Off-axis sputtering control method for improving thickness uniformity of film

An off-axis sputtering and control method technology, which is applied in the field of thin film preparation, can solve the problems of taking a long time, not explaining the adjustability of eccentricity D, time-consuming and labor-intensive, etc., and achieve the effect of uniform film distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

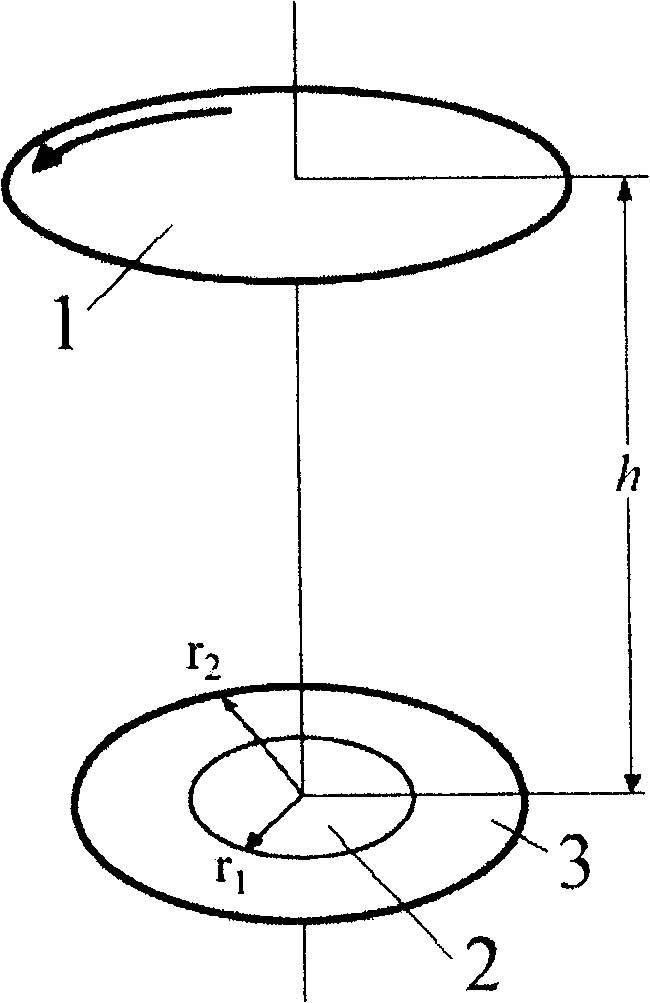

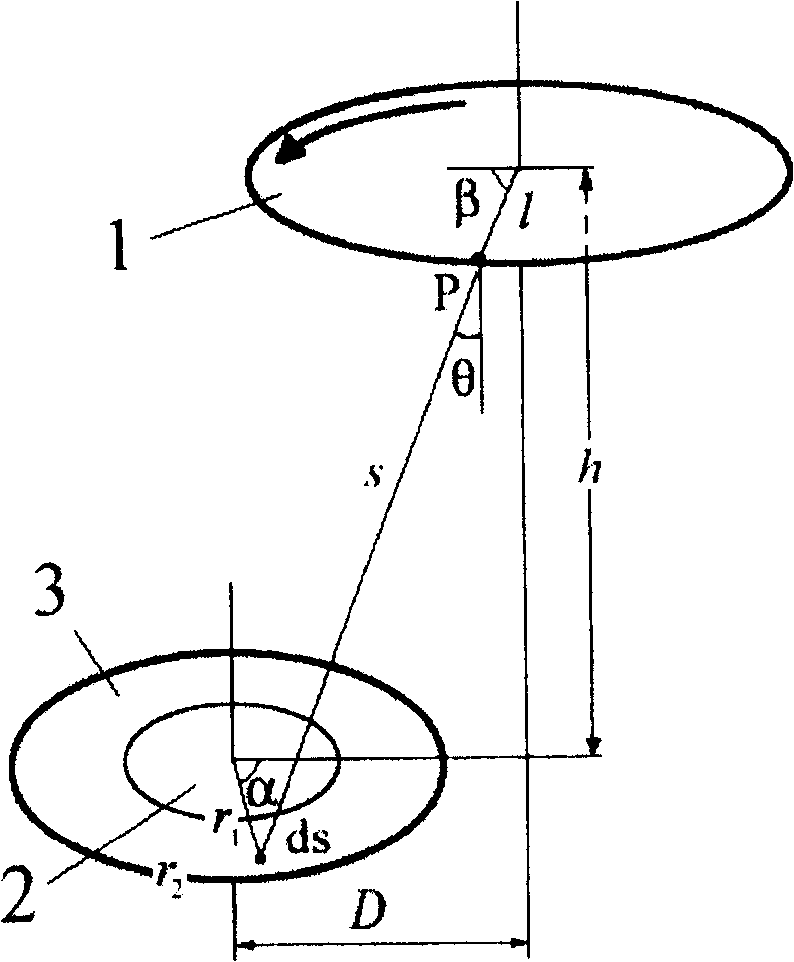

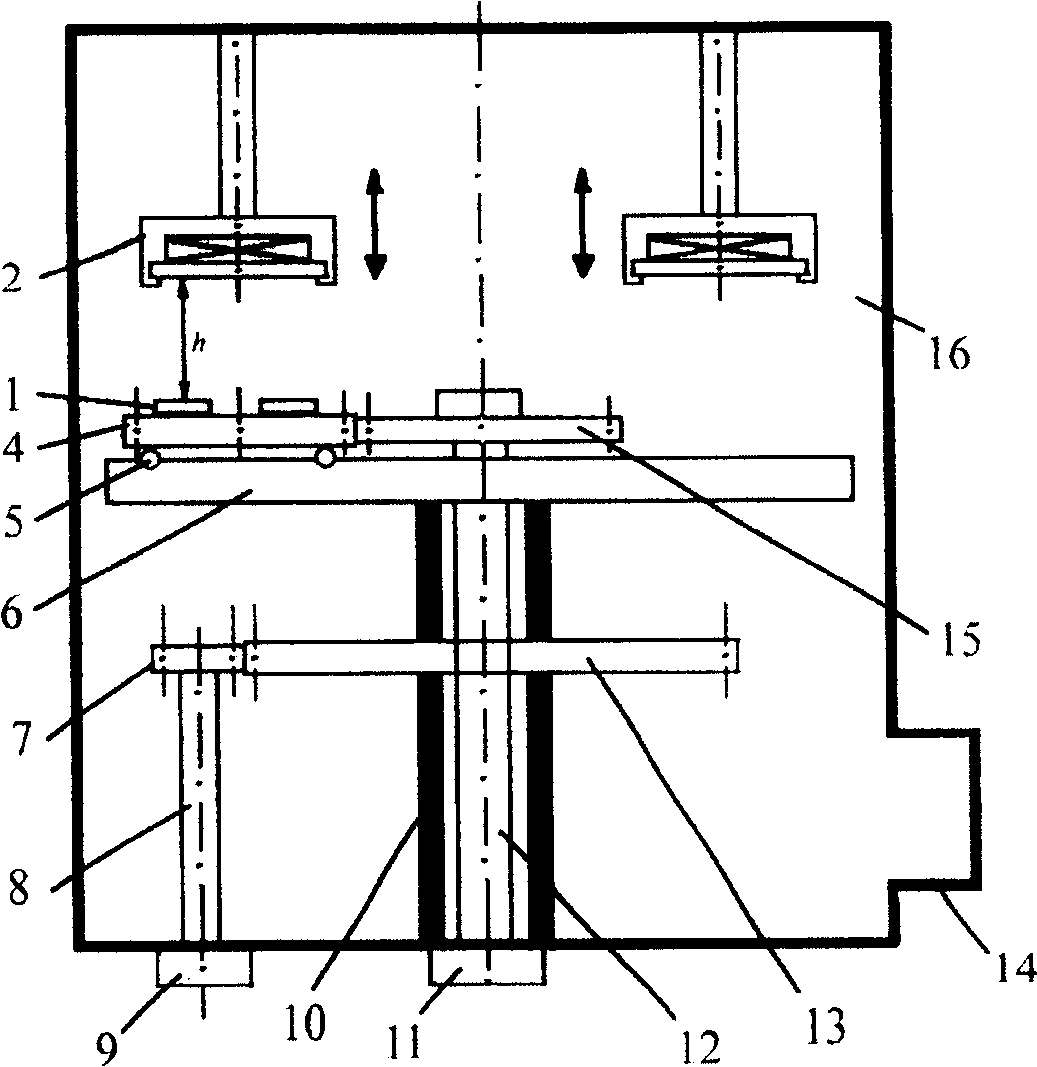

Method used

Image

Examples

specific Embodiment

[0024] The copper film is sputtered by using the above device and the control method of the present invention, the diameter of the plane target 2 is 60 mm, and the inner and outer radii of the etching ring 3 are 13 and 22 mm respectively. The base distance D of the target is 50mm, and the optimized eccentricity calculated by the formula provided by the present invention is 52 ± 5mm. In the experiment, the eccentricity of 50mm is adopted, and the common glass with a diameter of 100mm is used as the substrate, which is installed on the substrate support (rotation turntable 4 ), the pressure of argon gas during sputtering is 0.5Pa, the power is 50W, and the sputtering time is 15 minutes. After sputtering, the film thickness was measured with an interference microscope, and the results were as follows: Figure 5 As shown, it can be seen that the thickness uniformity of the film is within 4% within the range of 80 mm in diameter.

[0025] By adopting the off-axis sputtering method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com