Falling film evaporator with side feed

A falling film evaporator and lateral feeding technology, applied in evaporation, chemical instruments and methods, separation methods, etc., can solve problems such as inconvenient installation and maintenance, easy to block pipes, and large flow resistance, and achieve easy cleaning and liquid circulation The effect of large amount and uniform film distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

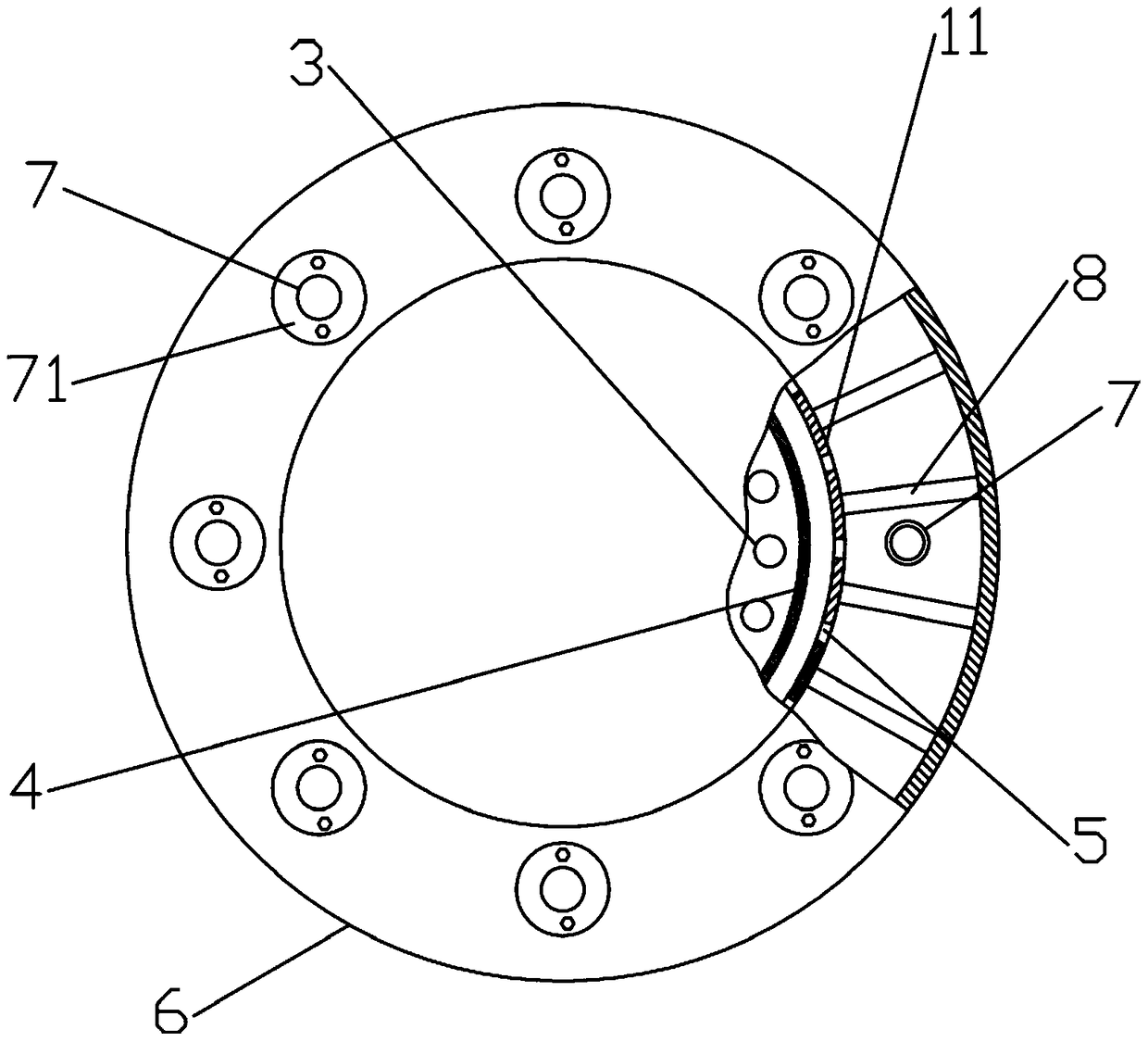

[0028] This embodiment is basically the same as Embodiment 1, the difference is that the overflow baffle 4 is a cylinder, and its upper end has a flange outer edge, so that the cross section of the overflow baffle is in an inverted "L" shape, and the overflow The outer edge of the flange of the baffle plate 4 is welded to the inner wall of the housing 11 to form a liquid distribution channel.

