Evaporation device for heat-sensitive materials with high boiling point and high viscosity

A heat-sensitive material and evaporation device technology, applied in evaporation, evaporator accessories, climate sustainability, etc., can solve the problems of long residence time of materials, high boiling point and high viscosity heat-sensitive materials, product quality cannot be guaranteed, uneven distribution, etc. , to avoid denaturation and decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

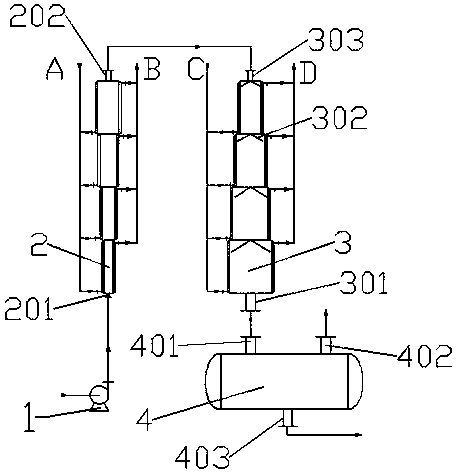

[0021] Such as figure 1 As shown, the evaporating device of the high boiling point and high viscosity heat-sensitive material of the present invention includes a feed pump 1, the discharge port of the feed pump 1 is connected to the rising film variable diameter evaporator inlet 201 at the lower end of the rising film variable diameter evaporator 2 , the rising film variable diameter evaporator inlet 202 at the upper end of the rising film variable diameter evaporator 2 is connected to the falling film variable diameter evaporator inlet 303 at the upper end of the falling film variable diameter evaporator 3, inside the falling film variable diameter evaporator 3 A conical baffle 302 is provided, and the outlet 301 of the falling-film variable-diameter evaporator at the lower end of the falling-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com