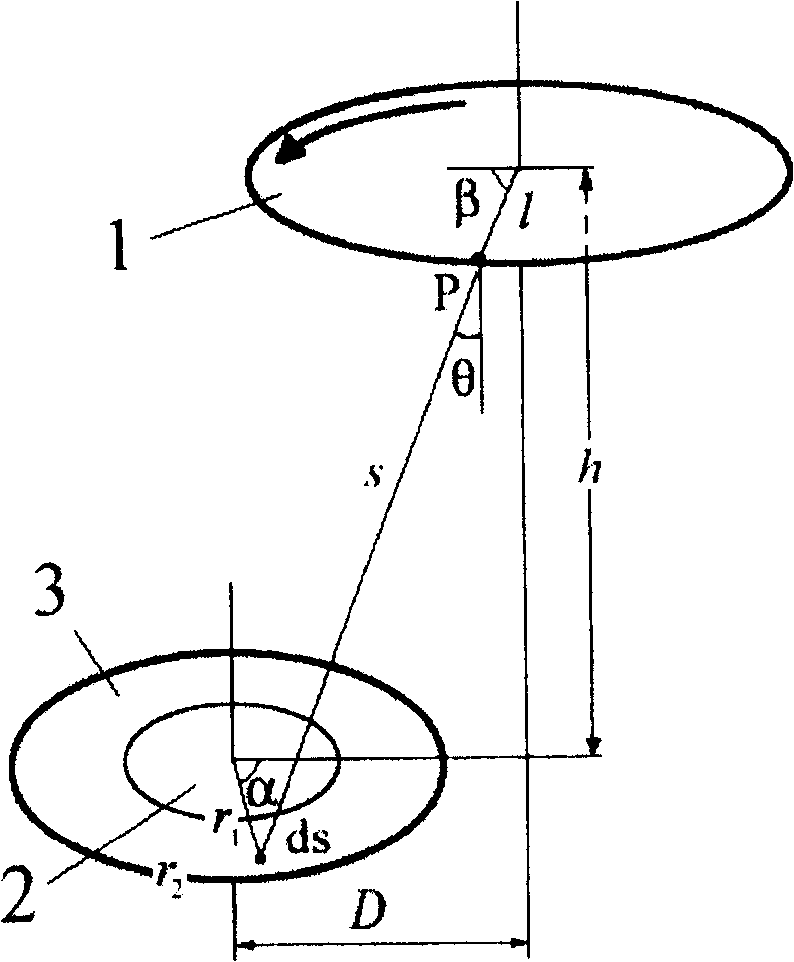

Off-axis sputtering control method for improving thickness uniformity of film

InactiveCN100443627CUniform film distributionVersatilityVacuum evaporation coatingSputtering coatingAtmospheric pressureMaterials science

The invention discloses an off-axis sputtering controlling method to improve film thickness evenness, which is characterized by the following: adopting round flat target 2 to splash the film; making base 1 eccentric for target 2; making 1 or 2 self-rotate around its center; adjusting thickness evenness of film through target base distance h and eccentric distance D; making the section of etching ring 3 as U-shape or similar rectangle; setting the splashing pressure lower than 5Pa; controlling the optimizing rate of h and D at D=3+0.7r1+0.3r2+(2 / 3+-0.1) .h, wherein r1 and r2 is inner and outer radius of etching ring 3 on the target 2. The invention can splash the eccentric shaft, which affirms the proportional relationship of target base distance h-eccentric distance D.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A Vertical Tube Falling Film Absorption Reactor

ActiveCN106268595BUniform film distributionUniform supplyLiquid-gas reaction of thin-film typeChemical/physical/physico-chemical stationary reactorsVertical tubeBarrel Shaped

Owner:LUOYANG SUNRUI SPECIAL EQUIP

A method and device for treating waste water containing organic matter

ActiveCN106630336BAchieve recyclingReach outWater contaminantsEvaporationProcess engineeringOrganic matter

Owner:CHINA PETROLEUM & CHEM CORP +1

Falling film evaporator with side feed

ActiveCN106267869BCompact structureIncrease the heat exchange areaEvaporationEngineeringFalling film evaporator

The invention relates to the field of chemical heating equipment, and discloses a lateral-feed falling-film evaporator including a shell body, a pipe plate, evaporation pipes and a liquid supply device, and the pipe plate is arranged on the upper part of the shell body; a plurality of evaporation pipes are vertically arranged in the shell body, and the upper ends of the evaporation pipes pass through the pipe plate; the upper ends of the evaporation pipes are provided with a flow guiding device; the liquid supply device comprises a liquid inlet groove and branched feed pipes, and the liquid inlet groove is vertically arranged at the upper part of the outer wall of the shell body and surrounds the whole shell body; the liquid inlet groove is uniformly provided with a plurality of branched feed inlets; the branched feed inlets are formed on the upper side wall of the liquid inlet groove, the lower ends of the branched feed pipes vertically pass through the branched feed inlets and extend into the liquid inlet groove, and the lower ends of the branched feed pipes are close to the bottom of the liquid inlet groove; the shell body is provided with a plurality of overflow channels communicating with the liquid inlet groove. The lateral-feed falling-film evaporator has the advantages of simple and compact structure, and effectively shrinks the height of the device; the lateral-feed falling-film evaporator has the advantages of large liquid flowing amount, and convenience in operation and maintenance; and with use of the device, the liquid distribution rate is high, the film distribution is uniform, and the device is not easy to block and is easy to clean.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com