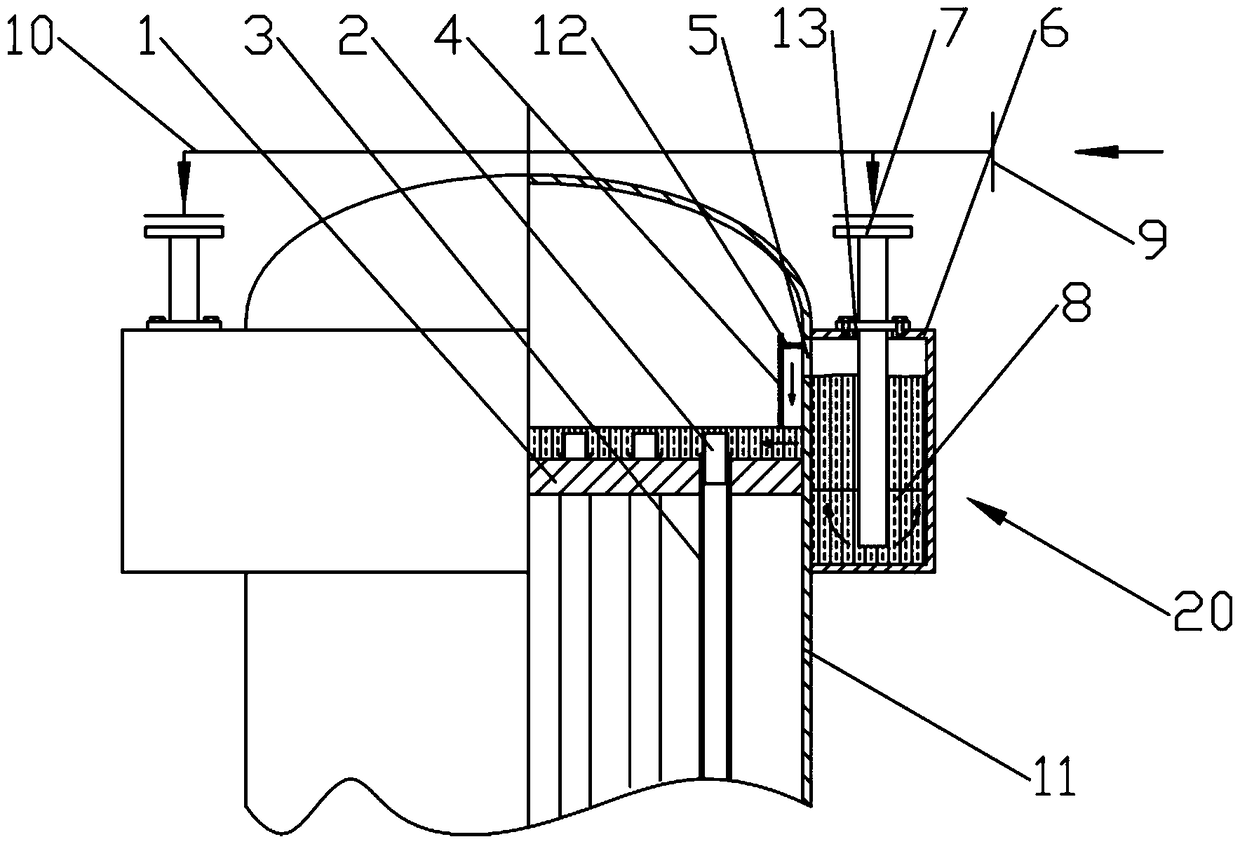

[0029] During the use of the present invention, the liquid is input through the main feeding port 9, and the liquid is distributed to the sub-feeding pipes 7 through the main feeding pipe 10. Since the liquid inlet tank 6 is arranged outside the casing 11, the distance from the tube sheet 1 in the casing 11 to the top of the casing is greatly shortened, and the space of the membrane cloth chamber is also greatly reduced. Such as figure 1As shown in the direction of the middle arrow, the liquid enters the bottom of the liquid inlet tank 6 from the sub-feeding pipe 7, and the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com